Ac system INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1075 of 2395

23 CHECK FUEL LEVEL SENSOR

Refer to EL-108, ªFuel Level Sensor Unit Checkº.

OK or NG

OK©GO TO 24.

NG©Replace fuel level sensor unit.

24 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

DTC P1441 EVAP CONTROL SYSTEM (VERY SMALL LEAK)

Diagnostic Procedure (Cont'd)

EC-540

Page 1076 of 2395

DescriptionNBEC0319SYSTEM DESCRIPTIONNBEC0319S01

Sensor Input Signal to ECMECM

functionActuator

Crankshaft position sensor (POS) Engine speed (POS signal)

EVAP can-

ister purge

flow controlEVAP canister purge volume

control solenoid valve Crankshaft position sensor (REF) Engine speed (REF signal)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Throttle position switch Closed throttle position

Heated oxygen sensorsDensity of oxygen in exhaust gas

(Mixture ratio feedback signal)

Fuel tank temperature sensor Fuel temperature in fuel tank

Vehicle speed sensor Vehicle speed

This system controls flow rate of fuel vapor from the EVAP canis-

ter. The opening of the vapor by-pass passage in the EVAP canis-

ter purge volume control solenoid valve changes to control the flow

rate. The EVAP canister purge volume control solenoid valve

repeats ON/OFF operation according to the signal sent from the

ECM. The opening of the valve varies for optimum engine control.

The optimum value stored in the ECM is determined by consider-

ing various engine conditions. When the engine is operating, the

flow rate of fuel vapor from the EVAP canister is regulated as the

air flow changes.

SEF337U

COMPONENT DESCRIPTIONNBEC0319S02The EVAP canister purge volume control solenoid valve uses a

ON/OFF duty to control the flow rate of fuel vapor from the EVAP

canister. The EVAP canister purge volume control solenoid valve

is moved by ON/OFF pulses from the ECM. The longer the ON

pulse, the greater the amount of fuel vapor that will flow through the

valve.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0320Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

PURG VOL C/VIEngine: After warming up

IAir conditioner switch ªOFFº

IShift lever: ªNº

INo-loadIdle (Vehicle stopped) 0%

2,000 rpm Ð

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1444 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Description

EC-541

Page 1077 of 2395

ECM Terminals and Reference ValueNBEC0678Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

1 L/YEVAP canister purge

volume control sole-

noid valve[Engine is running]

IIdle speedBATTERY VOLTAGE

(11 - 14V)

SEF994U

[Engine is running]

IEngine speed is about 2,000 rpm (More than 100

seconds after starting engine).BATTERY VOLTAGE

(11 - 14V)

SEF995U

On Board Diagnosis LogicNBEC0322Malfunction is detected when the canister purge flow is detected

during the specified driving conditions, even when EVAP canister

purge volume control solenoid valve is completely closed.

Possible CauseNBEC0588IEVAP control system pressure sensor

IEVAP canister purge volume control solenoid valve (The valve

is stuck open.)

IEVAP canister vent control valve

IEVAP canister

IHoses

(Hoses are connected incorrectly or clogged.)

DTC P1444 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

ECM Terminals and Reference Value

EC-542

Page 1081 of 2395

4 CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR HOSE

Check disconnection or improper connection of hose connected to EVAP control system pressure sensor.

SEF495R

OK or NG

OK©GO TO 5.

NG©Repair it.

5 CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR

1. Disconnect EVAP control system pressure sensor harness connector.

2. Check connectors for water.

Water should not exist.

OK or NG

OK©GO TO 6.

NG©Replace EVAP control system pressure sensor.

DTC P1444 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Diagnostic Procedure (Cont'd)

