oil reset INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 563 of 2395

Multiport Fuel Injection (MFI) System

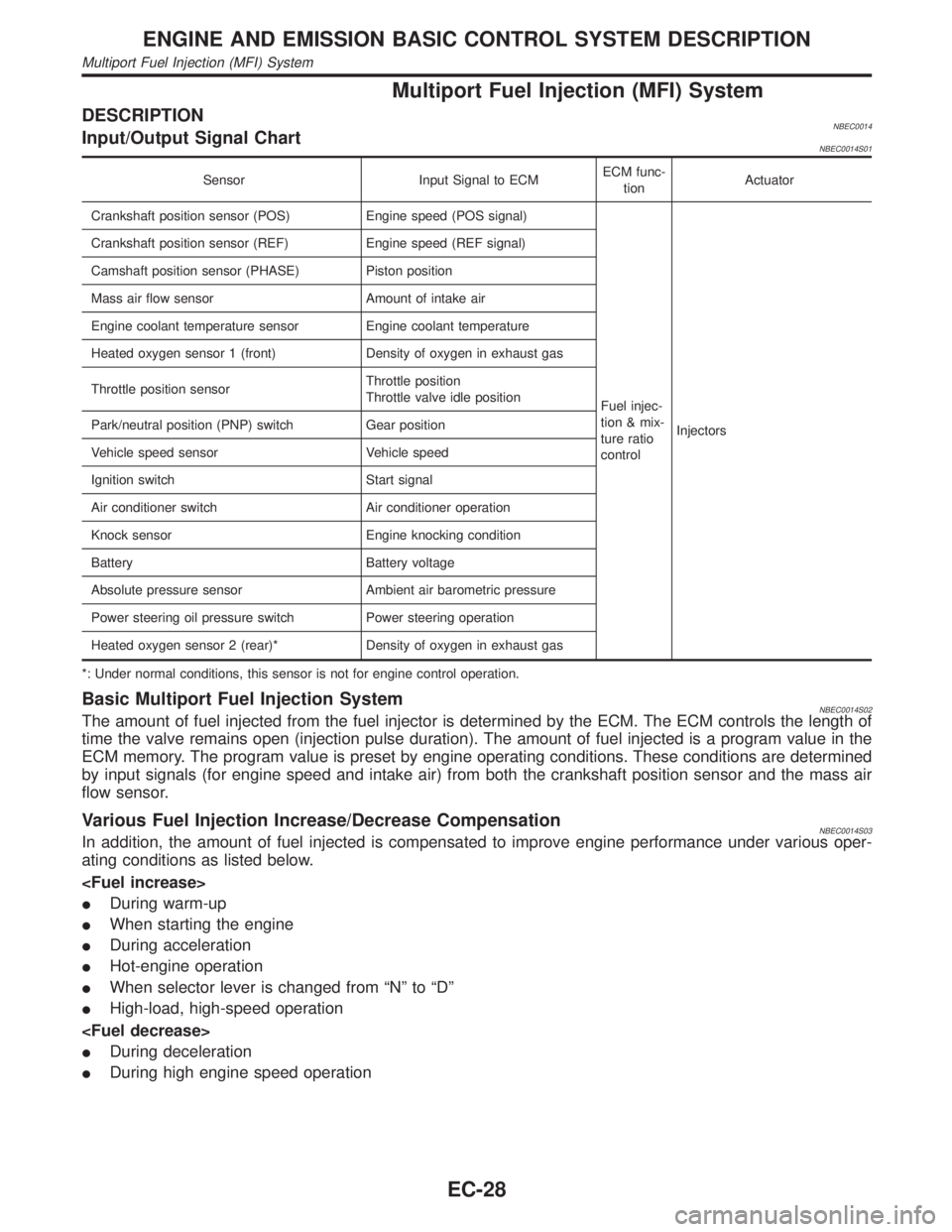

DESCRIPTIONNBEC0014Input/Output Signal ChartNBEC0014S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed (POS signal)

Fuel injec-

tion & mix-

ture ratio

controlInjectors Crankshaft position sensor (REF) Engine speed (REF signal)

Camshaft position sensor (PHASE) Piston position

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Heated oxygen sensor 1 (front) Density of oxygen in exhaust gas

Throttle position sensorThrottle position

Throttle valve idle position

Park/neutral position (PNP) switch Gear position

Vehicle speed sensor Vehicle speed

Ignition switch Start signal

Air conditioner switch Air conditioner operation

Knock sensor Engine knocking condition

Battery Battery voltage

Absolute pressure sensor Ambient air barometric pressure

Power steering oil pressure switch Power steering operation

Heated oxygen sensor 2 (rear)* Density of oxygen in exhaust gas

*: Under normal conditions, this sensor is not for engine control operation.

