service INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1 of 2395

EDITION: FEBRUARY 2000

REVISION: FEBRUARY 2001

PUBLICATION NO. SM1E-1J50U5

QUICK REFERENCE INDEX

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any form, or

by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan Motor

Company Ltd., Tokyo, Japan.

Page 2 of 2395

FOREWORD

This manual contains maintenance and repair procedures for the

2001 INFINITI QX4.

In order to assure your safety and the efficient functioning of the

vehicle, this manual should be read thoroughly. It is especially

important that the PRECAUTIONS in the GI section be completely

understood before starting any repair task.

All information in this manual is based on the latest product infor-

mation at the time of publication. The right is reserved to make

changes in specifications and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of

the technician and the efficient functioning of the vehicle.

The service methods in this Service Manual are described in such a

manner that the service may be performed safely and accurately.

Service varies with the procedures used, the skills of the technician

and the tools and parts available. Accordingly, anyone using service

procedures, tools or parts which are not specifically recommended

by INFINITI must first be completely satisfied that neither personal

safety nor the vehicle's safety will be jeopardized by the service

method selected.

Page 3 of 2395

PLEASE HELP MAKE THIS SERVICE MANUAL BETTER!

Your comments are important to INFINITI and will help us to improve our Service Manuals.

Use this form to report any issues or comments you may have regarding our Service Manuals.

Please print this form and type or write your comments below. Mail or fax to:

Nissan North America, Inc.

Technical Service Information

39001 Sunrise Drive, P.O. Box 9200

Farmington Hills, MI USA 48331

FAX: (248) 488-3910

SERVICE MANUAL: Model:Year:

PUBLICATION NO. (Please photocopy back cover):

VEHICLE INFORMATION VIN:Production Date:

Please describe any issues or problems in detail:

Page number(s)

Note: Please include a copy of each page, marked with your comments.

Are the trouble diagnosis procedures logical and easy to use? (circle your answer) YES NO

If no, what page number(s)?

Note: Please include a copy of each page, marked with your comments.

Please describe the issue or problem in detail:

Is the organization of the manual clear and easy to follow? (circle your answer) YES NO

Please comment:

What information should be included in INFINITI Service Manuals to better support you in servicing or

repairing customer vehicles?

DATE:YOUR NAME:POSITION:

DEALER:DEALER NO.:ADDRESS:

CITY:STATE/PROV./COUNTRY:ZIP/POSTAL CODE:

Page 6 of 2395

AUTOMATIC TRANSMISSION

SECTION

AT

CONTENTS

TROUBLE DIAGNOSIS - INDEX....................................4

Alphabetical & P No. Index for DTC ...........................4

PRECAUTIONS...............................................................6

Precautions for Supplemental Restraint System

(SRS)²AIR BAG²and²SEAT BELT

PRE-TENSIONER²......................................................6

Precautions for On Board Diagnostic (OBD)

System of A/T and Engine...........................................6

Precautions ..................................................................6

Service Notice or Precautions .....................................8

Wiring Diagrams and Trouble Diagnosis .....................9

PREPARATION.............................................................10

Special Service Tools ................................................10

OVERALL SYSTEM......................................................12

A/T Electrical Parts Location .....................................12

Circuit Diagram ..........................................................13

Cross-sectional View .................................................14

Hydraulic Control Circuit ............................................15

Shift Mechanism ........................................................16

Control System ..........................................................25

Control Mechanism ....................................................26

Control Valve .............................................................31

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................33

Introduction ................................................................33

OBD-II Function for A/T System ................................33

One or Two Trip Detection Logic of OBD-II ..............33

OBD-II Diagnostic Trouble Code (DTC) ....................33

Malfunction Indicator Lamp (MIL) ..............................37

CONSULT-II ...............................................................37

Diagnostic Procedure Without CONSULT-II ..............46

TROUBLE DIAGNOSIS - INTRODUCTION..................53

Introduction ................................................................53

Work Flow ..................................................................57

TROUBLE DIAGNOSIS - BASIC INSPECTION...........59

A/T Fluid Check .........................................................59

Stall Test ....................................................................59

Line Pressure Test .....................................................62

Road Test...................................................................63TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................81

