turn signal INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1614 of 2395

GPS signal reception conditions are good. However, the position mark does not return to its proper

position.

Ihe system senses the vehicle location with an error of approximately 100 m (328 ft). Due to the limitation

of precision, the position marker may be inaccurate even if the GPS signal reception condition is good.

IThe navigation system uses GPS data to determine vehicle location. GPS data is compared with other

locational sensing data during the map matching process. The system decides which data is more pre-

cise and uses that data.

IWhen the vehicle is stationary, GPS data cannot be used to make system corrections.

Area designations on the map display and the BIRDVIEWTdisplay differ.

To prevent the display from becoming congested, alphanumeric information is abridged.

[No problem]

Correct position of your vehicle is not displayed.

Vehicle position changed after ignition key was turned to the OFF position (Vehicle is transported on car ferry,

car train, or by some other means).

[Operate vehicle for short time under GPS receiving conditions.]

The display does not change to night-time mode even though the light switch has been turned ON.

Lights have been turned on. In ªDISPLAY CHANGEº mode, night-time mode on display has been switched to

day-time mode and still is.

[Turn lights on again. Set the display to night-time mode. Refer to EL-412.]

Map does not scroll even though the position of your vehicle is changed.

Present area does not appear on the display.

[Press the ªMAPº switch.]

Vehicle position marker does not appear.

Present area does not appear on the display.

[Press the ªMAPº switch.]

The map surface precision display (GPS satellite marker) still remains gray.

Vehicle is parked inside a building or in the shadow of a large building. This intercepts the GPS signal.

[Move the vehicle to a more open position.]

GPS signal is not received because objects are placed on the rear parcel shelf.

[Remove objects from the rear parcel shelf.]

GPS satellite position is bad.

[Wait until GPS satellite position improves.]

Vehicle position precision is bad.

The map surface precision display (GPS satellite marker) still remains gray.

[Refer to ªThe map surface precision display (GPS satellite marker) still remains grayº item (Symptoms)]

Vehicle speed and elapsed distance is calculated from the vehicle speed pulse. This pulse is dependent upon

tire size. If tire chains are used on the vehicle, accuracy will be affected (pulse rate will be too fast or too slow).

The same is true if the system installed to your vehicle is removed and installed on another vehicle.

[Drive the vehicle at a speed higher than 30 km/h (19 MPH) for approximately 30 minutes. Automatic read-

justment should occur. If it does not (remains too fast or too slow), distance calibration is required. Or, drive

the vehicle for a short distance. Perform ªSPEED CALIBRATIONº (EL-409). After removing the tire chains,

sensing accuracy may recover by itself.]

Bad map data or system defect (same error consistently occurs in the same area)

ROUTE SEARCH/ROUTE GUIDENBEL0235S03IIf the present location or the destination location is displayed in the avoid area, it is not possible to search

routes.

IIf the avoid area is set to wide range area, it may not be possible to find appropriate routes or search for

alternate routes.

IThe automatic re-route calculates a return to the original route. Because of this, it may not be possible to

search appropriate new routes. If you deviate from the original route and wish to select an appropriate new

route, touch ªRoute Calculationº.

IThe automatic re-route function may sometimes require considerable time.

IDisplayed route number and directional information at a highway junction may differ from the information

posted on the actual road signs.

IDisplayed street name information at a highway exit may differ from the information posted on the actual

road signs.

IStreet name information displayed on the enlarged intersection map may differ from the information posted

on the actual road signs.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

NAVIGATION SYSTEM

This Condition is Not Abnormal (Cont'd)

EL-429

Page 1641 of 2395

NBEL0144

HeadlampNBEL0144S03

Item Wattage W

High/Low (Semi-sealed beam)55/35 (HB3/D2R)