Basic Multiport Fuel Injection SystemNBEC0014S02The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from both the crankshaft position sensor and the mass air

flow sensor.

Various Fuel Injection Increase/Decrease CompensationNBEC0014S03In addition, the amount of fuel injected is compensated to improve engine performance under various oper-

ating conditions as listed below.

IDuring warm-up

IWhen starting the engine

IDuring acceleration

IHot-engine operation

IWhen selector lever is changed from ªNº to ªDº

IHigh-load, high-speed operation

IDuring deceleration

IDuring high engine speed operation

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTION

Multiport Fuel Injection (MFI) System

EC-28

Page 1351 of 2395

Trouble DiagnosesNBEL0082AUDIO UNITNBEL0082S01

Symptom Possible causes Repair order

Audio unit inoperative (no

digital display and no

sound from speakers).1. 10A fuse

2. Poor audio unit case ground

3. Audio unit1. Check 10A fuse [No. 10, located in fuse block (J/B)].

Turn ignition switch ON and verify that battery posi-

tive voltage is present at terminal 10 of audio unit.

2. Check audio unit case ground.

3. Remove audio unit for repair.

Audio unit presets are lost

when ignition switch is

turned OFF.1. 15A fuse

2. Audio unit1. Check 15A fuse [No. 4, located in fuse block (J/B)]

and verify that battery positive voltage is present at

terminal 6 of audio unit.

2. Remove audio unit for repair.

AM stations are weak or

noisy (FM stations OK).1. Antenna

2. Poor audio unit ground

3. Audio unit1. Check antenna.

2. Check audio unit ground.

3. Remove audio unit for repair.

FM stations are weak or

noisy (AM stations OK).1. Window antenna

2. Audio unit1. Check window antenna.

2. Remove audio unit for repair.

Audio unit generates noise

in AM and FM modes with

engine running.1. Poor audio unit ground

2. Loose or missing ground bonding

straps

3. Ignition condenser or rear window

defogger noise suppressor condenser

4. Alternator

5. Ignition coil or secondary wiring

6. Audio unit1. Check audio unit ground.

2. Check ground bonding straps.

3. Replace ignition condenser or rear window defogger

noise suppressor condenser.

4. Check alternator.

5. Check ignition coil and secondary wiring.

6. Remove audio unit for repair.

Audio unit generates noise

in AM and FM modes with

accessories on (switch

pops and motor noise).1. Poor audio unit ground

2. Antenna

3. Accessory ground

4. Faulty accessory1. Check audio unit ground.

2. Check antenna.

3. Check accessory ground.

4. Replace accessory.

Audio unit controls are

operational, but no sound

is heard from any speaker.1. 15A fuse

2. Audio unit output

3. Audio unit1. Check 15A fuse [No. 4, located in fuse block (J/B)].

Verify battery positive voltage is present at terminal 3

of audio amp. relay.

2. Check audio unit output voltage (Terminal 12).

3. Remove audio unit for repair.

All front speakers are inop-

erative.1. Audio amp. relay

2. Audio amp. relay ground

3. Amp. ON signal1. Check audio amp. relay.

2. Check audio amp. relay ground (Terminal 2).

3. Turn ignition switch ACC and audio unit ON. Verify

battery positive voltage is present at terminal 1 of

audio amp. relay.

