transmission INFINITI QX4 2001 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 132 of 2395

SAT014K

SAT971J

SAT021J

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NBAT0042S01CAUTION:

IAlways drive vehicle at a safe speed.

IBe careful not to rev engine into the red zone on the

tachometer.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

TESTING CONDITIONS:

Always drive vehicle on a level road to improve the accuracy

of test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Start engine and select ªDATA MONITORº mode for ªA/Tº with

CONSULT-II.

2) Make sure that output voltage of A/T fluid temperature sensor

is within the range below.

FLUID TEMP SEN: 0.4 - 1.5V

If out of range, drive the vehicle to decrease the voltage (warm

up the fluid) or stop engine to increase the voltage (cool down

the fluid).

3) Select ª2ND GR FNCTN P0732º of ªDTC WORK SUPPORTº

mode for ªA/Tº with CONSULT-II and touch ªSTARTº.

4) Accelerate vehicle to 25 to 30 km/h (16 to 19 MPH) under the

following condition and release the accelerator pedal com-

pletely.

THROTTLE POSI: Less than 1.0/8 (at all times during step

4)

Selector lever: D position (OD ªONº)

ICheck that ªGEARº shows ª3º or ª4º after releasing pedal.

5) Depress accelerator pedal to WOT (more than 7.0/8 of

ªTHROTTLE POSIº) quickly from a speed of 25 to 30 km/h (16

to 19 MPH) until ªTESTINGº changes to ªSTOP VEHICLEº or

ªCOMPLETEDº. (It will take approximately 3 seconds.)

If the check result NG appears on CONSULT-II screen, go to

ªDIAGNOSTIC PROCEDUREº, AT-130.

If ªSTOP VEHICLEº appears on CONSULT-II screen, go to

following step.

ICheck that ªGEARº shows ª2º when depressing accelera-

tor pedal to WOT.

IIf ªTESTINGº does not appear on CONSULT-II for a long

time, select ªSELF-DIAG RESULTSº for ªENGINEº. In case

a 1st trip DTC other than P0732 is shown, refer to appli-

cable ªTROUBLE DIAGNOSIS FOR DTCº.

6) Stop vehicle.

7) Follow the instruction displayed. (Check for normal shifting

referring to the table below.)

Vehicle conditionGear on actual transmission shift pattern when

screen is changed to 1,2,3,4

No malfunction exists 1,2,3,4

Malfunction for P0732 exists. 4,3,3,4

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0732 IMPROPER SHIFTING TO 2ND GEAR POSITION

Description (Cont'd)

AT-127

Page 138 of 2395

SAT014K

SAT971J

SAT021J

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NBAT0045S01CAUTION:

IAlways drive vehicle at a safe speed.

IBe careful not to rev engine into the red zone on the

tachometer.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

TESTING CONDITIONS:

Always drive vehicle on a level road to improve the accuracy

of test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Start engine and select ªDATA MONITORº mode for ªA/Tº with

CONSULT-II.

2) Make sure that output voltage of A/T fluid temperature sensor

is within the range below.

FLUID TEMP SEN: 0.4 - 1.5V

If out of range, drive the vehicle to decrease the voltage (warm

up the fluid) or stop engine to increase the voltage (cool down

the fluid).

3) Select ª3RD GR FNCTN P0733º of ªDTC WORK SUPPORTº

mode for ªA/Tº with CONSULT-II and touch ªSTARTº.

4) Accelerate vehicle to 35 to 45 km/h (22 to 28 MPH) under the

following condition and release the accelerator pedal com-

pletely.

THROTTLE POSI: Less than 1.0/8 (at all times during step

4)

Selector lever: D position (OD ªONº)

ICheck that ªGEARº shows ª4º after releasing pedal.

5) Depress accelerator pedal steadily with 3.5/8 - 4.5/8 of

ªTHROTTLE POSIº from a speed of 35 to 45 km/h (22 to 28

MPH) until ªTESTINGº changes to ªSTOP VEHICLEº or ªCOM-

PLETEDº. (It will take approximately 3 seconds.)

If the check result NG appears on CONSULT-II screen, go to

ªDIAGNOSTIC PROCEDUREº, AT-136.

