charge INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 36 of 2395

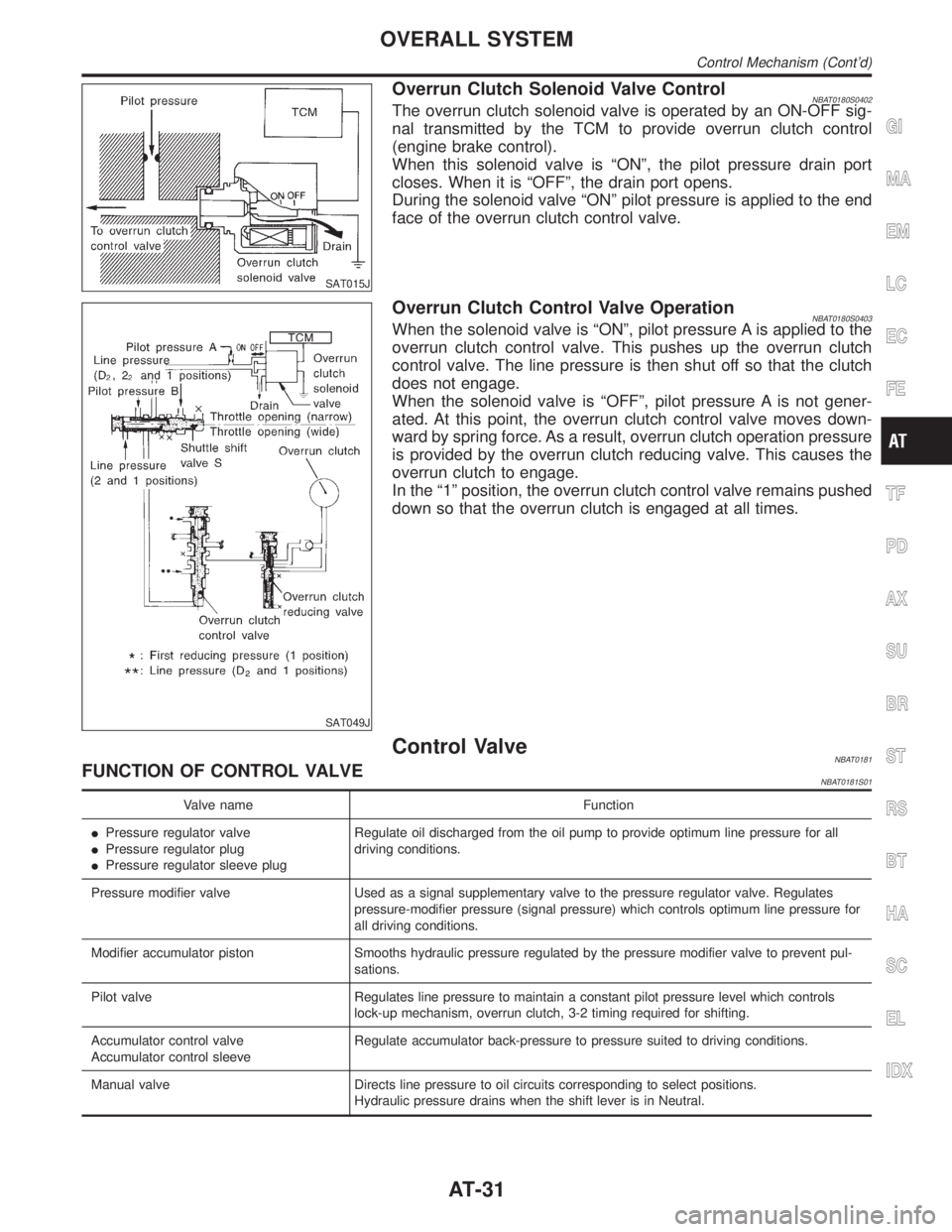

SAT015J

Overrun Clutch Solenoid Valve ControlNBAT0180S0402The overrun clutch solenoid valve is operated by an ON-OFF sig-

nal transmitted by the TCM to provide overrun clutch control

(engine brake control).

When this solenoid valve is ªONº, the pilot pressure drain port

closes. When it is ªOFFº, the drain port opens.

During the solenoid valve ªONº pilot pressure is applied to the end

face of the overrun clutch control valve.

SAT049J

Overrun Clutch Control Valve OperationNBAT0180S0403When the solenoid valve is ªONº, pilot pressure A is applied to the

overrun clutch control valve. This pushes up the overrun clutch

control valve. The line pressure is then shut off so that the clutch

does not engage.

When the solenoid valve is ªOFFº, pilot pressure A is not gener-

ated. At this point, the overrun clutch control valve moves down-

ward by spring force. As a result, overrun clutch operation pressure

is provided by the overrun clutch reducing valve. This causes the

overrun clutch to engage.

