Crankshaft position INFINITI QX4 2001 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 567 of 2395

IWhen the engine coolant temperature becomes excessively high.

IWhen operating power steering during low engine speed or low vehicle speed.

IWhen engine speed is excessively low.

IWhen refrigerant pressure is excessively low or high.

Fuel Cut Control (at no load & high engine

speed)

DESCRIPTIONNBEC0017Input/Output Signal ChartNBEC0017S01

Sensor Input Signal to ECMECM func-

tionActuator

Vehicle speed sensor Vehicle speed

Fuel cut

controlInjectors Park/neutral position (PNP) switch Neutral position

Throttle position sensor Throttle position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (POS) Engine speed (POS signal)

Crankshaft position sensor (REF) Engine speed (REF signal)

If the engine speed is above 1,800 rpm with no load (for example, in neutral and engine speed over 1,800

rpm) fuel will be cut off after some time. The exact time when the fuel is cut off varies based on engine speed.

Fuel cut will operate until the engine speed reaches 1,500 rpm, then fuel cut is cancelled.

NOTE:

This function is different from deceleration control listed under ªMultiport Fuel Injection (MFI) Systemº, EC-28.

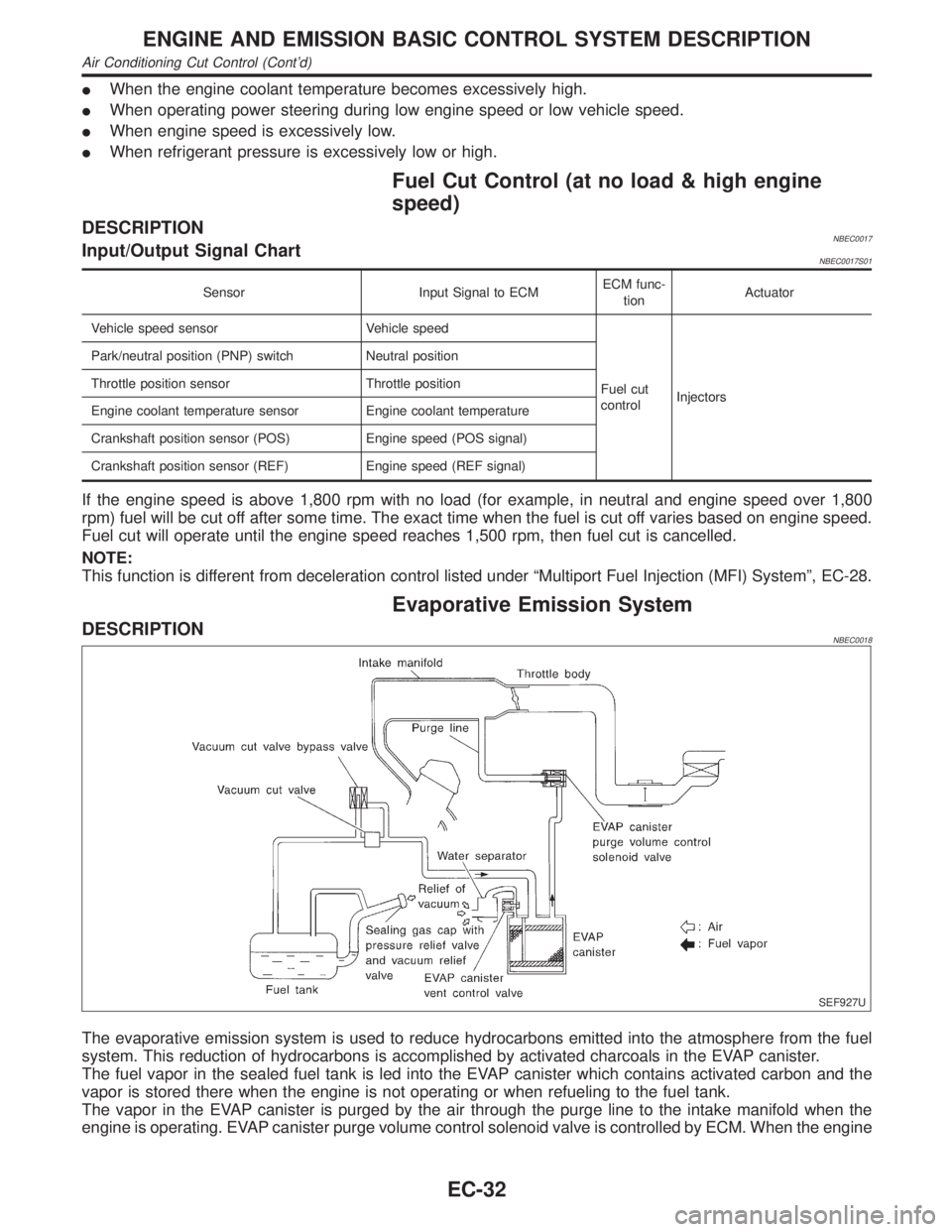

Evaporative Emission System

DESCRIPTIONNBEC0018

SEF927U

The evaporative emission system is used to reduce hydrocarbons emitted into the atmosphere from the fuel

system. This reduction of hydrocarbons is accomplished by activated charcoals in the EVAP canister.

The fuel vapor in the sealed fuel tank is led into the EVAP canister which contains activated carbon and the

vapor is stored there when the engine is not operating or when refueling to the fuel tank.

The vapor in the EVAP canister is purged by the air through the purge line to the intake manifold when the

engine is operating. EVAP canister purge volume control solenoid valve is controlled by ECM. When the engine

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTION

Air Conditioning Cut Control (Cont'd)

EC-32

Page 617 of 2395

ENGINE CONTROL COMPONENT PARTS/CONTROL

SYSTEMS APPLICATION

NBEC0034S02

ItemDIAGNOSTIC TEST MODE

WORK

SUP-

PORTSELF-DIAGNOSTIC

RESULTS

D ATA

MONI-

TORD ATA

MONI-

TOR

(SPEC)ACTIVE

TESTDTC & SRT

CONFIRMATION

DTC*1FREEZE