Exterior LampNBEL0144S01

Item Wattage W

Front fog lamp55

Front turn signal lamp21

Parking lamp5

Rear combination lampTurn signal lamp 27

Stop/Tail lamp 21/5

Back-up lamp18

License plate lamp3.8

High-mounted stop lamp5

Interior LampNBEL0144S02

Item Wattage W

Interior lamp10

Spot lamp8

Luggage room lamp10

BULB SPECIFICATIONS

Headlamp

EL-456

Page 1643 of 2395

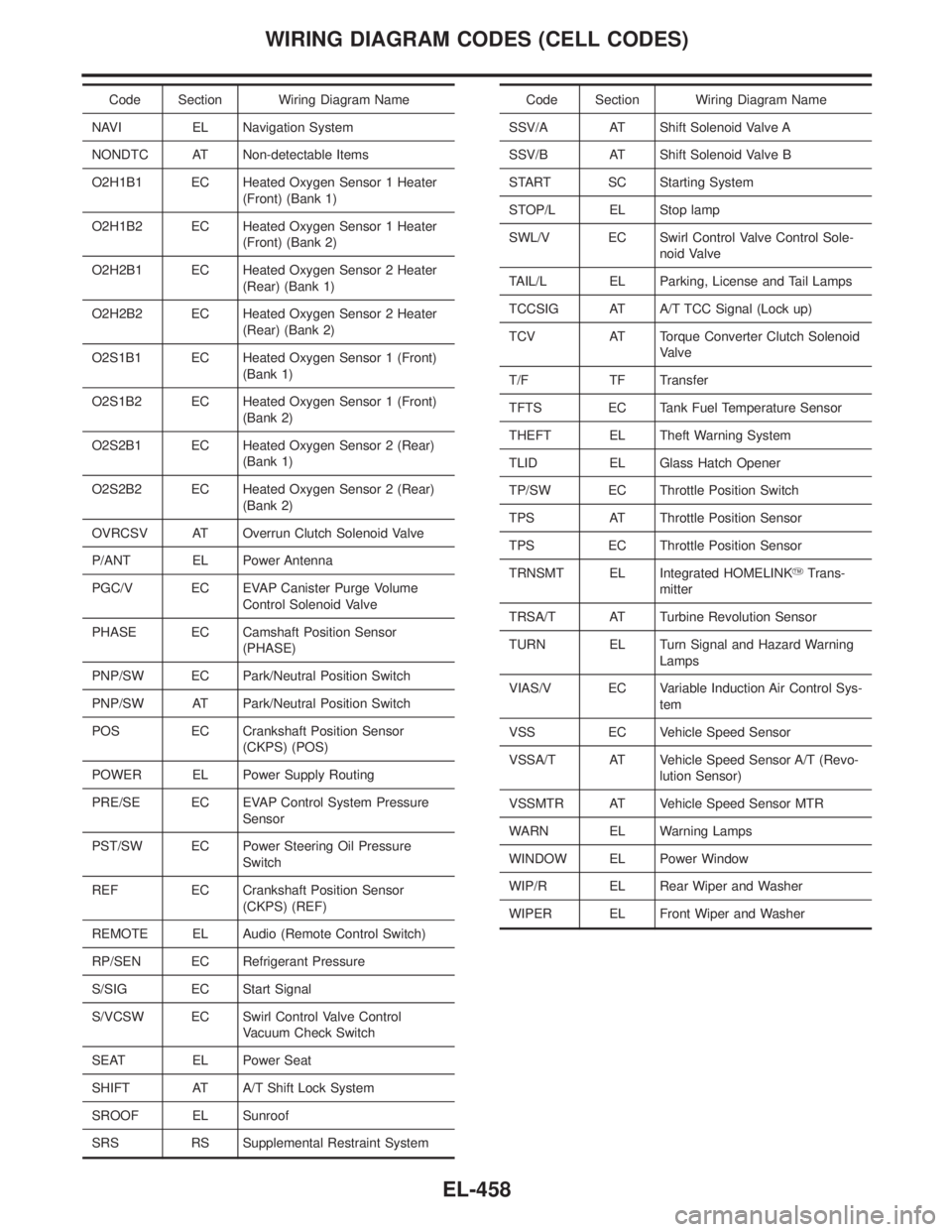

Code Section Wiring Diagram Name

NAVI EL Navigation System

NONDTC AT Non-detectable Items

O2H1B1 EC Heated Oxygen Sensor 1 Heater

(Front) (Bank 1)

