width INFINITI QX4 2001 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1688 of 2395

SEM934C

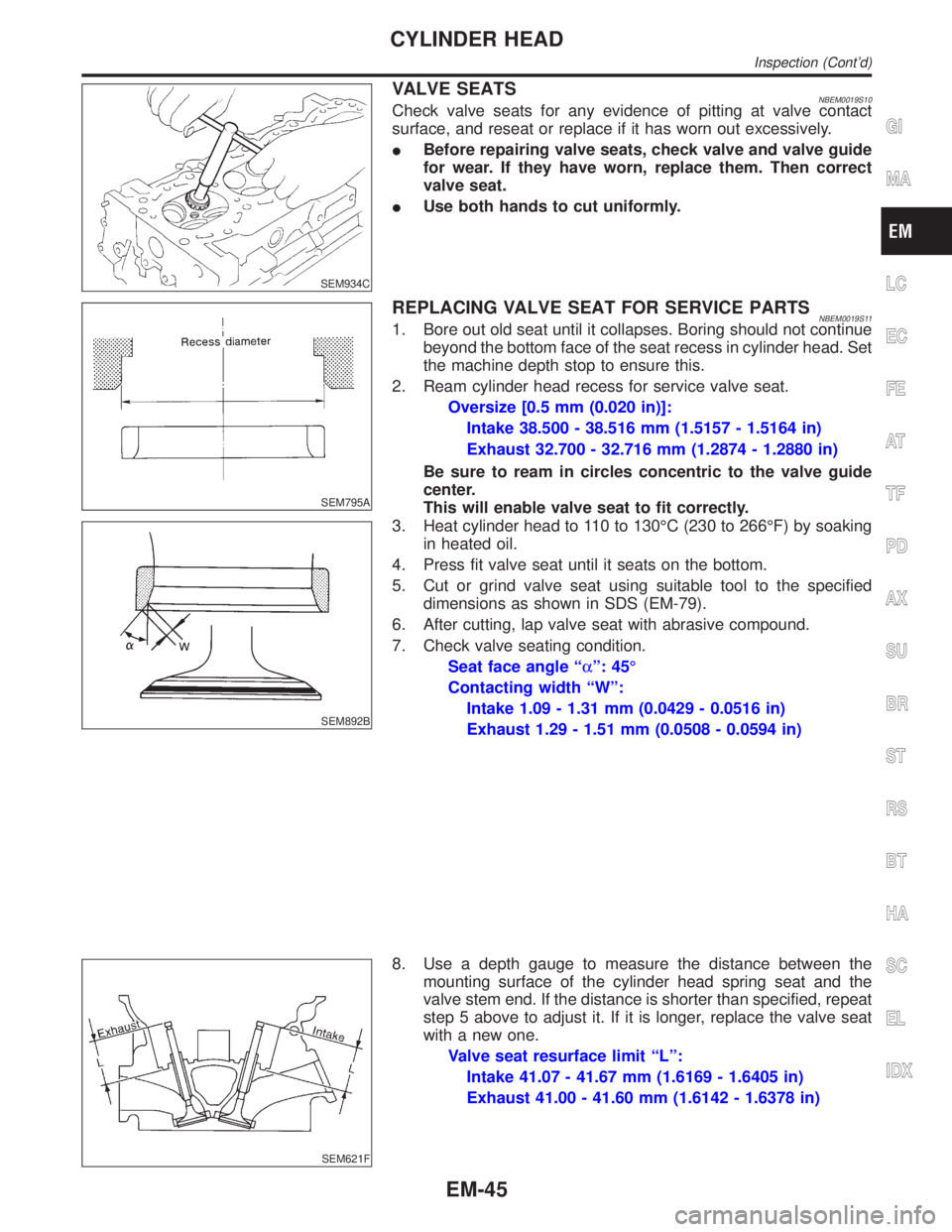

VALVE SEATSNBEM0019S10Check valve seats for any evidence of pitting at valve contact

surface, and reseat or replace if it has worn out excessively.

