IDX INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 526 of 2395

SBF034B

Removal and InstallationNBBT0019

SBT472

SBT473

REMOVALNBBT0019S01After removing moldings, remove glass using piano wire or power

cutting tool and an inflatable pump bag.

WARNING:

When cutting the glass from the vehicle, always wear safety

glasses and heavy gloves to help prevent glass splinters from

entering your eyes or cutting your hands.

CAUTION:

IBe careful not to scratch the glass when removing.

IDo not set or stand the glass on its edge. Small chips may

develop into cracks.

INSTALLATIONNBBT0019S02IUse a genuine Nissan Urethane Adhesive Kit or equivalent

and follow the instructions furnished with it.

IWhile the urethane adhesive is curing, open a door win-

dow. This will prevent the glass from being forced out by

passenger compartment air pressure when a door is

closed.

IThe molding must be installed securely so that it is in

position and leaves no gap.

IInform the customer that the vehicle should remain sta-

tionary until the urethane adhesive has completely cured

(preferably 24 hours). Curing time varies with temperature

and humidity.

WARNING:

IKeep heat and open flames away as primers and adhesive

are flammable.

IThe materials contained in the kit are harmful if

swallowed, and may irritate skin and eyes. Avoid contact

with the skin and eyes.

IUse in an open, well ventilated location. Avoid breathing

the vapors. They can be harmful if inhaled. If affected by

vapor inhalation, immediately move to an area with fresh

air.

IDriving the vehicle before the urethane adhesive has com-

pletely cured may affect the performance of the wind-

shield in case of an accident.

CAUTION:

IDo not use an adhesive which is past its usable term.

Shelf life of this product is limited to six months after the

date of manufacture. Carefully adhere to the expiration or

manufacture date printed on the box.

IKeep primers and adhesive in a cool, dry place. Ideally,

they should be stored in a refrigerator.

IDo not leave primers or adhesive cartridge unattended

with their caps open or off.

IThe vehicle should not be driven for at least 24 hours or

until the urethane adhesive has completely cured. Curing

time varies depending on temperature and humidities. The

curing time will increase under higher temperatures and

lower humidities.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

HA

SC

EL

IDX

WINDSHIELD AND WINDOWS

Removal and Installation

BT-53

Page 528 of 2395

REAR SIDE WINDOWNBBT0019S04

SBT359-A

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

HA

SC

EL

IDX

WINDSHIELD AND WINDOWS

Removal and Installation (Cont'd)

BT-55

Page 530 of 2395

AlignmentNBBT0021IAll dimensions indicated in figures are actual ones.

IWhen using a tracking gauge, adjust both pointers to equal length. Then check the pointers and gauge

itself to make sure there is no free play.

IWhen a measuring tape is used, check to be sure there is no elongation, twisting or bending.

IMeasurements should be taken at the center of the mounting holes.

IAn asterisk (H) following the value at the measuring point indicates that the measuring point on the other

side is symmetrically the same value.

IThe coordinates of the measurement points are the distances measured from the standard line of ªXº, ªYº

and ªZº.

SBF874GD

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

HA

SC

EL

IDX

BODY (ALIGNMENT)

Alignment

BT-57

Page 532 of 2395

Measurement PointsNBBT0021S0102

SBT195

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

HA

SC

EL

IDX

BODY (ALIGNMENT)

Alignment (Cont'd)

BT-59

Page 534 of 2395

Measurement PointsNBBT0021S0202

SBT361

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

HA

SC

EL

IDX

BODY (ALIGNMENT)

Alignment (Cont'd)