FRAME

DATA*2SRT

STATUSDTC

WORK

SUP-

PORT

ENGINE CONTROL COMPONENT PARTS

INPUT

Crankshaft position sensor

(POS)XXXX

Crankshaft position sensor (REF) X X X

Mass air flow sensor X X X

Engine coolant temperature sen-

sorXXXXX

Heated oxygen sensor 1 (front) X X X X X

Heated oxygen sensor 2 (rear) X X X X X

Vehicle speed sensorXXXX

Throttle position sensor X X X

Fuel tank temperature sensor X X X X

EVAP control system pressure

sensorXXX

Absolute pressure sensor X X X

Intake air temperature sensor X X X

Knock sensor X

Ignition switch (start signal) X X

Closed throttle position switch X X X

Closed throttle position switch

(throttle position sensor signal)XX

Air conditioner switch X X

Park/neutral position (PNP)

switchXXX

Power steering oil pressure

switchXX

Battery voltage X X

Ambient air temperature switch X X

Load signal X X

Swirl control valve control

vacuum check switchXXX

Fuel level sensor X X X

Intake valve timing control posi-

tion sensorXXX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-82

Page 622 of 2395

![INFINITI QX4 2001 Factory User Guide DATA MONITOR MODE=NBEC0034S06

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED [rpm]qqIIndicates the engine speed computed

from the REF signal (120É signal) of the

cran INFINITI QX4 2001 Factory User Guide DATA MONITOR MODE=NBEC0034S06

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED [rpm]qqIIndicates the engine speed computed

from the REF signal (120É signal) of the

cran](/img/42/57027/w960_57027-621.png)

DATA MONITOR MODE=NBEC0034S06

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED [rpm]qqIIndicates the engine speed computed

from the REF signal (120É signal) of the

crankshaft position sensor (REF).

CKPS´RPM (POS)

[rpm]qIIndicates the engine speed computed

from the POS signal (1É signal) of the

crankshaft position sensor (POS).IAccuracy becomes poor if engine

speed drops below the idle rpm.

IIf the signal is interrupted while the

engine is running, an abnormal value

may be indicated.

POS COUNTqIIndicates the number of signal plate

(Flywheel/Drive Plate) cogs (tooth) dur-

ing one revolution of the engine.

MAS A/F SE-B1 [V]qqIThe signal voltage of the mass air flow

sensor is displayed.IWhen the engine is stopped, a certain

value is indicated.