In the ª1º position, the overrun clutch control valve remains pushed

down so that the overrun clutch is engaged at all times.

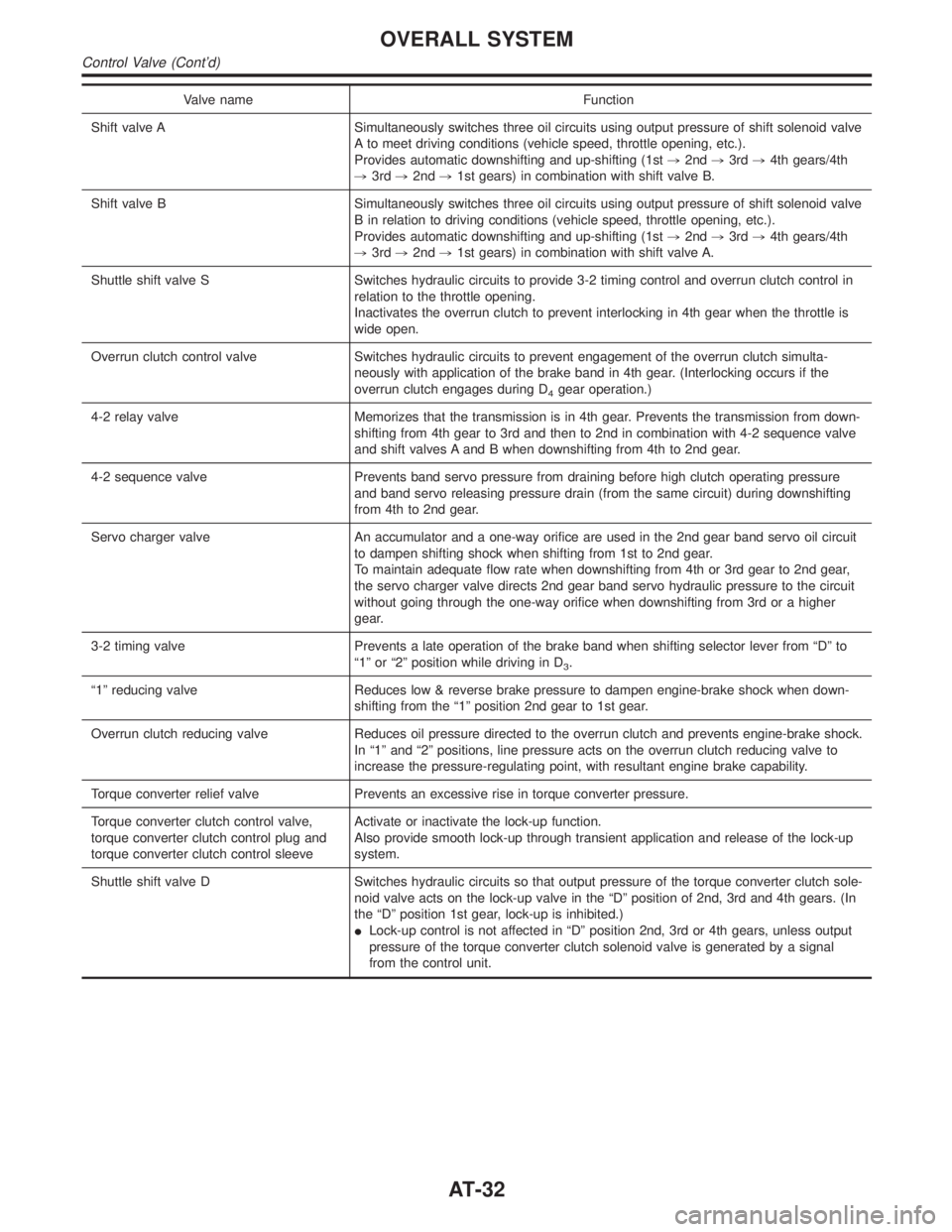

Control ValveNBAT0181FUNCTION OF CONTROL VALVENBAT0181S01

Valve name Function

IPressure regulator valve

IPressure regulator plug

IPressure regulator sleeve plugRegulate oil discharged from the oil pump to provide optimum line pressure for all

driving conditions.

Pressure modifier valve Used as a signal supplementary valve to the pressure regulator valve. Regulates

pressure-modifier pressure (signal pressure) which controls optimum line pressure for

all driving conditions.

Modifier accumulator piston Smooths hydraulic pressure regulated by the pressure modifier valve to prevent pul-

sations.

Pilot valve Regulates line pressure to maintain a constant pilot pressure level which controls

lock-up mechanism, overrun clutch, 3-2 timing required for shifting.