Symptom Chart ..........................................................81

TCM Terminals and Reference Value........................92

TROUBLE DIAGNOSIS FOR POWER SUPPLY..........96

Wiring Diagram - AT - MAIN ......................................96

Diagnostic Procedure ................................................97

DTC P0705 PARK/NEUTRAL POSITION SWITCH.....99

Description .................................................................99

Wiring Diagram - AT - PNP/SW...............................101

Diagnostic Procedure ..............................................102

Component Inspection .............................................103

DTC P0710 A/T FLUID TEMPERATURE SENSOR

CIRCUIT.......................................................................105

Description ...............................................................105

Wiring Diagram - AT - FTS ......................................107

Diagnostic Procedure ..............................................108

Component Inspection ............................................. 110

DTC P0720 VEHICLE SPEED SENSOR.A/T

(REVOLUTION SENSOR)........................................... 111

Description ............................................................... 111

Wiring Diagram - AT - VSSA/T ................................ 113

Diagnostic Procedure .............................................. 114

Component Inspection ............................................. 115

DTC P0725 ENGINE SPEED SIGNAL....................... 116

Description ............................................................... 116

Wiring Diagram - AT - ENGSS ................................ 117

Diagnostic Procedure .............................................. 118

DTC P0731 IMPROPER SHIFTING TO 1ST GEAR

POSITION....................................................................120

Description ...............................................................120

Wiring Diagram - AT - 1ST ......................................123

Diagnostic Procedure ..............................................124

Component Inspection .............................................125

DTC P0732 IMPROPER SHIFTING TO 2ND GEAR

POSITION....................................................................126

Description ...............................................................126

Wiring Diagram - AT - 2ND......................................129

Diagnostic Procedure ..............................................130

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 8 of 2395

19. A/T Does Not Shift: 22-> 11, When Selector

Lever²2²->²1²Position .........................................255

20. Vehicle Does Not Decelerate By Engine

Brake........................................................................256

21. TCM Self-diagnosis Does Not Activate (PNP,

Overdrive Control and Throttle Position Switches

Circuit Checks) ........................................................257

A/T SHIFT LOCK SYSTEM.........................................265

Description ...............................................................265

Wiring Diagram - SHIFT -........................................266

Diagnostic Procedure ..............................................267

KEY INTERLOCK CABLE..........................................271

Components.............................................................271

Removal ...................................................................271

Installation ................................................................272

ON-VEHICLE SERVICE..............................................273

Control Valve Assembly and Accumulators .............273

Revolution Sensor Replacement .............................274

Turbine Revolution Sensor Replacement................274

Rear Oil Seal Replacement .....................................274

Rear Oil Seal and Companion Flange Oil Seal

Replacement ............................................................275

Parking Components Inspection..............................275

Park/Neutral Position Switch Adjustment ................276

Manual Control Linkage Adjustment........................276

REMOVAL AND INSTALLATION...............................277

Removal ...................................................................277

Installation ................................................................278

OVERHAUL.................................................................281

Components.............................................................281

Oil Channel ..............................................................284

Locations of Needle Bearings, Thrust Washers

and Snap Rings .......................................................285

DISASSEMBLY............................................................286

REPAIR FOR COMPONENT PARTS.........................297Oil Pump ..................................................................297

Control Valve Assembly ...........................................301

Control Valve Upper Body .......................................307

Control Valve Lower Body .......................................312

Reverse Clutch ........................................................314

High Clutch ..............................................................317

Forward and Overrun Clutches ...............................320

Low & Reverse Brake..............................................324

Forward Clutch Drum Assembly ..............................328

Rear Internal Gear and Forward Clutch Hub ..........330

Band Servo Piston Assembly ..................................333

Parking Pawl Components ......................................337

ASSEMBLY..................................................................339

Assembly (1) ............................................................339

Adjustment ...............................................................347

Assembly (2) ............................................................349

SERVICE DATA AND SPECIFICATIONS (SDS).......356

General Specifications .............................................356

Shift Schedule..........................................................356

Stall Revolution ........................................................356

Line Pressure...........................................................356

Return Springs .........................................................357

Accumulator O-ring ..................................................358

Clutches and Brakes ...............................................358

Oil Pump and Low One-way Clutch ........................360

Total End Play..........................................................360

Reverse Clutch Drum End Play ..............................361

Removal and Installation .........................................361

Shift Solenoid Valves ...............................................361

Solenoid Valves .......................................................361

A/T Fluid Temperature Sensor.................................361

Turbine Revolution Sensor ......................................361

Revolution Sensor ...................................................362

Dropping Resistor ....................................................362GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CONTENTS(Cont'd)