EC-546

Page 1082 of 2395

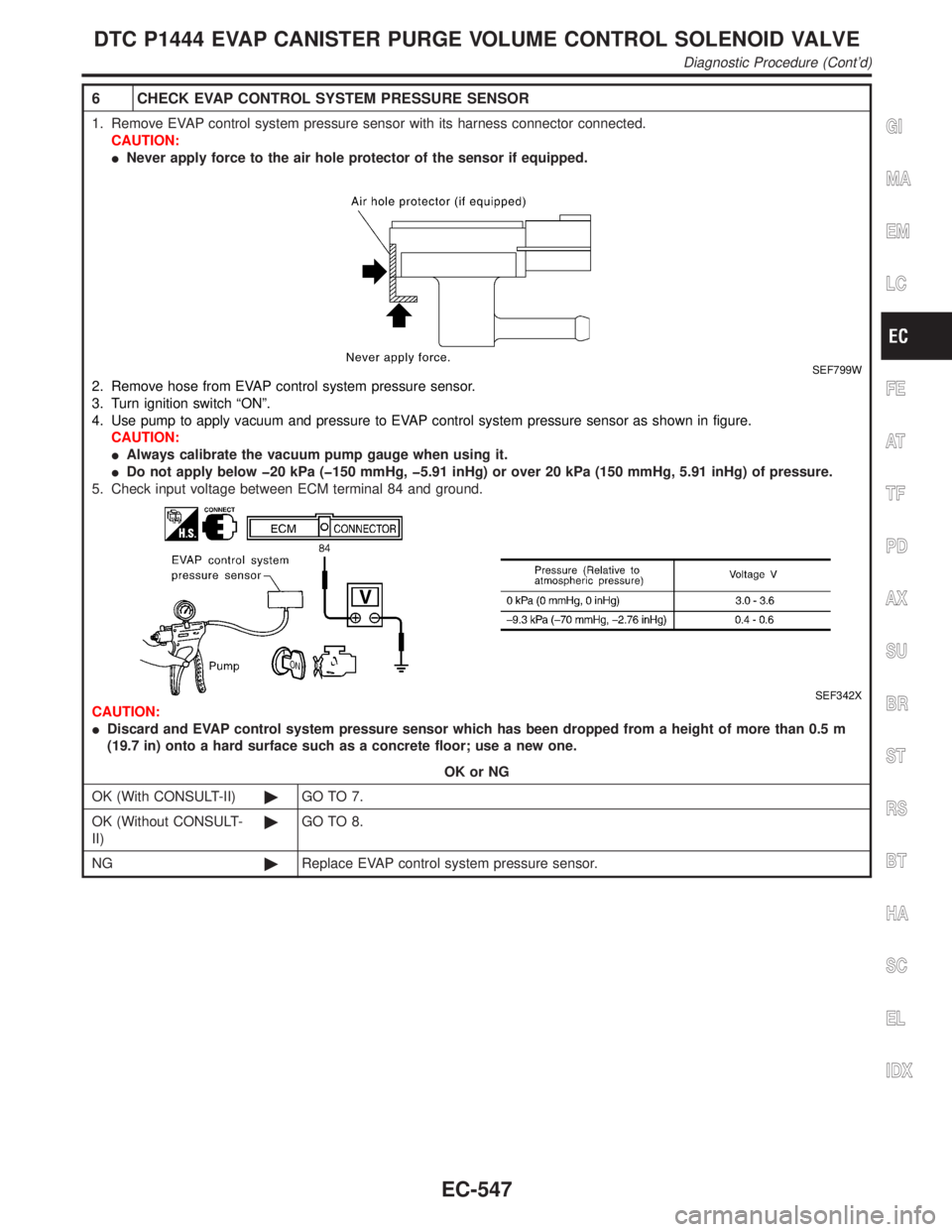

6 CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

1. Remove EVAP control system pressure sensor with its harness connector connected.

CAUTION:

INever apply force to the air hole protector of the sensor if equipped.

SEF799W

2. Remove hose from EVAP control system pressure sensor.

3. Turn ignition switch ªONº.

4. Use pump to apply vacuum and pressure to EVAP control system pressure sensor as shown in figure.

CAUTION:

IAlways calibrate the vacuum pump gauge when using it.

IDo not apply below þ20 kPa (þ150 mmHg, þ5.91 inHg) or over 20 kPa (150 mmHg, 5.91 inHg) of pressure.

5. Check input voltage between ECM terminal 84 and ground.

SEF342X

CAUTION:

IDiscard and EVAP control system pressure sensor which has been dropped from a height of more than 0.5 m

(19.7 in) onto a hard surface such as a concrete floor; use a new one.

OK or NG

OK (With CONSULT-II)©GO TO 7.

OK (Without CONSULT-

II)©GO TO 8.

NG©Replace EVAP control system pressure sensor.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1444 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

Diagnostic Procedure (Cont'd)

EC-547

Page 1088 of 2395

SEF032W

SEF143S

Component DescriptionNBEC0326The EVAP canister vent control valve is located on the EVAP can-

ister and is used to seal the canister vent.

This solenoid valve responds to signals from the ECM. When the

ECM sends an ON signal, the coil in the solenoid valve is ener-

gized. A plunger will then move to seal the canister vent. The abil-

ity to seal the vent is necessary for the on board diagnosis of other

evaporative emission control system components.

