ECO mode INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1125 of 2395

6 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors B152, B151 and B101, B43

IHarness connectors B1, M2 and M94, F27

IHarness for open or short between vacuum cut valve bypass valve and ECM

©Repair open circuit or short to ground or short to power in harness or connectors.

7 CHECK VACUUM CUT VALVE BYPASS VALVE

With CONSULT-II

1. Reconnect harness disconnected connectors.

2. Turn ignition switch ON.

3. Perform ªVC/V BYPASS/Vº in ªACTIVE TESTº mode.

4. Check air passage continuity and operation delay time under the following conditions.

SEF016Z

Without CONSULT-II

Check air passage continuity and operation delay time under the following conditions.

SEF358X

OK or NG

OK©GO TO 8.

NG©Replace vacuum cut valve bypass valve.

8 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

DTC P1490 VACUUM CUT VALVE BYPASS VALVE (CIRCUIT)

Diagnostic Procedure (Cont'd)

EC-590

Page 1127 of 2395

On Board Diagnosis LogicNBEC0356Malfunction is detected when vacuum cut valve bypass valve does

not operate properly.

Possible CauseNBEC0593IVacuum cut valve bypass valve

IVacuum cut valve

IBypass hoses for clogging

IEVAP control system pressure sensor and circuit

IEVAP canister vent control valve

IHose between fuel tank and vacuum cut valve clogged

IHose between vacuum cut valve and EVAP canister clogged

IEVAP canister

IEVAP purge port of fuel tank for clogging

SEF210Y

SEF211Y

SEF239Y

DTC Confirmation ProcedureNBEC0357CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

TESTING CONDITION:

For best results, perform test at a temperature of 5 to 30ÉC (41

to 86ÉF).

WITH CONSULT-IINBEC0357S011) Turn ignition switch ªONº.

2) Start engine and warm it up to normal operating temperature.

3) Turn ignition switch ªOFFº and wait at least 10 seconds.

4) Start engine and let it idle for at least 70 seconds.

5) Select ªVC CUT/V BP/V P1491º of ªEVAPORATIVE SYSTEMº

in ªDTC WORK SUPPORTº mode with CONSULT-II.

6) Touch ªSTARTº.

7) When the following conditions are met, ªTESTINGº will be dis-

played on the CONSULT-II screen. Maintain the conditions

continuously until ªTESTINGº changes to ªCOMPLETEDº. (It

will take at least 30 seconds.)

ENG SPEED Idle speed or more

Selector lever Suitable position

Vehicle speed 37 km/h (23 MPH) or more

B/FUEL SCHDL 1.3 - 10 msec

If ªTESTINGº is not displayed after 5 minutes, retry from

step 3.

8) Make sure that ªOKº is displayed after touching ªSELF-DIAG

DTC P1491 VACUUM CUT VALVE BYPASS VALVE

On Board Diagnosis Logic

EC-592

Page 1136 of 2395

14 CHECK EVAP CANISTER VENT CONTROL VALVE-I

1. Remove EVAP canister vent control valve from EVAP canister.

2. Check portionBof EVAP canister vent control valve for being rusted.

SEF337X

OK or NG

OK©GO TO 15.

NG©Replace EVAP canister vent control valve.

15 CHECK EVAP CANISTER VENT CONTROL VALVE-II

With CONSULT-II

1. Reconnect harness disconnected connectors.

2. Turn ignition switch ON.

3. Perform ªVENT CONTROL/Vº in ªACTIVE TESTº mode.

4. Check air passage continuity and operation delay time.

SEF991Y

Without CONSULT-II

Check air passage continuity and operation delay time under the following conditions.

SEF339X

Make sure new O-ring is installed properly.

OK or NG

OK©GO TO 17.

NG©GO TO 16.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1491 VACUUM CUT VALVE BYPASS VALVE

Diagnostic Procedure (Cont'd)

EC-601

Page 1138 of 2395

Component DescriptionNBEC0361The malfunction information related to A/T (Automatic Transmission) is transferred through the line (circuit)

from TCM (Transmission control module) to ECM. Therefore, be sure to erase the malfunction information such

as DTC not only in TCM (Transmission control module) but also ECM after the A/T related repair.

