clutch INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2346 of 2395

NBTF0038

SMT858D

4WD Shift SwitchNBTF0038S01Check continuity between each terminal.

Terminals Switch position Continuity

1-22WD Yes

Except 2WD No

1-3,1-4AUTO Yes

Except AUTO No

1-4,1-54H Yes

Except 4H No

1-4,1-64LO Yes

Except 4LO No

SMT079D

2-4WD Shift Solenoid Valve and Transfer Fluid

Temperature Sensor

NBTF0038S02Measure resistance between terminals of transfer terminal cord

assembly sub-harness connector located on rear-right of transfer

unit.

Component parts Terminals Resistance

2-4WD shift solenoid valve 4 - 5Approx. 20ÉC (68ÉF):

Approx. 22.8 - 25.2W

Transfer fluid temperature

sensor2-3Approx. 20ÉC (68ÉF): Approx. 2.5 kW

Approx. 80ÉC (176ÉF): Approx. 0.3

kW

SMT080D

4WD Solenoid Valve, Clutch Pressure Switch

and Line Pressure Switch

NBTF0038S03Measure resistance between terminals of transfer terminal cord

assembly sub-harness connector located on rear-right of transfer

unit.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

COMPONENT INSPECTION

4WD Shift Switch

TF-111

Page 2347 of 2395

Component

partsTerminals Remarks

4WD solenoid

valve6

Ground

terminalApprox. 20ÉC (68ÉF): Approx. 3.0 - 3.4W

Clutch pres-

sure switch7In room temperature

I2-4WD shift solenoid valve ªOFFº: No

continuity

I2-4WD shift solenoid valve and transfer

motor ªONº: Continuity exists

Line pressure

switch1In room temperature

ITurn ignition switch to ªOFFº position

and leave vehicle for more than 5 min-

utes. (OFF): No continuity

ITransfer motor ªONº: Continuity exists

SMT081D

Front Revolution SensorNBTF0038S04Measure resistance between terminals of front revolution sensor

sub-harness connector located on rear-right of transfer unit.

Terminals Resistance

16 - 17 500 - 650W

18 - 17 No continuity

18 - 16 No continuity

SMT806D

Transfer Dropping ResistorNBTF0038S07Check resistance between terminals.

Resistance: 11.2 - 12.8W

SMT083D

ATP Switch, Neutral-4LO Switch and Wait

Detection Switch

NBTF0038S06Measure resistance between terminals of transfer switch assembly

sub-harness connector located on rear-right of transfer unit.

COMPONENT INSPECTION

4WD Solenoid Valve, Clutch Pressure Switch and Line Pressure Switch (Cont'd)

TF-112

Page 2349 of 2395

SMT087D

TRANSFER SWITCH ASSEMBLY SUB-HARNESS

CONNECTOR

NBTF0038S0902Check continuity between terminals shown in the figure.

SMT088D

TRANSFER TERMINAL CORD ASSEMBLY

SUB-HARNESS CONNECTOR

NBTF0038S0903Check continuity between terminals shown in the figure.

Terminals on solenoid valve

Terminals Components

6 4WD solenoid valve

4, 5 2-4WD shift solenoid valve

2, 3 Transfer fluid temperature sensor

7 Clutch pressure switch

1 Line pressure switch

SMT807D

Transfer Shift Relay (High & low)NBTF0038S10Check continuity between terminals 3 and 4.

Condition Continuity

12V direct current supply

between terminals 1 and 2No

No current supply Yes

COMPONENT INSPECTION

Transfer Sub-harness (Cont'd)

