wheel INFINITI QX4 2001 Factory Manual Online

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1189 of 2395

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NBEL0001The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of side air bag module (located in the outer side of front seat),

satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring harness,

warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized INFINITI dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Wiring Diagrams and Trouble DiagnosisNBEL0002When you read wiring diagrams, refer to the following:

IGI-11, ªHOW TO READ WIRING DIAGRAMSº

IEL-9, ªPOWER SUPPLY ROUTINGº for power distribution circuit

When you perform trouble diagnosis, refer to the following:

IGI-35, ªHOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSESº

IGI-24, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº

Check for any Service bulletins before servicing the vehicle.

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

EL-4

Page 1214 of 2395

MEL304D

ReplacementNBEL0010For removal and installation of spiral cable, refer to RS-18,

ªInstallation Ð Air Bag Module and Spiral Cableº.

IEach switch can be replaced without removing combination

switch base.

MEL326G

ITo remove combination switch base, remove base attaching

screw.

SEL151V

IBefore installing the steering wheel, align the steering wheel

guide pins with the screws which secure the combination

switch as shown in the left figure.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

COMBINATION SWITCH

Replacement

EL-29

Page 1241 of 2395

Trouble DiagnosesNBEL0193DAYTIME LIGHT CONTROL UNIT INSPECTION TABLENBEL0193S01

Terminal

No.Wire

colorItem ConditionVoltage

(Approximate values)

1 Y/B Alternator

When turning ignition switch to ªONº Less than 1V

When engine is running Battery voltage

When turning ignition switch to ªOFFº Less than 1V

2 Y/R Start signal

When turning ignition switch to ªSTº Battery voltage

When turning ignition switch to ªONº from ªSTº Less than 1V

When turning ignition switch to ªOFFº Less than 1V

3 G Power source

When turning ignition switch to ªONº Battery voltage

When turning ignition switch to ªSTº Battery voltage

When turning ignition switch to ªOFFº Less than 1V

4 R/L Power source

When turning ignition switch to ªONº Battery voltage

When turning ignition switch to ªOFFº Battery voltage

5 R/W Power source

When turning ignition switch to ªONº Battery voltage

When turning ignition switch to ªOFFº Battery voltage

6 R LH hi beam When lighting switch is turned to the 2ND position with

ªHI BEAMº positionBattery voltage

When releasing parking brake with engine running and

turning lighting switch to ªOFFº (daytime light operation)

CAUTION:

Block wheels and ensure selector lever is in N or P

position.Approx. half battery

voltage

HEADLAMP (FOR CANADA) Ð DAYTIME LIGHT SYSTEM Ð

Trouble Diagnoses

EL-56

Page 1242 of 2395

Terminal

No.Wire

colorItem ConditionVoltage

(Approximate values)

7 L/R RH hi beam When lighting switch is turned to the 2ND position with

ªHI BEAMº positionBattery voltage

When releasing parking brake with engine running and

turning lighting switch to ªOFFº (daytime light operation)

CAUTION:

Block wheels and ensure selector lever is in N or P

position.Approx. half battery

voltage

9 PU RH hi beam

(ground)When lighting switch is turned to the 2ND position with

ªHI BEAMº positionLess than 1V

When releasing parking brake with engine running and

turning lighting switch to ªOFFº (daytime light operation)

CAUTION:

Block wheels and ensure selector lever is in N or P

position.Approx. half battery

voltage

10 GY LH hi beam

(ground)When lighting switch is turned to the 2ND position with

ªHI BEAMº positionLess than 1V

When releasing parking brake with engine running and

turning lighting switch to ªOFFº (daytime light operation)

CAUTION:

Block wheels and ensure selector lever is in N or P

position.Approx. half battery

voltage

13

14L/W

W/RLighting switch

(Hi beam)When turning lighting switch to ªHI BEAMº Battery voltage

When turning lighting switch to ªFLASH TO PASSº Battery voltage

16 B Ground Ð Ð

17 L/G Parking brake

switch

When parking brake is released Battery voltage

When parking brake is set Less than 1.5V

BATTERY SAVER CONTROL UNIT INSPECTION TABLENBEL0193S02Refer to ªHEADLAMP (FOR USA)º, EL-42.

Bulb ReplacementNBEL0194Refer to ªHEADLAMP (FOR USA)º (EL-43).

