INFINITI QX4 2001 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2021 of 2395

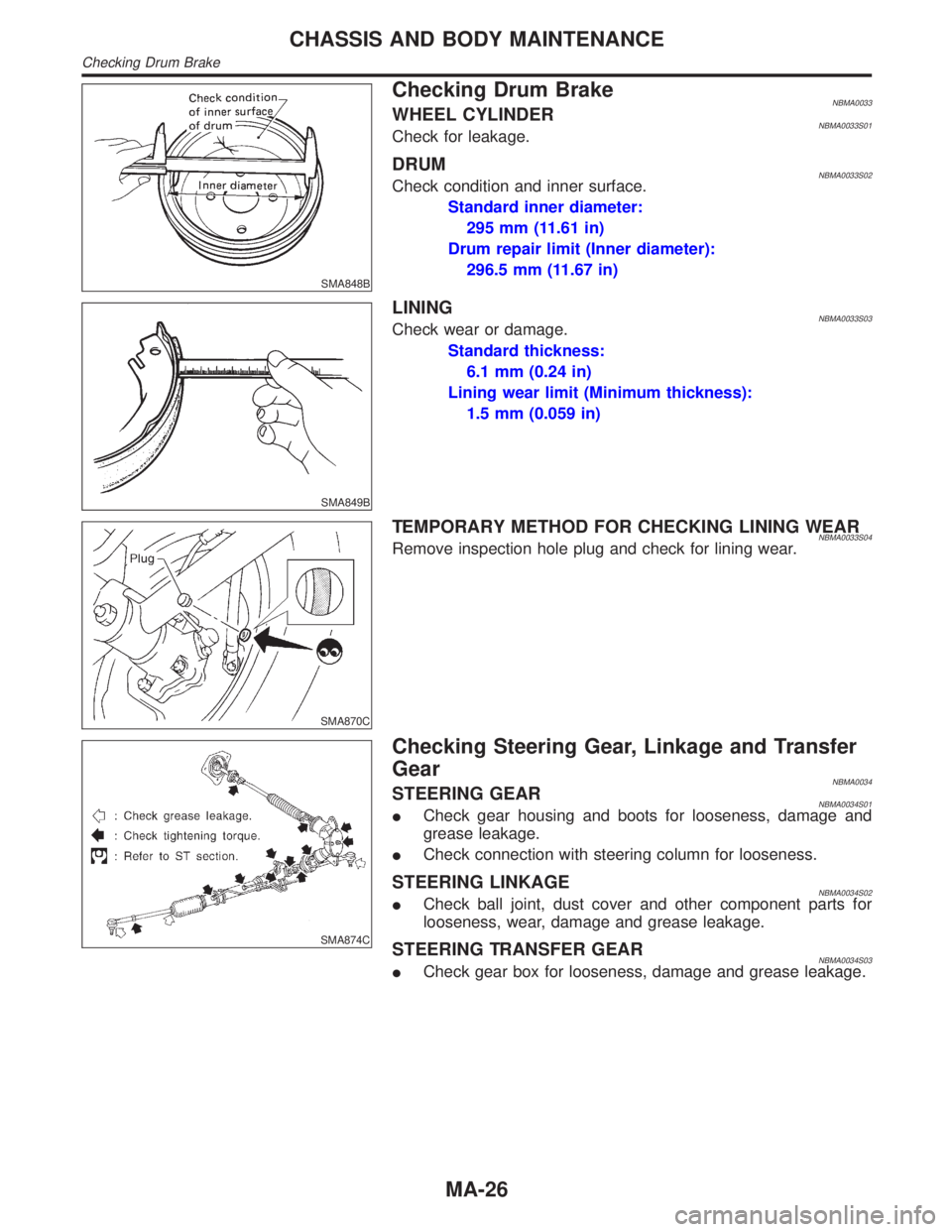

SMA848B

Checking Drum BrakeNBMA0033WHEEL CYLINDERNBMA0033S01Check for leakage.

DRUMNBMA0033S02Check condition and inner surface.