Individual front speaker is

noisy or inoperative.1. Speaker ground

2. Power supply

3. Audio unit output

4. Speaker1. Check speaker ground (Terminal 5).

2. Check power supply for speaker (Terminal 4).

3. Check audio unit output voltage for speaker.

4. Replace speaker.

Both rear speakers are

inoperative.1. Poor rear speaker amp. ground

2. Power supply

3. Amp. ON signal

4. Rear speaker amp.1. Check rear speaker amp. ground circuit.

2. Check power supply for rear speaker amp. (Terminal

11).

3. Turn ignition switch ACC and audio unit ON. Verify

battery positive voltage is present at terminal 9 of

rear speaker amp.

4. Remove rear speaker amp. for repair.

Individual rear speaker is

noisy or inoperative.1. Speaker

2. Audio unit/amp. output

3. Speaker circuit

4. Audio unit1. Check speaker.

2. Check audio unit/amp. output.

3. Check wires for open or short between audio unit/

amp. and speakers.

4. Remove audio unit for repair.

AUDIO

Trouble Diagnoses

EL-166

Page 1745 of 2395

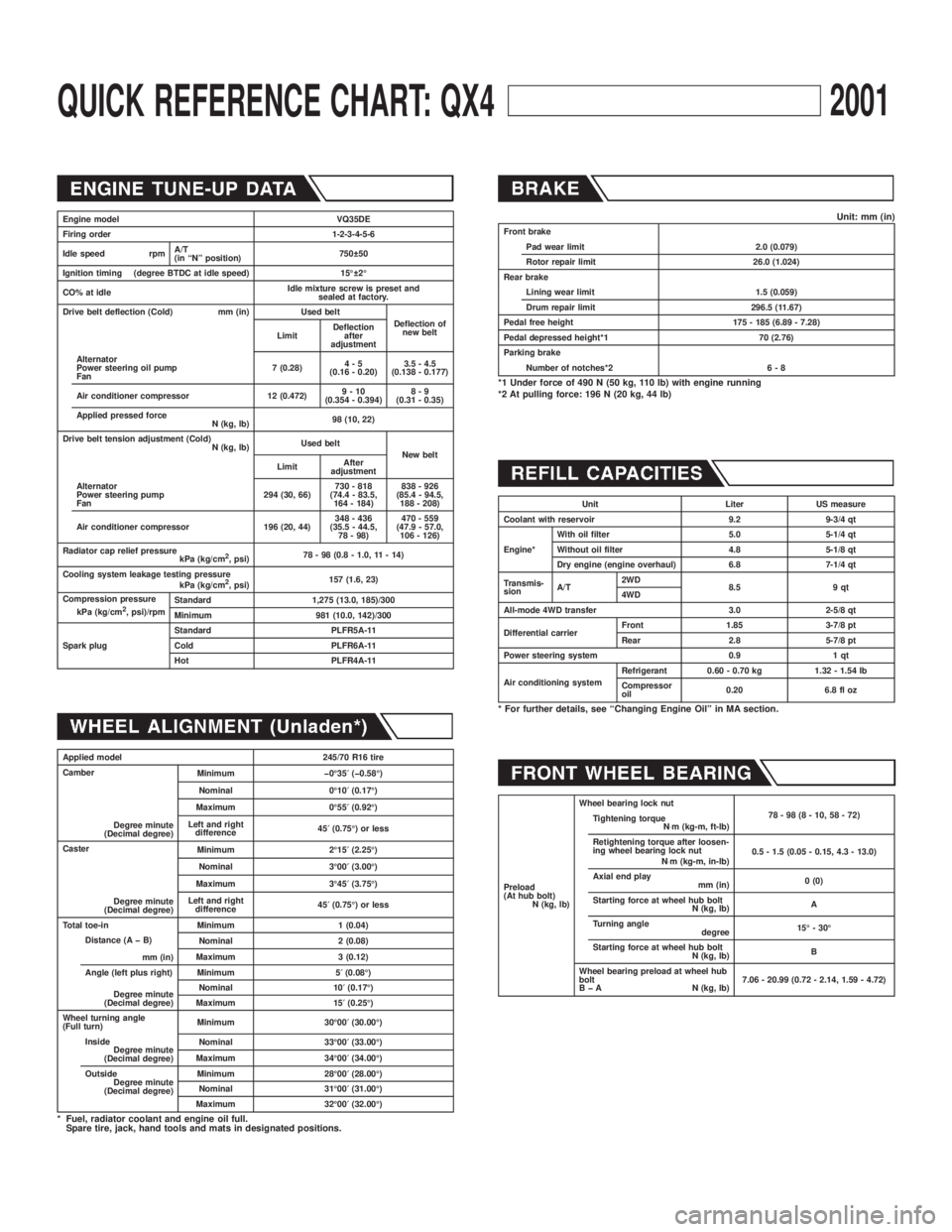

QUICK REFERENCE CHART: QX42001

Engine model VQ35DE

Firing order 1-2-3-4-5-6

Idle speed rpmA/T

(in ªNº position)750 50

Ignition timing (degree BTDC at idle speed) 15É 2É

CO% at idleIdle mixture screw is preset and

sealed at factory.

Drive belt deflection (Cold) mm (in) Used belt

Deflection of

new belt

LimitDeflection

after

adjustment

Alternator

Power steering oil pump

Fan7 (0.28)4-5

(0.16 - 0.20)3.5 - 4.5

(0.138 - 0.177)

Air conditioner compressor 12 (0.472)9-10

(0.354 - 0.394)8-9

(0.31 - 0.35)

Applied pressed force