If ªSTOP VEHICLEº appears on CONSULT-II screen, go to

following step.

ICheck that ªGEARº shows ª3º when depressing accelera-

tor pedal with 3.5/8 - 4.5/8 of ªTHROTTLE POSIº.

IIf ªTESTINGº does not appear on CONSULT-II for a long

time, select ªSELF-DIAG RESULTSº for ªENGINEº. In case

a 1st trip DTC other than P0733 is shown, refer to appli-

cable ªTROUBLE DIAGNOSIS FOR DTCº.

6) Stop vehicle.

7) Follow the instruction displayed. (Check for normal shifting

referring to the table below.)

Vehicle conditionGear on actual transmission shift pattern

when screen is changed to 1,2,3,4

No malfunction exists. 1,2,3,4

Malfunction for P0733 exists. 1,1,4,4

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0733 IMPROPER SHIFTING TO 3RD GEAR POSITION

Description (Cont'd)

AT-133

Page 145 of 2395

SAT014K

SAT971J

SAT021J

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NBAT0048S01CAUTION:

IAlways drive vehicle at a safe speed.

IBe careful not to rev engine into the red zone on the

tachometer.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

TESTING CONDITIONS:

Always drive vehicle on a level road to improve the accuracy

of test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Start engine and select ªDATA MONITORº mode for ªA/Tº with

CONSULT-II.

2) Make sure that output voltage of A/T fluid temperature sensor

is within the range below.

FLUID TEMP SEN: 0.4 - 1.5V

If out of range, drive the vehicle to decrease the voltage (warm

up the fluid) or stop engine to increase the voltage (cool down

the fluid).

3) Select ª4TH GR FNCTN P0734º of ªDTC WORK SUPPORTº

mode for ªA/Tº with CONSULT-II and touch ªSTARTº.

4) Accelerate vehicle to 55 to 65 km/h (34 to 40 MPH) under the

following condition and release the accelerator pedal com-

pletely.

THROTTLE POSI: Less than 5.5/8 (at all times during step

4)

Selector lever: D position (OD ªONº)

ICheck that ªGEARº shows ª3º after releasing pedal.

5) Depress accelerator pedal steadily with 1.0/8 - 2.0/8 of

ªTHROTTLE POSIº from a speed of 55 to 65 km/h (34 to 40

MPH) until ªTESTINGº has turned to ªSTOP VEHICLEº or

ªCOMPLETEDº. (It will take approximately 3 seconds.)

If the check result NG appears on CONSULT-II screen, go to

ªDIAGNOSTIC PROCEDUREº, AT-143.

If ªSTOP VEHICLEº appears on CONSULT-II screen, go to

following step.

ICheck that ªGEARº shows ª4º when depressing accelera-

tor pedal with 1.0/8 - 2.0/8 of ªTHROTTLE POSIº.

IIf ªTESTINGº does not appear on CONSULT-II for a long

time, select ªSELF-DIAG RESULTSº for ªENGINEº. In case

a 1st trip DTC other than P0734 is shown, refer to appli-

cable ªTROUBLE DIAGNOSIS FOR DTCº.

6) Stop vehicle.

7) Follow the instruction displayed. (Check for normal shifting

referring to the table below.)

Vehicle conditionGear on actual transmission shift pattern when

screen is changed to 1,2,3,4

No malfunction exists 1,2,3,4

Malfunction for P0734 exists. 1,2,2,1

DTC P0734 IMPROPER SHIFTING TO 4TH GEAR POSITION

Description (Cont'd)

AT-140

Page 173 of 2395

SAT341H

DescriptionNBAT0060Shift solenoid valves A and B are turned ªONº or ªOFFº by the TCM

in response to signals sent from the PNP switch, vehicle speed and

throttle position sensors. Gears will then be shifted to the optimum

position.

Gear position1234

Shift solenoid valve A ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed) ON (Closed) OFF (Open) OFF (Open)

TCM TERMINALS AND REFERENCE VALUENBAT0060S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

11 L/WShift solenoid

valve A

When shift solenoid valve A operates.