IBefore repairing valve seats, check valve and valve guide

for wear. If they have worn, replace them. Then correct

valve seat.

IUse both hands to cut uniformly.

SEM795A

REPLACING VALVE SEAT FOR SERVICE PARTSNBEM0019S111. Bore out old seat until it collapses. Boring should not continue

beyond the bottom face of the seat recess in cylinder head. Set

the machine depth stop to ensure this.

2. Ream cylinder head recess for service valve seat.

Oversize [0.5 mm (0.020 in)]:

Intake 38.500 - 38.516 mm (1.5157 - 1.5164 in)

Exhaust 32.700 - 32.716 mm (1.2874 - 1.2880 in)

Be sure to ream in circles concentric to the valve guide

center.

This will enable valve seat to fit correctly.

SEM892B

3. Heat cylinder head to 110 to 130ÉC (230 to 266ÉF) by soaking

in heated oil.

4. Press fit valve seat until it seats on the bottom.

5. Cut or grind valve seat using suitable tool to the specified

dimensions as shown in SDS (EM-79).

6. After cutting, lap valve seat with abrasive compound.

7. Check valve seating condition.

Seat face angle ªaº: 45É

Contacting width ªWº:

Intake 1.09 - 1.31 mm (0.0429 - 0.0516 in)

Exhaust 1.29 - 1.51 mm (0.0508 - 0.0594 in)

SEM621F

8. Use a depth gauge to measure the distance between the

mounting surface of the cylinder head spring seat and the

valve stem end. If the distance is shorter than specified, repeat

step 5 above to adjust it. If it is longer, replace the valve seat

with a new one.

Valve seat resurface limit ªLº:

Intake 41.07 - 41.67 mm (1.6169 - 1.6405 in)

Exhaust 41.00 - 41.60 mm (1.6142 - 1.6378 in)

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CYLINDER HEAD

Inspection (Cont'd)

EM-45

Page 1728 of 2395

Available Main BearingNBEM0039

SEM175F

Grade number Thickness ªTº mm (in)Width ªWº

mm (in)Identification color

(UPR/LWR)Remarks

0 2.000 - 2.003 (0.0787 - 0.0789)

19.9 - 20.1

(0.783 - 0.791)Black

Grade is the same for

upper and lower bearings. 1 2.003 - 2.006 (0.0789 - 0.0790) Brown

2 2.006 - 2.009 (0.0790 - 0.0791) Green

3 2.009 - 2.012 (0.0791 - 0.0792) Yellow

4 2.012 - 2.015 (0.0792 - 0.0793) Blue

5 2.015 - 2.018 (0.0793 - 0.0794) Pink

6 2.018 - 2.021 (0.0794 - 0.0796) Purple

7 2.021 - 2.024 (0.0796 - 0.0797) White

01UPP 2.003 - 2.006 (0.0789 - 0.0790)

Brown/Black

Grade is different for upper

and lower bearings. LWR 2.000 - 2.003 (0.0787 - 0.0789)

12UPR 2.006 - 2.009 (0.0790 - 0.0791)

Green/Brown

LWR 2.003 - 2.006 (0.0789 - 0.0790)

23UPR 2.009 - 2.012 (0.0791 - 0.0792)

Yellow/Green

LWR 2.006 - 2.009 (0.0790 - 0.0791)

34UPR 2.012 - 2.015 (0.0792 - 0.0793)

Blue/Yellow

LWR 2.009 - 2.012 (0.0791 - 0.0792)

45UPR 2.015 - 2.018 (0.0793 - 0.0794)

Pink/Blue

LWR 2.012 - 2.015 (0.0792 - 0.0793)

56UPR 2.018 - 2.021 (0.0794 - 0.0796)

Purple/Pink

LWR 2.015 - 2.018 (0.0793 - 0.0794)