Standard inner diameter:

295 mm (11.61 in)

Drum repair limit (Inner diameter):

296.5 mm (11.67 in)

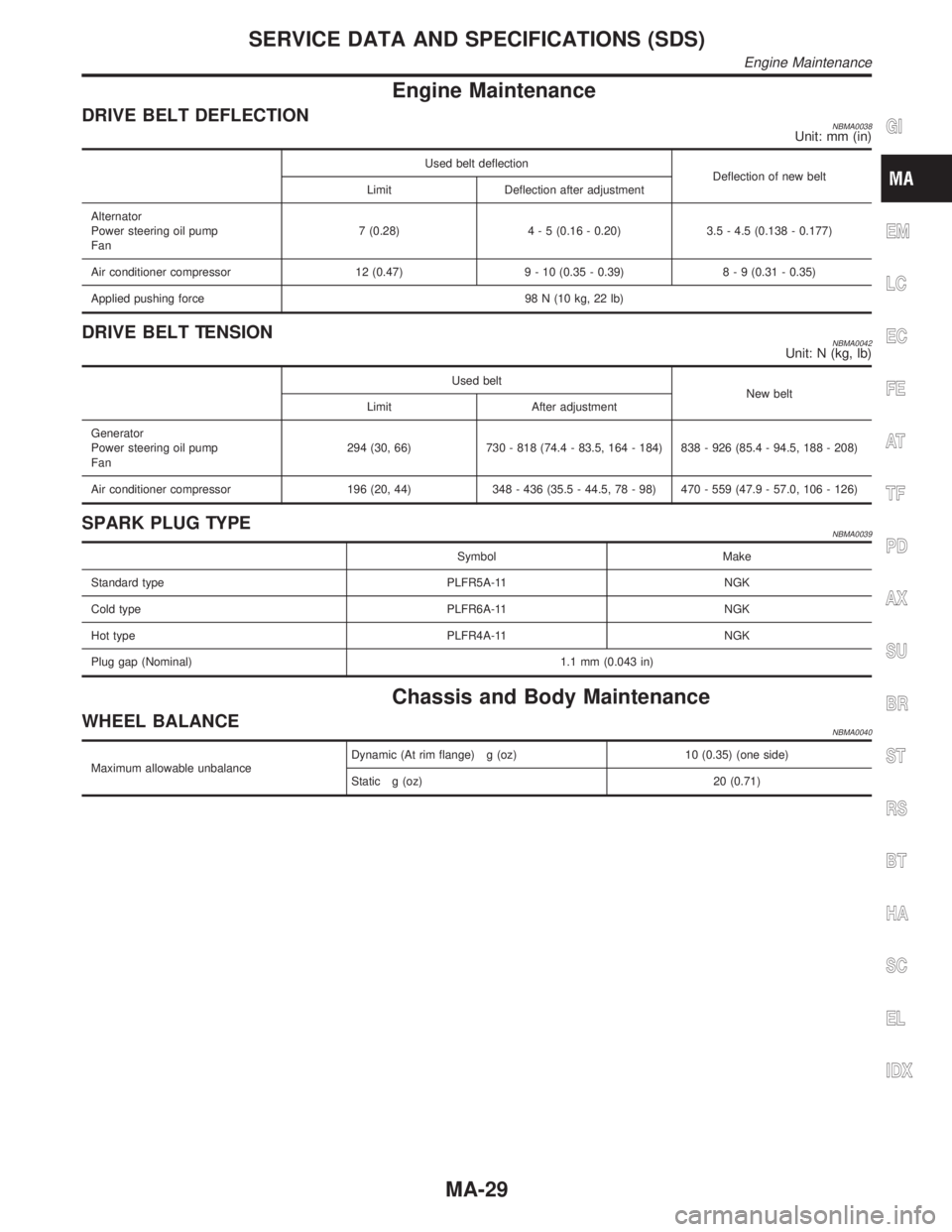

SMA849B

LININGNBMA0033S03Check wear or damage.

Standard thickness:

6.1 mm (0.24 in)

Lining wear limit (Minimum thickness):

1.5 mm (0.059 in)

SMA870C

TEMPORARY METHOD FOR CHECKING LINING WEARNBMA0033S04Remove inspection hole plug and check for lining wear.