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

HEADLAMP (FOR CANADA) Ð DAYTIME LIGHT SYSTEM Ð

Trouble Diagnoses (Cont'd)

EL-57

Page 1420 of 2395

VEHICLE SPEED SENSOR CHECK=NBEL0218S06

1 CHECK SPEEDOMETER OPERATION

Does speedometer operate normally?

Ye s©GO TO 2.

No©Check speedometer and vehicle speed sensor circuit. Refer to wiring diagram in EL-228.

2 CHECK VEHICLE SPEED INPUT

1. Apply wheel chocks and jack up drive wheel.

2. Disconnect ASCD control unit harness connector.

3. Check voltage between control unit terminal 22 and ground with turning drive wheel slowly by hand.

SEL263WB

Refer to wiring diagram in EL-227.

Ye s©Vehicle speed sensor is OK.

No©Check harness for open or short between ASCD control unit terminal 22 and combination

meter terminal 13.

ASCD PUMP CIRCUIT CHECKNBEL0218S07

1 CHECK ASCD PUMP

1. Disconnect ASCD pump connector.

2. Measure resistance between ASCD pump terminals 1 and 2, 3, 4.

SEL262WB

Refer to wiring diagram in EL-227.

OK or NG

OK©GO TO 2.

NG©Replace ASCD pump.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

Trouble Diagnoses (Cont'd)

EL-235

Page 1421 of 2395

2 CHECK ASCD PUMP CIRCUIT

1. Disconnect ASCD control unit harness connector.

2. Check harness for open or short between ASCD control unit and ASCD pump.

SEL269WB

OK or NG

OK©GO TO 3.

NG©Repair harness.

3 CHECK ASCD PUMP POWER SUPPLY

1. Jack-up the drive wheels.

2. Maintain the conditions below.

IVehicle speed is more than 40 km/h (25 MPH).

IMain switch (CRUISE lamp) is ON.

ISet/coast switch (SET lamp) is ON.

Check voltage between ASCD control unit harness connector terminal 12 and ground.

SEL381WB

OK or NG

OK©ASCD pump power supply is OK.

NG©Replace ASCD control unit.

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

Trouble Diagnoses (Cont'd)