AT-3

Page 11 of 2395

Precautions for Supplemental Restraint System

(SRS) ªAIR BAGº and ªSEAT BELT

PRE-TENSIONERº

NBAT0001The supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring

harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized INFINITI dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for On Board Diagnostic (OBD)

System of A/T and Engine

NBAT0002The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

IBe sure to turn the ignition switch ªOFFº and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc.

will cause the MIL to light up.

IBe sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

IBe sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

IBe sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to a malfunction of the EGR system or fuel injection system,

etc.

IBe sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

SEF289H

PrecautionsNBAT0003IBefore connecting or disconnecting the TCM harness

connector, turn ignition switch ªOFFº and disconnect

negative battery terminal. Failure to do so may damage

the TCM. Because battery voltage is applied to TCM even

if ignition switch is turned ªOFFº.

PRECAUTIONS

Precautions for Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

AT-6

Page 12 of 2395

SEF291H

IWhen connecting or disconnecting pin connectors into or

from TCM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on TCM

pin terminal, when connecting pin connectors.

MEF040DA

IBefore replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions prop-

erly or not. (Refer to AT-92.)

SAT964I

IAfter performing each TROUBLE DIAGNOSIS, perform

ªDTC (Diagnostic Trouble Code) CONFIRMATION PROCE-

DUREº.

The DTC should not be displayed in the ªDTC CONFIRMA-

TION PROCEDUREº if the repair is completed.

IBefore proceeding with disassembly, thoroughly clean the out-

side of the transmission. It is important to prevent the internal

parts from becoming contaminated by dirt or other foreign mat-

ter.

IDisassembly should be done in a clean work area.

IUse lint-free cloth or towels for wiping parts clean. Common

shop rags can leave fibers that could interfere with the opera-

tion of the transmission.

IPlace disassembled parts in order for easier and proper

assembly.

IAll parts should be carefully cleaned with a general purpose,

non-flammable solvent before inspection or reassembly.

IGaskets, seals and O-rings should be replaced any time the

transmission is disassembled.

IIt is very important to perform functional tests whenever they

are indicated.

IThe valve body contains precision parts and requires extreme

care when parts are removed and serviced. Place disas-

sembled valve body parts in order for easier and proper

assembly. Care will also prevent springs and small parts from

becoming scattered or lost.

IProperly installed valves, sleeves, plugs, etc. will slide along

bores in valve body under their own weight.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Precautions (Cont'd)

AT-7

Page 13 of 2395

IBefore assembly, apply a coat of recommended ATF to all

parts. Apply petroleum jelly to protect O-rings and seals, or

hold bearings and washers in place during assembly. Do not

use grease.

IExtreme care should be taken to avoid damage to O-rings,

seals and gaskets when assembling.

IReplace ATF cooler if excessive foreign material is found in oil

pan or clogging strainer. Refer to ªATF COOLER SERVICEº,

AT-9.

IAfter overhaul, refill the transmission with new ATF.

IWhen the A/T drain plug is removed, only some of the fluid is

drained. Old A/T fluid will remain in torque converter and ATF

cooling system.

Always follow the procedures when changing A/T fluid. Refer

to MA-21, ªChanging A/T Fluidº.

Service Notice or PrecautionsNBAT0004FAIL-SAFENBAT0004S01The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear, even with a shift lever position of ª1º, ª2º or ªDº. The

customer may complain of sluggish or poor acceleration.

When the ignition key is turned ªONº following Fail-Safe operation, O/D OFF indicator lamp blinks for about

8 seconds. (For ªTCM SELF-DIAGNOSTIC PROCEDURE (No Tools)º, refer to AT-46.)