On Board Diagnosis LogicNBEC0363Malfunction is detected when an incorrect signal from TCM (Trans-

mission control module) is sent to ECM.

Possible CauseNBEC0594IHarness or connectors

[The communication line circuit between ECM and TCM

(Transmission control module) is open or shorted.]

IDead (Weak) battery

ITCM (Transmission control module)

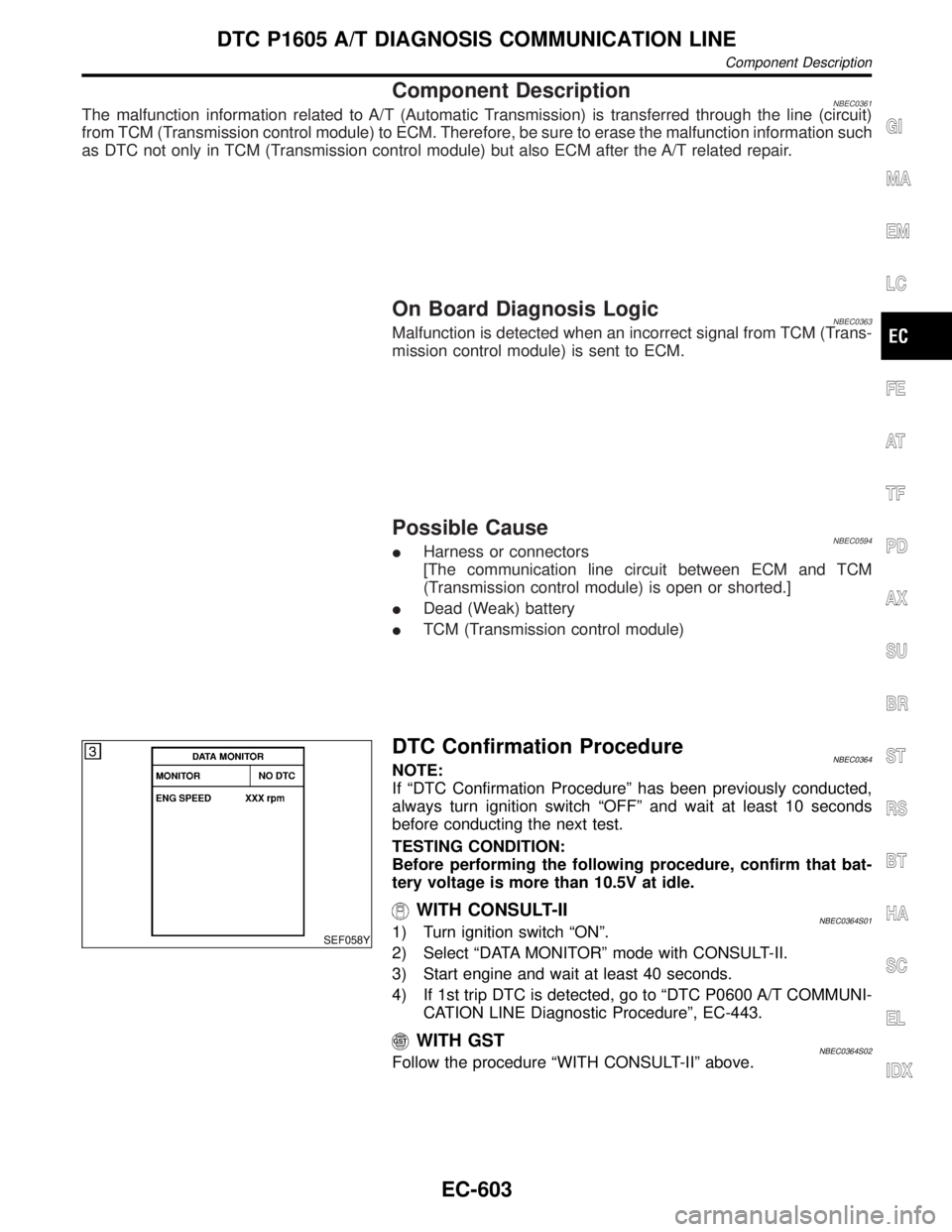

SEF058Y

DTC Confirmation ProcedureNBEC0364NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 10.5V at idle.