(When driving in ªD

1ºorªD4º.)Battery volt-

age

When shift solenoid valve A does not operate.

(When driving in ªD

2ºorªD3º.)0V

ON BOARD DIAGNOSIS LOGICNBAT0060S03

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: SFT SOL A/CIRC TCM detects an improper voltage drop

when it tires to operate the solenoid

valve.IHarness or connectors

(The solenoid circuit is open or shorted.)

IShift solenoid valve A

: P0750

SAT014K

SAT020K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NBAT0060S01CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

2) Start engine.

3) Drive vehicle in ªDº position and allow the transmission to shift

ª1º,ª2º (ªGEARº).

With GST

Follow the procedure ªWith CONSULT-IIº.

DTC P0750 SHIFT SOLENOID VALVE A

Description

AT-168

Page 177 of 2395

SAT341H

DescriptionNBAT0063Shift solenoid valves A and B are turned ªONº or ªOFFº by the TCM

in response to signals sent from the PNP switch, vehicle speed and

throttle position sensors. Gears will then be shifted to the optimum

position.

Gear position1234

Shift solenoid valve A ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Shift solenoid valve B ON (Closed) ON (Closed) OFF (Open) OFF (Open)

TCM TERMINALS AND REFERENCE VALUENBAT0063S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

12 L/RShift solenoid

valve B

When shift solenoid valve B operates.

(When driving in ªD

1ºorªD2º.)Battery volt-

age

When shift solenoid valve B does not operate.

(When driving in ªD

3ºorªD4º.)0V

ON BOARD DIAGNOSIS LOGICNBAT0063S03

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: SFT SOL B/CIRC TCM detects an improper voltage drop

when it tires to operate the solenoid

valve.IHarness or connectors

(The solenoid circuit is open or shorted.)

IShift solenoid valve B

: P0755

SAT014K

SAT020K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NBAT0063S01CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

2) Drive vehicle in ªDº position and allow the transmission to shift

1,2,3 (ªGEARº).

With GST

Follow the procedure ªWith CONSULT-IIº.

DTC P0755 SHIFT SOLENOID VALVE B

Description

AT-172

Page 207 of 2395

SAT136K

DescriptionNBAT0224The turbine revolution sensor detects input shaft rpm (revolutions

per minute). It is located on the input side of the automatic trans-

mission. The vehicle speed sensor A/T (Revolution sensor) is

located on the output side of the automatic transmission. With the

two sensors, input and output shaft rpms are accurately detected.

The result is optimal shift timing during deceleration and improved

shifting.

TCM TERMINALS AND REFERENCE VALUENBAT0224S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

38 WTurbine revolution

sensor

(Measure in AC

range)

When engine is running at 1,000 rpm1.2V

Voltage rises

gradually in

response to

engine speed.

42 BThrottle position

sensor (Ground)

Ð0V

ON BOARD DIAGNOSIS LOGICNBAT0224S02

Diagnostic trouble code Malfunction is detected when ... Check item (Possible cause)

: TURBINE REV

TCM does not receive the proper voltage

signal from the sensor.IHarness or connectors

(The sensor circuit is open or shorted.)

ITurbine revolution sensor

: 10th judgement flicker

DTC TURBINE REVOLUTION SENSOR

Description

AT-202

Page 262 of 2395

SAT136K

21. TCM Self-diagnosis Does Not Activate (PNP,

Overdrive Control and Throttle Position

Switches Circuit Checks)

NBAT0204

SAT143K

SAT142K

SYMPTOM:

O/D OFF indicator lamp does not come on in TCM self-diag-

nostic procedure even the lamp circuit is good.

DESCRIPTIONNBAT0204S01IPNP switch

The PNP switch assemble includes a transmission range

switch. The transmission range switch detects the selector

position and sends a signal to the TCM.

IOverdrive control switch

Detects the overdrive control switch position (ON or OFF) and

sends a signal to the TCM.

IThrottle position switch

Consists of a wide open throttle position switch and a closed

throttle position switch.