COOLAN TEMP/S

[ÉC] or [ÉF]qqIThe engine coolant temperature (deter-

mined by the signal voltage of the

engine coolant temperature sensor) is

displayed.IWhen the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine cool-

ant temperature determined by the

ECM is displayed.

HO2S1 (B1) [V]qq

IThe signal voltage of the front heated

oxygen sensor is displayed.

HO2S1 (B2) [V]qq

HO2S2 (B1) [V]qq

IThe signal voltage of the rear heated

oxygen sensor is displayed.

HO2S2 (B2) [V]qq

HO2S1 MNTR (B1)

[RICH/LEAN]qIDisplay of front heated oxygen sensor

signal during air-fuel ratio feedback

control:

RICH ... means the mixture became

ªrichº, and control is being affected

toward a leaner mixture.

LEAN ... means the mixture became

ªleanº, and control is being affected

toward a rich mixture.IAfter turning ON the ignition switch,

ªRICHº is displayed until air-fuel mixture

ratio feedback control begins.

IWhen the air-fuel ratio feedback is

clamped, the value just before the

clamping is displayed continuously. HO2S1 MNTR (B2)

[RICH/LEAN]q

HO2S2 MNTR (B1)

[RICH/LEAN]qIDisplay of rear heated oxygen sensor

signal:

RICH ... means the amount of oxygen

after three way catalyst is relatively

small.

LEAN ... means the amount of oxygen

after three way catalyst is relatively

large.IWhen the engine is stopped, a certain

value is indicated.

HO2S2 MNTR (B2)

[RICH/LEAN]q

VHCL SPEED SE

[km/h] or [mph]qqIThe vehicle speed computed from the

vehicle speed sensor signal is dis-

played.

BATTERY VOLT [V]qqIThe power supply voltage of ECM is

displayed.

THRTL POS SEN [V]qqIThe throttle position sensor signal volt-

age is displayed.

