engine oil INFINITI QX4 2001 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 93 of 2395

Items Symptom Condition Diagnostic Item Reference Page

Slips/Will Not

EngageRaces extremely

fast or slips in

changing from D

4or D3to D1when

depressing pedal.ON vehicle1. Fluid level AT-59

2. Throttle position sensor (Adjustment) EC-174

3. Line pressure test AT-62

4. Line pressure solenoid valve AT-162

5. Control valve assembly AT-273

OFF vehicle6. Forward clutch AT-320

7. Forward one-way clutch AT-330

8. Low one-way clutch AT-328

Vehicle will not

run in any posi-

tion.ON vehicle1. Fluid level AT-59

2. Manual control linkage adjustment AT-276

3. Line pressure test AT-62

4. Line pressure solenoid valve AT-162

OFF vehicle5. Oil pump AT-297

6. High clutch AT-317

7. Brake band AT-333

8. Low & reverse brake AT-324

9. Torque converter AT-286

10. Parking pawl components AT-337

NOT USEDEngine cannot be

started in P and N

positions.

AT-221ON vehicle1. Ignition switch and starter EL-9, and SC-10

2. Manual control linkage adjustment AT-276

3. Park/neutral position (PNP) switch

adjustmentAT-276

Engine starts in

positions other

than P and N.

AT-221ON vehicle1. Manual control linkage adjustment AT-276

2. Park/neutral position (PNP) switch

adjustmentAT-276

Transmission

noise in P and N

positions.ON vehicle1. Fluid level AT-59

2. Line pressure test AT-62

3. Throttle position sensor (Adjustment) EC-174

4. Vehicle speed sensor´A/T (Revolution

sensor) and vehicle speed sensor´MTRAT- 111 , 1 9 7

5. Engine speed signal AT-116

OFF vehicle6. Oil pump AT-297

7. Torque converter AT-286

Vehicle moves

when changing

into P position or

parking gear does

not disengage

when shifted out

of P position.

AT-222ON vehicle 1. Manual control linkage adjustment AT-276

OFF vehicle 2. Parking pawl components AT-337

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Chart (Cont'd)

AT-88

Page 95 of 2395

Items Symptom Condition Diagnostic Item Reference Page

NOT USEDMaximum speed

not attained.

Acceleration poor.ON vehicle1. Fluid level AT-59

2. Park/neutral position (PNP) switch

adjustmentAT-276

3. Shift solenoid valve A AT-168

4. Shift solenoid valve B AT-172

5. Control valve assembly AT-273

OFF vehicle6. Reverse clutch AT-314

7. High clutch AT-317

8. Brake band AT-333

9. Low & reverse brake AT-324

10. Oil pump AT-297

11. Torque converter AT-286

Transmission

noise in D, 2, 1

and R positions.ON vehicle 1. Fluid level AT-59

ON vehicle 2. Torque converter AT-286

Engine brake

does not operate

in ª1º position.

AT-252ON vehicle1. Park/neutral position (PNP) switch

adjustmentAT-276

2. Manual control linkage adjustment AT-276

3. Throttle position sensor (Adjustment) EC-174

4. Vehicle speed sensor´A/T (Revolution

sensor) and vehicle speed sensor´MTRAT- 111 , 1 9 7

5. Shift solenoid valve A AT-168

6. Control valve assembly AT-273

7. Overrun clutch solenoid valve AT-185

OFF vehicle8. Overrun clutch AT-320

9. Low & reverse brake AT-324

Transmission

overheats.ON vehicle1. Fluid level AT-59

2. Engine idling rpm EC-431

3. Throttle position sensor (Adjustment) EC-174

4. Line pressure test AT-62

5. Line pressure solenoid valve AT-162

6. Control valve assembly AT-273

OFF vehicle7. Oil pump AT-297

8. Reverse clutch AT-314

9. High clutch AT-317

10. Brake band AT-333

11. Forward clutch AT-320

12. Overrun clutch AT-320

13. Low & reverse brake AT-324

14. Torque converter AT-286

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Chart (Cont'd)