BT-61

Page 536 of 2395

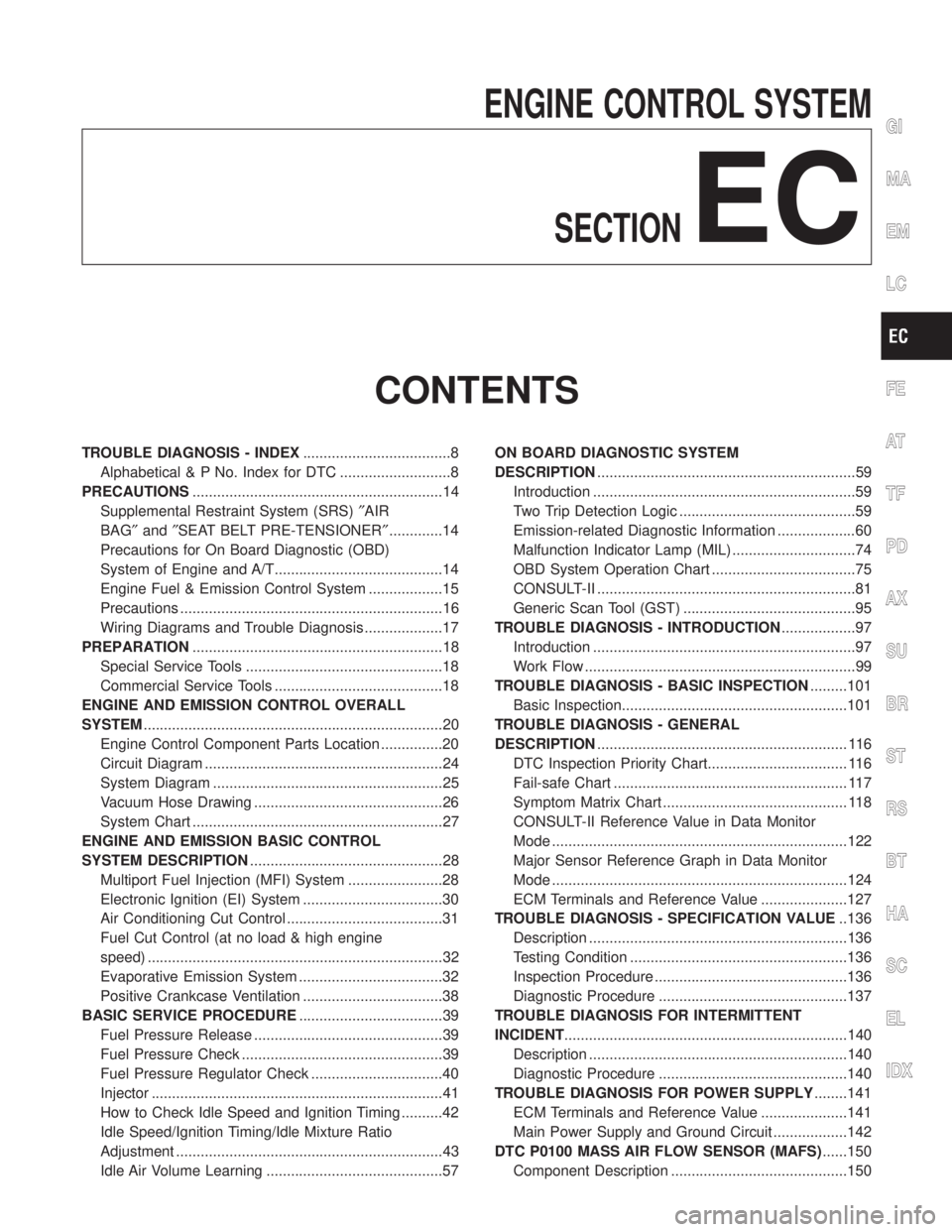

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

TROUBLE DIAGNOSIS - INDEX....................................8

Alphabetical & P No. Index for DTC ...........................8

PRECAUTIONS.............................................................14

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER².............14

Precautions for On Board Diagnostic (OBD)

System of Engine and A/T.........................................14

Engine Fuel & Emission Control System ..................15

Precautions ................................................................16

Wiring Diagrams and Trouble Diagnosis ...................17

PREPARATION.............................................................18

Special Service Tools ................................................18

Commercial Service Tools .........................................18

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.........................................................................20

Engine Control Component Parts Location ...............20

Circuit Diagram ..........................................................24

System Diagram ........................................................25

Vacuum Hose Drawing ..............................................26

System Chart .............................................................27

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION...............................................28

Multiport Fuel Injection (MFI) System .......................28

Electronic Ignition (EI) System ..................................30

Air Conditioning Cut Control ......................................31

Fuel Cut Control (at no load & high engine

speed) ........................................................................32

Evaporative Emission System ...................................32

Positive Crankcase Ventilation ..................................38

BASIC SERVICE PROCEDURE...................................39

Fuel Pressure Release ..............................................39

Fuel Pressure Check .................................................39

Fuel Pressure Regulator Check ................................40

Injector .......................................................................41

How to Check Idle Speed and Ignition Timing ..........42

Idle Speed/Ignition Timing/Idle Mixture Ratio

Adjustment .................................................................43

Idle Air Volume Learning ...........................................57ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................59