67UPR 2.021 - 2.024 (0.0796 - 0.0797)

White/Purple

LWR 2.018 - 2.021 (0.0794 - 0.0796)

UNDERSIZENBEM0039S01Unit: mm (in)

Thickness Main journal diameter ªDmº

0.25 (0.0098) 2.132 - 2.140 (0.0839 - 0.0843)Grind so that bearing clearance is the specified

value.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Available Main Bearing

EM-85

Page 1788 of 2395

SGI136A

ENGINE SERIAL NUMBERNBGI0007S0203

MGI042A

AUTOMATIC TRANSMISSION NUMBERNBGI0007S0204

MGI043A

TRANSFER SERIAL NUMBERNBGI0007S0205

DimensionsNBGI0007S03Unit: mm (in)

Wagon

VQ35DE

Overall length 4,650 (183.1)

Overall width 1,840 (72.4)

Overall height1,730 (68.1)

1,795 (70.7)*

Front tread 1,540 (60.6)

Rear tread 1,545 (60.8)

Wheelbase 2,700 (106.3)

*: With luggage rack

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

IDENTIFICATION INFORMATION

Identification Number (Cont'd)

GI-43

Page 1967 of 2395

S/VCSW - Wiring diagram ...........................EC-493

Swirl control valve control solenoid

valve .........................................................EC-458

Swirl control valve control vacuum

check switch .............................................EC-493

SWL/V - Wiring diagram ..............................EC-458

Symbols and abbreviations .............................GI-10

Symptom matrix chart...................................EC-118

System readiness test (SRT) code ................EC-61

T

2-4WD shift solenoid valve............................TF-111

Tachometer .....................................................EL-94

Tail lamp ..........................................................EL-61

TAIL/L - Wiring diagram ..................................EL-63

TCM circuit diagram ........................................AT-13

TCM inspection table ......................................AT-92

TFTS - Wiring diagram .................................EC-311

THEFT - Wiring diagram ...............................EL-300

Theft warning system....................................EL-294

Thermometer .................................................EL-110

Thermostat ......................................................LC-16

Three way catalyst function (Left bank) .......EC-347

Three way catalyst function (Right

bank) .........................................................EC-347

Three way catalyst precautions.........................GI-6

Throttle bodies ...............................................EM-12

Throttle position sensor (TPS) .....................EC-174

Throttle position sensor adjustment .............EC-101

Throttle position switch ...........EC-431, AT-184, 264

Tie-rod .............................................................ST-21

Tie-rod ball joints.............................................ST-21

Tightening torque of standard bolts.................GI-50

Timing chain ...................................................EM-20

Tire rotation ....................................................MA-24

Tire size ...........................................................GI-44

TLID - Wiring diagram ..................................EL-179

Tooth contact (front final drive 4WD) .............PD-29

Tooth contact diff. ...........................................PD-56

Torque converter installation .........................AT-278

Torque convertor clutch solenoid

valve ..................................................AT-152, 161

Tow truck towing ..............................................GI-47

Towing point.....................................................GI-49

TP/SW - Wiring diagram ..............................EC-434

TPS - Wiring diagram...................................EC-180

Transfer control unit inspection table..............TF-55

Transfer dropping resistor .............................TF-112

Transfer fluid replacement (Part time

4WD model) ...............................................MA-22

Transfer fluid temperature sensor .................TF-111

Transfer motor ...............................................TF-117

Transfer motor relay ......................................TF-113

Transfer serial number ....................................GI-43

TRANSMT - Wiring diagram .........................EL-325

Tread-FR&RR (Dimensions)............................GI-43

Trim .................................................................BT-28

Trouble diagnoses ...........................................GI-34

Trunk lid opener, electric...............................EL-178Turbine revolution sensor..............................AT-202