O2H1B2 EC Heated Oxygen Sensor 1 Heater

(Front) (Bank 2)

O2H2B1 EC Heated Oxygen Sensor 2 Heater

(Rear) (Bank 1)

O2H2B2 EC Heated Oxygen Sensor 2 Heater

(Rear) (Bank 2)

O2S1B1 EC Heated Oxygen Sensor 1 (Front)

(Bank 1)

O2S1B2 EC Heated Oxygen Sensor 1 (Front)

(Bank 2)

O2S2B1 EC Heated Oxygen Sensor 2 (Rear)

(Bank 1)

O2S2B2 EC Heated Oxygen Sensor 2 (Rear)

(Bank 2)

OVRCSV AT Overrun Clutch Solenoid Valve

P/ANT EL Power Antenna

PGC/V EC EVAP Canister Purge Volume

Control Solenoid Valve

PHASE EC Camshaft Position Sensor

(PHASE)

PNP/SW EC Park/Neutral Position Switch

PNP/SW AT Park/Neutral Position Switch

POS EC Crankshaft Position Sensor

(CKPS) (POS)

POWER EL Power Supply Routing

PRE/SE EC EVAP Control System Pressure

Sensor

PST/SW EC Power Steering Oil Pressure

Switch

REF EC Crankshaft Position Sensor

(CKPS) (REF)

REMOTE EL Audio (Remote Control Switch)

RP/SEN EC Refrigerant Pressure

S/SIG EC Start Signal

S/VCSW EC Swirl Control Valve Control

Vacuum Check Switch

SEAT EL Power Seat

SHIFT AT A/T Shift Lock System

SROOF EL Sunroof

SRS RS Supplemental Restraint SystemCode Section Wiring Diagram Name

SSV/A AT Shift Solenoid Valve A

SSV/B AT Shift Solenoid Valve B

START SC Starting System

STOP/L EL Stop lamp

SWL/V EC Swirl Control Valve Control Sole-

noid Valve

TAIL/L EL Parking, License and Tail Lamps

TCCSIG AT A/T TCC Signal (Lock up)

TCV AT Torque Converter Clutch Solenoid

Valve

T/F TF Transfer

TFTS EC Tank Fuel Temperature Sensor

THEFT EL Theft Warning System

TLID EL Glass Hatch Opener

TP/SW EC Throttle Position Switch

TPS AT Throttle Position Sensor

TPS EC Throttle Position Sensor

TRNSMT EL Integrated HOMELINKYTrans-

mitter

TRSA/T AT Turbine Revolution Sensor

TURN EL Turn Signal and Hazard Warning

Lamps

VIAS/V EC Variable Induction Air Control Sys-

tem

VSS EC Vehicle Speed Sensor

VSSA/T AT Vehicle Speed Sensor A/T (Revo-

lution Sensor)

VSSMTR AT Vehicle Speed Sensor MTR

WARN EL Warning Lamps

WINDOW EL Power Window

WIP/R EL Rear Wiper and Washer

WIPER EL Front Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

EL-458

Page 1668 of 2395

SEM415G

17. Disconnect injector harness connectors.

18. Remove fuel tube assembly in reverse order of installation.

Refer to EM-12, ªFuel Tubeº.

SEM416G

19. Remove ignition coils.

20. Remove RH and LH rocker covers from cylinder head.

SEM417G

21. Set No. 1 piston at TDC on the compression stroke by rotat-

ing crankshaft.

IAlign pointer with TDC mark on crankshaft pulley.

SEM418G

ICheck that intake and exhaust cam nose on No. 1 cylinder are

installed as shown left.

If not, turn the crankshaft one revolution (360É) and align as

above.

SEM485G

22. Remove starter motor, and set ring gear stopper using the

mounting bolt hole.