Introduction ................................................................59

Two Trip Detection Logic ...........................................59

Emission-related Diagnostic Information ...................60

Malfunction Indicator Lamp (MIL) ..............................74

OBD System Operation Chart ...................................75

CONSULT-II ...............................................................81

Generic Scan Tool (GST) ..........................................95

TROUBLE DIAGNOSIS - INTRODUCTION..................97

Introduction ................................................................97

Work Flow ..................................................................99

TROUBLE DIAGNOSIS - BASIC INSPECTION.........101

Basic Inspection.......................................................101

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION............................................................. 116

DTC Inspection Priority Chart.................................. 116

Fail-safe Chart ......................................................... 117

Symptom Matrix Chart ............................................. 118

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................122

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................124

ECM Terminals and Reference Value .....................127

TROUBLE DIAGNOSIS - SPECIFICATION VALUE..136

Description ...............................................................136

Testing Condition .....................................................136

Inspection Procedure ...............................................136

Diagnostic Procedure ..............................................137

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT.....................................................................140

Description ...............................................................140

Diagnostic Procedure ..............................................140

TROUBLE DIAGNOSIS FOR POWER SUPPLY........141

ECM Terminals and Reference Value .....................141

Main Power Supply and Ground Circuit ..................142

DTC P0100 MASS AIR FLOW SENSOR (MAFS)......150

Component Description ...........................................150

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 538 of 2395

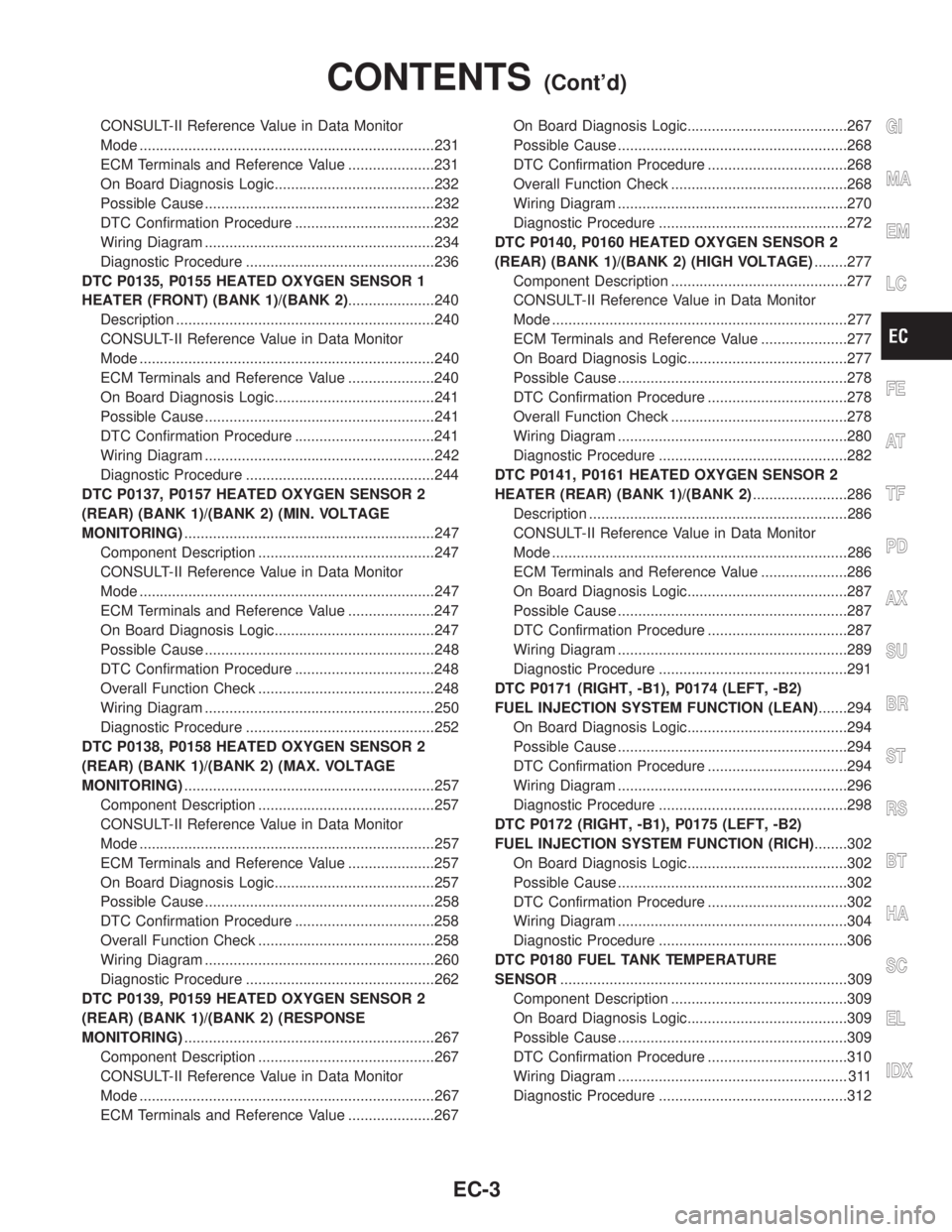

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................231

ECM Terminals and Reference Value .....................231

On Board Diagnosis Logic.......................................232

Possible Cause ........................................................232

DTC Confirmation Procedure ..................................232

Wiring Diagram ........................................................234

Diagnostic Procedure ..............................................236

DTC P0135, P0155 HEATED OXYGEN SENSOR 1

HEATER (FRONT) (BANK 1)/(BANK 2).....................240

Description ...............................................................240

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................240

ECM Terminals and Reference Value .....................240

On Board Diagnosis Logic.......................................241

Possible Cause ........................................................241

DTC Confirmation Procedure ..................................241

Wiring Diagram ........................................................242

Diagnostic Procedure ..............................................244

DTC P0137, P0157 HEATED OXYGEN SENSOR 2

(REAR) (BANK 1)/(BANK 2) (MIN. VOLTAGE

MONITORING).............................................................247

Component Description ...........................................247

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................247

ECM Terminals and Reference Value .....................247

On Board Diagnosis Logic.......................................247

Possible Cause ........................................................248

DTC Confirmation Procedure ..................................248

Overall Function Check ...........................................248

Wiring Diagram ........................................................250

Diagnostic Procedure ..............................................252

DTC P0138, P0158 HEATED OXYGEN SENSOR 2

(REAR) (BANK 1)/(BANK 2) (MAX. VOLTAGE