N (kg, lb)98 (10, 22)

Drive belt tension adjustment (Cold)

N (kg, lb)Used belt

New belt

LimitAfter

adjustment

Alternator

Power steering pump

Fan294 (30, 66)730 - 818

(74.4 - 83.5,

164 - 184)838 - 926

(85.4 - 94.5,

188 - 208)

Air conditioner compressor 196 (20, 44)348 - 436

(35.5 - 44.5,

78 - 98)470 - 559

(47.9 - 57.0,

106 - 126)

Radiator cap relief pressure

kPa (kg/cm

2, psi)78 - 98 (0.8 - 1.0, 11 - 14)

Cooling system leakage testing pressure

kPa (kg/cm

2, psi)157 (1.6, 23)

Compression pressure

kPa (kg/cm

2, psi)/rpmStandard 1,275 (13.0, 185)/300

Minimum 981 (10.0, 142)/300

Spark plugStandard PLFR5A-11

Cold PLFR6A-11

Hot PLFR4A-11

Applied model 245/70 R16 tire

Camber

Degree minute

(Decimal degree)Minimum þ0É35¢(þ0.58É)

Nominal 0É10¢(0.17É)

Maximum 0É55¢(0.92É)

Left and right

difference45¢(0.75É) or less

Caster

Degree minute

(Decimal degree)Minimum 2É15¢(2.25É)

Nominal 3É00¢(3.00É)

Maximum 3É45¢(3.75É)

Left and right

difference45¢(0.75É) or less

Total toe-in Minimum 1 (0.04)

Distance (A þ B)

mm (in)Nominal 2 (0.08)

Maximum 3 (0.12)

Angle (left plus right)

Degree minute

(Decimal degree)Minimum 5¢(0.08É)

Nominal 10¢(0.17É)

Maximum 15¢(0.25É)

Wheel turning angle

(Full turn)Minimum 30É00¢(30.00É)

Inside

Degree minute

(Decimal degree)Nominal 33É00¢(33.00É)

Maximum 34É00¢(34.00É)

Outside

Degree minute

(Decimal degree)Minimum 28É00¢(28.00É)

Nominal 31É00¢(31.00É)

Maximum 32É00¢(32.00É)

* Fuel, radiator coolant and engine oil full.

Spare tire, jack, hand tools and mats in designated positions.