FUEL T/TMP SE

[ÉC] or [ÉF]IThe fuel temperature judged from the

tank fuel temperature sensor signal

voltage is displayed.GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-87

Page 651 of 2395

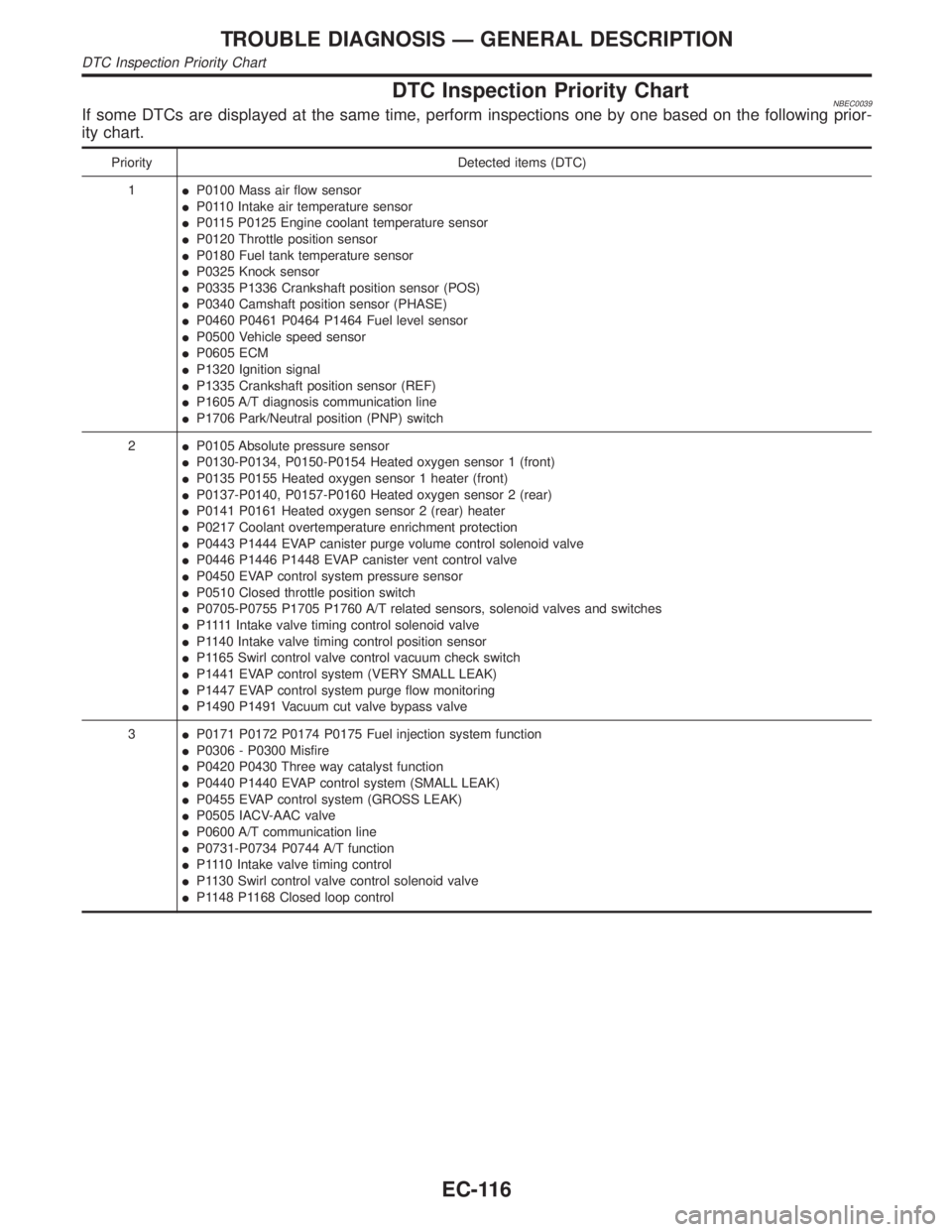

DTC Inspection Priority ChartNBEC0039If some DTCs are displayed at the same time, perform inspections one by one based on the following prior-

ity chart.

Priority Detected items (DTC)

1IP0100 Mass air flow sensor

IP0110 Intake air temperature sensor

IP0115 P0125 Engine coolant temperature sensor

IP0120 Throttle position sensor

IP0180 Fuel tank temperature sensor

IP0325 Knock sensor

IP0335 P1336 Crankshaft position sensor (POS)

IP0340 Camshaft position sensor (PHASE)

IP0460 P0461 P0464 P1464 Fuel level sensor

IP0500 Vehicle speed sensor

IP0605 ECM

IP1320 Ignition signal

IP1335 Crankshaft position sensor (REF)

IP1605 A/T diagnosis communication line

IP1706 Park/Neutral position (PNP) switch

2IP0105 Absolute pressure sensor

IP0130-P0134, P0150-P0154 Heated oxygen sensor 1 (front)

IP0135 P0155 Heated oxygen sensor 1 heater (front)

IP0137-P0140, P0157-P0160 Heated oxygen sensor 2 (rear)

IP0141 P0161 Heated oxygen sensor 2 (rear) heater

IP0217 Coolant overtemperature enrichment protection

IP0443 P1444 EVAP canister purge volume control solenoid valve

IP0446 P1446 P1448 EVAP canister vent control valve

IP0450 EVAP control system pressure sensor

IP0510 Closed throttle position switch

IP0705-P0755 P1705 P1760 A/T related sensors, solenoid valves and switches

IP 1111Intake valve timing control solenoid valve

IP1140 Intake valve timing control position sensor

IP1165 Swirl control valve control vacuum check switch

IP1441 EVAP control system (VERY SMALL LEAK)

IP1447 EVAP control system purge flow monitoring

IP1490 P1491 Vacuum cut valve bypass valve

3IP0171 P0172 P0174 P0175 Fuel injection system function

IP0306 - P0300 Misfire

IP0420 P0430 Three way catalyst function

IP0440 P1440 EVAP control system (SMALL LEAK)

IP0455 EVAP control system (GROSS LEAK)