EL-236

Page 1571 of 2395

SEL683V

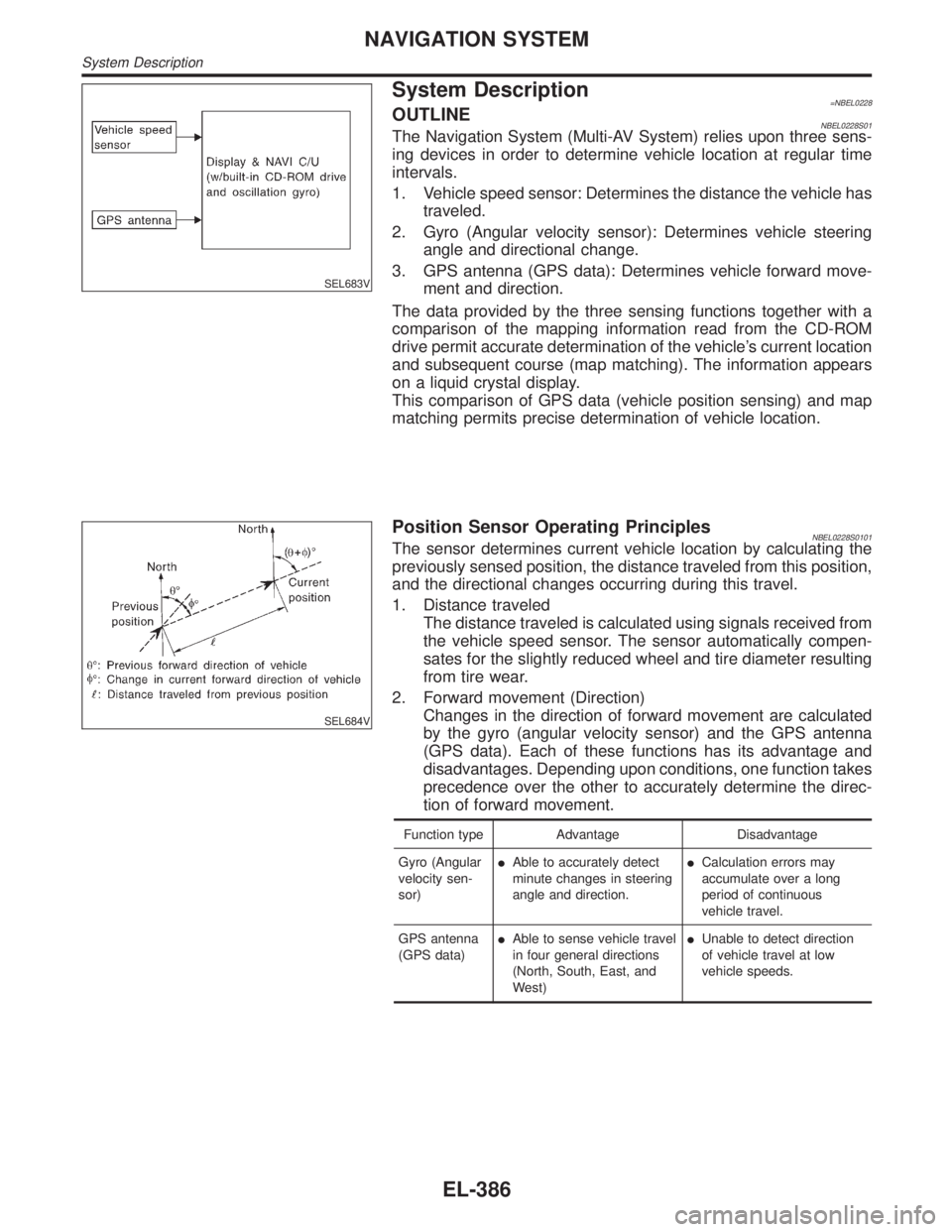

System Description=NBEL0228OUTLINENBEL0228S01The Navigation System (Multi-AV System) relies upon three sens-

ing devices in order to determine vehicle location at regular time

intervals.

1. Vehicle speed sensor: Determines the distance the vehicle has

traveled.

2. Gyro (Angular velocity sensor): Determines vehicle steering

angle and directional change.

3. GPS antenna (GPS data): Determines vehicle forward move-

ment and direction.

The data provided by the three sensing functions together with a

comparison of the mapping information read from the CD-ROM

drive permit accurate determination of the vehicle's current location

and subsequent course (map matching). The information appears

on a liquid crystal display.

This comparison of GPS data (vehicle position sensing) and map

matching permits precise determination of vehicle location.

SEL684V

Position Sensor Operating PrinciplesNBEL0228S0101The sensor determines current vehicle location by calculating the

previously sensed position, the distance traveled from this position,

and the directional changes occurring during this travel.

1. Distance traveled

The distance traveled is calculated using signals received from

the vehicle speed sensor. The sensor automatically compen-

sates for the slightly reduced wheel and tire diameter resulting

from tire wear.

2. Forward movement (Direction)

Changes in the direction of forward movement are calculated

by the gyro (angular velocity sensor) and the GPS antenna

(GPS data). Each of these functions has its advantage and

disadvantages. Depending upon conditions, one function takes

precedence over the other to accurately determine the direc-

tion of forward movement.

Function type Advantage Disadvantage

Gyro (Angular

velocity sen-

sor)IAble to accurately detect

minute changes in steering

angle and direction.ICalculation errors may

accumulate over a long

period of continuous

vehicle travel.

GPS antenna

(GPS data)IAble to sense vehicle travel

in four general directions

(North, South, East, and

West)IUnable to detect direction

of vehicle travel at low

vehicle speeds.