AT-90

Page 96 of 2395

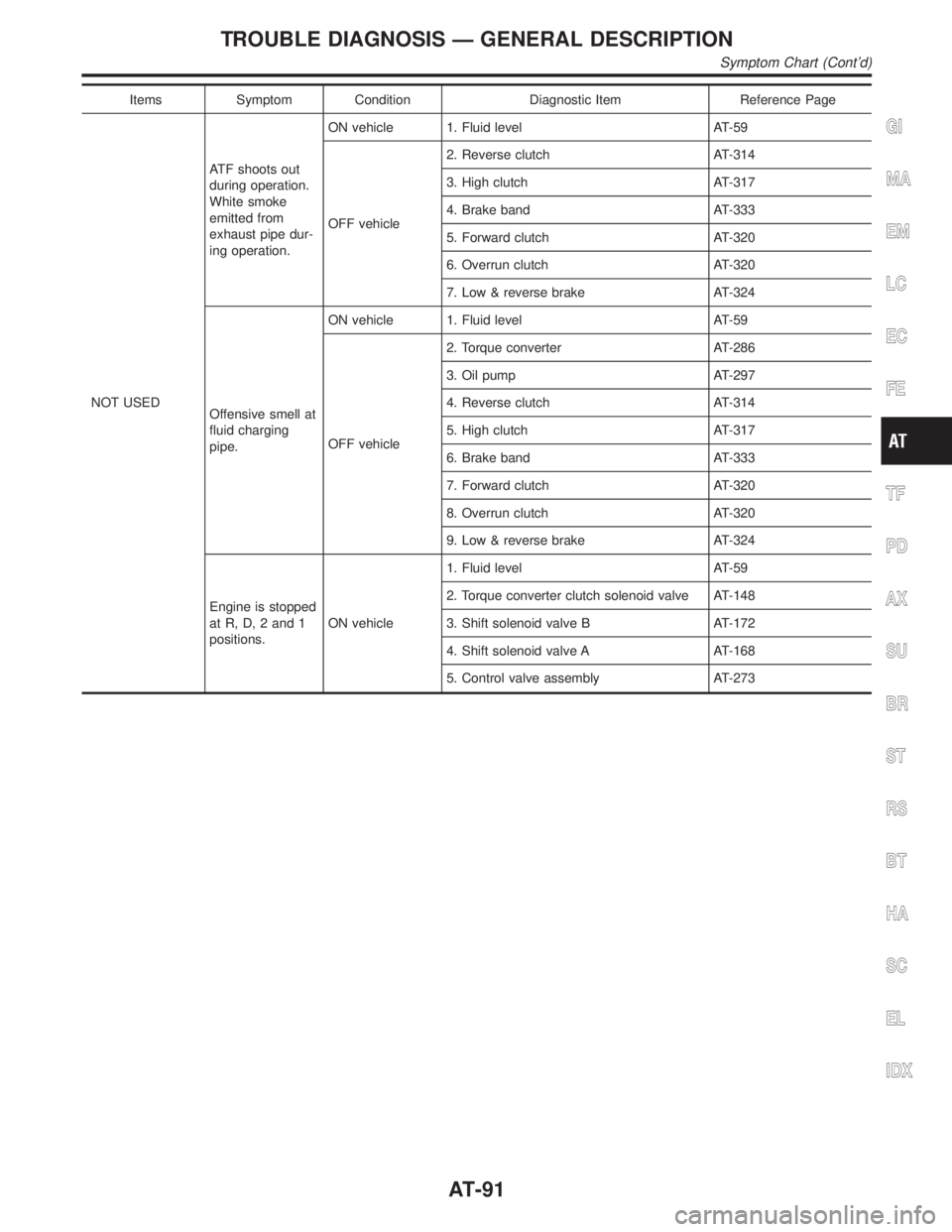

Items Symptom Condition Diagnostic Item Reference Page

NOT USEDATF shoots out

during operation.

White smoke

emitted from

exhaust pipe dur-

ing operation.ON vehicle 1. Fluid level AT-59

OFF vehicle2. Reverse clutch AT-314

3. High clutch AT-317

4. Brake band AT-333

5. Forward clutch AT-320

6. Overrun clutch AT-320

7. Low & reverse brake AT-324

Offensive smell at

fluid charging

pipe.ON vehicle 1. Fluid level AT-59

OFF vehicle2. Torque converter AT-286

3. Oil pump AT-297

4. Reverse clutch AT-314

5. High clutch AT-317

6. Brake band AT-333

7. Forward clutch AT-320

8. Overrun clutch AT-320

9. Low & reverse brake AT-324

Engine is stopped

at R, D, 2 and 1

positions.ON vehicle1. Fluid level AT-59

2. Torque converter clutch solenoid valve AT-148

3. Shift solenoid valve B AT-172

4. Shift solenoid valve A AT-168

5. Control valve assembly AT-273

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Chart (Cont'd)

AT-91

Page 114 of 2395

4 CHECK A/T FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector on the right side of transfer assmebly.

3. Check resistance between terminals 8 and 9 when A/T is cold [20ÉC (68ÉF)].

SAT697I

Is resistance approx. 2.5 kW?

