cooling INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 13 of 2395

IBefore assembly, apply a coat of recommended ATF to all

parts. Apply petroleum jelly to protect O-rings and seals, or

hold bearings and washers in place during assembly. Do not

use grease.

IExtreme care should be taken to avoid damage to O-rings,

seals and gaskets when assembling.

IReplace ATF cooler if excessive foreign material is found in oil

pan or clogging strainer. Refer to ªATF COOLER SERVICEº,

AT-9.

IAfter overhaul, refill the transmission with new ATF.

IWhen the A/T drain plug is removed, only some of the fluid is

drained. Old A/T fluid will remain in torque converter and ATF

cooling system.

Always follow the procedures when changing A/T fluid. Refer

to MA-21, ªChanging A/T Fluidº.

Service Notice or PrecautionsNBAT0004FAIL-SAFENBAT0004S01The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear, even with a shift lever position of ª1º, ª2º or ªDº. The

customer may complain of sluggish or poor acceleration.

When the ignition key is turned ªONº following Fail-Safe operation, O/D OFF indicator lamp blinks for about

8 seconds. (For ªTCM SELF-DIAGNOSTIC PROCEDURE (No Tools)º, refer to AT-46.)

Fail-Safe may occur without electrical circuit damage if the vehicle is driven under extreme conditions (such

as excessive wheel spin followed by sudden braking). To recover normal shift pattern, turn the ignition key

ªOFFº for 5 seconds, then ªONº.

The blinking of the O/D OFF indicator lamp for about 8 seconds will appear only once and be cleared. The

customer may resume normal driving conditions.

Always follow the ªWORK FLOWº (Refer to AT-57).

The SELF-DIAGNOSIS results will be as follows:

The first SELF-DIAGNOSIS will indicate damage to the vehicle speed sensor or the revolution sensor.

During the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

TORQUE CONVERTER SERVICENBAT0004S04The torque converter should be replaced under any of the following conditions:

IExternal leaks in the hub weld area.

IConverter hub is scored or damaged.

IConverter pilot is broken, damaged or fits poorly into crankshaft.

ISteel particles are found after flushing the cooler and cooler lines.

IPump is damaged or steel particles are found in the converter.

IVehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

IConverter is contaminated with engine coolant containing antifreeze.

IInternal failure of stator roller clutch.

IHeavy clutch debris due to overheating (blue converter).

ISteel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged Ð indicates that lining material came from converter.

The torque converter should not be replaced if:

IThe fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

PRECAUTIONS

Precautions (Cont'd)

AT-8

Page 579 of 2395

IAir intake system

(Oil filler cap, oil level gauge, etc.)

IFuel pressure

IEngine compression

IThrottle valve

IEvaporative emission system

2) On air conditioner equipped models, checks should be carried out while the air conditioner is ªOFFº.

3) On automatic transmission equipped models, when checking idle rpm, ignition timing and mixture ratio,

checks should be carried out while shift lever is in ªNº position.

4) When measuring ªCOº percentage, insert probe more than 40 cm (15.7 in) into tail pipe.

5) Turn off headlamps, heater blower, rear defogger.

6) Keep front wheels pointed straight ahead.

7) Make the check after the cooling fan has stopped.

