stop start INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2118 of 3061

IP-6

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000003533145

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Page 2232 of 3061

HEADLAMP (FOR CANADA) - DAYTIME LIGHT SYSTEM -

LT-25

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

lamps turn off when lighting switch is in the 2ND position or AUTO position (Headlamp is "ON") and when light-

ing switch is in the PASSING position. (Daytime light lamps are not turned off only by parking brake itself.)

A parking brake signal and engine run or stop signal are sent to BCM (body control module) by CAN commu-

nication line.

OUTLINE

Power is supplied at all times

• to ignition relay, located in the IPDM E/R (intelligent power distribution module engine room),

• through 50A fusible link (letter f , located in the fuse and fusible link box)

• to BCM terminal 70,

• through 20A fuse (No. 53, located in the IPDM E/R)

• to CPU (central processing unit) of the IPDM E/R,

• through 10A fuse [No. 19, located in the fuse block (J/B)]

• to combination meter terminal 8, and

• through 10A fuse (No. 45, located in the IPDM E/R)

• to daytime light relay terminals 2 and 5.

When the ignition switch is in ON or START position, power is supplied

• to ignition relay, located in the IPDM E/R,

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38, and

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal 24.

Ground is supplied

• to BCM terminal 67 and

• to combination meter terminal 17

• through grounds M57, M61 and M79.

DAYTIME LIGHT OPERATION

With the engine running, the lighting switch in the OFF or 1ST position and parking brake released, the IPDM

E/R receives input requesting the daytime lights illuminate. This input is communicated across the CAN com-

munication lines. The CPU of the IPDM E/R controls the daytime light relay coil. When energized, this relay

directs power

• through daytime light relay terminal 3

• to front combination lamp LH terminal 2

• through front combination lamp LH terminal 6

• to IPDM E/R terminal 55

• through 10A fuse (No. 35, located in the IPDM E/R)

• through 10A fuse (No. 34, located in the IPDM E/R)

• through IPDM E/R terminal 56

• to front combination lamp RH terminal 6.

Ground is supplied

• to front combination lamp RH terminal 2

• through grounds E9, E15 and E24.

With power and ground supplied, the daytime lights illuminate. The high beam headlamps are now wired in

series and illuminate at a reduced intensity.

COMBINATION SWITCH READING FUNCTION

Refer to BCS-3, "System Description" .

AUTO LIGHT OPERATION

Refer to LT-34, "System Description" .

CAN Communication System DescriptionINFOID:0000000003533355

Refer to LAN-4, "CAN Communication System" .

Page 2242 of 3061

AUTO LIGHT SYSTEM

LT-35

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

OUTLINE

The auto light control system uses an optical sensor that detects outside brightness.

When the lighting switch is in "AUTO" position, it automatically turns on/off the parking lamps and the head-

lamps in accordance with the ambient light. Sensitivity can be adjusted in four steps. For the details of the set-

ting, refer to LT-40, "

Preliminary Check" .

Optical sensor ground is supplied

• to optical sensor terminal 3

• through BCM (body control module) terminal 18.

When ignition switch is turned to “ON” position and when outside brightness is darker than prescribed level,

input is supplied

• to BCM terminal 58

• through optical sensor terminal 4.

The headlamps will then illuminate. For a description of headlamp operation, refer to LT- 5 , "

System Descrip-

tion" .

COMBINATION SWITCH READING FUNCTION

Refer to BCS-3, "System Description" .

EXTERIOR LAMP BATTERY SAVER CONTROL

When the combination switch (lighting switch) is in the AUTO position, and the ignition switch is turned from

ON or ACC to OFF, and one of the front doors is opened, the battery saver control feature is activated.

Under this condition, the headlamps remain illuminated for 5 minutes, then the headlamps are turned off.

Exterior lamp battery saver control mode can be changed by the function setting of CONSULT-II.

DELAY TIMER FUNCTION

When the ignition switch is ON and auto light switch is ON, the BCM turns on/off the headlamps. In delay timer

function, ignition is OFF, auto light sensor power source is OFF and the headlamps are not turned on/off by the

BCM. On condition that:

• when the state of ignition switch ON or ACC is ON and output judgment by auto light function is headlamp

ON changes to ignition switch and ACC are OFF and any door switch is ON, output judgment by BCM

should be headlamp ON for 5 minutes by timer. After time out, output judgment by BCM should be headlamp

OFF.