MONITORING).............................................................257

Component Description ...........................................257

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................257

ECM Terminals and Reference Value .....................257

On Board Diagnosis Logic.......................................257

Possible Cause ........................................................258

DTC Confirmation Procedure ..................................258

Overall Function Check ...........................................258

Wiring Diagram ........................................................260

Diagnostic Procedure ..............................................262

DTC P0139, P0159 HEATED OXYGEN SENSOR 2

(REAR) (BANK 1)/(BANK 2) (RESPONSE

MONITORING).............................................................267

Component Description ...........................................267

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................267

ECM Terminals and Reference Value .....................267On Board Diagnosis Logic.......................................267

Possible Cause ........................................................268

DTC Confirmation Procedure ..................................268

Overall Function Check ...........................................268

Wiring Diagram ........................................................270

Diagnostic Procedure ..............................................272

DTC P0140, P0160 HEATED OXYGEN SENSOR 2

(REAR) (BANK 1)/(BANK 2) (HIGH VOLTAGE)........277

Component Description ...........................................277

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................277

ECM Terminals and Reference Value .....................277

On Board Diagnosis Logic.......................................277

Possible Cause ........................................................278

DTC Confirmation Procedure ..................................278

Overall Function Check ...........................................278

Wiring Diagram ........................................................280

Diagnostic Procedure ..............................................282

DTC P0141, P0161 HEATED OXYGEN SENSOR 2

HEATER (REAR) (BANK 1)/(BANK 2).......................286

Description ...............................................................286

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................286

ECM Terminals and Reference Value .....................286

On Board Diagnosis Logic.......................................287

Possible Cause ........................................................287

DTC Confirmation Procedure ..................................287

Wiring Diagram ........................................................289

Diagnostic Procedure ..............................................291

DTC P0171 (RIGHT, -B1), P0174 (LEFT, -B2)

FUEL INJECTION SYSTEM FUNCTION (LEAN).......294

On Board Diagnosis Logic.......................................294

Possible Cause ........................................................294

DTC Confirmation Procedure ..................................294

Wiring Diagram ........................................................296

Diagnostic Procedure ..............................................298

DTC P0172 (RIGHT, -B1), P0175 (LEFT, -B2)

FUEL INJECTION SYSTEM FUNCTION (RICH)........302

On Board Diagnosis Logic.......................................302

Possible Cause ........................................................302

DTC Confirmation Procedure ..................................302

Wiring Diagram ........................................................304

Diagnostic Procedure ..............................................306

DTC P0180 FUEL TANK TEMPERATURE

SENSOR......................................................................309

Component Description ...........................................309

On Board Diagnosis Logic.......................................309

Possible Cause ........................................................309

DTC Confirmation Procedure ..................................310

Wiring Diagram ........................................................ 311

Diagnostic Procedure ..............................................312GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CONTENTS(Cont'd)