Ye s©GO TO 7.

No©GO TO 5.

5 DETECT MALFUNCTIONING ITEM

1. Remove oil pan.

2. Check the following items:

IA/T fluid temperature sensor

Refer to ªComponent Inspectionº, AT-110.

IHarness of terminal cord assembly for short or open

OK or NG

OK©GO TO 7.

NG©Repair or replace damaged parts.

6 CHECK INPUT SIGNAL OF A/T FLUID TEMPERATURE SENSOR (WITHOUT CONSULT-II)

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 47 and ground while warming up A/T.

Voltage:

Cold [20ÉC (68ÉF)]®Hot [80ÉC (176ÉF)]:

Approximately 1.5V®0.5V

SAT518J

OK or NG

OK©GO TO 4.

NG©GO TO 3.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0710 A/T FLUID TEMPERATURE SENSOR CIRCUIT

Diagnostic Procedure (Cont'd)

AT-109

Page 123 of 2395

Diagnostic ProcedureNBAT0038

1 CHECK DTC WITH ECM

ICheck P code with CONSULT-II.

Turn ignition switch ªONº and select ªSELF-DIAG RESULTSº mode for ªENGINEº with CONSULT-II.

Refer to EC-74, ªDESCRIPTIONº.

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-

II)©GO TO 4.

NG©Check ignition signal circuit for engine control. Refer to EC-499, ªComponent Descrip-

tionº.

2 CHECK INPUT SIGNAL (WITH CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

3. Read out the value of ªENGINE SPEEDº.

Check engine speed changes according to throttle position.

SAT645J

Refer toEC-127, ªECM INSPECTION TABLEº.

Ye s©GO TO 5.

No©GO TO 3.

3 DETECT MALFUNCTIONING ITEM

Check the following items:

IHarness for short or open between TCM and ECM

IResistor

IIgnition coil

Refer to EC-499, ªComponent Descriptionº.

OK or NG

OK©GO TO 5.

NG©Repair or replace damaged parts.

DTC P0725 ENGINE SPEED SIGNAL

Diagnostic Procedure

AT-118

Page 143 of 2395

DescriptionNBAT0048IThis is an OBD-II self-diagnostic item and not available in TCM

self-diagnosis.

IThis malfunction will not be detected while the O/D OFF indi-

cator lamp is indicating another self-diagnosis malfunction.

IThis malfunction is detected when the A/T does not shift into

fourth gear position or the torque converter clutch does not

lock up as instructed by the TCM. This is not caused by elec-

trical malfunction (circuits open or shorted) but by mechanical

malfunction such as control valve sticking, improper solenoid

valve operation, malfunctioning oil pump or torque converter

clutch, etc.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NBAT0048S04Remarks: Specification data are reference values.

Monitor item Condition Specification

Line pressure solenoid valve

dutySmall throttle opening (Low line pressure)

"

Large throttle opening (High line pressure)Approximately 24%

"

Approximately 95%

Gear position1234

Shift solenoid valve A ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed) ON (Closed) OFF (Open) OFF (Open)

TCM TERMINALS AND REFERENCE VALUENBAT0048S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

1GYLine pressure

solenoid valve

When releasing accelerator pedal after warm-

ing up engine.1.5 - 3.0V

When depressing accelerator pedal fully after

warming up engine.0V

2 BR/YLine pressure

solenoid valve

(with dropping

resistor)When releasing accelerator pedal after warm-

ing up engine.5 - 14V

When depressing accelerator pedal fully after

warming up engine.0V

11 L/WShift solenoid

valve A

When shift solenoid valve A operates.

(When driving in ªD

1ºorªD4º.)Battery volt-

age

When shift solenoid valve A does not operate.

(When driving in ªD

2ºorªD3º.)0V

12 L/RShift solenoid

valve BWhen shift solenoid valve B operates.

(When driving in ªD

1ºorªD2º.)Battery volt-

age

When shift solenoid valve B does not operate.