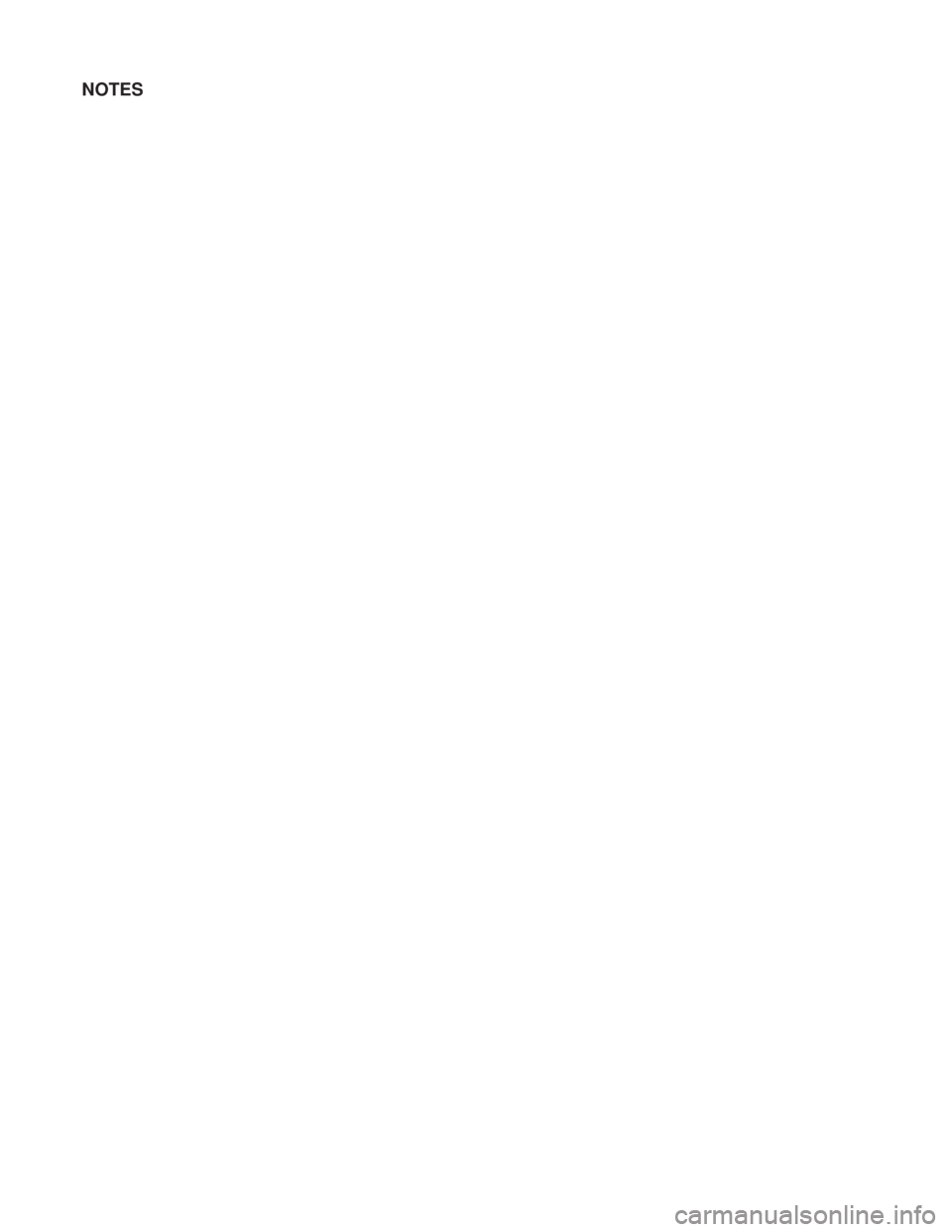

SMA874C

Checking Steering Gear, Linkage and Transfer

Gear

NBMA0034STEERING GEARNBMA0034S01ICheck gear housing and boots for looseness, damage and

grease leakage.

ICheck connection with steering column for looseness.

STEERING LINKAGENBMA0034S02ICheck ball joint, dust cover and other component parts for

looseness, wear, damage and grease leakage.