IP0505 IACV-AAC valve

IP0600 A/T communication line

IP0731-P0734 P0744 A/T function

IP1110 Intake valve timing control

IP1130 Swirl control valve control solenoid valve

IP1148 P1168 Closed loop control

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

DTC Inspection Priority Chart

EC-116

Page 652 of 2395

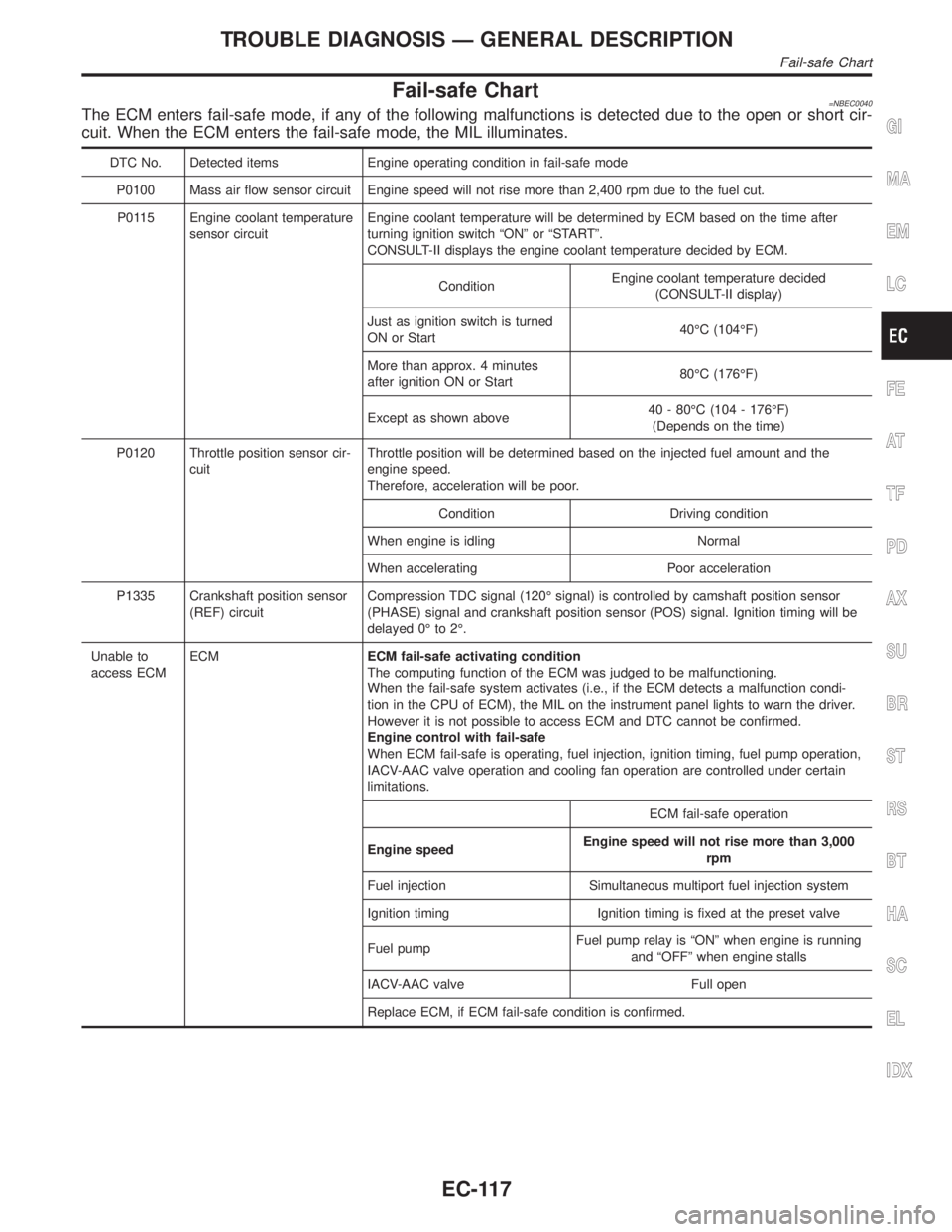

Fail-safe Chart=NBEC0040The ECM enters fail-safe mode, if any of the following malfunctions is detected due to the open or short cir-

cuit. When the ECM enters the fail-safe mode, the MIL illuminates.

DTC No. Detected items Engine operating condition in fail-safe mode

P0100 Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.

P0115 Engine coolant temperature

sensor circuitEngine coolant temperature will be determined by ECM based on the time after

turning ignition switch ªONº or ªSTARTº.

CONSULT-II displays the engine coolant temperature decided by ECM.