BASIC SERVICE PROCEDURE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-44

Page 592 of 2395

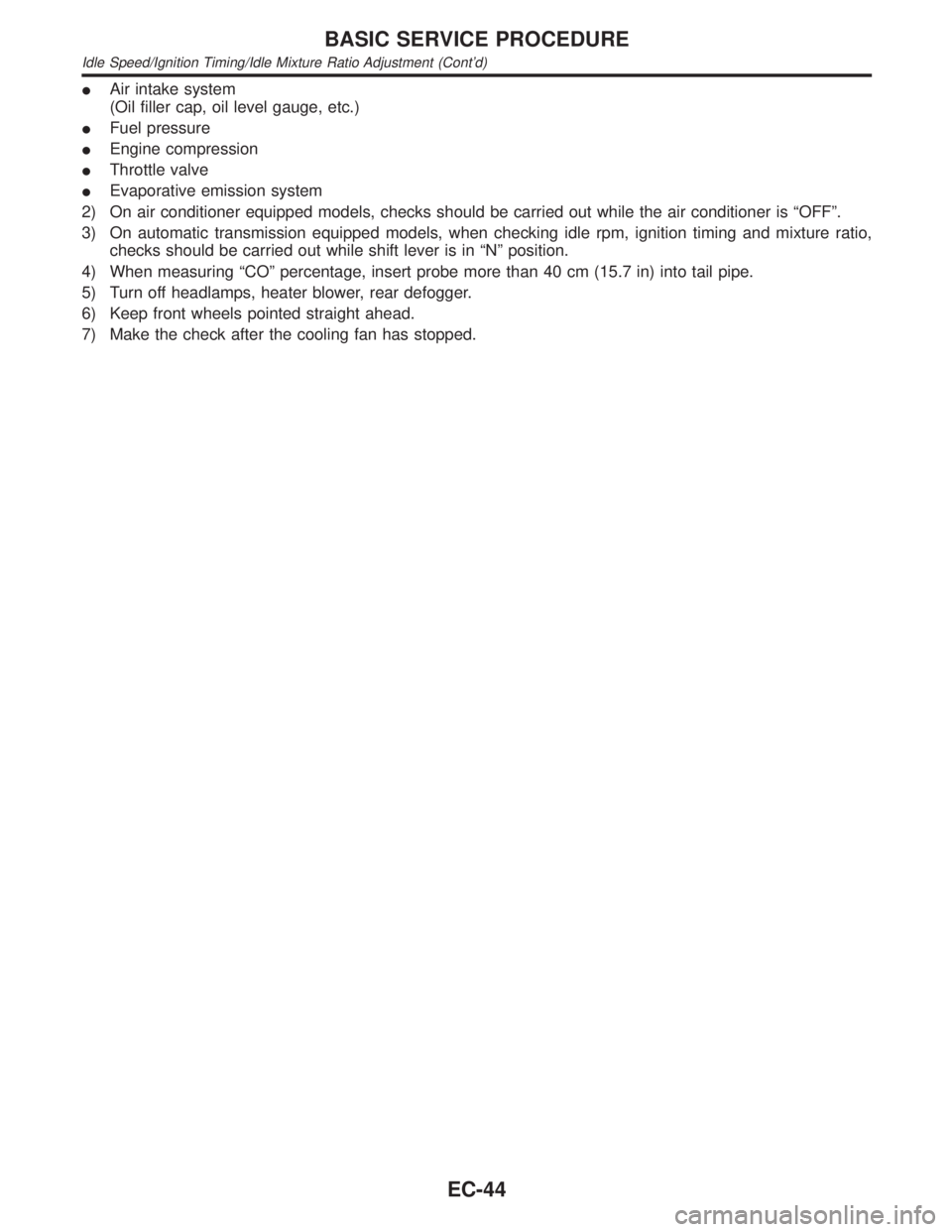

SEF452Y

Idle Air Volume LearningNBEC0642

SEF454Y

SEF455Y

DESCRIPTIONNBEC0642S01ªIdle Air Volume Learningº is an operation to learn the idle air vol-

ume that keeps each engine within the specific range. It must be

performed under any of the following conditions:

IEach time IACV-AAC valve, throttle body or ECM is replaced.

IIdle speed or ignition timing is out of specification.

PRE-CONDITIONINGNBEC0642S02Before performing ªIdle Air Volume Learningº, make sure that all of

the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are

missed for even a moment.

IBattery voltage: More than 12.9V (At idle)

IEngine coolant temperature: 70 - 99ÉC (158 - 210ÉF)

IPNP switch: ON

IElectric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime running light systems, if

the parking brake is applied before the engine is started the

headlamp will not illuminate.

ICooling fan motor: Not operating

ISteering wheel: Neutral (Straight-ahead position)

IVehicle speed: Stopped

ITransmission: Warmed-up

For A/T models with CONSULT-II, drive vehicle until ªFLUID

TEMP SEº in ªDATA MONITORº mode of ªA/Tº system indi-

cates less than 0.9V.

For A/T models without CONSULT-II, drive vehicle for 10 min-

utes.

OPERATION PROCEDURENBEC0642S03With CONSULT-IINBEC0642S03011. Turn ignition switch ªONº and wait at least 1 second.

2. Turn ignition switch ªOFFº and wait at least 10 seconds.

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic ªPRE-CONDITION-

INGº (previously mentioned) are in good order.

5. Turn ignition switch ªOFFº and wait at least 10 seconds.

6. Start the engine and let it idle for at least 30 seconds.

7. Select ªIDLE AIR VOL LEARNº in ªWORK SUPPORTº mode.

8. Touch ªSTARTº and wait 20 seconds.

9. Make sure that ªCMPLTº is displayed on CONSULT-II screen.

If ªINCMPº is displayed, ªIdle Air Volume Learningº will not be

carried out successfully. In this case, find the cause of the

problem by referring to the NOTE below.

10. Rev up the engine two or three times. Make sure that idle

speed and ignition timing are within specifications.

ITEM SPECIFICATION

Idle speed 750±50 rpm (in ªPº or ªNº position)

Ignition timing 15ɱ5É BTDC (in ªPº or ªNº position)