Accumulator control valve

Accumulator control sleeveRegulate accumulator back-pressure to pressure suited to driving conditions.

Manual valve Directs line pressure to oil circuits corresponding to select positions.

Hydraulic pressure drains when the shift lever is in Neutral.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OVERALL SYSTEM

Control Mechanism (Cont'd)

AT-31

Page 37 of 2395

Valve name Function

Shift valve A Simultaneously switches three oil circuits using output pressure of shift solenoid valve

A to meet driving conditions (vehicle speed, throttle opening, etc.).

Provides automatic downshifting and up-shifting (1st,2nd,3rd,4th gears/4th

,3rd,2nd,1st gears) in combination with shift valve B.

Shift valve B Simultaneously switches three oil circuits using output pressure of shift solenoid valve

B in relation to driving conditions (vehicle speed, throttle opening, etc.).

Provides automatic downshifting and up-shifting (1st,2nd,3rd,4th gears/4th

,3rd,2nd,1st gears) in combination with shift valve A.

Shuttle shift valve S Switches hydraulic circuits to provide 3-2 timing control and overrun clutch control in

relation to the throttle opening.

Inactivates the overrun clutch to prevent interlocking in 4th gear when the throttle is

wide open.

Overrun clutch control valve Switches hydraulic circuits to prevent engagement of the overrun clutch simulta-

neously with application of the brake band in 4th gear. (Interlocking occurs if the

overrun clutch engages during D

4gear operation.)

4-2 relay valve Memorizes that the transmission is in 4th gear. Prevents the transmission from down-

shifting from 4th gear to 3rd and then to 2nd in combination with 4-2 sequence valve

and shift valves A and B when downshifting from 4th to 2nd gear.

4-2 sequence valve Prevents band servo pressure from draining before high clutch operating pressure

and band servo releasing pressure drain (from the same circuit) during downshifting

from 4th to 2nd gear.

Servo charger valve An accumulator and a one-way orifice are used in the 2nd gear band servo oil circuit

to dampen shifting shock when shifting from 1st to 2nd gear.

To maintain adequate flow rate when downshifting from 4th or 3rd gear to 2nd gear,

the servo charger valve directs 2nd gear band servo hydraulic pressure to the circuit

without going through the one-way orifice when downshifting from 3rd or a higher

gear.

3-2 timing valve Prevents a late operation of the brake band when shifting selector lever from ªDº to

ª1º or ª2º position while driving in D

3.

ª1º reducing valve Reduces low & reverse brake pressure to dampen engine-brake shock when down-

shifting from the ª1º position 2nd gear to 1st gear.

Overrun clutch reducing valve Reduces oil pressure directed to the overrun clutch and prevents engine-brake shock.

In ª1º and ª2º positions, line pressure acts on the overrun clutch reducing valve to

increase the pressure-regulating point, with resultant engine brake capability.

Torque converter relief valve Prevents an excessive rise in torque converter pressure.

Torque converter clutch control valve,

torque converter clutch control plug and

torque converter clutch control sleeveActivate or inactivate the lock-up function.

Also provide smooth lock-up through transient application and release of the lock-up

system.

Shuttle shift valve D Switches hydraulic circuits so that output pressure of the torque converter clutch sole-

noid valve acts on the lock-up valve in the ªDº position of 2nd, 3rd and 4th gears. (In

the ªDº position 1st gear, lock-up is inhibited.)

ILock-up control is not affected in ªDº position 2nd, 3rd or 4th gears, unless output

pressure of the torque converter clutch solenoid valve is generated by a signal

from the control unit.

OVERALL SYSTEM

Control Valve (Cont'd)

AT-32

Page 167 of 2395

SAT341H

DescriptionNBAT0057The line pressure solenoid valve regulates the oil pump discharge

pressure to suit the driving condition in response to a signal sent

from the TCM.

The line pressure duty cycle value is not consistent when the

closed throttle position switch is ªONº. To confirm the line

pressure duty cycle at low pressure, the accelerator (throttle)

should be open until the closed throttle position switch is

ªOFFº.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NBAT0057S02Remarks: Specification data are reference values.

Monitor item Condition Specification

Line pressure solenoid

valve dutySmall throttle opening (Low line pressure)

"

Large throttle opening (High line pressure)Approximately 24%

"

Approximately 95%

NOTE:

The line pressure duty cycle value is not consistent when the closed throttle position switch is ªONº. To confirm the line pressure duty

cycle at low pressure, the accelerator (throttle) should be open until the closed throttle position switch is ªOFFº.