WITH CONSULT-IINBEC0364S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 40 seconds.

4) If 1st trip DTC is detected, go to ªDTC P0600 A/T COMMUNI-

CATION LINE Diagnostic Procedureº, EC-443.

WITH GSTNBEC0364S02Follow the procedure ªWITH CONSULT-IIº above.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1605 A/T DIAGNOSIS COMMUNICATION LINE

Component Description

EC-603

Page 1140 of 2395

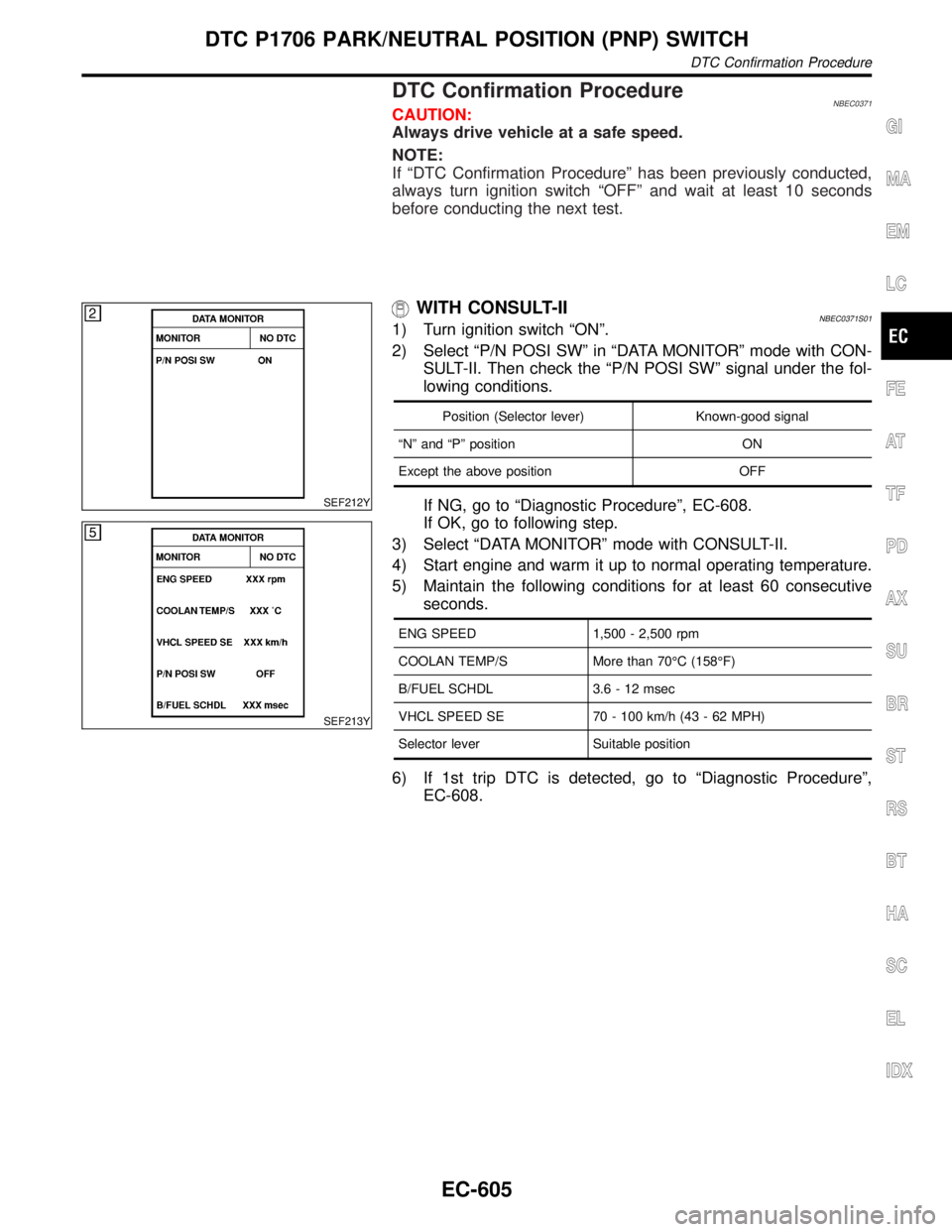

DTC Confirmation ProcedureNBEC0371CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

SEF212Y

SEF213Y

WITH CONSULT-IINBEC0371S011) Turn ignition switch ªONº.