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

BASIC SERVICE PROCEDURE

Idle Air Volume Learning

EC-57

Page 652 of 2395

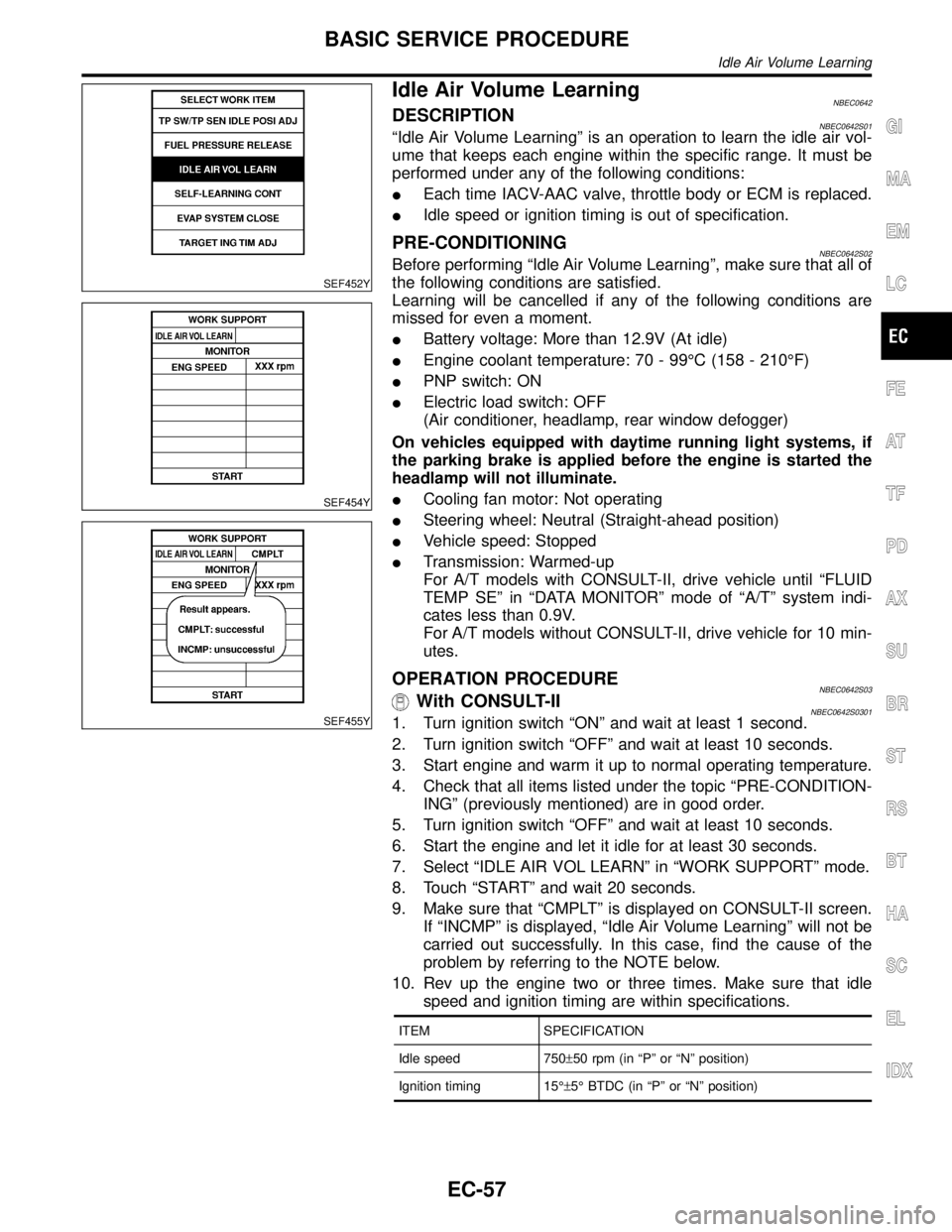

Fail-safe Chart=NBEC0040The ECM enters fail-safe mode, if any of the following malfunctions is detected due to the open or short cir-

cuit. When the ECM enters the fail-safe mode, the MIL illuminates.

DTC No. Detected items Engine operating condition in fail-safe mode

P0100 Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.

P0115 Engine coolant temperature

sensor circuitEngine coolant temperature will be determined by ECM based on the time after

turning ignition switch ªONº or ªSTARTº.

CONSULT-II displays the engine coolant temperature decided by ECM.

ConditionEngine coolant temperature decided

(CONSULT-II display)

Just as ignition switch is turned

ON or Start40ÉC (104ÉF)

More than approx. 4 minutes

after ignition ON or Start80ÉC (176ÉF)

Except as shown above40 - 80ÉC (104 - 176ÉF)

(Depends on the time)

P0120 Throttle position sensor cir-

cuitThrottle position will be determined based on the injected fuel amount and the

engine speed.

Therefore, acceleration will be poor.

Condition Driving condition

When engine is idling Normal

When accelerating Poor acceleration

P1335 Crankshaft position sensor

(REF) circuitCompression TDC signal (120É signal) is controlled by camshaft position sensor

(PHASE) signal and crankshaft position sensor (POS) signal. Ignition timing will be

delayed 0É to 2É.

Unable to

access ECMECMECM fail-safe activating condition

The computing function of the ECM was judged to be malfunctioning.

When the fail-safe system activates (i.e., if the ECM detects a malfunction condi-

tion in the CPU of ECM), the MIL on the instrument panel lights to warn the driver.

However it is not possible to access ECM and DTC cannot be confirmed.

Engine control with fail-safe

When ECM fail-safe is operating, fuel injection, ignition timing, fuel pump operation,

IACV-AAC valve operation and cooling fan operation are controlled under certain

limitations.

ECM fail-safe operation

Engine speedEngine speed will not rise more than 3,000

rpm

Fuel injection Simultaneous multiport fuel injection system

Ignition timing Ignition timing is fixed at the preset valve

Fuel pumpFuel pump relay is ªONº when engine is running

and ªOFFº when engine stalls

IACV-AAC valve Full open

Replace ECM, if ECM fail-safe condition is confirmed.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Fail-safe Chart