IBe careful not to damage the signal plate teeth.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TIMING CHAIN

Removal (Cont'd)

EM-25

Page 1676 of 2395

SEM439G

SEM440G

17. Install RH and LH rocker covers.

Rocker cover tightening procedure:

ITighten in numerical order as shown in the figure.

a. Tighten bolts 1 to 10 in that order to 6.9 to 8.8 N´m (0.7 to 0.9

kg-m, 61 to 78 in-lb).

b. Then tighten bolts 1 to 10 as indicated in figure to 6.9 to 8.8

N´m (0.7 to 0.9 kg-m, 61 to 78 in-lb).

18. Hang engine using the right and left side engine slingers with

a suitable hoist.

19. Set a suitable transmission jack under the suspension mem-

ber.

20. Remove right and left side engine mounting nuts.

21. Remove right and left side suspension member bolts.

22. Install aluminum oil pan. Refer to EM-18, ªInstallationº.

23. Set ring gear stopper using the mounting bolt hole.

IBe careful not to damage the signal plate teeth.

SEM417G

24. Install crankshaft pulley to crankshaft.

IAlign pointer with TDC mark on crankshaft pulley.

SEM531G

25. Install crankshaft pulley bolt.

ILubricate thread and seat surface of the bolt with new

engine oil.

a. Tighten to 39 to 49 N´m (4.0 to 5.0 kg-m, 29 to 36 ft-lb).

b. Put a paint mark on the crankshaft pulley.

SEM963E

c. Again tighten by turning 60É to 66É, about the angle from one

hexagon bolt head corner to another.

26. Install camshaft position sensor (PHASE), crankshaft position

sensors (REF)/(POS) and CVTC sensors.

27. Reinstall removed parts in the reverse order of removal.

IWhen installing fuel tube and intake manifold collectors, refer

to EM-12, ªTIGHTENING PROCEDURESº.

IAfter starting engine, keep idling for three minutes. Then

rev engine up to 3,000 rpm under no load to purge air from

the high-pressure chamber of the chain tensioners. The

engine may produce a rattling noise. This indicates that

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TIMING CHAIN

Installation (Cont'd)