Fail-Safe may occur without electrical circuit damage if the vehicle is driven under extreme conditions (such

as excessive wheel spin followed by sudden braking). To recover normal shift pattern, turn the ignition key

ªOFFº for 5 seconds, then ªONº.

The blinking of the O/D OFF indicator lamp for about 8 seconds will appear only once and be cleared. The

customer may resume normal driving conditions.

Always follow the ªWORK FLOWº (Refer to AT-57).

The SELF-DIAGNOSIS results will be as follows:

The first SELF-DIAGNOSIS will indicate damage to the vehicle speed sensor or the revolution sensor.

During the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

TORQUE CONVERTER SERVICENBAT0004S04The torque converter should be replaced under any of the following conditions:

IExternal leaks in the hub weld area.

IConverter hub is scored or damaged.

IConverter pilot is broken, damaged or fits poorly into crankshaft.

ISteel particles are found after flushing the cooler and cooler lines.

IPump is damaged or steel particles are found in the converter.

IVehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

IConverter is contaminated with engine coolant containing antifreeze.

IInternal failure of stator roller clutch.

IHeavy clutch debris due to overheating (blue converter).

ISteel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged Ð indicates that lining material came from converter.

The torque converter should not be replaced if:

IThe fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

PRECAUTIONS

Precautions (Cont'd)

AT-8

Page 14 of 2395

IThe threads in one or more of the converter bolt holes are damaged.

ITransmission failure did not display evidence of damaged or worn internal parts, steel particles or clutch

plate lining material in unit and inside the fluid filter.

IVehicle has been exposed to high mileage (only). The exception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such

as taxi, delivery or police use.

ATF COOLER SERVICENBAT0004S02Replace ATF cooler if excessive foreign material is found in oil pan or clogging strainer.

Replace radiator lower tank (which includes ATF cooler) with a new one and flush cooler line using cleaning

solvent and compressed air. Refer to LC-19, ªREMOVAL AND INSTALLATIONº.

OBD-II SELF-DIAGNOSISNBAT0004S03IA/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the O/D OFF indicator or the malfunction indicator lamp (MIL). Refer to the table on

AT-38 for the indicator used to display each self-diagnostic result.

IThe self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM

memories.

Always perform the procedure ªHOW TO ERASE DTCº on AT-35 to complete the repair and avoid

unnecessary blinking of the MIL.

IThe following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when

the O/D OFF indicator lamp does not indicate any malfunctions.

þ PNP switch

þ A/T 1st, 2nd, 3rd, or 4th gear function

þ A/T TCC S/V function (lock-up)

*: For details of OBD-II, refer to EC-59, ªIntroductionº.

ICertain systems and components, especially those related to OBD, may use the new style slide-

locking type harness connector. For description and how to disconnect, refer to EL-5, ªDescrip-

tionº.

Wiring Diagrams and Trouble DiagnosisNBAT0005When you read wiring diagrams, refer to the following:

IGI-11, ªHOW TO READ WIRING DIAGRAMSº.

IEL-9, ªPOWER SUPPLY ROUTINGº for power distribution circuit.

When you perform trouble diagnosis, refer to the following:

IGI-35, ªHOW TO FOLLOW TEST GROUP IN TROUBLE DIAGNOSISº.

IGI-24, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Service Notice or Precautions (Cont'd)