TURN - Wiring diagram ..................................EL-77

Turn signal lamp .............................................EL-75

Two trip detection logic ..................................EC-59

Two-pole lift .....................................................GI-47

U

Under body .....................................................BT-60

V

Vacuum cut valve ...........................................EC-32

Vacuum cut valve bypass valve.....EC-32, 585, 591

Vacuum hose (brake system).........................BR-21

Vacuum hose drawing (Engine control) .........EC-26

Valve clearance ..............................................EM-52

Valve guide.....................................................EM-43

Valve seat.......................................................EM-45

Valve spring....................................................EM-46

Vehicle identification number...........................GI-42

Vehicle recovery (freeing a stuck

vehicle) .........................................................GI-49

Vehicle speed sensor (VSS) ........................EC-417

VENT/V - Wiring diagram ............EC-376, 555, 576

Ventilation air filter ........................................HA-159

VIAS .............................................................EC-610

VIAS - Wiring diagram .................................EC-610

Viscosity number (SAE) .................................MA-12

VSS - Wiring diagram ..................................EC-420

W

Wait detection switch ....................................TF-112

WARN - Wiring diagram................................EL-115

Warning chime ..............................................EL-125

Warning lamps ..............................................EL-114

Washer, front .................................................EL-136

Washer, rear..................................................EL-141

Water pump ....................................................LC-12

Water temperature gauge ...............................EL-94

Weatherstrip - See Exterior ............................BT-35

Wheel balance ...............................................MA-24

Wheel bearing (front)........................................AX-4

Wheel bearing (rear) ......................................AX-18

Wheel hub (front)..............................................AX-6

Wheel sensors (ABS)...............................BR-56, 80

Wheel size .......................................................GI-44

Wheelarch height .............................................SU-5

Wheelbase (Dimensions) ................................GI-43

Wide open & closed throttle position

switch ........................................................EC-174

Width (Dimensions) .........................................GI-43

WINDOW - Wiring diagram ..........................EL-245

Window, door ..................................................BT-18

Window, rear side ...........................................BT-55

Window, side - See Rear side window ...........BT-55

ALPHABETICAL INDEX

IDX-8

Page 2159 of 2395

SEL406X

5. Locate the battery type and rating stamped or written on the

top case of the battery to be tested.

NOTE:

The battery type and rating will have either of the following.

CCA: Cold Cranking Amps (490 CCA, 550 CCA, etc.)

JIS: Japanese Industrial Standard.

Battery is stamped with a number such as:

80D26L: 80 (rank of output), D (physical size-depth), 26 (width

in cm). The last character L (post configuration) is not input into

the tester.

The tester requires the rating for the battery be entered exactly

as it is written or stamped on the battery. Do not attempt a CCA

conversion for JIS stamped batteries. JIS must be input

directly.

6. Using the arrow and ªENTERº keys alternately, select the bat-

tery type and rating.

NOTE:

The tester lists five choices; CCA, JIS, IEC, DIN, and EN. Only use

CCA or JIS.

SEL407X

7. Press ªENTERº to begin the test. Diagnosis results are dis-

played on the tester. Refer to ªDIAGNOSTIC RESULT ITEM

CHARTº SC-9.

SEL576X

8. Press ªENTERº, then test output code is displayed. Record the

test output code on the repair order.

9. Toggle back to the ªDIAGNOSTIC SCREENº for test results.

NOTE:

IIf necessary, the tester will ask the user to determine if the

battery has just been charged. Choose the appropriate selec-

tion by pressing the up or down arrow button and then press

the ªENTERº button to make the selection.

IWhen testing a battery installed in a vehicle that has recently

been driven, select ªBEFORE CHANGEº.

IIf the battery has just been slow charged due to a ªCHARGE

& RETESTº decision by the tester, and the tester asks the user

ªBEFORE CHARGE/AFTER CHARGEº, select ªAFTER

CHARGEº.