NAVIGATION SYSTEM

System Description

EL-386

Page 1582 of 2395

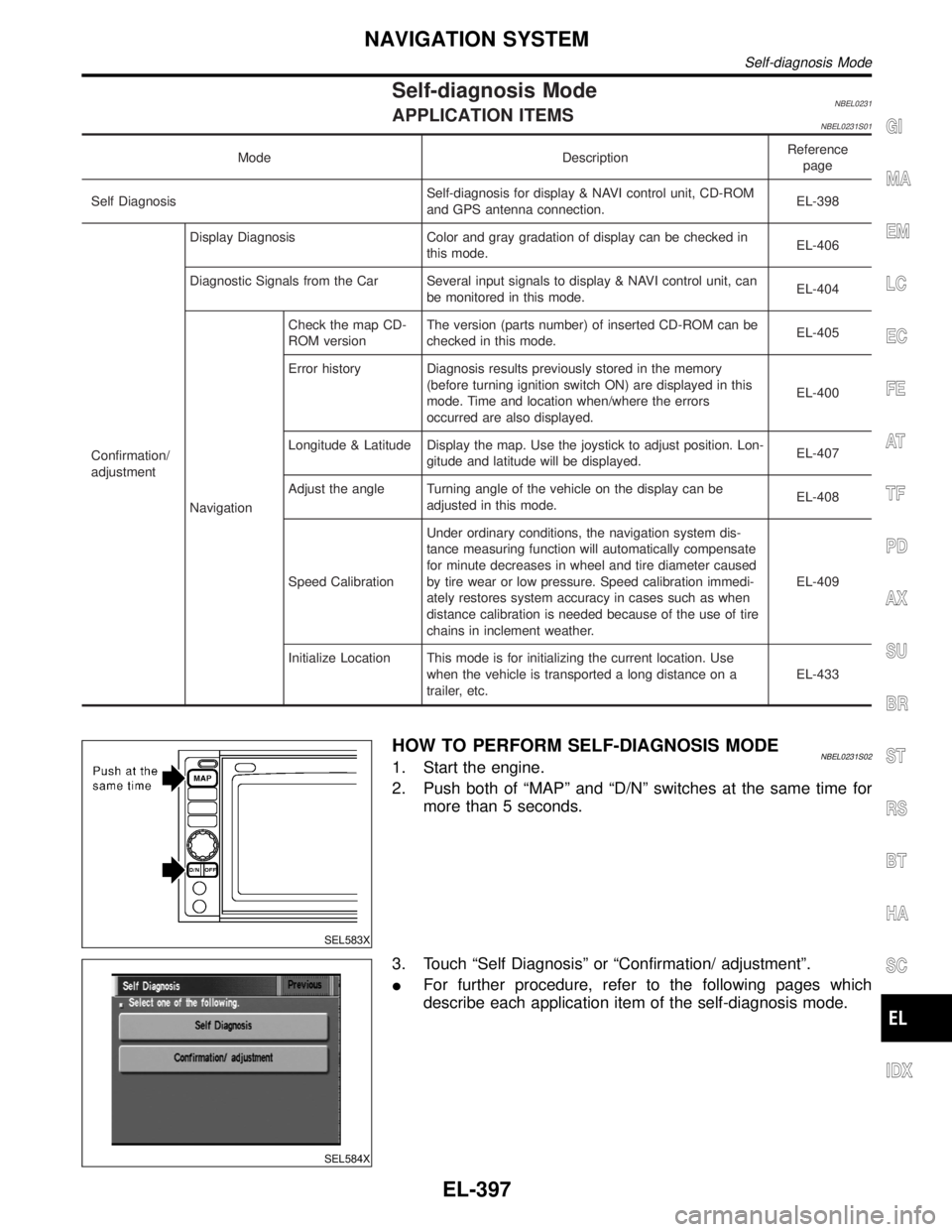

Self-diagnosis ModeNBEL0231APPLICATION ITEMSNBEL0231S01

Mode DescriptionReference

page

Self DiagnosisSelf-diagnosis for display & NAVI control unit, CD-ROM

and GPS antenna connection.EL-398

Confirmation/

adjustmentDisplay Diagnosis Color and gray gradation of display can be checked in

this mode.EL-406

Diagnostic Signals from the Car Several input signals to display & NAVI control unit, can

be monitored in this mode.EL-404

NavigationCheck the map CD-

ROM versionThe version (parts number) of inserted CD-ROM can be

checked in this mode.EL-405

Error history Diagnosis results previously stored in the memory

(before turning ignition switch ON) are displayed in this

mode. Time and location when/where the errors

occurred are also displayed.EL-400

Longitude & Latitude Display the map. Use the joystick to adjust position. Lon-

gitude and latitude will be displayed.EL-407

Adjust the angle Turning angle of the vehicle on the display can be

adjusted in this mode.EL-408

Speed CalibrationUnder ordinary conditions, the navigation system dis-

tance measuring function will automatically compensate

for minute decreases in wheel and tire diameter caused

by tire wear or low pressure. Speed calibration immedi-

ately restores system accuracy in cases such as when

distance calibration is needed because of the use of tire

chains in inclement weather.EL-409

Initialize Location This mode is for initializing the current location. Use

when the vehicle is transported a long distance on a

trailer, etc.EL-433

SEL583X

HOW TO PERFORM SELF-DIAGNOSIS MODENBEL0231S021. Start the engine.