EM-33

Page 1713 of 2395

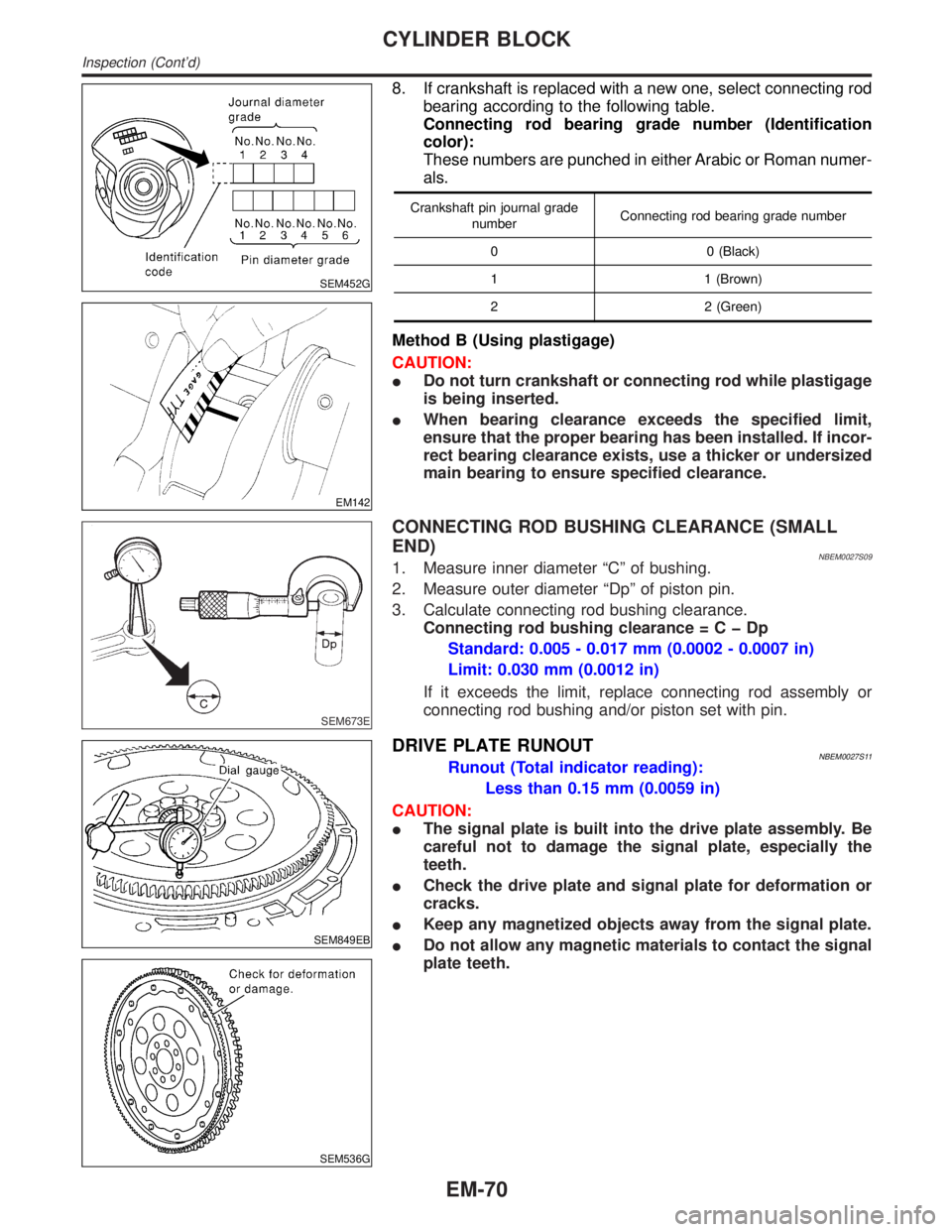

SEM452G

EM142

8. If crankshaft is replaced with a new one, select connecting rod

bearing according to the following table.

Connecting rod bearing grade number (Identification

color):

These numbers are punched in either Arabic or Roman numer-

als.

Crankshaft pin journal grade

numberConnecting rod bearing grade number

0 0 (Black)

1 1 (Brown)

2 2 (Green)

Method B (Using plastigage)

CAUTION:

IDo not turn crankshaft or connecting rod while plastigage

is being inserted.

IWhen bearing clearance exceeds the specified limit,

ensure that the proper bearing has been installed. If incor-

rect bearing clearance exists, use a thicker or undersized

main bearing to ensure specified clearance.

SEM673E

CONNECTING ROD BUSHING CLEARANCE (SMALL

END)

NBEM0027S091. Measure inner diameter ªCº of bushing.

2. Measure outer diameter ªDpº of piston pin.

3. Calculate connecting rod bushing clearance.

Connecting rod bushing clearance=CþDp

Standard: 0.005 - 0.017 mm (0.0002 - 0.0007 in)

Limit: 0.030 mm (0.0012 in)

If it exceeds the limit, replace connecting rod assembly or

connecting rod bushing and/or piston set with pin.

SEM849EB

SEM536G

DRIVE PLATE RUNOUTNBEM0027S11Runout (Total indicator reading):

Less than 0.15 mm (0.0059 in)

CAUTION:

IThe signal plate is built into the drive plate assembly. Be

careful not to damage the signal plate, especially the

teeth.

ICheck the drive plate and signal plate for deformation or

cracks.

IKeep any magnetized objects away from the signal plate.

IDo not allow any magnetic materials to contact the signal

plate teeth.