TCM TERMINALS AND REFERENCE VALUENBAT0057S03Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

1GYLine pressure

solenoid valve

When releasing accelerator pedal after warm-

ing up engine.1.5 - 3.0V

When depressing accelerator pedal fully after

warming up engine.0V

2 BR/YLine pressure

solenoid valve

(with dropping

resistor)When releasing accelerator pedal after warm-

ing up engine.5 - 14V

When depressing accelerator pedal fully after

warming up engine.0V

ON BOARD DIAGNOSIS LOGICNBAT0057S04

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: L/PRESS SOL/CIRCTCM detects an improper voltage drop

when it tries to operate the solenoid

valve.IHarness or connectors

(The solenoid circuit is open or shorted.)

ILine pressure solenoid valve

: P0745

DTC P0745 LINE PRESSURE SOLENOID VALVE

Description

AT-162

Page 362 of 2395

Return SpringsNBAT0165Unit: mm (in)

PartsItem

Part No.* Free length Outer diameter

Control valveUpper body1 Torque converter relief valve spring 31742-41X23 38.0 (1.496) 9.0 (0.354)

2 Pressure regulator valve spring 31742-41X24 44.02 (1.7331) 14.0 (0.551)

3 Pressure modifier valve spring 31742-41X19 31.95 (1.2579) 6.8 (0.268)

Ð Accumulator control valve spring Ð Ð Ð

4 Shuttle shift valve D spring 31762-41X01 25.0 (0.984) 7.0 (0.276)

5 4-2 sequence valve spring 31756-41X00 29.1 (1.146) 6.95 (0.2736)

6 Shift valve B spring 31762-41X01 25.0 (0.984) 7.0 (0.276)

7 4-2 relay valve spring 31756-41X00 29.1 (1.146) 6.95 (0.2736)

8 Shift valve A spring 31762-41X01 25.0 (0.984) 7.0 (0.276)

9 Overrun clutch control valve spring 31762-41X03 23.6 (0.929) 7.0 (0.276)

10 Overrun clutch reducing valve spring 31742-41X14 38.9 (1.531) 7.0 (0.276)

11 Shuttle shift valve S spring 31762-41X04 51.0 (2.008) 5.65 (0.2224)

12 Pilot valve spring 31742-41X13 25.7 (1.012) 9.0 (0.354)

13 Torque converter clutch control valve spring 31742-41X22 18.5 (0.728) 13.0 (0.512)

Lower body1 Modifier accumulator piston spring 31742-27X70 31.4 (1.236) 9.8 (0.386)

2 1st reducing valve spring 31756-60X00 20.5 (0.807) 7.0 (0.276)

3 3-2 timing valve spring 31742-41X06 23.0 (0.906) 6.7 (0.264)

4 Servo charger valve spring 31742-41X06 23.0 (0.906) 6.7 (0.264)

Reverse clutch Ð 31505-41X07 Ð Ð

High clutch10 pcs31521-41X03

(Assembly)24.2 (0.9528) 11.6 (0.457)

Forward clutch (Overrun clutch) 20 pcs31521-41X04

(Assembly)35.77 (1.4083) 9.7 (0.382)

Low & reverse brake 18 pcs31655-41X00

(Assembly)22.3 (0.878) 11.2 (0.441)

Band servoSpring A 31605-4AX03 45.6 (1.795) 34.3 (1.350)

Spring B 31605-41X01 29.7 (1.169) 27.6 (1.087)

AccumulatorAccumulator A 31605-41X02 43.0 (1.693) 18.0 (0.709)

Accumulator B 31605-41X14 47.6 (1.874) 26.5 (1.043)

Accumulator C 31605-41X09 45.0 (1.772) 29.3 (1.154)

Accumulator D 31605-41X06 58.4 (2.299) 17.3 (0.681)

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Return Springs

AT-357

Page 620 of 2395

WORK SUPPORT MODE=NBEC0034S04

WORK ITEM CONDITION USAGE

TP SW/TP SEN IDLE POSI ADJIFOLLOW THE BASIC INSPECTION INSTRUCTION IN

THE SERVICE MANUAL.When adjusting the idle throttle

position

FUEL PRESSURE RELEASEIFUEL PUMP WILL STOP BY TOUCHING ªSTARTº

DURING IDLING.

CRANK A FEW TIMES AFTER ENGINE STALLS.When releasing fuel pressure

from fuel line

IDLE AIR VOL LEARNITHE IDLE AIR VOLUME THAT KEEPS THE ENGINE

WITHIN THE SPECIFIED RANGE IS MEMORIZED IN

ECM.When learning the idle air volume

SELF-LEARNING CONTITHE COEFFICIENT OF SELF-LEARNING CONTROL

MIXTURE RATIO RETURNS TO THE ORIGINAL

COEFFICIENT.When clearing the coefficient of

self-learning control valve

EVAP SYSTEM CLOSE OPEN THE VACUUM CUT VALVE BYPASS VALVE AND

CLOSE THE EVAP CANISTER VENT CONTROL VALVE

IN ORDER TO MAKE EVAP SYSTEM CLOSE UNDER

THE FOLLOWING CONDITIONS.