AT-9

Page 15 of 2395

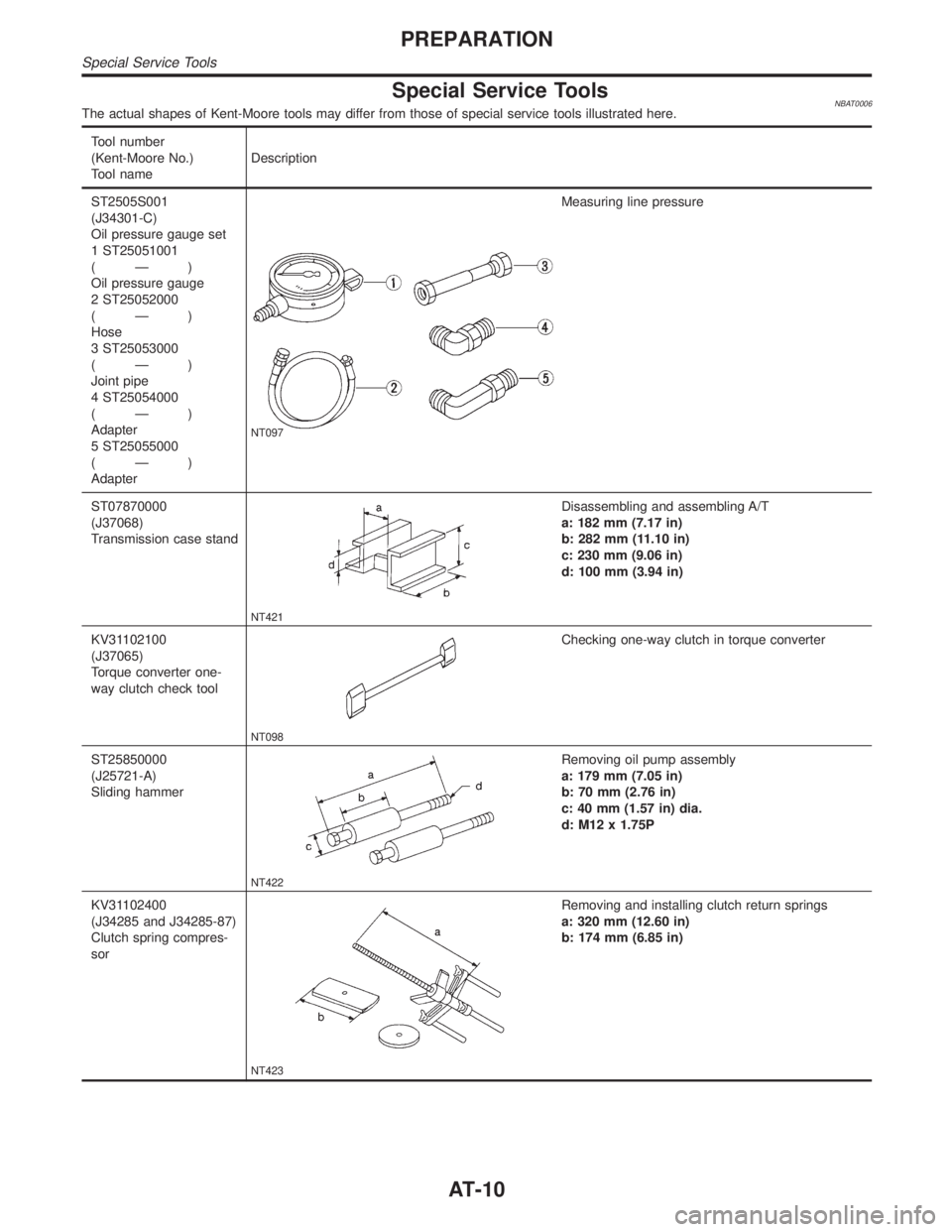

Special Service ToolsNBAT0006The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

ST2505S001

(J34301-C)

Oil pressure gauge set

1 ST25051001

(Ð)

Oil pressure gauge

2 ST25052000

(Ð)

Hose

3 ST25053000

(Ð)

Joint pipe

4 ST25054000

(Ð)

Adapter

5 ST25055000

(Ð)

Adapter

NT097

Measuring line pressure

ST07870000

(J37068)

Transmission case stand

NT421

Disassembling and assembling A/T

a: 182 mm (7.17 in)

b: 282 mm (11.10 in)

c: 230 mm (9.06 in)

d: 100 mm (3.94 in)

KV31102100

(J37065)

Torque converter one-

way clutch check tool

NT098

Checking one-way clutch in torque converter

ST25850000

(J25721-A)

Sliding hammer

NT422

Removing oil pump assembly

a: 179 mm (7.05 in)

b: 70 mm (2.76 in)

c: 40 mm (1.57 in) dia.

d: M12 x 1.75P

KV31102400

(J34285 and J34285-87)

Clutch spring compres-

sor

NT423

Removing and installing clutch return springs

a: 320 mm (12.60 in)

b: 174 mm (6.85 in)

PREPARATION

Special Service Tools

AT-10