2. Push both of ªMAPº and ªD/Nº switches at the same time for

more than 5 seconds.

SEL584X

3. Touch ªSelf Diagnosisº or ªConfirmation/ adjustmentº.

IFor further procedure, refer to the following pages which

describe each application item of the self-diagnosis mode.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

NAVIGATION SYSTEM

Self-diagnosis Mode

EL-397

Page 1610 of 2395

Possible cause Drive condition Service procedure

AreaSlippery road surfaceOn wet, icy, or gravel road where

frequent wheel slippage occurs, dis-

tance calculations may be errone-

ous. The position marker may show

the vehicle to be in inaccurate posi-

tion.

If the position marker does not

move to the correct position

even after the vehicle has been

driven approximately 10 km (6

miles), perform ªADJUST CUR-

RENT LOCATIONº (EL-411). If

necessary, perform ªSPEED

CALIBRATIONº (EL-409). Slanted areaHilly areas where the road has

banked curves. When the vehicle

enters these banked curves, there

may be an error in steering angle

measurement. The position marker

may show the vehicle to be in inac-

curate position.

Map

dataMap display for a given road does not appear.

SEL699V

When the vehicle is driven on a

newly constructed road that does

not appear on the existing map.

Map marking and calibration are not

possible. The position marker may

indicate inaccurate position in close

proximity to the actual position.

Subsequently, when the vehicle is

driven on a road which is available

as map data, the position marker

may still indicate an inaccurate posi-

tion.

The vehicle is driven on a road whose course

has been altered (usually to improve the road or

to eliminate some hazard).

SEL700V

When the map data shown on the

display and the actual conditions are

different. Map matching will not be

possible. The position marker may

indicate inaccurate position in close

proximity to the actual position. If

the vehicle is driven on the indicated

road, further errors may occur.

Vehicle Use of tire chains (Stormy weather)Tire chains will affect distance sens-

ing. The position marker may indi-

cate inaccurate position.If the position marker does not

move to the correct position

even after the vehicle has been

driven approximately 10 km (6

miles), perform ªSPEED CALI-

BRATIONº (EL-409). After

removing the tire chains, sens-

ing accuracy may recover by

itself.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

NAVIGATION SYSTEM

This Condition is Not Abnormal (Cont'd)

EL-425

Page 1611 of 2395

Possible cause Drive condition Service procedure

Opera-

tionDriving immediately after starting engine.The gyro (angular velocity sensor)

needs about 15 seconds after the

engine is started to precisely sense

the angular velocity. Directional

sensing errors will occur if the

vehicle is moved immediately after

starting the engine. The position

marker may indicate inaccurate

position.Wait a few moments between

starting the engine and actually

driving the vehicle.

Continuous driving for long distances (non-stop)When the vehicle is driven continu-

ously without stopping over a long

distance, errors in directional sens-

ing may occur. The position marker

may indicate inaccurate position.Stop the vehicle. Perform

ªSPEED CALIBRATIONº (EL-

409).

Rough or violent drivingWheel spinning (peeling out) or simi-

lar rough driving techniques can

adversely affect sensing accuracy.

The position marker may indicate

inaccurate position.If the position marker does not

move to the correct position

even after the vehicle has been

driven approximately 10 km (6

miles), perform ªADJUST CUR-

RENT LOCATIONº (EL-411).

Posi-

tional

calibra-

tion pro-

ceduresPositional calibration precision

SEL701V

If current vehicle location is roughly

set, the system may be unable to

locate the road that the vehicle is

traveling on. (This is especially true

in an area where there are many

roads.)Perform ªADJUST CURRENT

LOCATIONº (EL-411) within a

precision standard of 1 mm

(0.04 in) on the display.

Note: During calibration, use

the most detailed map pos-

sible.

Position calibration direction

SEL702V

When calibrating the position, check

the vehicle direction. If the vehicle

direction is not correct, subsequent

precision of current location will be

affected.Perform ªADJUST CURRENT

LOCATIONº, refer to EL-411.

NAVIGATION SYSTEM

This Condition is Not Abnormal (Cont'd)

EL-426