IIGN SW ªONº

IENGINE NOT RUNNING

IAMBIENT TEMPERATURE IS ABOVE 0ÉC (32ÉF).

INO VACUUM AND NO HIGH PRESSURE IN EVAP

SYSTEM

ITANK FUEL TEMP. IS MORE THAN 0ÉC (32ÉF).

IWITHIN 10 MINUTES AFTER STARTING ªEVAP SYS-

TEM CLOSEº

IWHEN TRYING TO EXECUTE ªEVAP SYSTEM

CLOSEº UNDER THE CONDITION EXCEPT ABOVE,

CONSULT-II WILL DISCONTINUE IT AND DISPLAY

APPROPRIATE INSTRUCTION.

NOTE:

WHEN STARTING ENGINE, CONSULT-II MAY DIS-

PLAY ªBATTERY VOLTAGE IS LOW. CHARGE

BATTERYº, EVEN IN USING CHARGED BATTERY.When detecting EVAP vapor leak

point of EVAP system

TARGET IGNITION TIMING ADJ*IIDLE CONDITIONIWhen adjusting target ignition

timing

After adjustment, confirm target

ignition timing with a timing

light.

IIf once the ªTARGET IDLE

RPM ADJº has been done, the

Idle Air Volume Learning proce-

dure will not be completed.

TARGET IDLE RPM ADJ*IIDLE CONDITION When setting target idle speed

*: This function is not necessary in the usual service procedure.

SELF-DIAGNOSTIC MODENBEC0034S05DTC and 1st Trip DTCNBEC0034S0501Regarding items of ªDTC and 1st trip DTCº, refer to ªTROUBLE

DIAGNOSIS Ð INDEXº (See EC-8.)

Freeze Frame Data and 1st Trip Freeze Frame DataNBEC0034S0502

Freeze frame data

item*1Description

DIAG TROUBLE

CODE

[PXXXX]IThe engine control component part/control system has a trouble code, it is displayed as ªPXXXXº.

(Refer to ªTROUBLE DIAGNOSIS Ð INDEXº, EC-8.)