2) Select ªP/N POSI SWº in ªDATA MONITORº mode with CON-

SULT-II. Then check the ªP/N POSI SWº signal under the fol-

lowing conditions.

Position (Selector lever) Known-good signal

ªNº and ªPº position ON

Except the above position OFF

If NG, go to ªDiagnostic Procedureº, EC-608.

If OK, go to following step.

3) Select ªDATA MONITORº mode with CONSULT-II.

4) Start engine and warm it up to normal operating temperature.

5) Maintain the following conditions for at least 60 consecutive

seconds.

ENG SPEED 1,500 - 2,500 rpm

COOLAN TEMP/S More than 70ÉC (158ÉF)

B/FUEL SCHDL 3.6 - 12 msec

VHCL SPEED SE 70 - 100 km/h (43 - 62 MPH)

Selector lever Suitable position

6) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-608.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCH

DTC Confirmation Procedure

EC-605

Page 1160 of 2395

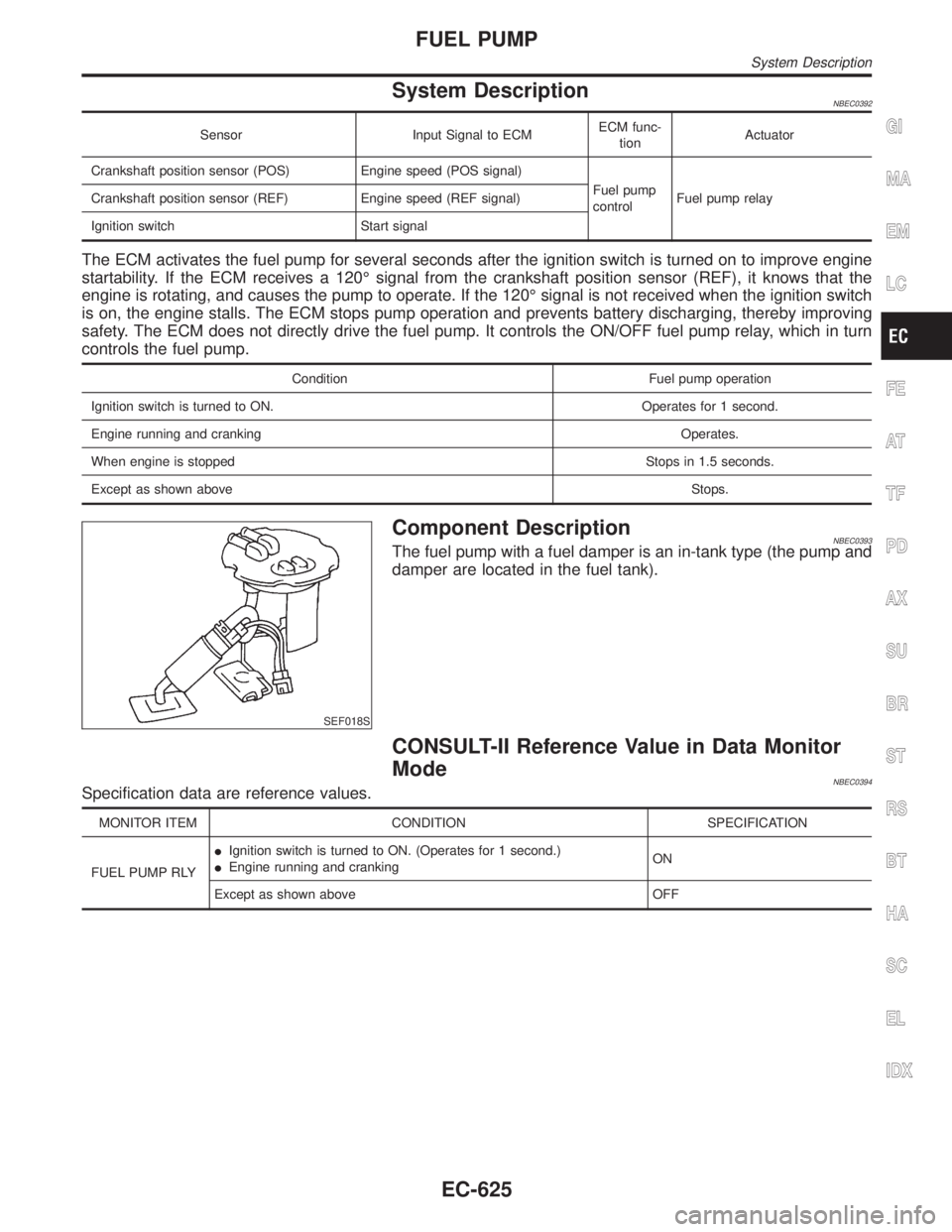

System DescriptionNBEC0392

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed (POS signal)

Fuel pump

controlFuel pump relay Crankshaft position sensor (REF) Engine speed (REF signal)

Ignition switch Start signal

The ECM activates the fuel pump for several seconds after the ignition switch is turned on to improve engine

startability. If the ECM receives a 120É signal from the crankshaft position sensor (REF), it knows that the

engine is rotating, and causes the pump to operate. If the 120É signal is not received when the ignition switch

is on, the engine stalls. The ECM stops pump operation and prevents battery discharging, thereby improving

safety. The ECM does not directly drive the fuel pump. It controls the ON/OFF fuel pump relay, which in turn

controls the fuel pump.

Condition Fuel pump operation

Ignition switch is turned to ON. Operates for 1 second.

Engine running and cranking Operates.

When engine is stopped Stops in 1.5 seconds.

Except as shown aboveStops.

SEF018S

Component DescriptionNBEC0393The fuel pump with a fuel damper is an in-tank type (the pump and

damper are located in the fuel tank).

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0394Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

FUEL PUMP RLYIIgnition switch is turned to ON. (Operates for 1 second.)