Unit: mm (in)Front brake

Pad wear limit 2.0 (0.079)

Rotor repair limit 26.0 (1.024)

Rear brake

Lining wear limit 1.5 (0.059)

Drum repair limit 296.5 (11.67)

Pedal free height 175 - 185 (6.89 - 7.28)

Pedal depressed height*1 70 (2.76)

Parking brake

Number of notches*2 6 - 8

*1 Under force of 490 N (50 kg, 110 lb) with engine running

*2 At pulling force: 196 N (20 kg, 44 lb)

Unit Liter US measure

Coolant with reservoir 9.2 9-3/4 qt

Engine*With oil filter 5.0 5-1/4 qt

Without oil filter 4.8 5-1/8 qt

Dry engine (engine overhaul) 6.8 7-1/4 qt

Transmis-

sionA/T2WD

8.5 9 qt

4WD

All-mode 4WD transfer 3.0 2-5/8 qt

Differential carrierFront 1.85 3-7/8 pt

Rear 2.8 5-7/8 pt

Power steering system 0.9 1 qt

Air conditioning systemRefrigerant 0.60 - 0.70 kg 1.32 - 1.54 lb

Compressor

oil0.20 6.8 fl oz

* For further details, see ªChanging Engine Oilº in MA section.

Preload

(At hub bolt)

N (kg, lb)Wheel bearing lock nut

78-98(8-10,58-72)

Tightening torque

N×m (kg-m, ft-lb)

Retightening torque after loosen-

ing wheel bearing lock nut

N×m (kg-m, in-lb)0.5 - 1.5 (0.05 - 0.15, 4.3 - 13.0)

Axial end play

mm (in)0 (0)

Starting force at wheel hub bolt

N (kg, lb)A

Turning angle

degree15É - 30É

Starting force at wheel hub bolt

N (kg, lb)B

Wheel bearing preload at wheel hub

bolt

B þ A N (kg, lb)7.06 - 20.99 (0.72 - 2.14, 1.59 - 4.72)

Page 2189 of 2395

SST601C

Checking Gear Housing MovementNBST00081. Check the movement of steering gear housing during station-

ary steering on a dry paved surface.

IApply a force of 49 N (5 kg, 11 lb) to steering wheel to check

the gear housing movement.

Turn off ignition key while checking.

Movement of gear housing:

±2mm(±0.08 in) or less

2. If movement exceeds the limit, replace mount insulator after

confirming proper installation of gear housing clamps.

SST602C

Adjusting Rack RetainerNBST0009IPerform this driving test on a flat road.

a) Check whether vehicle moves in a straight line when steering

wheel is released.

b) Check whether steering wheel returns to neutral position when

steering wheel is released from a slightly turned (approx. 20É)

position.

IIf any abnormality is found, correct it by resetting adjusting

screw.

Checking and Adjusting Drive BeltsNBST0010Refer to MA-13, ªChecking Drive Beltsº.

SST280BA

Checking Fluid LevelNBST0011Check fluid level.

Use the correct range of the dipstick depending on the fluid tem-

perature. Use the ªHOTº range at 50 to 80ÉC (122 to 176ÉF), or the

ªCOLDº range at 0 to 30ÉC (32 to 86ÉF).

CAUTION:

IDo not overfill.

IRecommended fluid is Genuine Nissan PSF II or equiva-

lent. Refer to MA-11, ªFluids and Lubricantsº.

SST458C

Checking Fluid LeakageNBST0012Check the lines for improper attachment and for leaks, cracks,

damage, loose connections, chafing and deterioration.

1. Run engine between idle speed and 1,000 rpm.

Make sure temperature of fluid in oil tank rises to 60 to 80ÉC

(140 to 176ÉF).

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each ªlockº position for five seconds

and carefully check for fluid leakage.