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-85

Page 653 of 2395

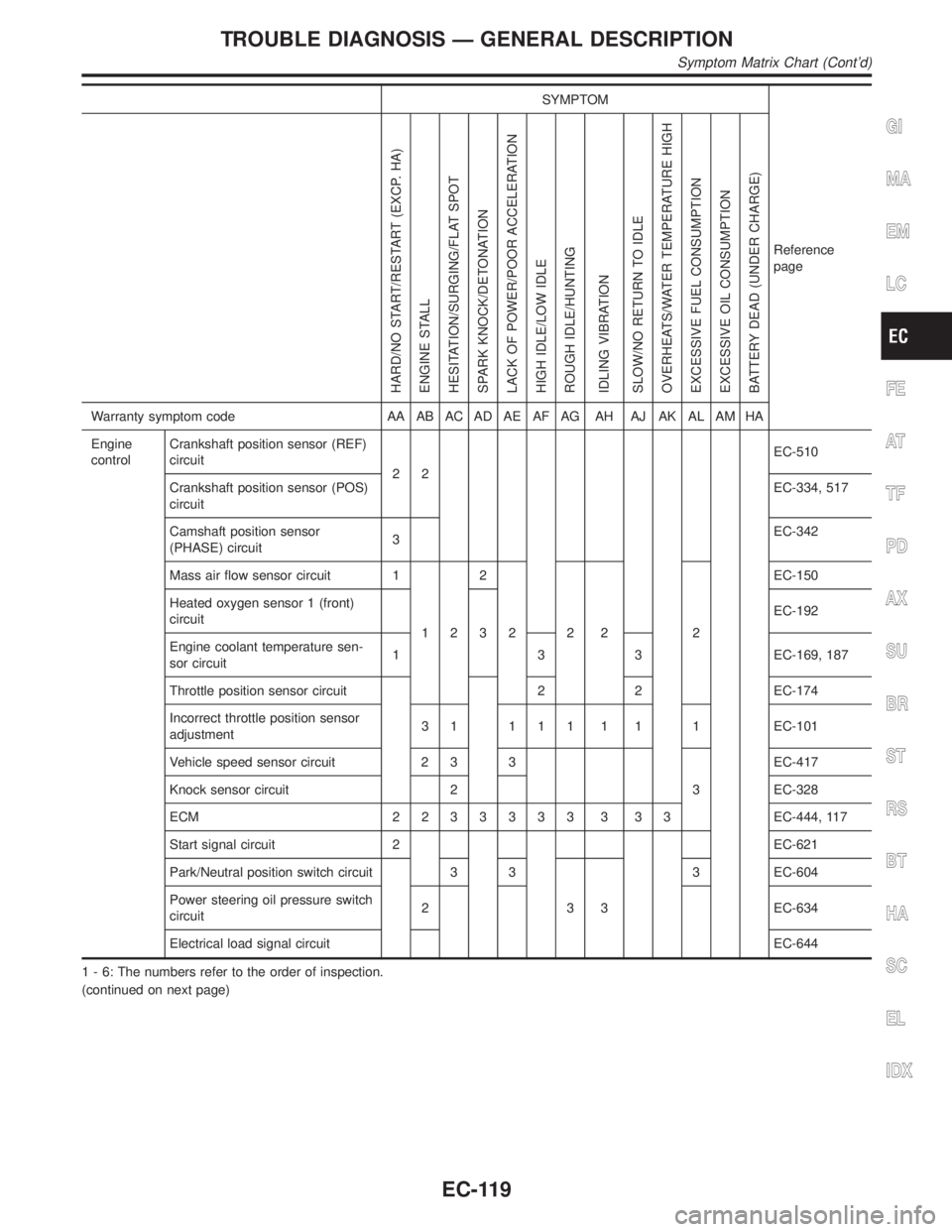

Symptom Matrix ChartNBEC0041SYSTEM Ð BASIC ENGINE CONTROL SYSTEMNBEC0041S01

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel pump circuit11232 2 2 3 2EC-625

Fuel pressure regulator system3344444 4 4 4EC-40

Injector circuit11232 2 2 2EC-616

Evaporative emission system

3344444 4 4 4EC-32

Air Positive crankcase ventilation sys-

tem1 EC-38

Incorrect idle speed adjustment 1 1 1 1 1 EC-101

IACV-AAC valve circuit1123322 2 2 2 2EC-422

Ignition Incorrect ignition timing adjustment33111 1 1 1EC-101

Ignition circuit 1 1 2 2 2 2 2 2 EC-499

Main power supply and ground circuit

22333 3 32

3EC-142

Air conditioner circuit 3 3 2 HA section

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart

EC-118

Page 654 of 2395

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Engine

controlCrankshaft position sensor (REF)

circuit

22EC-510

Crankshaft position sensor (POS)

circuitEC-334, 517

Camshaft position sensor

(PHASE) circuit3EC-342

Mass air flow sensor circuit 1

122

222 2EC-150

Heated oxygen sensor 1 (front)

circuit

3EC-192

Engine coolant temperature sen-

sor circuit1 3 3 EC-169, 187

Throttle position sensor circuit 2 2 EC-174

Incorrect throttle position sensor

adjustment3 1 1 1 1 1 1 1 EC-101

Vehicle speed sensor circuit 2 3 3

3EC-417

Knock sensor circuit 2 EC-328

ECM 2233333 3 33EC-444, 117

Start signal circuit 2 EC-621

Park/Neutral position switch circuit 3 3

333 EC-604

Power steering oil pressure switch

circuit2 EC-634

Electrical load signal circuitEC-644

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart (Cont'd)