This solenoid valve is used only for diagnosis, and usually remains

opened.

When the vent is closed, under normal purge conditions, the

evaporative emission control system is depressurized and allows

ªEVAP Control System (Small Leak)º diagnosis.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0327Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

VENT CONT/VIIgnition switch: ON OFF

ECM Terminals and Reference ValueNBEC0679Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

40 G/YEVAP canister vent

control valve[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

On Board Diagnosis LogicNBEC0329Malfunction is detected when EVAP canister vent control valve

remains closed under specified driving conditions.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1446 EVAPORATIVE EMISSION (EVAP) CANISTER VENT CONTROL

VALVE (CLOSE)

Component Description

EC-553

Page 1089 of 2395

Possible CauseNBEC0589IEVAP canister vent control valve

IEVAP control system pressure sensor and the circuit

IBlocked rubber tube to EVAP canister vent control valve

IWater separator

IEVAP canister is saturated with water.

SEF201Y

DTC Confirmation ProcedureNBEC0330CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

WITH CONSULT-IINBEC0330S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine.

4) Drive vehicle at a speed of approximately 80 km/h (50 MPH)

for a maximum of 15 minutes.

NOTE:

If a malfunction exists, NG result may be displayed quicker.

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-556.

WITH GSTNBEC0330S02Follow the procedure ªWITH CONSULT-IIº above.

DTC P1446 EVAPORATIVE EMISSION (EVAP) CANISTER VENT CONTROL

VALVE (CLOSE)

Possible Cause

EC-554

Page 1093 of 2395

5 CHECK EVAP CANISTER VENT CONTROL VALVE-III

1. Clean the air passage (PortionAtoB) of EVAP canister vent control valve using an air blower.

2. Perform the procedure 4 again.

OK or NG

OK©GO TO 6.

NG©Replace EVAP canister vent control valve.

6 CHECK IF EVAP CANISTER SATURATED WITH WATER

1. Remove EVAP canister with EVAP canister vent control valve attached.

2. Check if water will drain from the EVAP canister.

SEF596U

YesorNo

Ye s©GO TO 7.

No©GO TO 9.

7 CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve attached.

The weight should be less than 1.8 kg (4.0 lb).

OK or NG

OK©GO TO 9.

NG©GO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

IEVAP canister for damage

IEVAP hose between EVAP canister and water separator for clogging or poor connection

©Repair hose or replace EVAP canister.

9 CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR HOSE

Check disconnection or improper connection of hose connected to EVAP control system pressure sensor.

OK or NG

OK©GO TO 10.

NG©Repair it.

DTC P1446 EVAPORATIVE EMISSION (EVAP) CANISTER VENT CONTROL

VALVE (CLOSE)

Diagnostic Procedure (Cont'd)

EC-558

Page 1094 of 2395

10 CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR

1. Disconnect EVAP control system pressure sensor harness connector.

SEF495R

2. Check connectors for water.

Water should not exist.

OK or NG

OK©GO TO 11.

NG©Replace EVAP control system pressure sensor.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1446 EVAPORATIVE EMISSION (EVAP) CANISTER VENT CONTROL

VALVE (CLOSE)

Diagnostic Procedure (Cont'd)

EC-559

Page 1095 of 2395

11 CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

1. Remove EVAP control system pressure sensor with its harness connector connected.

CAUTION:

INever apply force to the air hole protector of the sensor if equipped.

SEF799W

2. Remove hose from EVAP control system pressure sensor.

3. Turn ignition switch ªONº.

4. Use pump to apply vacuum and pressure to EVAP control system pressure sensor as shown in figure.

CAUTION:

IAlways calibrate the vacuum pump gauge when using it.

IDo not apply below þ20 kPa (þ150 mmHg, þ5.91 inHg) or over 20 kPa (150 mmHg, 5.91 inHg) of pressure.

5. Check input voltage between ECM terminal 84 and ground.

SEF342X

CAUTION:

IDiscard and EVAP control system pressure sensor which has been dropped from a height of more than 0.5 m

(19.7 in) onto a hard surface such as a concrete floor; use a new one.

OK or NG

OK©GO TO 12.

NG©Replace EVAP control system pressure sensor.

12 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

DTC P1446 EVAPORATIVE EMISSION (EVAP) CANISTER VENT CONTROL

VALVE (CLOSE)

Diagnostic Procedure (Cont'd)

EC-560