IEngine running and crankingON

Except as shown above OFF

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FUEL PUMP

System Description

EC-625

Page 1167 of 2395

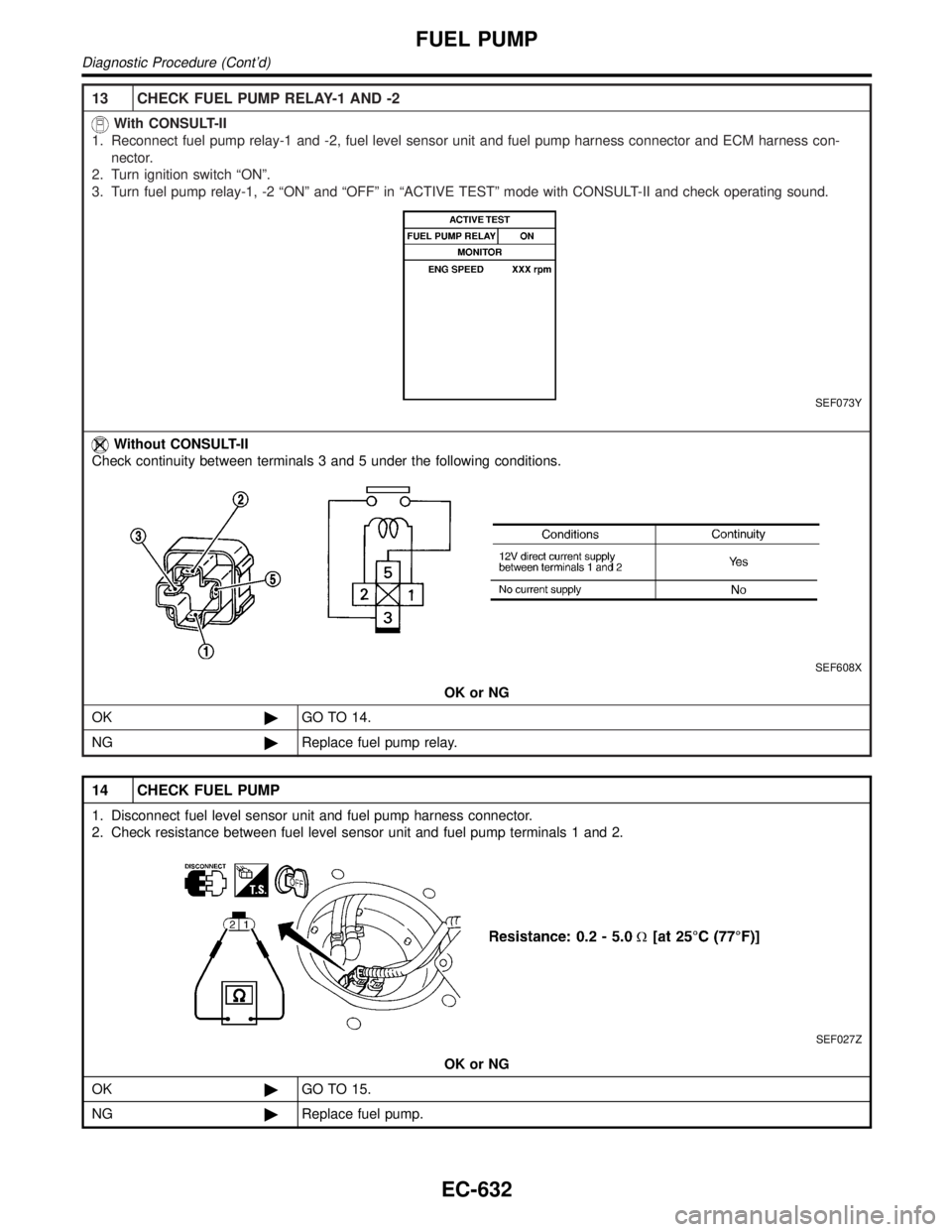

13 CHECK FUEL PUMP RELAY-1 AND -2

With CONSULT-II

1. Reconnect fuel pump relay-1 and -2, fuel level sensor unit and fuel pump harness connector and ECM harness con-

nector.

2. Turn ignition switch ªONº.

3. Turn fuel pump relay-1, -2 ªONº and ªOFFº in ªACTIVE TESTº mode with CONSULT-II and check operating sound.

SEF073Y

Without CONSULT-II

Check continuity between terminals 3 and 5 under the following conditions.

SEF608X

OK or NG

OK©GO TO 14.

NG©Replace fuel pump relay.

14 CHECK FUEL PUMP

1. Disconnect fuel level sensor unit and fuel pump harness connector.

2. Check resistance between fuel level sensor unit and fuel pump terminals 1 and 2.

SEF027Z

OK or NG

OK©GO TO 15.

NG©Replace fuel pump.

FUEL PUMP

Diagnostic Procedure (Cont'd)

EC-632

Page 1279 of 2395

Component Parts and Harness Connector

Location

NBEL0041

SEL351X

System DescriptionNBEL0042UNIFIED CONTROL METERNBEL0042S06ISpeedometer, odo/trip meter, tachometer, fuel gauge and water temperature gauge are controlled totally

by control unit.

IDigital meter is adopted for odo/trip meter.*

*The record of the odo meter is kept even if the battery cable is disconnected. The record of the trip meter

is erased when the battery cable is disconnected.

IOdo/trip meter is indicated for about 30 seconds after ignition switch has been turned OFF.

IOdo/trip meter segment can be checked in diagnosis mode.

IMeter/gauge can be checked in diagnosis mode.

HOW TO CHANGE THE DISPLAY FOR ODO/TRIP METERNBEL0042S07

SEL175W

NOTE:

Turn ignition switch to the ªONº position to operate odo/trip meter.