EC-117

Page 656 of 2395

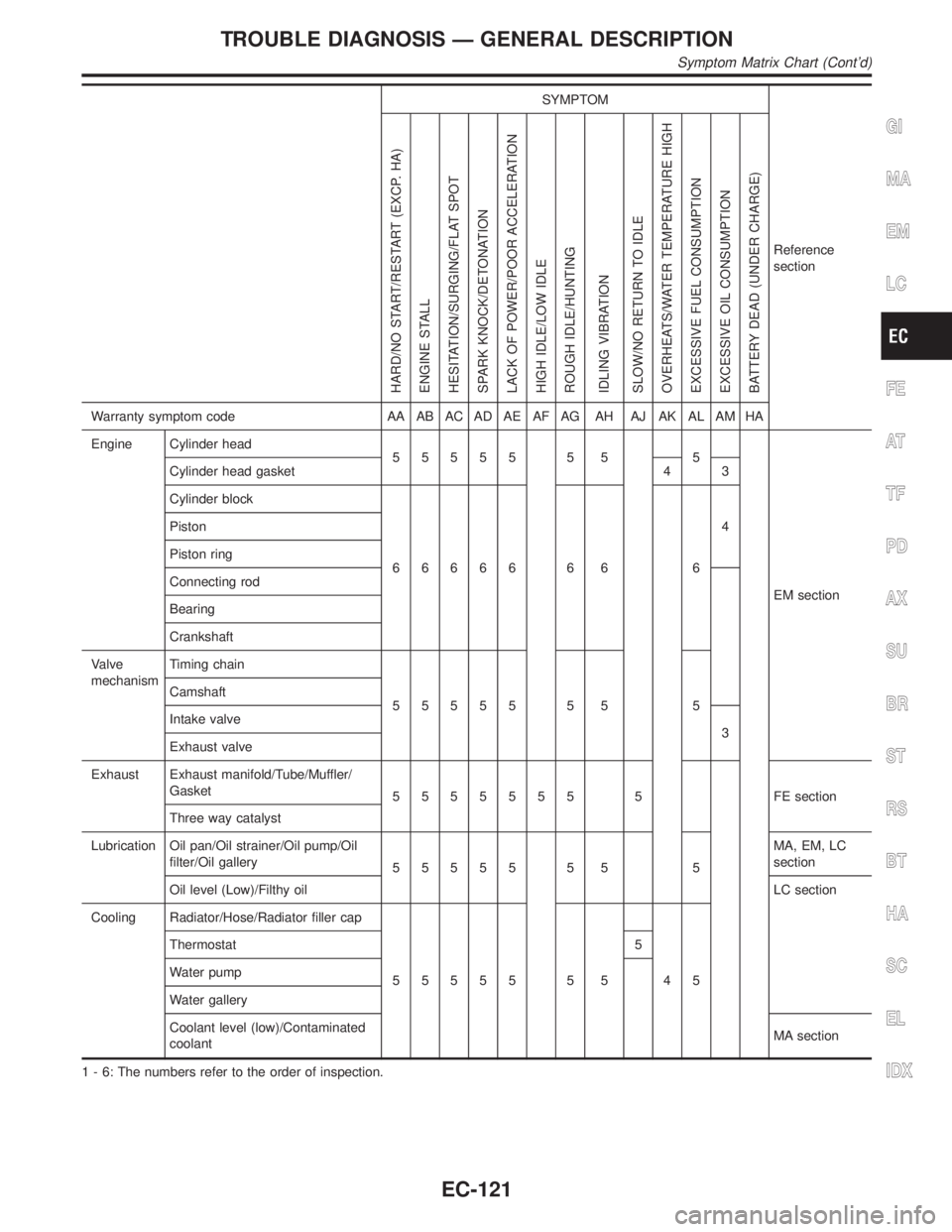

SYMPTOM

Reference

section

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Engine Cylinder head

55555 5 5 5

EM section Cylinder head gasket 4 3

Cylinder block

66666 6 6 64 Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Valve

mechanismTiming chain

55555 5 5 5 Camshaft

Intake valve

3

Exhaust valve

Exhaust Exhaust manifold/Tube/Muffler/

Gasket

5555555 5 FEsection

Three way catalyst

Lubrication Oil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery

55555 5 5 5MA, EM, LC

section

Oil level (Low)/Filthy oilLC section

Cooling Radiator/Hose/Radiator filler cap

55555 5 5 45 Thermostat 5

Water pump

Water gallery

Coolant level (low)/Contaminated

coolantMA section

1 - 6: The numbers refer to the order of inspection.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart (Cont'd)