The wide open throttle position switch sends a signal to the

TCM when the throttle valve is open at least 1/2 of the full

throttle position. The closed throttle position switch sends a

signal to the TCM when the throttle valve is fully closed.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSES FOR SYMPTOMS

21. TCM Self-diagnosis Does Not Activate (PNP, Overdrive Control and Throttle Position Switches Circuit Checks)

AT-257

Page 280 of 2395

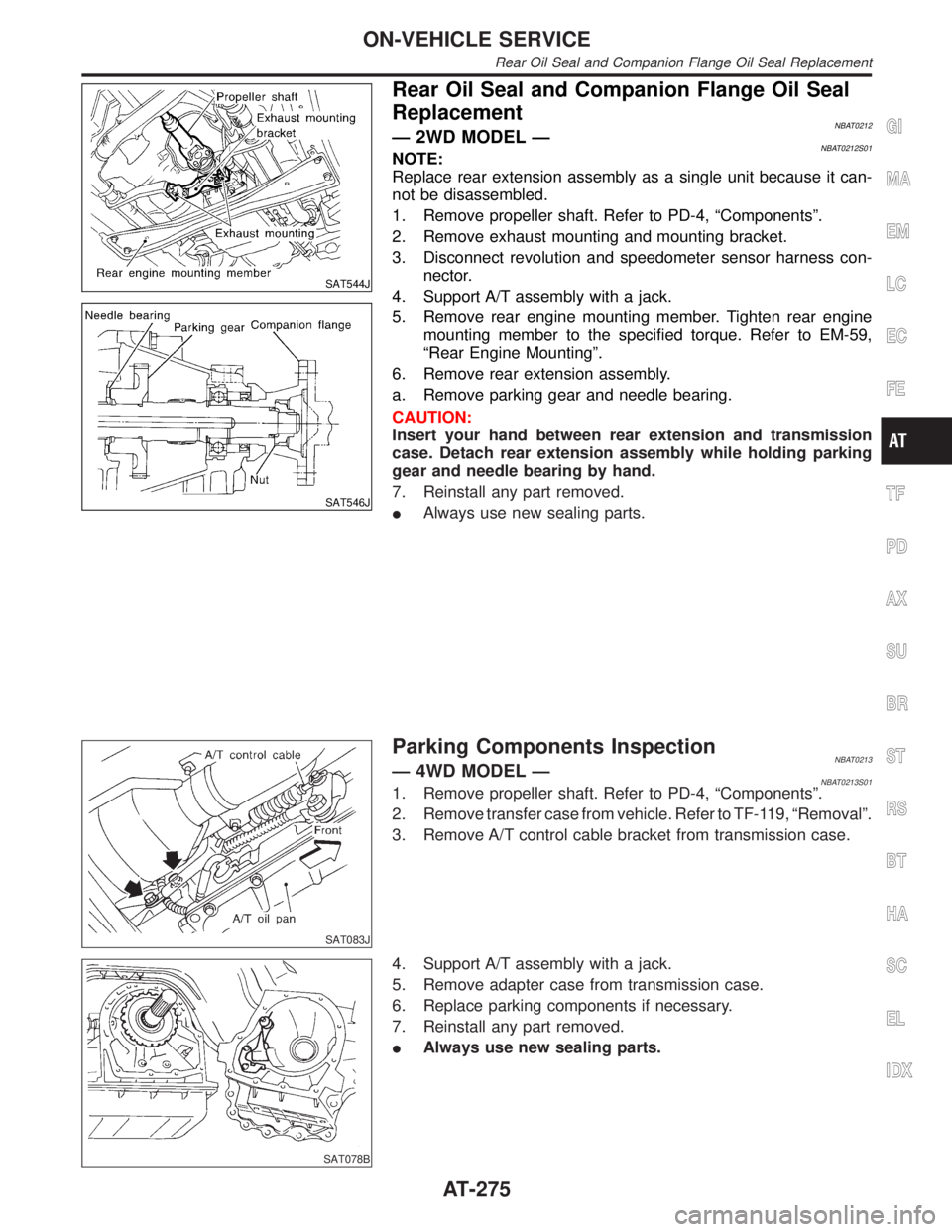

SAT544J

SAT546J

Rear Oil Seal and Companion Flange Oil Seal

Replacement

NBAT0212Ð 2WD MODEL ÐNBAT0212S01NOTE:

Replace rear extension assembly as a single unit because it can-

not be disassembled.