ON-VEHICLE SERVICE

Checking Gear Housing Movement

ST-8

Page 2221 of 2395

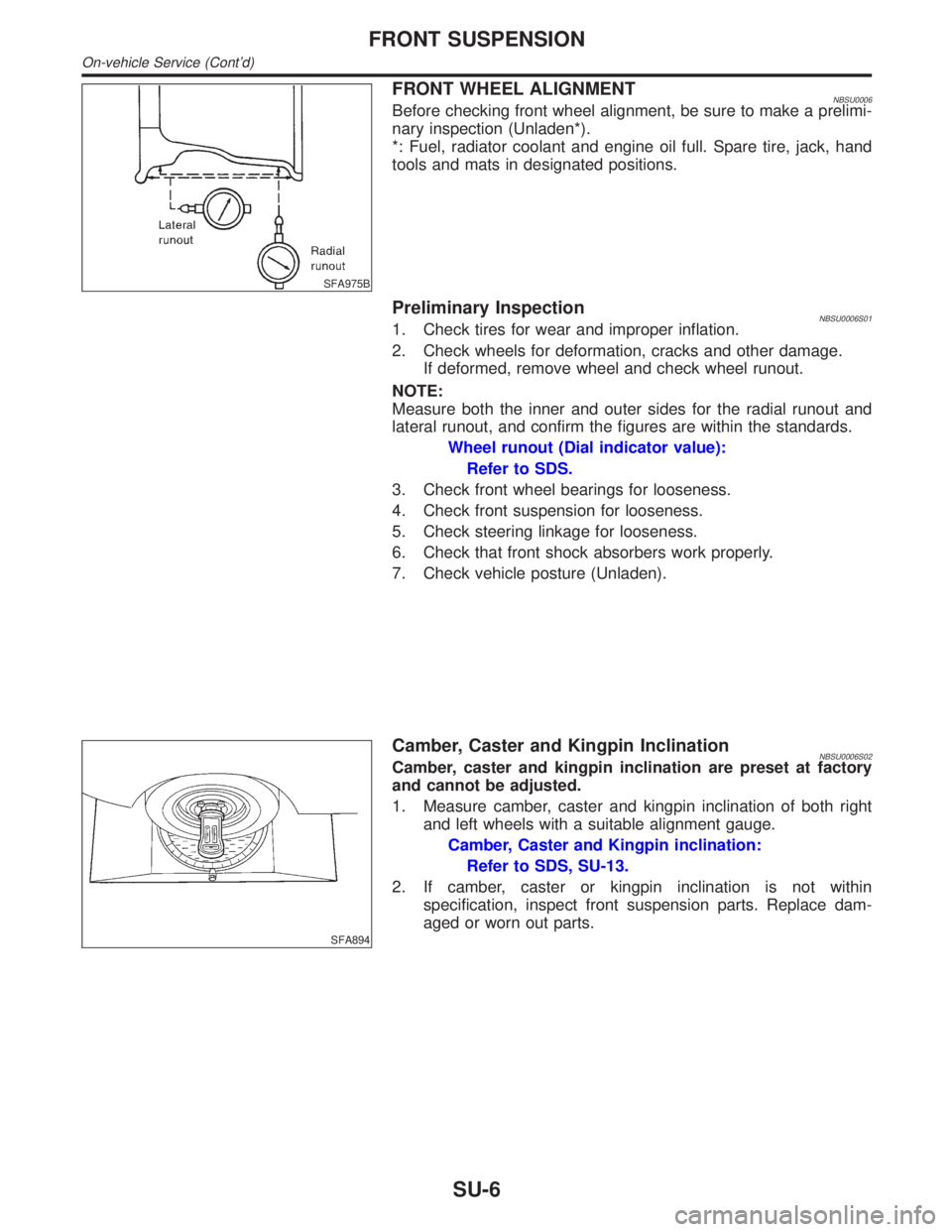

SFA975B

FRONT WHEEL ALIGNMENTNBSU0006Before checking front wheel alignment, be sure to make a prelimi-

nary inspection (Unladen*).

*: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand

tools and mats in designated positions.

Preliminary InspectionNBSU0006S011. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage.

If deformed, remove wheel and check wheel runout.

NOTE:

Measure both the inner and outer sides for the radial runout and

lateral runout, and confirm the figures are within the standards.

Wheel runout (Dial indicator value):

Refer to SDS.

3. Check front wheel bearings for looseness.

4. Check front suspension for looseness.

5. Check steering linkage for looseness.

6. Check that front shock absorbers work properly.

7. Check vehicle posture (Unladen).

SFA894

Camber, Caster and Kingpin InclinationNBSU0006S02Camber, caster and kingpin inclination are preset at factory

and cannot be adjusted.

1. Measure camber, caster and kingpin inclination of both right

and left wheels with a suitable alignment gauge.

Camber, Caster and Kingpin inclination:

Refer to SDS, SU-13.

2. If camber, caster or kingpin inclination is not within

specification, inspect front suspension parts. Replace dam-

aged or worn out parts.

FRONT SUSPENSION

On-vehicle Service (Cont'd)

SU-6