METERS AND GAUGES

Component Parts and Harness Connector Location

EL-94

Page 1285 of 2395

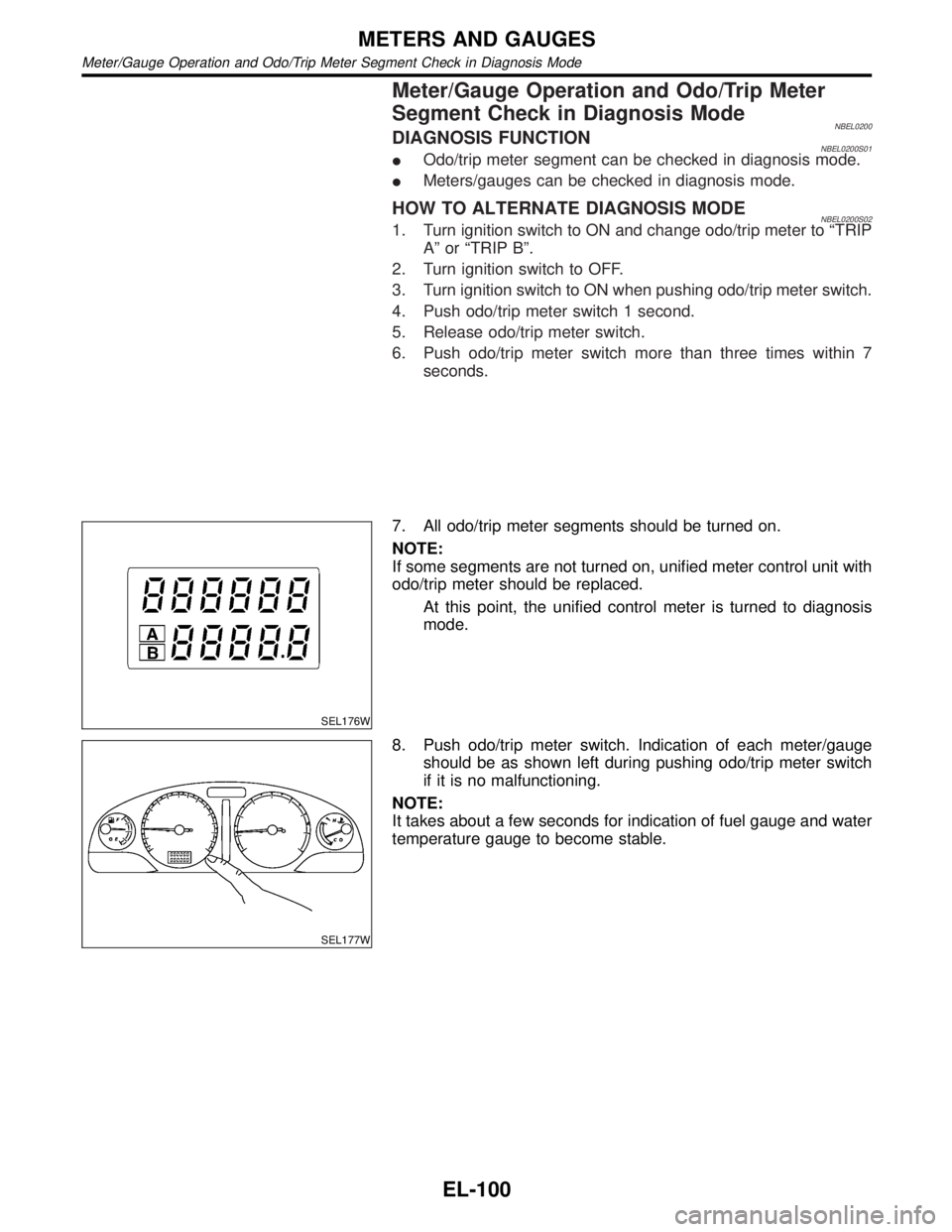

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode

NBEL0200DIAGNOSIS FUNCTIONNBEL0200S01IOdo/trip meter segment can be checked in diagnosis mode.

IMeters/gauges can be checked in diagnosis mode.

HOW TO ALTERNATE DIAGNOSIS MODENBEL0200S021. Turn ignition switch to ON and change odo/trip meter to ªTRIP

Aº or ªTRIP Bº.

2. Turn ignition switch to OFF.

3. Turn ignition switch to ON when pushing odo/trip meter switch.

4. Push odo/trip meter switch 1 second.

5. Release odo/trip meter switch.

6. Push odo/trip meter switch more than three times within 7

seconds.