1. Remove propeller shaft. Refer to PD-4, ªComponentsº.

2. Remove exhaust mounting and mounting bracket.

3. Disconnect revolution and speedometer sensor harness con-

nector.

4. Support A/T assembly with a jack.

5. Remove rear engine mounting member. Tighten rear engine

mounting member to the specified torque. Refer to EM-59,

ªRear Engine Mountingº.

6. Remove rear extension assembly.

a. Remove parking gear and needle bearing.

CAUTION:

Insert your hand between rear extension and transmission

case. Detach rear extension assembly while holding parking

gear and needle bearing by hand.

7. Reinstall any part removed.

IAlways use new sealing parts.

SAT083J

Parking Components InspectionNBAT0213Ð 4WD MODEL ÐNBAT0213S011. Remove propeller shaft. Refer to PD-4, ªComponentsº.

2. Remove transfer case from vehicle. Refer to TF-119, ªRemovalº.

3. Remove A/T control cable bracket from transmission case.

SAT078B

4. Support A/T assembly with a jack.

5. Remove adapter case from transmission case.

6. Replace parking components if necessary.

7. Reinstall any part removed.

IAlways use new sealing parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON-VEHICLE SERVICE

Rear Oil Seal and Companion Flange Oil Seal Replacement

AT-275

Page 281 of 2395

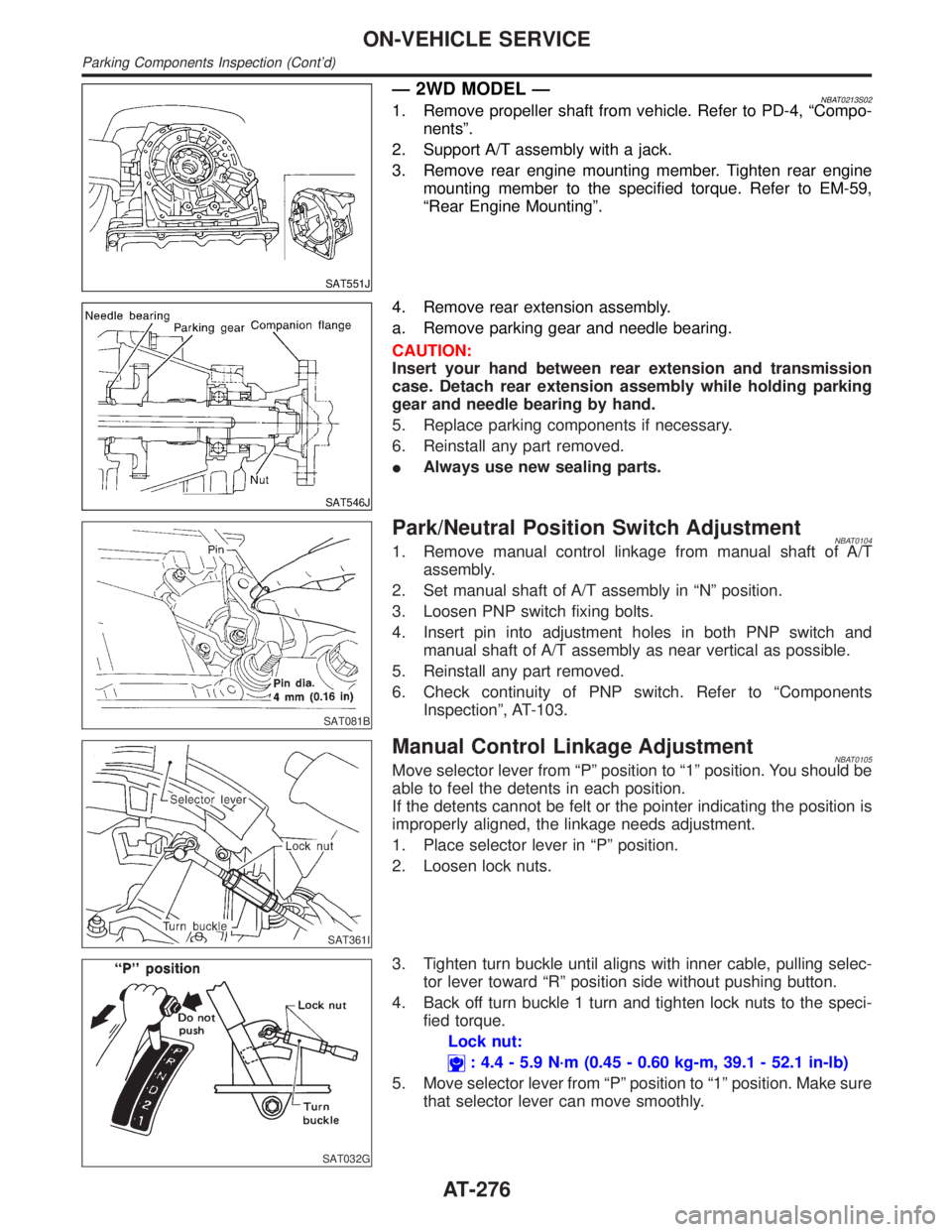

SAT551J

Ð 2WD MODEL ÐNBAT0213S021. Remove propeller shaft from vehicle. Refer to PD-4, ªCompo-

nentsº.

2. Support A/T assembly with a jack.

3. Remove rear engine mounting member. Tighten rear engine

mounting member to the specified torque. Refer to EM-59,

ªRear Engine Mountingº.

SAT546J