ConditionEngine coolant temperature decided

(CONSULT-II display)

Just as ignition switch is turned

ON or Start40ÉC (104ÉF)

More than approx. 4 minutes

after ignition ON or Start80ÉC (176ÉF)

Except as shown above40 - 80ÉC (104 - 176ÉF)

(Depends on the time)

P0120 Throttle position sensor cir-

cuitThrottle position will be determined based on the injected fuel amount and the

engine speed.

Therefore, acceleration will be poor.

Condition Driving condition

When engine is idling Normal

When accelerating Poor acceleration

P1335 Crankshaft position sensor

(REF) circuitCompression TDC signal (120É signal) is controlled by camshaft position sensor

(PHASE) signal and crankshaft position sensor (POS) signal. Ignition timing will be

delayed 0É to 2É.

Unable to

access ECMECMECM fail-safe activating condition

The computing function of the ECM was judged to be malfunctioning.

When the fail-safe system activates (i.e., if the ECM detects a malfunction condi-

tion in the CPU of ECM), the MIL on the instrument panel lights to warn the driver.

However it is not possible to access ECM and DTC cannot be confirmed.

Engine control with fail-safe

When ECM fail-safe is operating, fuel injection, ignition timing, fuel pump operation,

IACV-AAC valve operation and cooling fan operation are controlled under certain

limitations.

ECM fail-safe operation

Engine speedEngine speed will not rise more than 3,000

rpm

Fuel injection Simultaneous multiport fuel injection system

Ignition timing Ignition timing is fixed at the preset valve

Fuel pumpFuel pump relay is ªONº when engine is running

and ªOFFº when engine stalls

IACV-AAC valve Full open

Replace ECM, if ECM fail-safe condition is confirmed.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Fail-safe Chart