SEL176W

7. All odo/trip meter segments should be turned on.

NOTE:

If some segments are not turned on, unified meter control unit with

odo/trip meter should be replaced.

At this point, the unified control meter is turned to diagnosis

mode.

SEL177W

8. Push odo/trip meter switch. Indication of each meter/gauge

should be as shown left during pushing odo/trip meter switch

if it is no malfunctioning.

NOTE:

It takes about a few seconds for indication of fuel gauge and water

temperature gauge to become stable.

METERS AND GAUGES

Meter/Gauge Operation and Odo/Trip Meter Segment Check in Diagnosis Mode

EL-100

Page 1297 of 2395

Trouble DiagnosesNBEL0048PRELIMINARY CHECK FOR THERMOMETERNBEL0048S02

1 COOL DOWN CHECK

1. Turn the ignition key switch to the ªACCº position.

2. Cool down the ambient air temperature sensor with water or ice, so that the indicated temperature falls.

Does the indicated temperature fall?

Ye s©GO TO 2.

No©The system is malfunctioning. Check the system following ªINSPECTION/COMPASS

AND THERMOMETERº.

2 WARM UP CHECK

1. Leave the vehicle for 10 minutes, so that the indicated temperature rises.

2. With the ignition key in the ªACCº position, disconnect and reconnect the ambient air temperature sensor connector.

Does the indicated temperature rise?

Ye s©The system is OK.

No©The system is malfunctioning. Check the system following ªINSPECTION/COMPASS

AND THERMOMETERº.

NOTE:

IWhen the outside temperature is between 55ÉC (130ÉF) and 70ÉC (158ÉF), the display shows 55ÉC

(130ÉF). When the outside temperature is lower than þ30ÉC (þ20ÉF) or higher than 70ÉC (158ÉF), the dis-

play shows only ª---º.

IThe indicated temperature on the thermometer is not readily affected by engine heat. It changes only when

one of the following conditions is present.

a) The temperature detected by the ambient air temperature sensor is lower than the indicated temperature

on the thermometer.

b) The difference in temperature detected during a period of 40 seconds is less than 1ÉC (1.8ÉF) when vehicle

speed has been greater than 24 km/h (15 MPH) for more than 100 seconds.

(This is to prevent the indicated temperature from being affected by engine heat or cooling fan operation

during low-speed driving.)

c) The ignition key has been turned to the ªOFFº position for more than 4 hours. (The engine is cold.)

INSPECTION/COMPASS AND THERMOMETERNBEL0048S01

Symptom Possible causes Repair order

No display at all 1. 10A fuse

2. Ground circuit

3. Compass and thermometer1. Check 10A fuse [No. 9, located in fuse block (J/B)].

Turn the ignition switch ON and verify that battery positive

voltage is at terminal 7 of compass and thermometer.

2. Check ground circuit for compass and thermometer.

3. Replace compass and thermometer.

Forward direction indi-

cation slips off the

mark or incorrect.1. In manual correction mode (Bar

and display vanish.)

2. Zone variation change is not done.1. Drive the vehicle and turn at an angle of 90É.

2. Perform the zone variation change.

Compass reading

remains unchanged.1. Vehicle speed sensor is not

entered.

2. Compass and thermometer1. Check harness for open or short between combination meter

terminal 13 and compass and thermometer terminal 1.

2. Replace compass and thermometer.

Displays wrong tem-

perature when ambient

temperature is between

þ30ÉC (þ20ÉF) and

55ÉC (130ÉF). (See

NOTE above.)1. Check operation

2. Ambient air temperature sensor

circuit

3. Vehicle speed sensor is not

entered.

4. Ambient air temperature sensor

5. Compass and thermometer1. Perform preliminary check shown above.

2. Check harness for open or short between ambient air tem-

perature sensor and compass and thermometer.

3. Check harness for open or short between combination meter

terminal 13 and compass and thermometer terminal 1.

4. Replace ambient air temperature sensor.

5. Replace compass and thermometer.

COMPASS AND THERMOMETER

Trouble Diagnoses

EL-112