EC-119

Page 655 of 2395

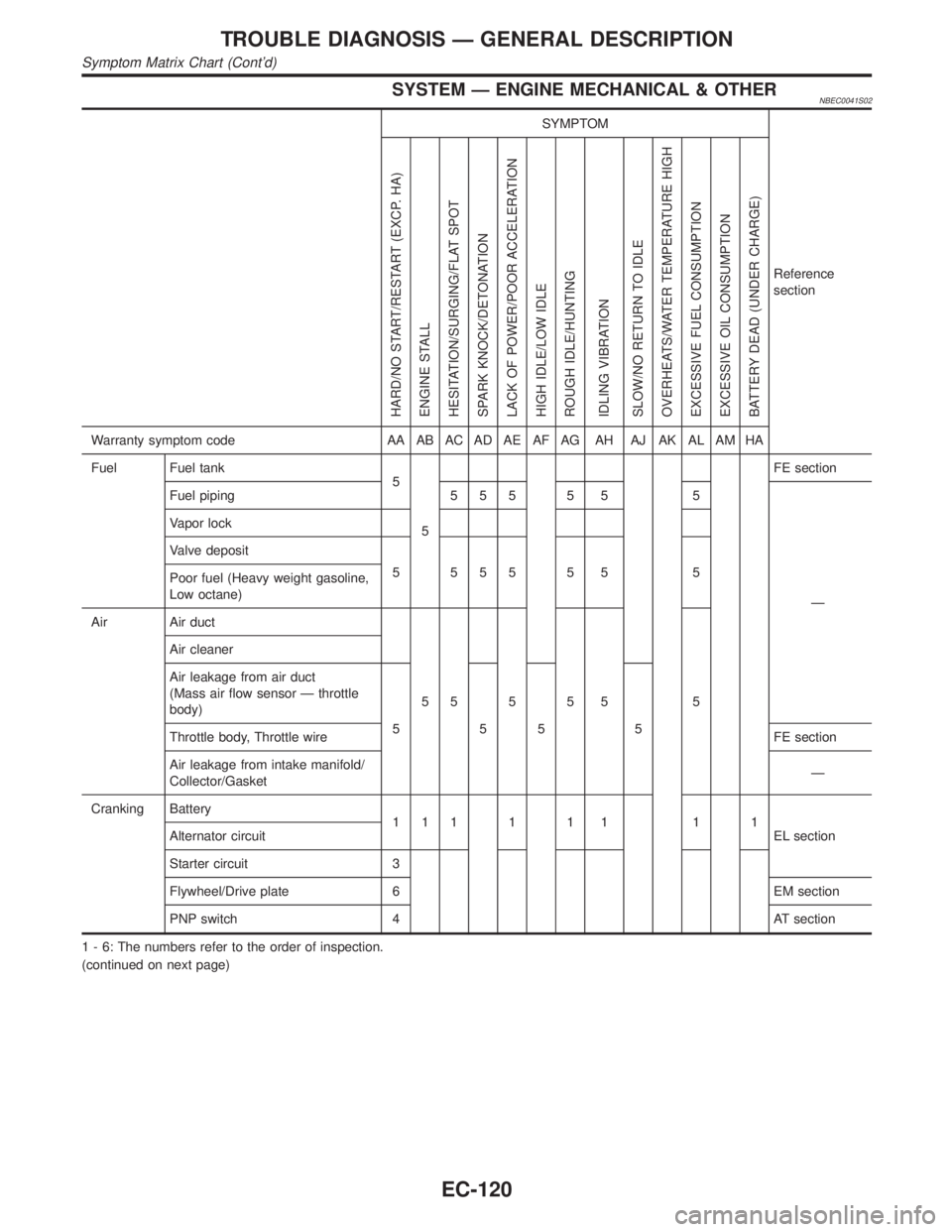

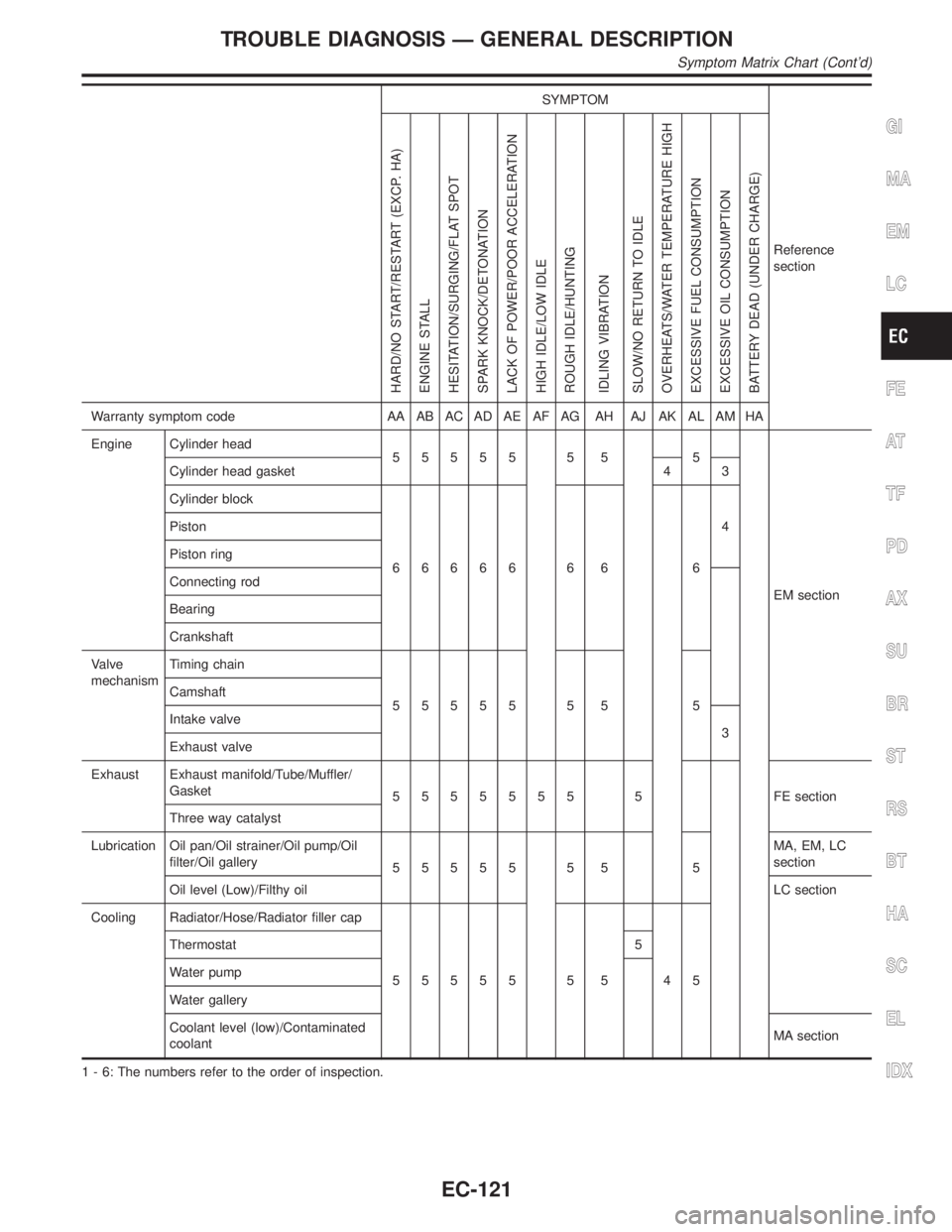

SYSTEM Ð ENGINE MECHANICAL & OTHERNBEC0041S02

SYMPTOM

Reference

section

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank

5

5FE section

Fuel piping 5 5 5 5 5 5

Ð Vapor lock

Valve deposit

5 555 5 5 5

Poor fuel (Heavy weight gasoline,

Low octane)

Air Air duct

55555 5 Air cleaner

Air leakage from air duct

(Mass air flow sensor Ð throttle

body)

555 5

Throttle body, Throttle wireFE section

Air leakage from intake manifold/

Collector/GasketÐ

Cranking Battery

111111 11

EL section Alternator circuit

Starter circuit 3

Flywheel/Drive plate 6 EM section

PNP switch 4 AT section

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart (Cont'd)

EC-120

Page 656 of 2395

SYMPTOM

Reference

section

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Engine Cylinder head

55555 5 5 5

EM section Cylinder head gasket 4 3

Cylinder block

66666 6 6 64 Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Valve

mechanismTiming chain

55555 5 5 5 Camshaft

Intake valve

3

Exhaust valve

Exhaust Exhaust manifold/Tube/Muffler/

Gasket

5555555 5 FEsection

Three way catalyst

Lubrication Oil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery

55555 5 5 5MA, EM, LC

section

Oil level (Low)/Filthy oilLC section

Cooling Radiator/Hose/Radiator filler cap

55555 5 5 45 Thermostat 5

Water pump

Water gallery

Coolant level (low)/Contaminated

coolantMA section

1 - 6: The numbers refer to the order of inspection.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart (Cont'd)

EC-121

Page 657 of 2395

SYMPTOM

Reference

section

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