EC-117

Page 654 of 2395

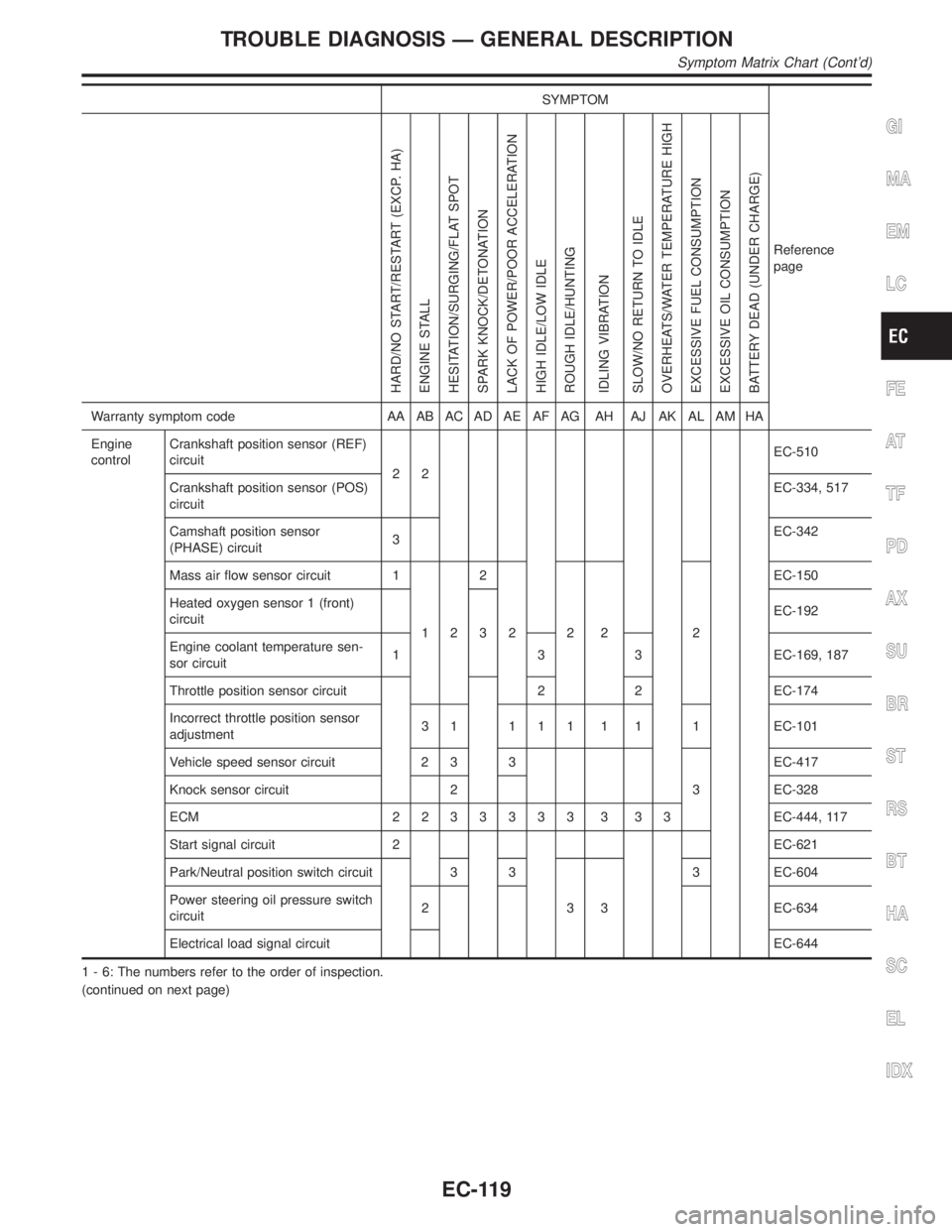

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Engine

controlCrankshaft position sensor (REF)

circuit

22EC-510

Crankshaft position sensor (POS)

circuitEC-334, 517

Camshaft position sensor

(PHASE) circuit3EC-342

Mass air flow sensor circuit 1

122

222 2EC-150

Heated oxygen sensor 1 (front)

circuit

3EC-192

Engine coolant temperature sen-

sor circuit1 3 3 EC-169, 187

Throttle position sensor circuit 2 2 EC-174

Incorrect throttle position sensor

adjustment3 1 1 1 1 1 1 1 EC-101

Vehicle speed sensor circuit 2 3 3

3EC-417

Knock sensor circuit 2 EC-328

ECM 2233333 3 33EC-444, 117

Start signal circuit 2 EC-621

Park/Neutral position switch circuit 3 3

333 EC-604

Power steering oil pressure switch

circuit2 EC-634

Electrical load signal circuitEC-644

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart (Cont'd)

EC-119

Page 667 of 2395

![INFINITI QX4 2001 Factory User Guide TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

61 OR Mass air flow sensor[Engine is running]

IWarm-up condition

IIdle speed1.2 - 1.8V

[Engine is running]

IWarm-up condition

IEngine speed is INFINITI QX4 2001 Factory User Guide TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

61 OR Mass air flow sensor[Engine is running]

IWarm-up condition

IIdle speed1.2 - 1.8V

[Engine is running]

IWarm-up condition

IEngine speed is](/img/42/57027/w960_57027-666.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

61 OR Mass air flow sensor[Engine is running]

IWarm-up condition

IIdle speed1.2 - 1.8V

[Engine is running]

IWarm-up condition

IEngine speed is 2,500 rpm.1.6 - 2.2V

62 G/BHeated oxygen sensor

1 (front) (bank 2)[Engine is running]

IWarm-up condition

IEngine speed is 2,000 rpm.0 - Approximately 1.0V (Peri-

odically change)

SEF059V

63 GHeated oxygen sensor

1 (front) (bank 1)[Engine is running]

IWarm-up condition

IEngine speed is 2,000 rpm.0 - Approximately 1.0V (Peri-

odically change)

SEF059V

64 Y/PUIntake air temperature

sensor[Engine is running]Approximately 0 - 4.8V

Output voltage varies with

intake air temperature.

65

75LG

LGCrankshaft position

sensor (REF)[Engine is running]

IWarm-up condition

IIdle speedApproximately 2.3VH

(AC voltage)

SEF581X

66

76L

LCamshaft position sen-

sor (PHASE)[Engine is running]

IWarm-up condition

IIdle speedApproximately 4.2VH

(AC voltage)

SEF582X

12

67W/RPower supply for ECM

(Buck-up)[Ignition switch ªOFFº]BATTERY VOLTAGE

(11 - 14V)

70 LG/REngine coolant tem-

perature sensor[Engine is running]Approximately 0 - 4.8V

Output voltage varies with

engine coolant temperature.