4. Remove rear extension assembly.

a. Remove parking gear and needle bearing.

CAUTION:

Insert your hand between rear extension and transmission

case. Detach rear extension assembly while holding parking

gear and needle bearing by hand.

5. Replace parking components if necessary.

6. Reinstall any part removed.

IAlways use new sealing parts.

SAT081B

Park/Neutral Position Switch AdjustmentNBAT01041. Remove manual control linkage from manual shaft of A/T

assembly.

2. Set manual shaft of A/T assembly in ªNº position.

3. Loosen PNP switch fixing bolts.

4. Insert pin into adjustment holes in both PNP switch and

manual shaft of A/T assembly as near vertical as possible.

5. Reinstall any part removed.

6. Check continuity of PNP switch. Refer to ªComponents

Inspectionº, AT-103.

SAT361I

Manual Control Linkage AdjustmentNBAT0105Move selector lever from ªPº position to ª1º position. You should be

able to feel the detents in each position.

If the detents cannot be felt or the pointer indicating the position is

improperly aligned, the linkage needs adjustment.

1. Place selector lever in ªPº position.

2. Loosen lock nuts.

SAT032G

3. Tighten turn buckle until aligns with inner cable, pulling selec-

tor lever toward ªRº position side without pushing button.

4. Back off turn buckle 1 turn and tighten lock nuts to the speci-

fied torque.

Lock nut:

: 4.4 - 5.9 N´m (0.45 - 0.60 kg-m, 39.1 - 52.1 in-lb)

5. Move selector lever from ªPº position to ª1º position. Make sure

that selector lever can move smoothly.

ON-VEHICLE SERVICE

Parking Components Inspection (Cont'd)