(When driving in ªD

3ºorªD4º.)0V

DTC P0734 IMPROPER SHIFTING TO 4TH GEAR POSITION

Description

AT-138

Page 158 of 2395

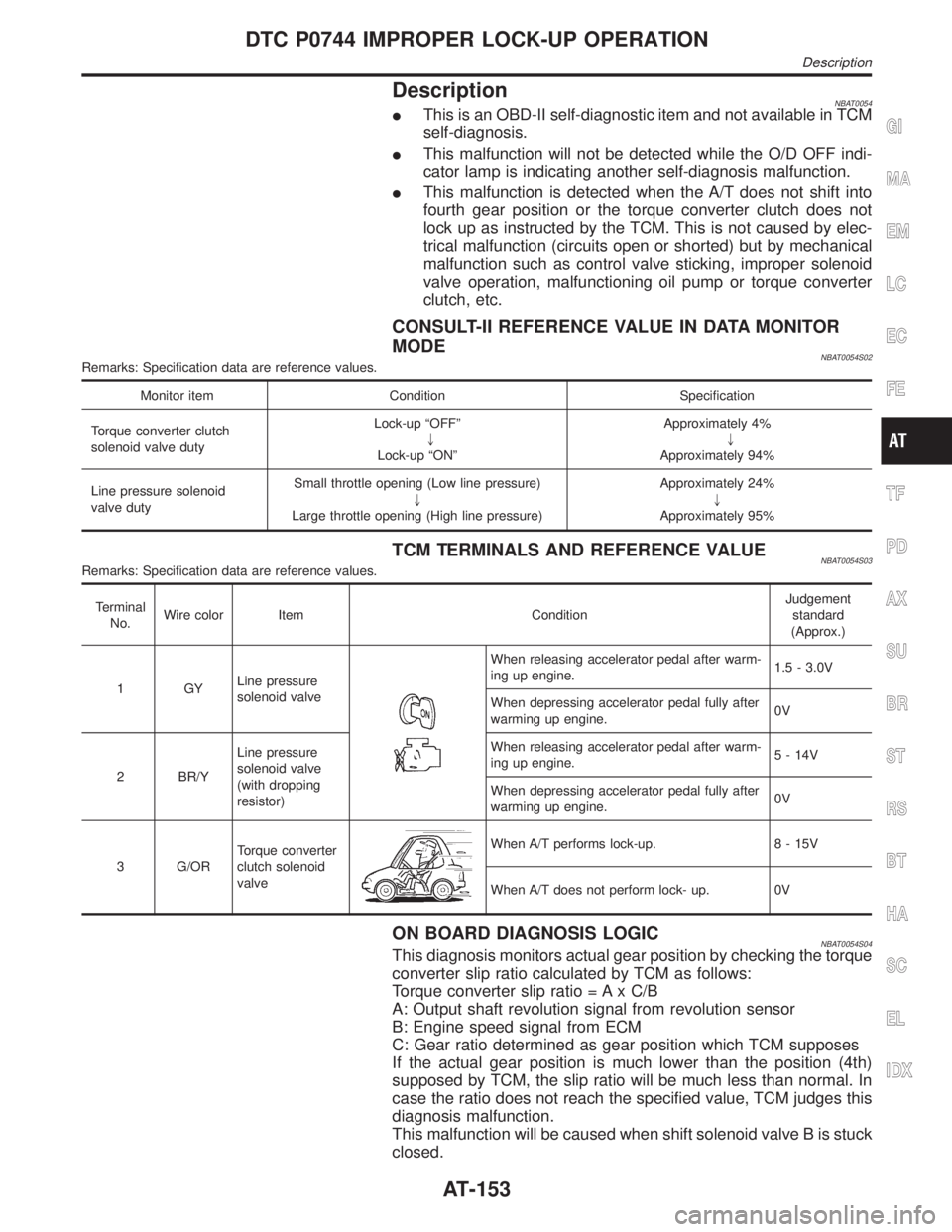

DescriptionNBAT0054IThis is an OBD-II self-diagnostic item and not available in TCM

self-diagnosis.

IThis malfunction will not be detected while the O/D OFF indi-

cator lamp is indicating another self-diagnosis malfunction.

IThis malfunction is detected when the A/T does not shift into

fourth gear position or the torque converter clutch does not

lock up as instructed by the TCM. This is not caused by elec-

trical malfunction (circuits open or shorted) but by mechanical

malfunction such as control valve sticking, improper solenoid

valve operation, malfunctioning oil pump or torque converter

clutch, etc.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NBAT0054S02Remarks: Specification data are reference values.

Monitor item Condition Specification

Torque converter clutch

solenoid valve dutyLock-up ªOFFº

"

Lock-up ªONºApproximately 4%

"

Approximately 94%

Line pressure solenoid

valve dutySmall throttle opening (Low line pressure)

"

Large throttle opening (High line pressure)Approximately 24%

"

Approximately 95%

TCM TERMINALS AND REFERENCE VALUENBAT0054S03Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

1GYLine pressure

solenoid valve

When releasing accelerator pedal after warm-

ing up engine.1.5 - 3.0V

When depressing accelerator pedal fully after

warming up engine.0V

2 BR/YLine pressure

solenoid valve

(with dropping

resistor)When releasing accelerator pedal after warm-

ing up engine.5 - 14V

When depressing accelerator pedal fully after

warming up engine.0V

3 G/ORTorque converter

clutch solenoid

valve

When A/T performs lock-up. 8 - 15V

When A/T does not perform lock- up. 0V

ON BOARD DIAGNOSIS LOGICNBAT0054S04This diagnosis monitors actual gear position by checking the torque

converter slip ratio calculated by TCM as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from revolution sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is much lower than the position (4th)

supposed by TCM, the slip ratio will be much less than normal. In

case the ratio does not reach the specified value, TCM judges this

diagnosis malfunction.