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

ECM Terminals and Reference Value (Cont'd)

EC-132

Page 669 of 2395

![INFINITI QX4 2001 Factory User Guide TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

85 YCrankshaft position

sensor (POS)[Engine is running]

IIdle speedApproximately 2.4V

SEF057V

[Engine is running]

IEngine speed is 2,000 rpm.Ap INFINITI QX4 2001 Factory User Guide TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

85 YCrankshaft position

sensor (POS)[Engine is running]

IIdle speedApproximately 2.4V

SEF057V

[Engine is running]

IEngine speed is 2,000 rpm.Ap](/img/42/57027/w960_57027-668.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

85 YCrankshaft position

sensor (POS)[Engine is running]

IIdle speedApproximately 2.4V

SEF057V

[Engine is running]

IEngine speed is 2,000 rpm.Approximately 2.3V

SEF058V

86 W/L Vehicle speed sensor[Engine is running]

IJack up front wheels.

IIn 1st gear position

I10 km/h (6 MPH)Approximately 2.5VSEF583X

[Engine is running]

IJack up front wheels.

IIn 2nd gear position

I30 km/h (19 MPH)Approximately 2.0V

SEF584X

89 ORIntake valve timing

control position sen-

sors (LH)[Engine is running]

IWarm-up condition

IIdle speedApproximatley 0.5VSEF351Z

[Engine is running]

IWarm-up condition

IEngine speed is 2,000 rpm.Approximatley 0.5V

SEF352Z

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

ECM Terminals and Reference Value (Cont'd)

EC-134

Page 711 of 2395

ICrankshaft position sensor (REF)

ICrankshaft position sensor (POS)

IMass air flow sensor

MALFUNCTION CNBEC0430S03IHarness or connectors

(The throttle position sensor circuit is open or shorted.)

IIntake air leaks

IThrottle position sensor

DTC Confirmation ProcedureNBEC0078NOTE:

IPerform ªPROCEDURE FOR MALFUNCTION Aº first. If the

1st trip DTC cannot be confirmed, perform ªPROCEDURE

FOR MALFUNCTION Bº.

If there is no problem on ªPROCEDURE FOR MALFUNC-

TION Bº, perform ªPROCEDURE FOR MALFUNCTION Cº.

IIf ªDTC Confirmation Procedureº has been previously

conducted, always turn ignition switch ªOFFº and wait at least

10 seconds before conducting the next test.

PROCEDURE FOR MALFUNCTION ANBEC0078S01CAUTION:

Always drive vehicle at a safe speed.

TESTING CONDITION:

IBefore performing the following procedure, confirm that

battery voltage is more than 10V at idle.

IThis test may be conducted with the drive wheels lifted in

the shop or by driving the vehicle. If a road test is

expected to be easier, it is unnecessary to lift the vehicle.

SEF065Y

With CONSULT-IINBEC0078S01011) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II.

2) Start engine and maintain the following conditions for at least

5 consecutive seconds.

Vehicle speed More than 5 km/h (3 MPH)

Selector lever Suitable position except ªPº or ªNº position

3) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-181.

With GSTNBEC0078S0102Follow the procedure ªWith CONSULT-IIº above.

DTC P0120 THROTTLE POSITION SENSOR

Possible Cause (Cont'd)

EC-176

Page 720 of 2395

12 CHECK MASS AIR FLOW SENSOR

1. Reconnect harness connectors disconneted.

2. Start engine and warm it up to normal operating temperature.

3. Check voltage between ECM terminal 61 (Mass air flow sensor signal) and ground.

SEF298X

4. If the voltage is out of specification, disconnect mass air flow sensor harness connector and connect it again.

Then repeat above check.

OK or NG

OK©GO TO 13.

NG©Replace mass air flow sensor.

13 CHECK CRANKSHAFT POSITION SENSOR (POS)

1. Install all removed parts.

2. Perform ªDTC Confirmation Procedureº for DTC P0335 and P1336. Refer to EC-336, 519.

OK or NG

OK©GO TO 14.

NG©Replace crankshaft position sensor (POS).

14 CHECK CRANKSHAFT POSITION SENSOR (REF)

Perform ªDTC Confirmation Procedureº for DTC P1335. Refer to EC-511.

OK or NG

OK©GO TO 15.

NG©Replace crankshaft position sensor (REF).

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0120 THROTTLE POSITION SENSOR

Diagnostic Procedure (Cont'd)

EC-185