EC-121

Page 671 of 2395

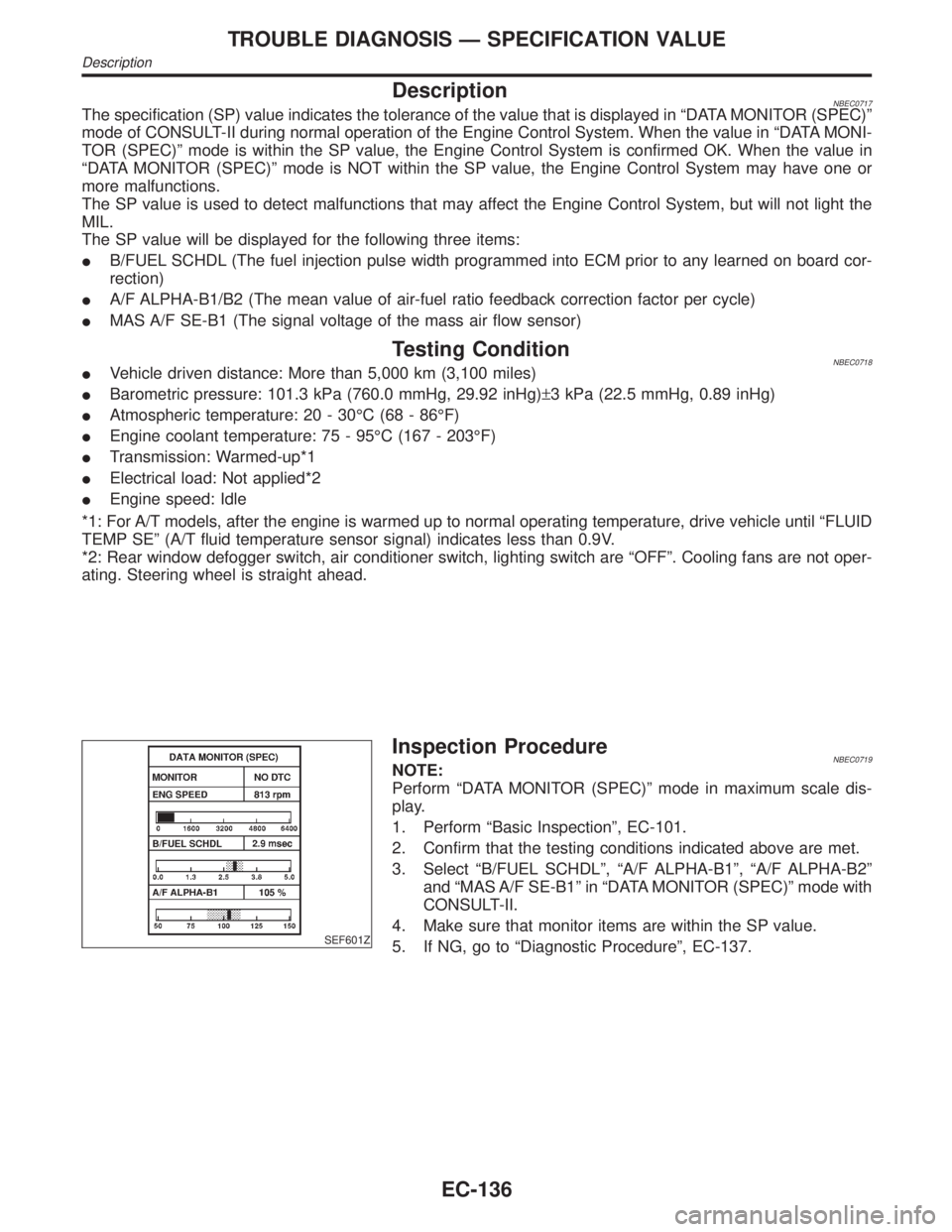

DescriptionNBEC0717The specification (SP) value indicates the tolerance of the value that is displayed in ªDATA MONITOR (SPEC)º

mode of CONSULT-II during normal operation of the Engine Control System. When the value in ªDATA MONI-

TOR (SPEC)º mode is within the SP value, the Engine Control System is confirmed OK. When the value in

ªDATA MONITOR (SPEC)º mode is NOT within the SP value, the Engine Control System may have one or

more malfunctions.

The SP value is used to detect malfunctions that may affect the Engine Control System, but will not light the

MIL.

The SP value will be displayed for the following three items:

IB/FUEL SCHDL (The fuel injection pulse width programmed into ECM prior to any learned on board cor-

rection)

IA/F ALPHA-B1/B2 (The mean value of air-fuel ratio feedback correction factor per cycle)

IMAS A/F SE-B1 (The signal voltage of the mass air flow sensor)

Testing ConditionNBEC0718IVehicle driven distance: More than 5,000 km (3,100 miles)

IBarometric pressure: 101.3 kPa (760.0 mmHg, 29.92 inHg)±3 kPa (22.5 mmHg, 0.89 inHg)

IAtmospheric temperature: 20 - 30ÉC (68 - 86ÉF)

IEngine coolant temperature: 75 - 95ÉC (167 - 203ÉF)

ITransmission: Warmed-up*1

IElectrical load: Not applied*2

IEngine speed: Idle

*1: For A/T models, after the engine is warmed up to normal operating temperature, drive vehicle until ªFLUID

TEMP SEº (A/T fluid temperature sensor signal) indicates less than 0.9V.

*2: Rear window defogger switch, air conditioner switch, lighting switch are ªOFFº. Cooling fans are not oper-

ating. Steering wheel is straight ahead.

SEF601Z

Inspection ProcedureNBEC0719NOTE:

Perform ªDATA MONITOR (SPEC)º mode in maximum scale dis-

play.

1. Perform ªBasic Inspectionº, EC-101.

2. Confirm that the testing conditions indicated above are met.

3. Select ªB/FUEL SCHDLº, ªA/F ALPHA-B1º, ªA/F ALPHA-B2º

and ªMAS A/F SE-B1º in ªDATA MONITOR (SPEC)º mode with

CONSULT-II.

4. Make sure that monitor items are within the SP value.

5. If NG, go to ªDiagnostic Procedureº, EC-137.

TROUBLE DIAGNOSIS Ð SPECIFICATION VALUE

Description

EC-136

Page 851 of 2395

4) Make sure that A/C switch is ªOFFº and air conditioner is not

operating. If NG, check air conditioner circuit. Refer to HA-35

or HA-30, ªTROUBLE DIAGNOSESº. After repair, go to the

next step.

5) Check for blocked coolant passage.

a) Warm up engine to normal operating temperature, then grasp

radiator upper hose and lower hose and make sure that cool-

ant flows.

If NG, go to ªDiagnostic Procedureº, EC-316. After repair, go

to the next step.

Be extremely careful not to touch any moving or adjacent

parts.

6) Check for blocked radiator air passage.

a) When market fog lamps have been installed, check for dam-

aged fans and clogging in the condenser and radiator.

b) Check the front end for clogging caused by insects or debris.

c) Check for improper fitting of front-end cover, damaged radia-

tor grille or bumper, damaged vehicle front.

If NG, take appropriate action and then go to the next step.

7) Check function of ECT sensor.

Refer to step 6 of ªDiagnostic Procedureº, EC-316.

If NG, replace ECT sensor and go to the next step.

8) Check ignition timing. Refer to basic inspection, EC-101.

Make sure that ignition timing is 15ɱ5É at idle.

If NG, adjust ignition timing and then recheck.