AT-276

Page 284 of 2395

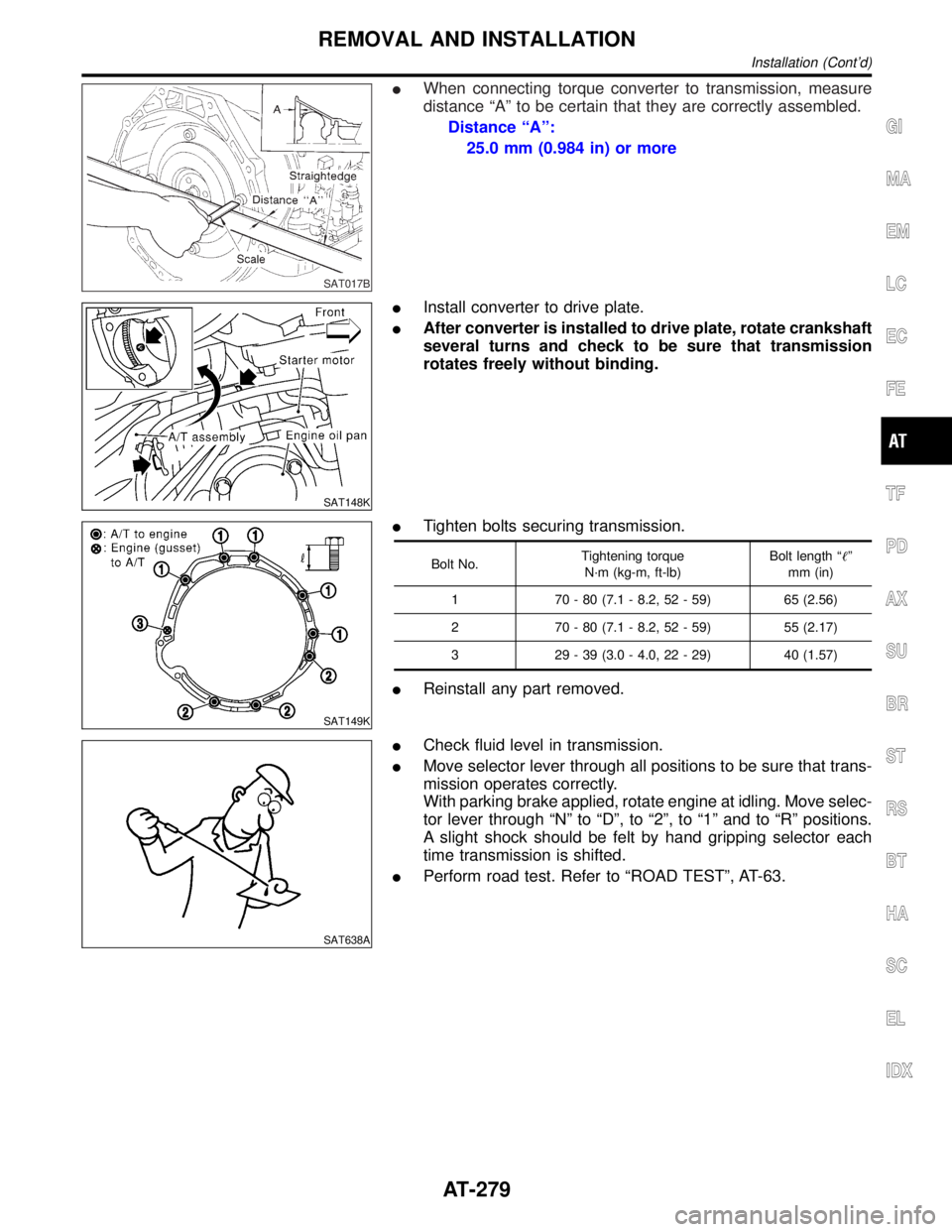

SAT017B

IWhen connecting torque converter to transmission, measure

distance ªAº to be certain that they are correctly assembled.

Distance ªAº:

25.0 mm (0.984 in) or more

SAT148K

IInstall converter to drive plate.

IAfter converter is installed to drive plate, rotate crankshaft

several turns and check to be sure that transmission

rotates freely without binding.

SAT149K

ITighten bolts securing transmission.

Bolt No.Tightening torque

N´m (kg-m, ft-lb)Bolt length ªº

mm (in)

1 70 - 80 (7.1 - 8.2, 52 - 59) 65 (2.56)

2 70 - 80 (7.1 - 8.2, 52 - 59) 55 (2.17)

3 29 - 39 (3.0 - 4.0, 22 - 29) 40 (1.57)

IReinstall any part removed.

SAT638A

ICheck fluid level in transmission.

IMove selector lever through all positions to be sure that trans-

mission operates correctly.

With parking brake applied, rotate engine at idling. Move selec-

tor lever through ªNº to ªDº, to ª2º, to ª1º and to ªRº positions.

A slight shock should be felt by hand gripping selector each

time transmission is shifted.

IPerform road test. Refer to ªROAD TESTº, AT-63.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REMOVAL AND INSTALLATION

Installation (Cont'd)

AT-279