This malfunction will be caused when shift solenoid valve B is stuck

closed.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0744 IMPROPER LOCK-UP OPERATION

Description

AT-153

Page 167 of 2395

SAT341H

DescriptionNBAT0057The line pressure solenoid valve regulates the oil pump discharge

pressure to suit the driving condition in response to a signal sent

from the TCM.

The line pressure duty cycle value is not consistent when the

closed throttle position switch is ªONº. To confirm the line

pressure duty cycle at low pressure, the accelerator (throttle)

should be open until the closed throttle position switch is

ªOFFº.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NBAT0057S02Remarks: Specification data are reference values.

Monitor item Condition Specification

Line pressure solenoid

valve dutySmall throttle opening (Low line pressure)

"

Large throttle opening (High line pressure)Approximately 24%

"

Approximately 95%

NOTE:

The line pressure duty cycle value is not consistent when the closed throttle position switch is ªONº. To confirm the line pressure duty

cycle at low pressure, the accelerator (throttle) should be open until the closed throttle position switch is ªOFFº.

TCM TERMINALS AND REFERENCE VALUENBAT0057S03Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

1GYLine pressure

solenoid valve

When releasing accelerator pedal after warm-

ing up engine.1.5 - 3.0V

When depressing accelerator pedal fully after

warming up engine.0V

2 BR/YLine pressure

solenoid valve

(with dropping

resistor)When releasing accelerator pedal after warm-

ing up engine.5 - 14V

When depressing accelerator pedal fully after

warming up engine.0V

ON BOARD DIAGNOSIS LOGICNBAT0057S04

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: L/PRESS SOL/CIRCTCM detects an improper voltage drop

when it tries to operate the solenoid

valve.IHarness or connectors

(The solenoid circuit is open or shorted.)

ILine pressure solenoid valve

: P0745

DTC P0745 LINE PRESSURE SOLENOID VALVE

Description

AT-162

Page 199 of 2395

4 CHECK A/T FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector on the right side of transfer assmebly.

3. Check resistance between terminals 8 and 9 when A/T is cold [20ÉC (68ÉF)].

SAT697I

Is resistance approx. 2.5 kW?

Ye s©GO TO 7.

No©GO TO 5.

5 DETECT MALFUNCTIONING ITEM

1. Remove oil pan.

2. Check the following items:

IA/T fluid temperature sensor

Refer to ªComponent Inspectionº, AT-110.

IHarness of terminal cord assembly for short or open

OK or NG

OK©GO TO 7.

NG©Repair or replace damaged parts.

6 CHECK INPUT SIGNAL OF A/T FLUID TEMPERATURE SENSOR (WITHOUT CONSULT-II)

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 47 and ground while warming up A/T.

Voltage:

Cold [20ÉC (68ÉF)]®Hot [80ÉC (176ÉF)]:

Approximately 1.5V®0.5V

SAT518J

OK or NG

OK©GO TO 4.

NG©GO TO 3.

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM

POWER SOURCE)

Diagnostic Procedure (Cont'd)

AT-194

Page 252 of 2395

13. A/T Does Not Hold Lock-up Condition=NBAT0085SYMPTOM:

A/T does not hold lock-up condition for more than 30 seconds.

1 CHECK DIAGNOSTIC RESULTS

Does self-diagnosis show damage to engine speed signal circuit after cruise test?

SAT582I

YesorNo

Ye s©Check engine speed signal circuit. Refer to ªDTC P0725º, AT-116.

No©GO TO 2.

2 CHECK A/T FLUID CONDITION

1. Remove oil pan.

2. Check A/T fluid condition.

SAT171B

OK or NG

OK©GO TO 3.

NG©GO TO 5.

3 DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-273.

2. Check the following items:

ITorque converter clutch control valve

IPilot valve

IPilot filter

OK or NG

OK©GO TO 4.

NG©Repair or replace damaged parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSES FOR SYMPTOMS

13. A/T Does Not Hold Lock-up Condition

AT-247