TF-114

Page 2356 of 2395

Transfer ComponentsNBTF0076

SMT810D

1. Oil seal

2. Transfer cover

3. Snap ring

4. Washer

5. Snap ring

6. Main gear bearing

7. Front case

8. Check plug

9. Check spring

10. Check ball

11. Internal gear

12. Snap ring

13. Bearing race

14. Thrust needle bearing

15. Planetary carrier

16. Thrust needle bearing

17. Sun gear18. L-H sleeve

19. 2-4 sleeve

20. Radial needle bearing

21. Front revolution sensor

22. Roll pin

23. L-H fork

24. 2-4 fork

25. Shift fork spring

26. Fork guide

27. Roll pin

28. Shift rod

29. Self-lock nut

30. Companion flange

31. Oil seal

32. Drain plug

33. Wait detection switch

34. Needle bearing35. Mainshaft

36. Drive chain

37. Clutch drum

38. Clutch hub

39. Snap ring

40. Driven plate

41. Drive plate

42. Retaining plate

43. Return spring assembly

44. Press flange

45. Washer

46. Thrust needle bearing

47. Snap ring

48. Seal ring

49. Front bearing

50. Front drive shaft

51. Rear bearing

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OVERHAUL

Transfer Components

TF-121

Page 2357 of 2395

SMT811D

55. Thrust needle bearing race

56. Clutch piston

57. D-ring

58. Lip seal

59. Oil gutter

60. Center case

61. Stem bleeder

62. Mainshaft rear bearing

63. Thrust washer

64. Speedometer drive gear

65. Snap ring

66. Rear case

67. ATP switch

68. Neutral-4LO switch69. Oil seal

70. Magnet

71. Baffle plate

72. Oil strainer

73. O-ring

74. Control valve assembly

75. Lip seal (7 pieces)

76. Filler plug

77. Inner gear

78. Outer gear

79. Oil pump housing

80. Bushing

81. Oil pump shaft

82. Oil pressure check plug83. Oil pump gasket

84. Sub-oil pump housing

85. Outer gear

86. Inner gear

87. O-ring

88. Sub-oil pump cover

89. O-ring

90. Transfer motor

91. O-ring

92. Oil filter stud

93. O-ring

94. O-ring

95. Oil filter

OVERHAUL

Transfer Components (Cont'd)

TF-122

Page 2360 of 2395

SMT900C

Front Drive Shaft and Drive ChainNBTF0078S011. Remove oil gutter from center case.

2. With front drive shaft held by one hand as shown in the figure,

tap center case with a plastic hammer to remove it with drive

chain.

IDo not tap drive chain with a plastic hammer.

SMT901CB

3. Set a puller (ST30021000) and an adapter (ST33052000).

Remove front drive shaft front bearing.

SMT902CB

4. Set the puller (ST30021000) and the adapter (ST33052000).

Remove front drive shaft rear bearing.

SMT903CA

Mainshaft and Clutch DrumNBTF0078S021. Remove mounting bolts to detach baffle plate.

SMT904C

2. Set center case to press stand. Remove mainshaft from cen-

ter case.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DISASSEMBLY

Center Case (Cont'd)

TF-125

Page 2362 of 2395

SMT910C

8. Remove press flange from mainshaft.

SMT911C

9. Remove return spring assembly from clutch hub.

SMT912C

10. Remove each plate from clutch drum.

SMT913C

11. Remove snap ring from mainshaft.

IDo not reuse snap ring.

SMT914C

12. Tap mainshaft with a plastic hammer to remove it from clutch

drum and clutch hub.

13. Remove needle bearing from mainshaft.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DISASSEMBLY

Center Case (Cont'd)