STEERING TRANSFER GEARNBMA0034S03ICheck gear box for looseness, damage and grease leakage.

CHASSIS AND BODY MAINTENANCE

Checking Drum Brake

MA-26

Page 2022 of 2395

SST280B

Checking Power Steering Fluid and LinesNBMA0035CHECKING FLUID LEVELNBMA0035S01ICheck fluid level with engine off.

ICheck fluid level with dipstick on reservoir cap. Use ªHOTº

range at fluid temperatures of 50 to 80ÉC (122 to 176ÉF). Use

ªCOLDº range at fluid temperatures of 0 to 30ÉC (32 to 86ÉF).

CAUTION:

IDo not overfill.

IRecommended fluid is Genuine NISSAN PSF II or equiva-

lent. Refer to ªRECOMMENDED FLUIDS AND

LUBRICANTSº, MA-11.

SST118B

CHECKING LINESNBMA0035S02ICheck lines for improper attachment, leaks, cracks, damage,

loose connections, chafing and deterioration.

ICheck rack boots for accumulation of power steering fluid.

Lubricating Locks, Hinges and Hood LatchesNBMA0036

SMA897C

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CHASSIS AND BODY MAINTENANCE

Checking Power Steering Fluid and Lines

MA-27

Page 2023 of 2395

Checking Seat Belts, Buckles, Retractors,

Anchors and Adjusters

NBMA0037

SMA854CE

CHASSIS AND BODY MAINTENANCE

Checking Seat Belts, Buckles, Retractors, Anchors and Adjusters

MA-28

Page 2024 of 2395

Engine Maintenance

DRIVE BELT DEFLECTIONNBMA0038Unit: mm (in)

Used belt deflection

Deflection of new belt

Limit Deflection after adjustment

Alternator

Power steering oil pump

Fan7 (0.28)4 - 5 (0.16 - 0.20) 3.5 - 4.5 (0.138 - 0.177)

Air conditioner compressor 12 (0.47) 9 - 10 (0.35 - 0.39)8 - 9 (0.31 - 0.35)

Applied pushing force 98 N (10 kg, 22 lb)

DRIVE BELT TENSIONNBMA0042Unit: N (kg, lb)

Used belt

New belt

Limit After adjustment

Generator

Power steering oil pump

Fan294 (30, 66) 730 - 818 (74.4 - 83.5, 164 - 184) 838 - 926 (85.4 - 94.5, 188 - 208)

Air conditioner compressor 196 (20, 44) 348 - 436 (35.5 - 44.5, 78 - 98) 470 - 559 (47.9 - 57.0, 106 - 126)

SPARK PLUG TYPENBMA0039

Symbol Make

Standard type PLFR5A-11 NGK

Cold type PLFR6A-11 NGK

Hot type PLFR4A-11 NGK

Plug gap (Nominal) 1.1 mm (0.043 in)

Chassis and Body Maintenance

WHEEL BALANCENBMA0040

Maximum allowable unbalanceDynamic (At rim flange) g (oz) 10 (0.35) (one side)

Static g (oz) 20 (0.71)

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Engine Maintenance

MA-29

Page 2025 of 2395

NOTES

Page 2026 of 2395

PROPELLER SHAFT &

DIFFERENTIAL CARRIER

SECTION

PD

CONTENTS

PROPELLER SHAFT......................................................3

Noise, Vibration and Harshness (NVH)

Troubleshooting ...........................................................3

NVH TROUBLESHOOTING CHART............................3

Components.................................................................4

FRONT PROPELLER SHAFT.....................................4

REAR PROPELLER SHAFT.......................................5

On-vehicle Service.......................................................6

PROPELLER SHAFT VIBRATION...............................6

APPEARANCE CHECKING........................................6

Removal and Installation .............................................6

Inspection.....................................................................7

Disassembly.................................................................7

CENTER BEARING - 2WD -.......................................7

JOURNAL (71H AND 80B)..........................................8

Assembly .....................................................................9

CENTER BEARING - 2WD -.......................................9

JOURNAL (71H AND 80B)..........................................9

Service Data and Specifications (SDS)..................... 11

GENERAL SPECIFICATIONS................................... 11

SERVICE DATA....................................................... 11

SNAP RING (80B).................................................... 11

SNAP RING (71H)...................................................12

R200A

FRONT FINAL DRIVE...................................................13

Preparation ................................................................13

SPECIAL SERVICE TOOLS......................................13

Noise, Vibration and Harshness (NVH)