BATTERY

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont'd)

SC-8

Page 2270 of 2395

![INFINITI QX4 2001 Factory User Guide Item [Unit]Monitor item

Remarks

ECU input

signalsMain sig-

nalsItem menu

selection

Duty solenoid valve [%]

(Transfer 4WD solenoid valve)qH

2-4WD shift solenoid valve [ON-OFF]qH

Control signal outputs INFINITI QX4 2001 Factory User Guide Item [Unit]Monitor item

Remarks

ECU input

signalsMain sig-

nalsItem menu

selection

Duty solenoid valve [%]

(Transfer 4WD solenoid valve)qH

2-4WD shift solenoid valve [ON-OFF]qH

Control signal outputs](/img/42/57027/w960_57027-2269.png)

Item [Unit]Monitor item

Remarks

ECU input

signalsMain sig-

nalsItem menu

selection

Duty solenoid valve [%]

(Transfer 4WD solenoid valve)qH

2-4WD shift solenoid valve [ON-OFF]qH

Control signal outputs of transfer control unit Transfer motor relay [ON-OFF]qH

Shift activating 1 [ON-OFF]qH

Shift activating 2 [ON-OFF]qH

2-4WD shift solenoid valve monitor

[ON-OFF]H

Check signal (re-input signal) of transfer control

unit control signal output is displayed. If circuit

is shorted or open, ON/OFF state does not

change. Transfer motor relay monitor [ON-OFF]H

Shift activating monitor 1 [ON-OFF]H

Shift activating monitor 2 [ON-OFF]H

4WD fail lamp [ON-OFF]qHTransfer control unit control signal output for

4WD warning lamp (left)

Shift position switch 1 [ON-OFF]qH

Shift position switch 2 [ON-OFF]qH

2WD indicator lamp [ON-OFF]HTransfer control unit control signal output for

4WD shift indicator lamp (rear)

AUTO indicator lamp [ON-OFF]HTransfer control unit control signal output for

4WD shift indicator lamp (front & rear)

LOCK indicator lamp [ON-OFF]HTransfer control unit control signal output for

4WD shift indicator lamp (center)

4LO indicator lamp [ON-OFF]HTransfer control unit control signal output for

4WD shift indicator lamp (right)

Offset at startingHAppears on monitor but does not function.

Clutch limit [N´m (kg-m, ft-lb)]HClutch force release limit value set in WORK

SUPPORT

Voltage [V]HValue measured by voltage probe is displayed.

Frequency [Hz]HValue measured by pulse probe is displayed. If

measurement is impossible, ª#º sign is dis-

played. ª#º sign is also displayed at the final

data value until the measurement result is

obtained.

DUTY-HIH

Duty cycle value for measurement probe is dis-

played.

DUTY-LOWH

PLS WIDTH-HIH

Measured pulse width of measurement probe is

displayed.

PLS WIDTH-LOWH

*: This item is indicated as ªCOMP CL TORQº.GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Trouble Diagnosis with CONSULT-II (Cont'd)

TF-35

Page 2353 of 2395

2. Align width across flat-notch with oil pump groove, and install

transfer motor.

3. Tighten bolts.

: 41 - 48 N´m (4.2 - 4.9 kg-m, 30 - 35 ft-lb)

4. Install breather pipe to transfer motor.

5. Connect transfer motor harness connector.

SMT875C

Transfer Oil Filter

REMOVALNBTF0071IRemove bolts to detach oil filter.

IWhen removing oil filter from transfer, avoid damaging it.

Be sure to loosen bolts evenly.

IWhen removing oil filter, be sure to replace O-ring with

new one.

INSTALLATIONNBTF00721. Apply petroleum jelly or ATF to O-ring.

2. Tighten bolts evenly to install oil filter.

:7-9N´m(0.7 - 0.9 kg-m, 61 - 78 in-lb)

IBe sure not to damage oil filter.

ON-VEHICLE SERVICE

Transfer Motor (Cont'd)

TF-118