EC-3

Page 540 of 2395

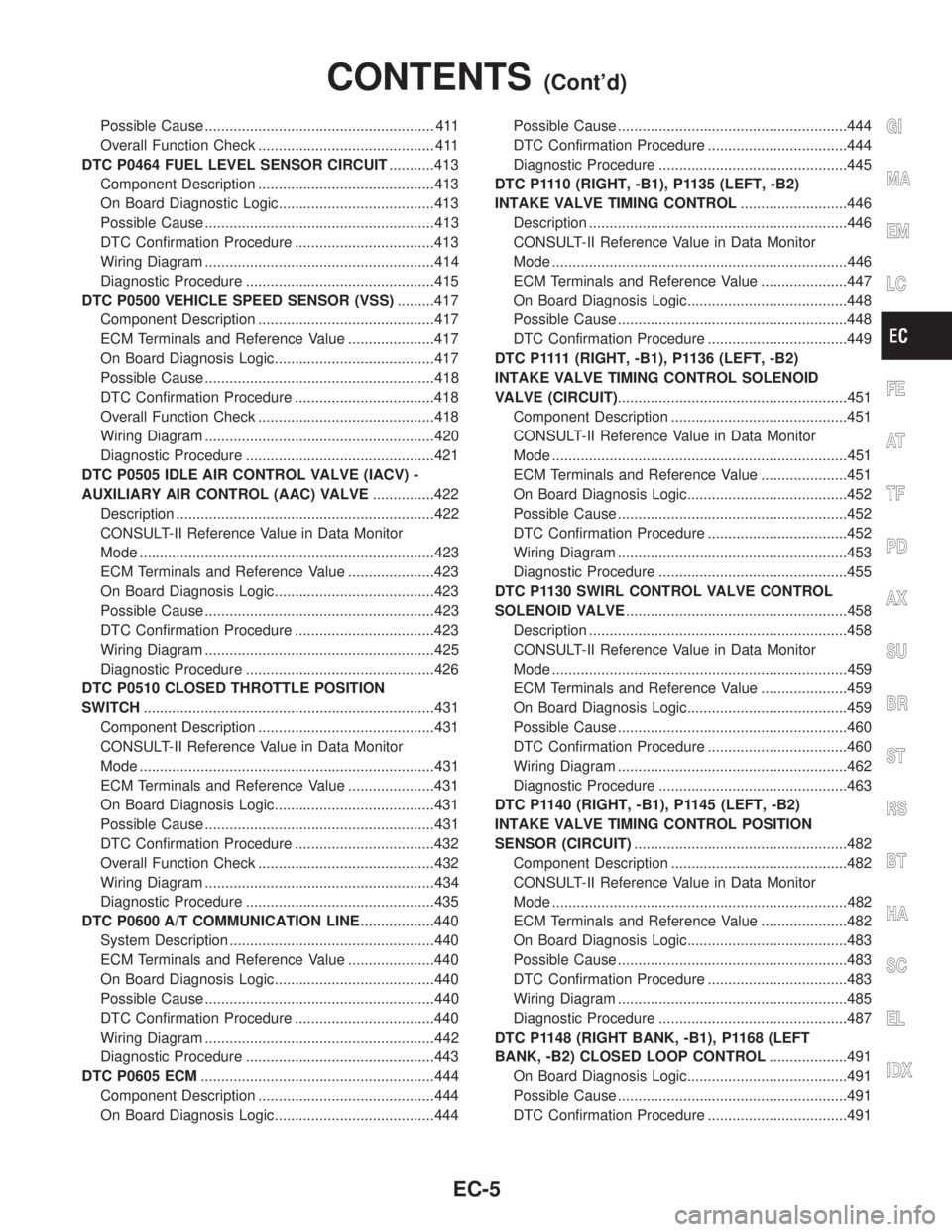

Possible Cause ........................................................ 411

Overall Function Check ........................................... 411

DTC P0464 FUEL LEVEL SENSOR CIRCUIT...........413

Component Description ...........................................413

On Board Diagnostic Logic......................................413

Possible Cause ........................................................413

DTC Confirmation Procedure ..................................413

Wiring Diagram ........................................................414

Diagnostic Procedure ..............................................415

DTC P0500 VEHICLE SPEED SENSOR (VSS).........417

Component Description ...........................................417

ECM Terminals and Reference Value .....................417

On Board Diagnosis Logic.......................................417

Possible Cause ........................................................418

DTC Confirmation Procedure ..................................418

Overall Function Check ...........................................418

Wiring Diagram ........................................................420

Diagnostic Procedure ..............................................421

DTC P0505 IDLE AIR CONTROL VALVE (IACV) -

AUXILIARY AIR CONTROL (AAC) VALVE...............422

Description ...............................................................422

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................423

ECM Terminals and Reference Value .....................423

On Board Diagnosis Logic.......................................423

Possible Cause ........................................................423

DTC Confirmation Procedure ..................................423

Wiring Diagram ........................................................425

Diagnostic Procedure ..............................................426

DTC P0510 CLOSED THROTTLE POSITION

SWITCH.......................................................................431

Component Description ...........................................431

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................431

ECM Terminals and Reference Value .....................431

On Board Diagnosis Logic.......................................431

Possible Cause ........................................................431

DTC Confirmation Procedure ..................................432

Overall Function Check ...........................................432

Wiring Diagram ........................................................434

Diagnostic Procedure ..............................................435

DTC P0600 A/T COMMUNICATION LINE..................440

System Description ..................................................440

ECM Terminals and Reference Value .....................440

On Board Diagnosis Logic.......................................440

Possible Cause ........................................................440

DTC Confirmation Procedure ..................................440

Wiring Diagram ........................................................442

Diagnostic Procedure ..............................................443

DTC P0605 ECM.........................................................444

Component Description ...........................................444

On Board Diagnosis Logic.......................................444Possible Cause ........................................................444

DTC Confirmation Procedure ..................................444

Diagnostic Procedure ..............................................445

DTC P1110 (RIGHT, -B1), P1135 (LEFT, -B2)

INTAKE VALVE TIMING CONTROL..........................446

Description ...............................................................446

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................446

ECM Terminals and Reference Value .....................447

On Board Diagnosis Logic.......................................448

Possible Cause ........................................................448

DTC Confirmation Procedure ..................................449