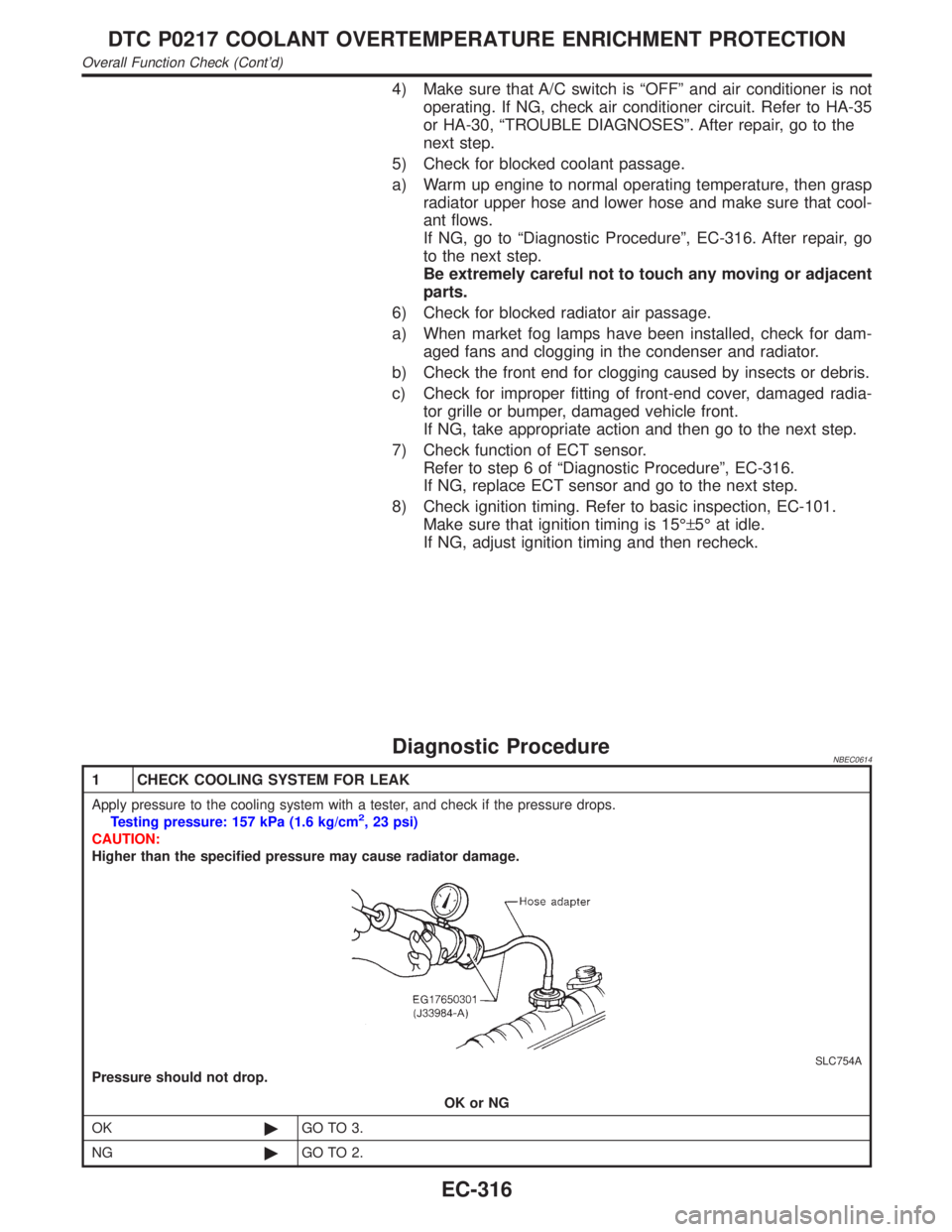

Diagnostic ProcedureNBEC0614

1 CHECK COOLING SYSTEM FOR LEAK

Apply pressure to the cooling system with a tester, and check if the pressure drops.

Testing pressure: 157 kPa (1.6 kg/cm2, 23 psi)

CAUTION:

Higher than the specified pressure may cause radiator damage.

SLC754A

Pressure should not drop.

OK or NG

OK©GO TO 3.

NG©GO TO 2.

DTC P0217 COOLANT OVERTEMPERATURE ENRICHMENT PROTECTION

Overall Function Check (Cont'd)