IVIS (INFINITI Vehicle Immobilizer System Ð

NATS)11EC-74 or EL

section

1 - 6: The numbers refer to the order of inspection.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0042Remarks:

ISpecification data are reference values.

ISpecification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

i.e. Adjust ignition timing with a timing light before monitoring IGN TIMING, because the monitor may show the specification data in

spite of the ignition timing not being adjusted to the specification data. This IGN TIMING monitors the data calculated by the ECM

according to the signals input from the camshaft position sensor and other ignition timing related sensors.

IIf the real-time diagnosis results are NG and the on board diagnostic system results are OK when diagnosing the mass air flow sensor,

first check to see if the fuel pump control circuit is normal.

MONITOR ITEM CONDITION SPECIFICATION

ENG SPEED

CKPS´RPM (POS)ITachometer: Connect

IRun engine and compare tachometer indication with the CONSULT-II

value.Almost the same speed as

the CONSULT-II value.

POS COUNTIEngine: Running 179 - 181

MAS A/F SE-B1IEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 1.2 - 1.8V

2,500 rpm 1.6 - 2.2V

COOLAN TEMP/SIEngine: After warming up More than 70ÉC (158ÉF)

HO2S1 (B1)

HO2S1 (B2)

IEngine: After warming upMaintaining engine speed at 2,000

rpm0 - 0.3V+,Approx. 0.6 -

1.0V

HO2S1 MNTR (B1)

HO2S1 MNTR (B2)LEAN+,RICH

Changes more than 5 times

during 10 seconds.

HO2S2 (B1)

HO2S2 (B2)

IEngine: After warming upMaintaining engine speed at 2,000

rpm0 - 0.3V+,Approx. 0.6 -

1.0V

HO2S2 MNTR (B1)

HO2S2 MNTR (B2)LEAN+,RICH

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Matrix Chart (Cont'd)

EC-122