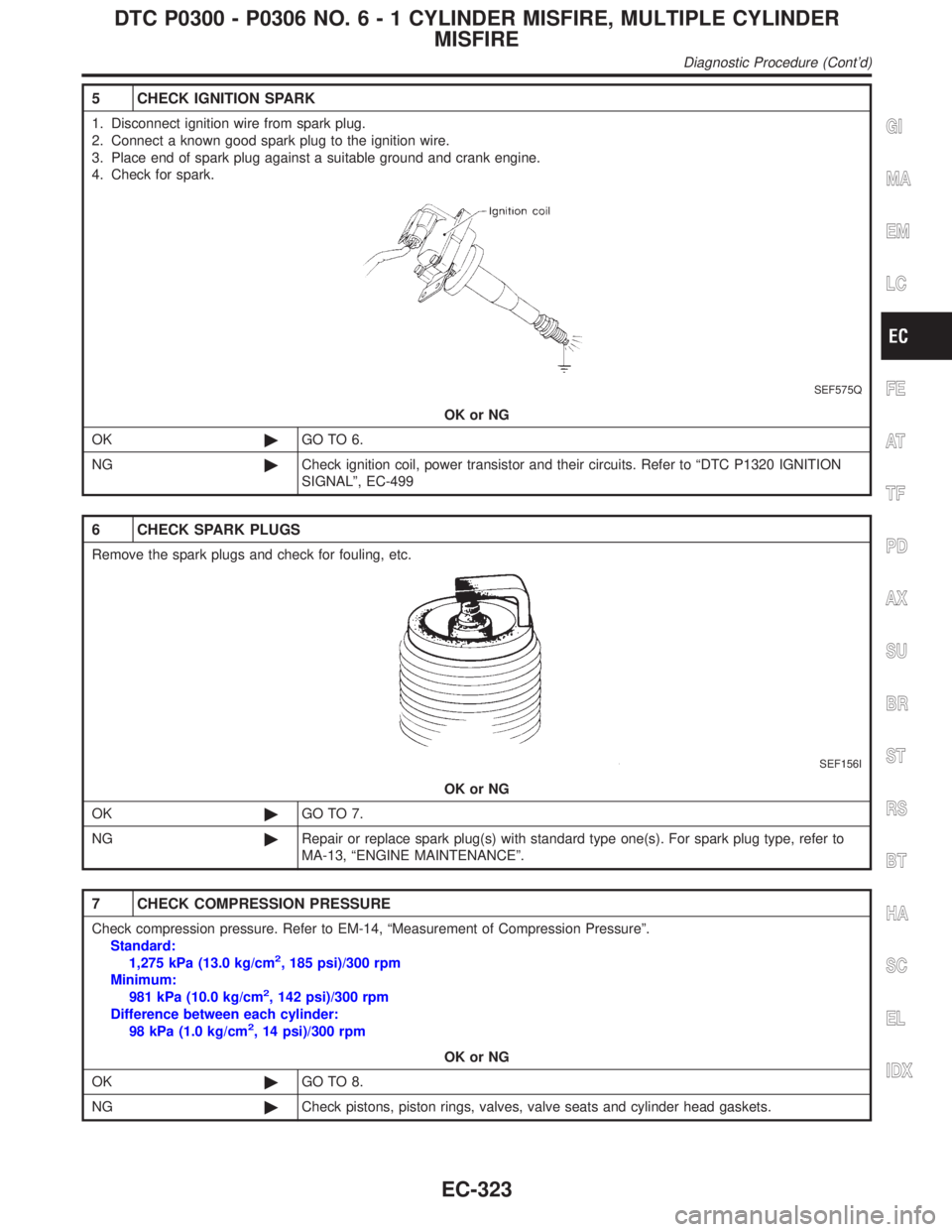

5 CHECK IGNITION SPARK

1. Disconnect ignition wire from spark plug.

2. Connect a known good spark plug to the ignition wire.

3. Place end of spark plug against a suitable ground and crank engine.

4. Check for spark.

SEF575Q

OK or NG

OK©GO TO 6.

NG©Check ignition coil, power transistor and their circuits. Refer to ªDTC P1320 IGNITION

SIGNALº, EC-499

6 CHECK SPARK PLUGS

Remove the spark plugs and check for fouling, etc.

SEF156I

OK or NG

OK©GO TO 7.

NG©Repair or replace spark plug(s) with standard type one(s). For spark plug type, refer to

MA-13, ªENGINE MAINTENANCEº.

7 CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to EM-14, ªMeasurement of Compression Pressureº.

Standard:

1,275 kPa (13.0 kg/cm

2, 185 psi)/300 rpm

Minimum:

981 kPa (10.0 kg/cm

2, 142 psi)/300 rpm

Difference between each cylinder:

98 kPa (1.0 kg/cm

2, 14 psi)/300 rpm

OK or NG

OK©GO TO 8.

NG©Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0300 - P0306 NO.6-1CYLINDER MISFIRE, MULTIPLE CYLINDER

MISFIRE

Diagnostic Procedure (Cont'd)

EC-323

SEM532G

3. Before installing the cylinder head gasket, be sure that No. 1

cylinder is at TDC.

IAt this time, the crankshaft key should face toward the right

bank.

SEM445G

4. Install cylinder heads with new gaskets.

IDo not rotate crankshaft and camshaft separately, or

valves will strike piston heads.

SEM957E

CAUTION:

Cylinder head bolts are tightened by plastic zone tightening

method. Whenever the size difference between d1 and d2

exceeds the limit, replace them with new ones.

Limit (d1 - d2):

0.11 mm (0.0043 in)

ILubricate threads and seat surfaces of the bolts with new

engine oil.

CYLINDER HEAD

Installation (Cont'd)

EM-48