Troubleshooting .........................................................15

On-vehicle Service.....................................................15

FRONT OIL SEAL REPLACEMENT...........................15

REAR COVER GASKET REPLACEMENT..................16

Components...............................................................17

Removal and Installation ...........................................18

REMOVAL...............................................................18

INSTALLATION........................................................18

Disassembly...............................................................18

PRE-INSPECTION...................................................18

FINAL DRIVE HOUSING..........................................19

DIFFERENTIAL CASE..............................................21

DIFFERENTIAL SIDE SHAFT...................................22

Inspection...................................................................23

RING GEAR AND DRIVE PINION.............................23

DIFFERENTIAL CASE ASSEMBLY...........................23

BEARING................................................................23

Adjustment .................................................................24

SIDE BEARING PRELOAD.......................................24

PINION GEAR HEIGHT AND PINION BEARING

PRELOAD

...............................................................25

TOOTH CONTACT...................................................29

Assembly ...................................................................30

DIFFERENTIAL SIDE SHAFT...................................30

DIFFERENTIAL CASE..............................................31

FINAL DRIVE HOUSING..........................................32

Service Data and Specifications (SDS).....................36

R200A.....................................................................36

H233B

REAR FINAL DRIVE.....................................................38

Preparation ................................................................38

SPECIAL SERVICE TOOLS......................................38

Noise, Vibration and Harshness (NVH)

Troubleshooting .........................................................40

On-vehicle Service.....................................................40

FRONT OIL SEAL REPLACEMENT...........................40

Components...............................................................42

Removal and Installation ...........................................43

REMOVAL...............................................................43

INSTALLATION........................................................43

Disassembly...............................................................43

PRE-INSPECTION...................................................43

DIFFERENTIAL CARRIER........................................44

DIFFERENTIAL CASE..............................................46

Inspection...................................................................47

RING GEAR AND DRIVE PINION.............................47

DIFFERENTIAL CASE ASSEMBLY...........................47

BEARING................................................................47

Limited Slip Differential ..............................................47

PREPARATION FOR DISASSEMBLY........................47

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 2027 of 2395

DISASSEMBLY........................................................48

INSPECTION...........................................................49

ADJUSTMENT.........................................................50

ASSEMBLY.............................................................51

Adjustment .................................................................53

PINION GEAR HEIGHT............................................53

TOOTH CONTACT...................................................56Assembly ...................................................................57

DIFFERENTIAL CASE..............................................57

DIFFERENTIAL CARRIER........................................58

Service Data and Specifications (SDS).....................62

H233B.....................................................................62

CONTENTS(Cont'd)

PD-2

Page 2028 of 2395

Noise, Vibration and Harshness (NVH)

Troubleshooting

=NBPD0049NVH TROUBLESHOOTING CHARTNBPD0049S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageÐ

Ð

Ð

Ð

PD-6

PD-6

PD-23, 47

PD-29, 56

PD-23, 47

PD-18, 43

Ð

Ð

Ð

Ð

AX-3

AX-3

SU-3

SU-3

SU-3

BR-6

ST-6

Possible cause and

SUSPECTED PARTS

Uneven rotation torque

Excessive center bearing axial end play

Center bearing mounting (insulator) cracks, damage or deterioration

Excessive joint angle

Rotation imbalance

Excessive runout

Rough gear tooth

Improper gear contact

Tooth surfaces worn

Incorrect backlash

Companion flange excessive runout

Improper gear oil

PROPELLER SHAFT

DIFFERENTIAL

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomPROPEL-

LER

SHAFTNoise´´´´´´ ´´´´´´´´

Shake´ ´´´´´´´

Vibration´´´´´´ ´´´´ ´

DIFFER-

ENTIALNoise´´´´´´´ ´´´´´´´

´: Applicable

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PROPELLER SHAFT

Noise, Vibration and Harshness (NVH) Troubleshooting

PD-3

Page 2029 of 2395

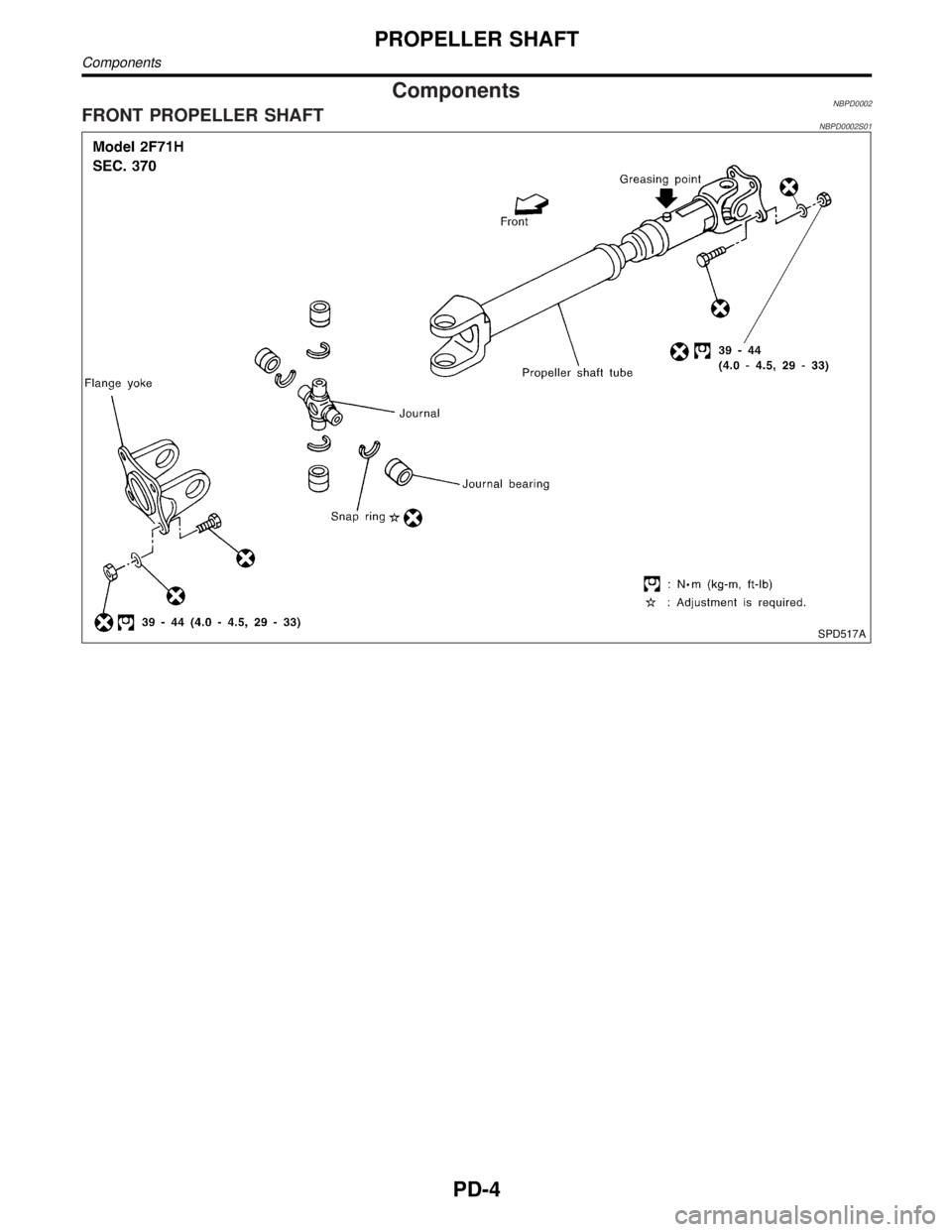

ComponentsNBPD0002FRONT PROPELLER SHAFTNBPD0002S01

SPD517A

PROPELLER SHAFT

Components

PD-4

Page 2030 of 2395

REAR PROPELLER SHAFTNBPD0002S02

SPD522A

SPD468AA

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PROPELLER SHAFT

Components (Cont'd)

PD-5