TF-127

Page 2363 of 2395

SMT915C

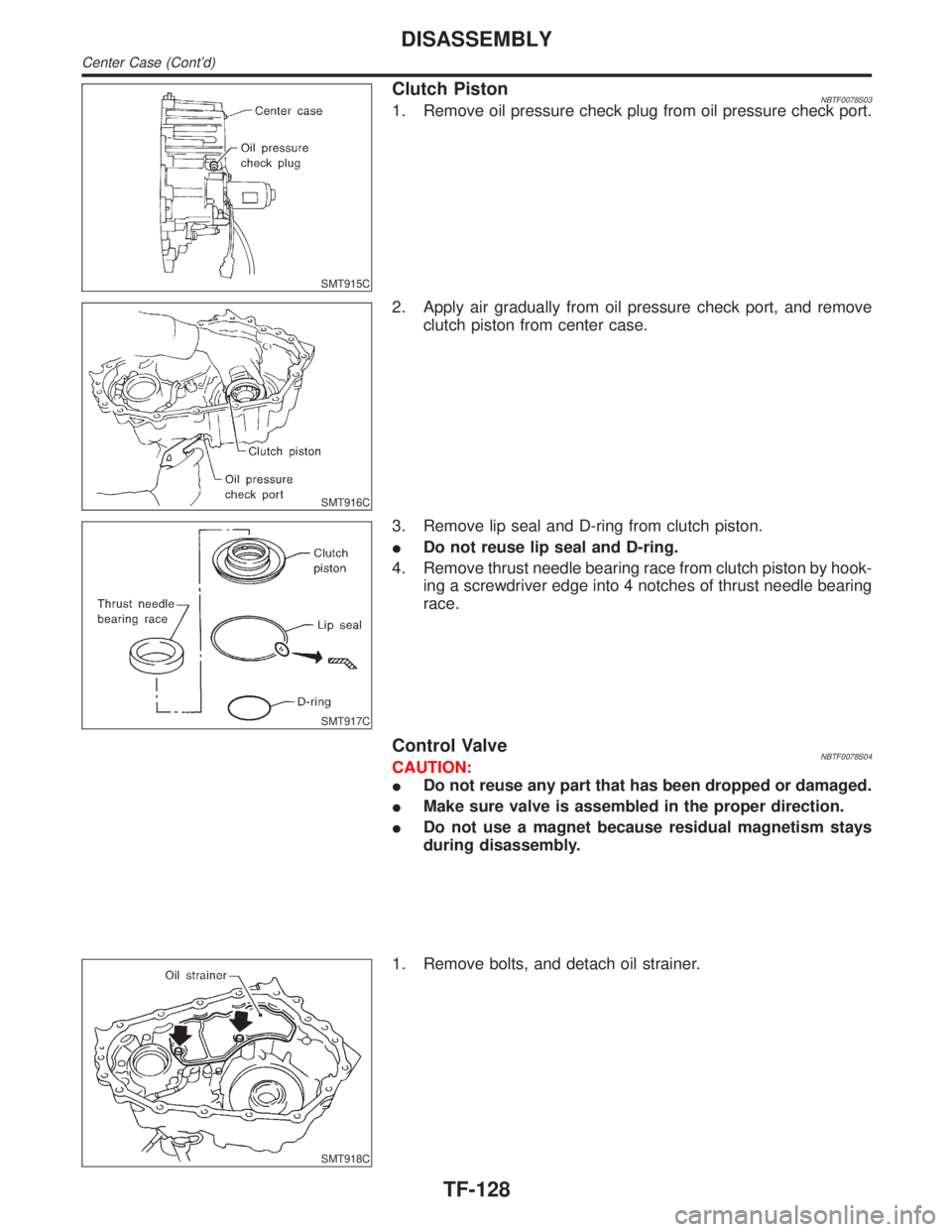

Clutch PistonNBTF0078S031. Remove oil pressure check plug from oil pressure check port.

SMT916C

2. Apply air gradually from oil pressure check port, and remove

clutch piston from center case.

SMT917C

3. Remove lip seal and D-ring from clutch piston.

IDo not reuse lip seal and D-ring.

4. Remove thrust needle bearing race from clutch piston by hook-

ing a screwdriver edge into 4 notches of thrust needle bearing

race.

Control ValveNBTF0078S04CAUTION:

IDo not reuse any part that has been dropped or damaged.

IMake sure valve is assembled in the proper direction.

IDo not use a magnet because residual magnetism stays

during disassembly.

SMT918C

1. Remove bolts, and detach oil strainer.

DISASSEMBLY

Center Case (Cont'd)

TF-128

Page 2365 of 2395

SMT924C

7. Remove 4WD solenoid valve, clutch pressure switch, 2-4WD

shift solenoid valve, line pressure switch, and transfer fluid

temperature sensor from control valve assembly.

8. Remove O-rings from each solenoid valve, switch and termi-

nal body.

IDo not reuse O-rings.

SMT925C

9. Place control valve with lower body facing up, remove two

mounting bolts, and then remove lower body and separator

plate from upper body.

CAUTION:

IBe careful not to drop relief balls. Detach lower body care-

fully.

IDo not reuse separator plate.

SMT926C

10. Make sure reverse balls, relief balls and relief springs, accu-

mulator pistons, valve springs, and filters are securely installed

as shown in the figure, and remove them.

SMT927C

11. Remove retainer plates.

SMT928CA

12. Remove each control valve, spring and plug.

DISASSEMBLY

Center Case (Cont'd)