CYLINDER BLOCK

Inspection (Cont'd)

EM-70

Page 1819 of 2395

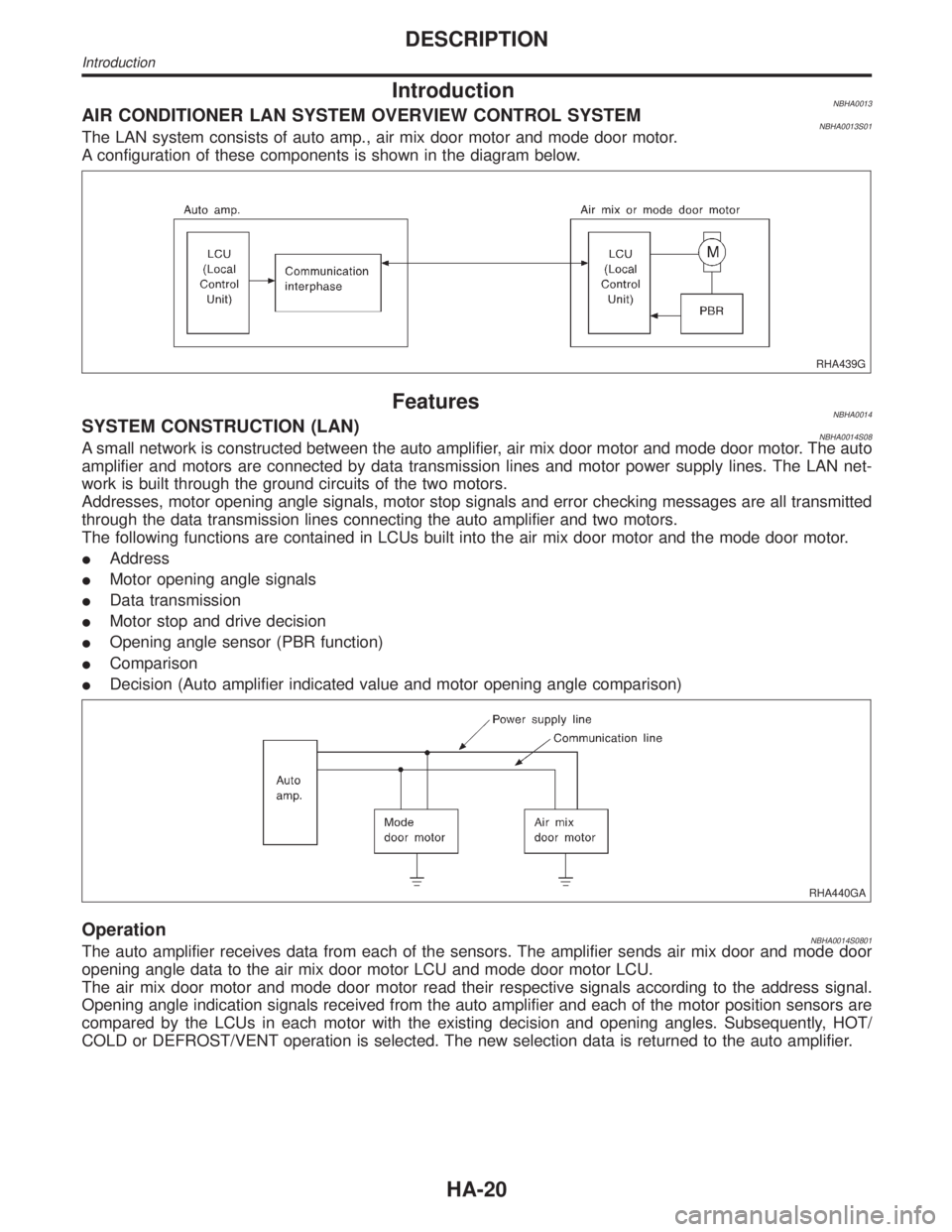

IntroductionNBHA0013AIR CONDITIONER LAN SYSTEM OVERVIEW CONTROL SYSTEMNBHA0013S01The LAN system consists of auto amp., air mix door motor and mode door motor.

A configuration of these components is shown in the diagram below.

RHA439G

FeaturesNBHA0014SYSTEM CONSTRUCTION (LAN)NBHA0014S08A small network is constructed between the auto amplifier, air mix door motor and mode door motor. The auto

amplifier and motors are connected by data transmission lines and motor power supply lines. The LAN net-

work is built through the ground circuits of the two motors.

Addresses, motor opening angle signals, motor stop signals and error checking messages are all transmitted

through the data transmission lines connecting the auto amplifier and two motors.