EC-316

Page 854 of 2395

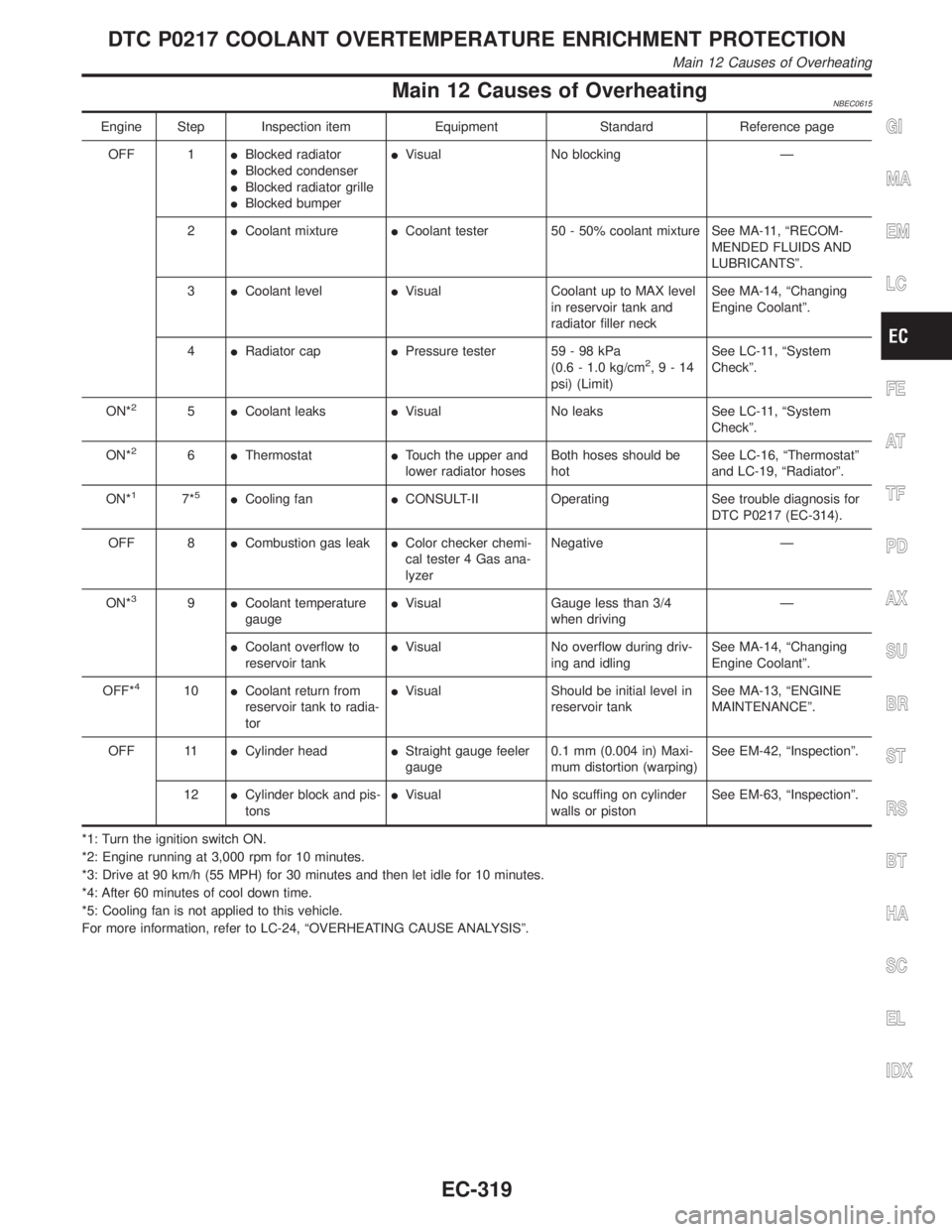

Main 12 Causes of OverheatingNBEC0615

Engine Step Inspection item Equipment Standard Reference page

OFF 1IBlocked radiator

IBlocked condenser

IBlocked radiator grille

IBlocked bumperIVisual No blocking Ð

2ICoolant mixtureICoolant tester 50 - 50% coolant mixture See MA-11, ªRECOM-

MENDED FLUIDS AND

LUBRICANTSº.

3ICoolant levelIVisual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee MA-14, ªChanging

Engine Coolantº.

4IRadiator capIPressure tester 59 - 98 kPa

(0.6 - 1.0 kg/cm

2,9-14

psi) (Limit)See LC-11, ªSystem

Checkº.

ON*

25ICoolant leaksIVisual No leaks See LC-11, ªSystem

Checkº.

ON*

26IThermostatITouch the upper and

lower radiator hosesBoth hoses should be

hotSee LC-16, ªThermostatº

and LC-19, ªRadiatorº.

ON*

17*5ICooling fanICONSULT-II Operating See trouble diagnosis for

DTC P0217 (EC-314).

OFF 8ICombustion gas leakIColor checker chemi-

cal tester 4 Gas ana-

lyzerNegative Ð

ON*

39ICoolant temperature

gaugeIVisual Gauge less than 3/4

when drivingÐ

ICoolant overflow to

reservoir tankIVisual No overflow during driv-

ing and idlingSee MA-14, ªChanging

Engine Coolantº.

OFF*

410ICoolant return from

reservoir tank to radia-

torIVisual Should be initial level in

reservoir tankSee MA-13, ªENGINE

MAINTENANCEº.

OFF 11ICylinder headIStraight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See EM-42, ªInspectionº.

12ICylinder block and pis-

tonsIVisual No scuffing on cylinder

walls or pistonSee EM-63, ªInspectionº.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

*5: Cooling fan is not applied to this vehicle.

For more information, refer to LC-24, ªOVERHEATING CAUSE ANALYSISº.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0217 COOLANT OVERTEMPERATURE ENRICHMENT PROTECTION

Main 12 Causes of Overheating

EC-319

Page 957 of 2395

DescriptionNBEC0249SYSTEM DESCRIPTIONNBEC0249S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed (POS signal)

Idle air

controlIACV-AAC valve Crankshaft position sensor (REF) Engine speed (REF signal)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Park/neutral position (PNP) switch Park/neutral position

Air conditioner switch Air conditioner operation

Power steering oil pressure switch Power steering load signal

Battery Battery voltage

Vehicle speed sensor Vehicle speed

Ambient air temperature switch Ambient air temperature

Intake air temperature sensor Intake air temperature

Absolute pressure sensor Ambient barometic pressure

This system automatically controls engine idle speed to a specified

level. Idle speed is controlled through fine adjustment of the

amount of air which by-passes the throttle valve via IACV-AAC

valve. The IACV-AAC valve changes the opening of the air by-pass

passage to control the amount of auxiliary air. This valve is actu-

ated by a step motor built into the valve, which moves the valve in

the axial direction in steps corresponding to the ECM output sig-

nals. One step of IACV-AAC valve movement causes the respec-

tive opening of the air by-pass passage. (i.e. when the step

advances, the opening is enlarged.) The opening of the valve is

varied to allow for optimum control of the engine idling speed. The

crankshaft position sensor (POS) detects the actual engine speed

and sends a signal to the ECM. The ECM then controls the step

position of the IACV-AAC valve so that engine speed coincides with

the target value memorized in ECM. The target engine speed is the

lowest speed at which the engine can operate steadily. The opti-

mum value stored in the ECM is determined by takig into consid-

eration various engine conditions, such as during warm up,

deceleration, and engine load (air conditioner, power steering and

cooling fan operation).