TF-130

Page 2373 of 2395

SMT010D

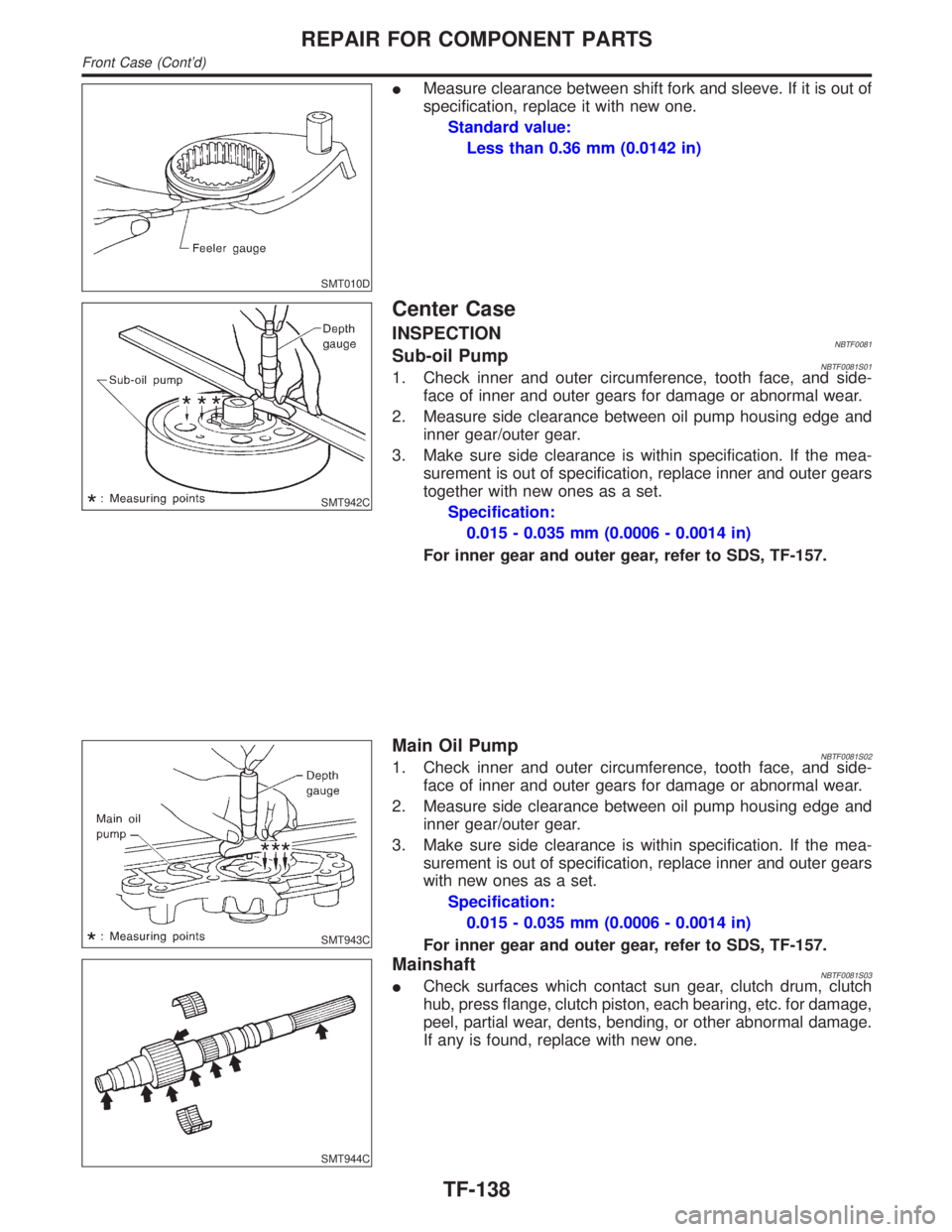

IMeasure clearance between shift fork and sleeve. If it is out of

specification, replace it with new one.

Standard value:

Less than 0.36 mm (0.0142 in)

SMT942C

Center Case

INSPECTIONNBTF0081Sub-oil PumpNBTF0081S011. Check inner and outer circumference, tooth face, and side-

face of inner and outer gears for damage or abnormal wear.

2. Measure side clearance between oil pump housing edge and

inner gear/outer gear.

3. Make sure side clearance is within specification. If the mea-

surement is out of specification, replace inner and outer gears

together with new ones as a set.

Specification:

0.015 - 0.035 mm (0.0006 - 0.0014 in)

For inner gear and outer gear, refer to SDS, TF-157.

SMT943C

Main Oil PumpNBTF0081S021. Check inner and outer circumference, tooth face, and side-

face of inner and outer gears for damage or abnormal wear.

2. Measure side clearance between oil pump housing edge and

inner gear/outer gear.

3. Make sure side clearance is within specification. If the mea-

surement is out of specification, replace inner and outer gears

with new ones as a set.

Specification:

0.015 - 0.035 mm (0.0006 - 0.0014 in)

For inner gear and outer gear, refer to SDS, TF-157.

SMT944C

MainshaftNBTF0081S03ICheck surfaces which contact sun gear, clutch drum, clutch

hub, press flange, clutch piston, each bearing, etc. for damage,

peel, partial wear, dents, bending, or other abnormal damage.

If any is found, replace with new one.

REPAIR FOR COMPONENT PARTS

Front Case (Cont'd)

TF-138