D T C P 1111(RIGHT, -B1), P1136 (LEFT, -B2)

INTAKE VALVE TIMING CONTROL SOLENOID

VALVE (CIRCUIT)........................................................451

Component Description ...........................................451

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................451

ECM Terminals and Reference Value .....................451

On Board Diagnosis Logic.......................................452

Possible Cause ........................................................452

DTC Confirmation Procedure ..................................452

Wiring Diagram ........................................................453

Diagnostic Procedure ..............................................455

DTC P1130 SWIRL CONTROL VALVE CONTROL

SOLENOID VALVE......................................................458

Description ...............................................................458

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................459

ECM Terminals and Reference Value .....................459

On Board Diagnosis Logic.......................................459

Possible Cause ........................................................460

DTC Confirmation Procedure ..................................460

Wiring Diagram ........................................................462

Diagnostic Procedure ..............................................463

DTC P1140 (RIGHT, -B1), P1145 (LEFT, -B2)

INTAKE VALVE TIMING CONTROL POSITION

SENSOR (CIRCUIT)....................................................482

Component Description ...........................................482

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................482

ECM Terminals and Reference Value .....................482

On Board Diagnosis Logic.......................................483

Possible Cause ........................................................483

DTC Confirmation Procedure ..................................483

Wiring Diagram ........................................................485

Diagnostic Procedure ..............................................487

DTC P1148 (RIGHT BANK, -B1), P1168 (LEFT

BANK, -B2) CLOSED LOOP CONTROL...................491

On Board Diagnosis Logic.......................................491

Possible Cause ........................................................491

DTC Confirmation Procedure ..................................491GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CONTENTS(Cont'd)

EC-5

Page 542 of 2395

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................585

ECM Terminals and Reference Value .....................585

On Board Diagnosis Logic.......................................586

Possible Cause ........................................................586

DTC Confirmation Procedure ..................................586

Wiring Diagram ........................................................587

Diagnostic Procedure ..............................................588

DTC P1491 VACUUM CUT VALVE BYPASS

VALVE..........................................................................591

Description ...............................................................591

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................591

ECM Terminals and Reference Value .....................591

On Board Diagnosis Logic.......................................592

Possible Cause ........................................................592

DTC Confirmation Procedure ..................................592

Overall Function Check ...........................................593

Wiring Diagram ........................................................594

Diagnostic Procedure ..............................................595

DTC P1605 A/T DIAGNOSIS COMMUNICATION

LINE.............................................................................603

Component Description ...........................................603

On Board Diagnosis Logic.......................................603

Possible Cause ........................................................603

DTC Confirmation Procedure ..................................603

DTC P1706 PARK/NEUTRAL POSITION (PNP)