The following functions are contained in LCUs built into the air mix door motor and the mode door motor.

IAddress

IMotor opening angle signals

IData transmission

IMotor stop and drive decision

IOpening angle sensor (PBR function)

IComparison

IDecision (Auto amplifier indicated value and motor opening angle comparison)

RHA440GA

OperationNBHA0014S0801The auto amplifier receives data from each of the sensors. The amplifier sends air mix door and mode door

opening angle data to the air mix door motor LCU and mode door motor LCU.

The air mix door motor and mode door motor read their respective signals according to the address signal.

Opening angle indication signals received from the auto amplifier and each of the motor position sensors are

compared by the LCUs in each motor with the existing decision and opening angles. Subsequently, HOT/

COLD or DEFROST/VENT operation is selected. The new selection data is returned to the auto amplifier.

DESCRIPTION

Introduction

HA-20

Page 1876 of 2395

SYSTEM DESCRIPTION=NBHA0052Component PartsNBHA0052S01Mode door control system components are:

1) Auto amp.

2) Mode door motor (LCU)

3) In-vehicle sensor

4) Ambient sensor

5) Sunload sensor

6) Intake sensor

System OperationNBHA0052S02The auto amplifier receives data from each of the sensors. The amplifier sends air mix door and mode door

opening angle data to the air mix door motor LCU and mode door motor LCU.

The air mix door motor and mode door motor read their respective signals according to the address signal.

Opening angle indication signals received from the auto amplifier and each of the motor position sensors are

compared by the LCUs in each motor with the existing decision and opening angles. Subsequently, HOT/

COLD or DEFROST/VENT operation is selected. The new selection data is returned to the auto amplifier.

RHA870H

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSES

Mode Door Motor (Cont'd)

HA-77

Page 1883 of 2395

SYSTEM DESCRIPTION=NBHA0059Component PartsNBHA0059S01Air mix door control system components are:

1) Auto amp.

2) Air mix door motor (LCU)

3) In-vehicle sensor

4) Ambient sensor

5) Sunload sensor

6) Intake sensor

System OperationNBHA0059S02The auto amplifier receives data from each of the sensors. The amplifier sends air mix door and mode door

opening angle data to the air mix door motor LCU and mode door motor LCU.

The air mix door motor and mode door motor read their respective signals according to the address signal.

Opening angle indication signals received from the auto amplifier and each of the motor position sensors are

compared by the LCUs in each motor with the existing decision and opening angles. Subsequently, HOT/

COLD or DEFROST/VENT operation is selected. The new selection data is returned to the auto amplifier.

RHA872H

TROUBLE DIAGNOSES

Air Mix Door Motor (Cont'd)

HA-84

Page 1905 of 2395

RHA094GB

SYSTEM DESCRIPTION=NBHA0066Auto amplifier controls compressor operation by ambient tempera-

ture and signal from ECM.

Low Temperature Protection ControlNBHA0066S01Auto amplifier will turn the compressor ªONº or ªOFFº as deter-

mined by a signal detected by ambient sensor.

When ambient temperatures are greater than ±2ÉC (28ÉF), the

compressor turns ªONº. The compressor turns ªOFFº when ambi-

ent temperatures are less than þ5ÉC (23ÉF).

RHA877H

DIAGNOSTIC PROCEDURENBHA0067SYMPTOM: Magnet clutch does not engage when AUTO

switch is ON.

1 CHECK POWER SUPPLY FOR COMPRESSOR

Disconnect compressor harness connector. Do approx. 12 volts exist between compressor harness terminal No. 1 and

body ground?

RHA096G

YesorNo

Ye s©Check magnet clutch coil.

1. If NG, replace magnet clutch. Refer to HA-150.

2. Go to self-diagnosis step-by-step procedure (HA-45) and perform self-diagnosis STEP

4.

Confirm that magnet clutch operation is normal.

No©Disconnect A/C relay. And GO TO 2.

TROUBLE DIAGNOSES

Magnet Clutch (Cont'd)

HA-106