SEF765P

COMPONENT DESCRIPTIONNBEC0249S02IACV-AAC ValveNBEC0249S0201The IACV-AAC valve is operated by a step motor for centralized

control of auxiliary air supply. This motor has four winding phases

and is actuated by the output signals of ECM which turns ON and

OFF two windings each in seqeunce. Each time the IACV-AAC

valve opens or closes to change tha auxiliary air quantity, the ECM

sends a pulse signal to the step motor. When no change in the

auxiliary air quantity is needed, the ECM does not issue the pulse

signal. A certain voltage signal is issued so that the valve remains

at that particular opening.

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

Description

EC-422

Page 1174 of 2395

SEF029Z

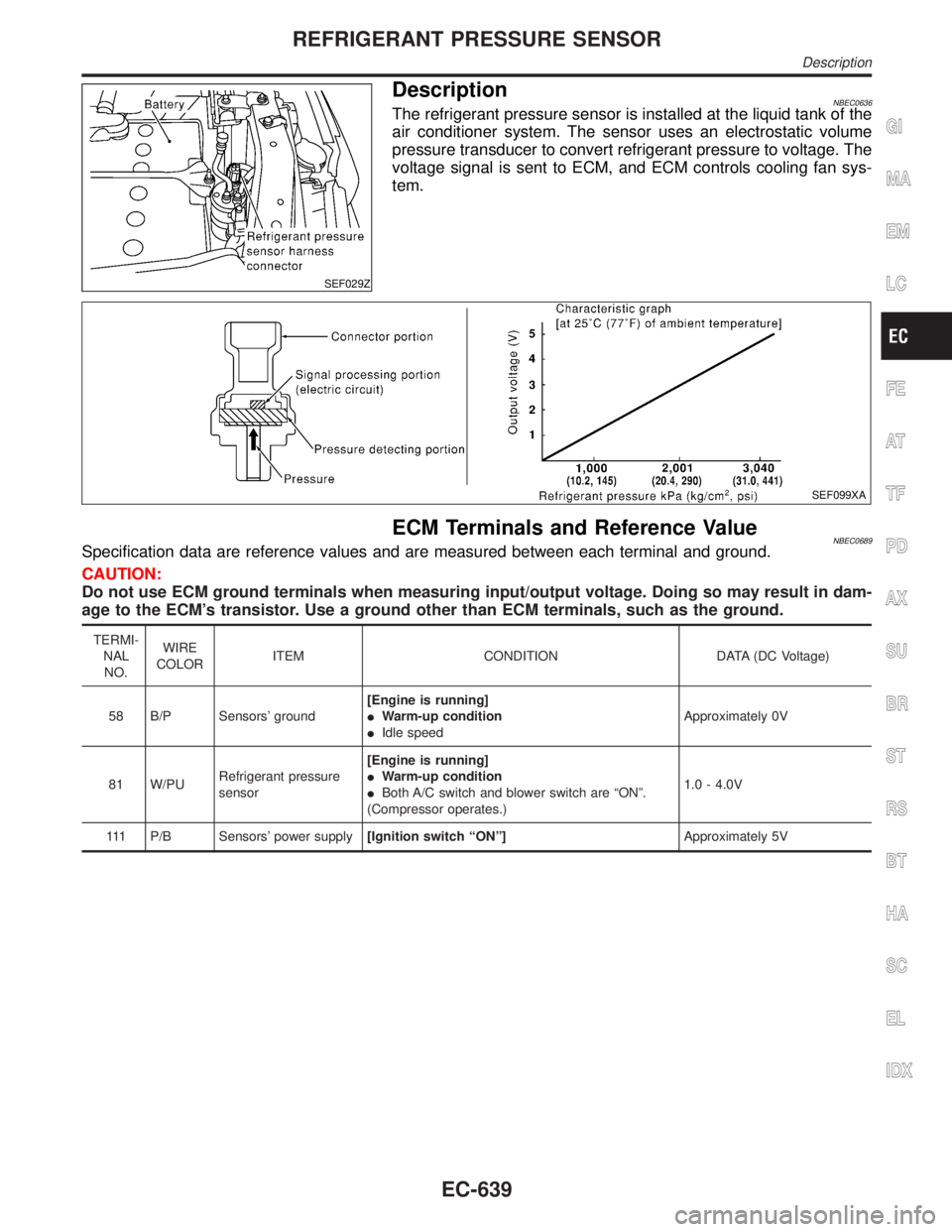

DescriptionNBEC0636The refrigerant pressure sensor is installed at the liquid tank of the

air conditioner system. The sensor uses an electrostatic volume

pressure transducer to convert refrigerant pressure to voltage. The

voltage signal is sent to ECM, and ECM controls cooling fan sys-

tem.

SEF099XA

ECM Terminals and Reference ValueNBEC0689Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

58 B/P Sensors' ground[Engine is running]

IWarm-up condition

IIdle speedApproximately 0V

81 W/PURefrigerant pressure

sensor[Engine is running]

IWarm-up condition

IBoth A/C switch and blower switch are ªONº.

(Compressor operates.)1.0 - 4.0V

111 P/B Sensors' power supply[Ignition switch ªONº]Approximately 5V

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REFRIGERANT PRESSURE SENSOR

Description

EC-639