SWITCH.......................................................................604

Component Description ...........................................604

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................604

ECM Terminals and Reference Value .....................604

On Board Diagnosis Logic.......................................604

Possible Cause ........................................................604

DTC Confirmation Procedure ..................................605

Overall Function Check ...........................................606

Wiring Diagram ........................................................607

Diagnostic Procedure ..............................................608

VARIABLE INDUCTION AIR CONTROL SYSTEM

(VIAS)...........................................................................610

Description ...............................................................610

ECM Terminals and Reference Value ..................... 611

Wiring Diagram ........................................................612

Diagnostic Procedure ..............................................613

INJECTOR...................................................................616

Component Description ...........................................616

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................616

ECM Terminals and Reference Value .....................616

Wiring Diagram ........................................................617Diagnostic Procedure ..............................................618

START SIGNAL...........................................................621

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................621

ECM Terminals and Reference Value .....................621

Wiring Diagram ........................................................622

Diagnostic Procedure ..............................................623

FUEL PUMP.................................................................625

System Description ..................................................625

Component Description ...........................................625

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................625

ECM Terminals and Reference Value .....................626

Wiring Diagram ........................................................627

Diagnostic Procedure ..............................................628

POWER STEERING OIL PRESSURE SWITCH.........634

Component Description ...........................................634

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................634

ECM Terminals and Reference Value .....................634

Wiring Diagram ........................................................635

Diagnostic Procedure ..............................................636

REFRIGERANT PRESSURE SENSOR......................639

Description ...............................................................639

ECM Terminals and Reference Value .....................639

Wiring Diagram ........................................................640

Diagnostic Procedure ..............................................641

ELECTRICAL LOAD SIGNAL.....................................643

ECM Terminals and Reference Value .....................643

Wiring Diagram ........................................................644

Diagnostic Procedure ..............................................645

MIL & DATA LINK CONNECTORS............................648

Wiring Diagram ........................................................648

SERVICE DATA AND SPECIFICATIONS (SDS).......649

Fuel Pressure Regulator..........................................649

Idle Speed and Ignition Timing ................................649

Mass Air Flow Sensor..............................................649

Engine Coolant Temperature Sensor ......................649

Heated Oxygen Sensor 1 Heater (Front) ................649

Fuel Pump ...............................................................649

IACV-AAC Valve ......................................................649

Injector .....................................................................649

Resistor ....................................................................649

Throttle Position Sensor ..........................................650

Calculated Load Value.............................................650

Intake Air Temperature Sensor ................................650

Heated Oxygen Sensor 2 Heater (Rear).................650

Crankshaft Position Sensor (REF) ..........................650

Fuel Tank Temperature Sensor ...............................650

Camshaft Position Sensor (PHASE) .......................650GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CONTENTS(Cont'd)

EC-7

Page 544 of 2395

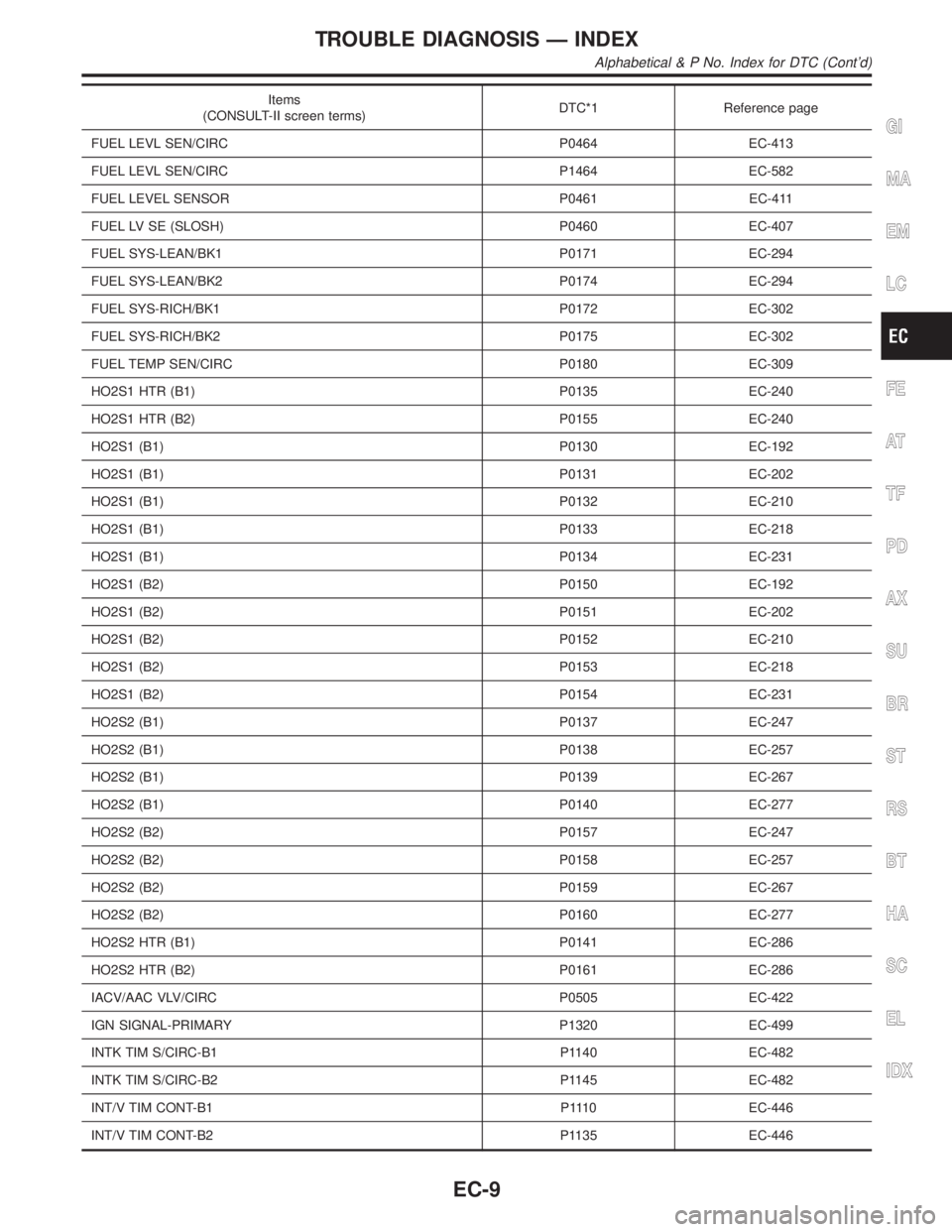

Items

(CONSULT-II screen terms)DTC*1 Reference page

FUEL LEVL SEN/CIRC P0464 EC-413

FUEL LEVL SEN/CIRC P1464 EC-582

FUEL LEVEL SENSOR P0461 EC-411

FUEL LV SE (SLOSH) P0460 EC-407

FUEL SYS-LEAN/BK1 P0171 EC-294

FUEL SYS-LEAN/BK2 P0174 EC-294

FUEL SYS-RICH/BK1 P0172 EC-302

FUEL SYS-RICH/BK2 P0175 EC-302

FUEL TEMP SEN/CIRC P0180 EC-309

HO2S1 HTR (B1) P0135 EC-240

HO2S1 HTR (B2) P0155 EC-240

HO2S1 (B1) P0130 EC-192

HO2S1 (B1) P0131 EC-202

HO2S1 (B1) P0132 EC-210

HO2S1 (B1) P0133 EC-218

HO2S1 (B1) P0134 EC-231

HO2S1 (B2) P0150 EC-192

HO2S1 (B2) P0151 EC-202

HO2S1 (B2) P0152 EC-210

HO2S1 (B2) P0153 EC-218

HO2S1 (B2) P0154 EC-231

HO2S2 (B1) P0137 EC-247

HO2S2 (B1) P0138 EC-257

HO2S2 (B1) P0139 EC-267

HO2S2 (B1) P0140 EC-277

HO2S2 (B2) P0157 EC-247

HO2S2 (B2) P0158 EC-257

HO2S2 (B2) P0159 EC-267

HO2S2 (B2) P0160 EC-277

HO2S2 HTR (B1) P0141 EC-286

HO2S2 HTR (B2) P0161 EC-286

IACV/AAC VLV/CIRC P0505 EC-422

IGN SIGNAL-PRIMARY P1320 EC-499

INTK TIM S/CIRC-B1 P1140 EC-482

INTK TIM S/CIRC-B2 P1145 EC-482

INT/V TIM CONT-B1 P1110 EC-446

INT/V TIM CONT-B2 P1135 EC-446

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð INDEX

Alphabetical & P No. Index for DTC (Cont'd)

EC-9