• when the state of any door switch is turned to ON from OFF while 45 second or 5 minute timer is counting,

timer stops, and restarts counting for 5 minutes, then BCM judges output as headlamp ON. After time out,

BCM judges output as headlamp OFF.

• when the state of front door switch (LH), front door switch (RH), rear door switch LH, rear door switch RH or

back door latch (door ajar switch) is ON turns to all door switches are OFF while 45 second or 5 minute timer

is counting, timer stops, and restarts counting for 45 seconds, then BCM judges output as headlamp ON.

After timer out, BCM judges output as headlamp OFF.

• when the state is ignition switch ON or ACC is ON or auto light switch OFF while timer is counting, timer

stops counting and BCM turns on/off lamps according to headlamp function, front fog lamp function, auto

light function and headlamp battery save function.

Delay timer control mode can be changed by the function setting of CONSULT-II.

CAN Communication System DescriptionINFOID:0000000003533370

Refer to LAN-4, "CAN Communication System" .

Major Component and FunctionsINFOID:0000000003533371

Components Functions

BCM• Turns on/off circuits of tail light and headlamp according to signals from light sensor, lighting switch

(AUTO), front door switch LH, front door switch RH, rear door switch, back door latch (door ajar

switch), and ignition switch (ON, OFF).

Optical sensor • Converts ambient light (lux) to voltage, and sends it to BCM. (Detects lightness of 50 to 1,300 lux)

Page 2271 of 3061

LT-64

< SERVICE INFORMATION >

TURN SIGNAL AND HAZARD WARNING LAMPS

3. Perform preliminary check. Refer to LT-64, "Preliminary Check" .

4. Check symptom and repair or replace the component.

5. Do turn signal and hazard warning lamps operate normally? If YES: GO TO 6. If NO: GO TO 4.

6. Inspection End.

Preliminary CheckINFOID:0000000003533410

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR BCM

Refer to BCS-15, "BCM Power Supply and Ground Circuit Inspection".

CONSULT-II Function (BCM)INFOID:0000000003533411

Refer to BCS-16, "CONSULT-II Function (BCM)".

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

DATA MONITOR

Display Item List

ACTIVE TEST

Display Item List

Front Turn Signal Lamp Does Not OperateINFOID:0000000003533412

1.CHECK COMBINATION SWITCH INPUT SIGNAL

With CONSULT-II

Select "BCM" on CONSULT-II. With "FLASHER" data monitor, make

sure "TURN SIGNAL R" and "TURN SIGNAL L" turns ON-OFF

linked with operation of lighting switch.

Without CONSULT-II

Refer to LT-73, "

Combination Switch Inspection" .

OK or NG

OK >> GO TO 2.

NG >> Check lighting switch. Refer to LT-73, "

Combination Switch Inspection".

2.ACTIVE TEST

With CONSULT-II

Monitor item Contents

IGN ON SW "ON/OFF" Displays "IGN position (ON)/OFF, ACC position (OFF)" judged from the ignition switch signal.

HAZARD SW "ON/OFF" Displays "Hazard ON (ON)/Hazard OFF (OFF)" status, determined from hazard switch signal.

TURN SIGNAL R "ON/OFF" Displays "Turn right (ON)/Other (OFF)" status, determined from lighting switch signal.

TURN SIGNAL L "ON/OFF" Displays "Turn left (ON)/Other (OFF)" status, determined from lighting switch signal.

BRAKE SW "ON/OFF" Displays status of stop lamp switch.

Test item Description

FLASHER (RH) Turn signal lamp (right) can be operated by any ON-OFF operations.

FLASHER (LH) Turn signal lamp (left) can be operated by any ON-OFF operations.

When lighting switch is in

TURN RH position: TURN SIGNAL R ON

When lighting switch is in

TURN LH position: TURN SIGNAL L ON

SKIA4499E

Page 2302 of 3061

TRAILER TOW

LT-95

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

• to trailer tow relay 1 terminal 3,

• through 20A fuse (No. 53, located in the IPDM E/R)

• to CPU (central processing unit) of the IPDM E/R,

• through 30A fusible link (letter j , located in the fuse and fusible link box)

• to trailer tow relay 2 terminals 3 and 6, and

• through 40A fusible link (letter k , located in the fuse and fusible link box)

• to electric brake (pre-wiring) terminal 5.

With the ignition switch in the ON or START position, power is supplied

• to ignition relay, located in the IPDM E/R,

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38, and

• through 10A fuse (No. 51, located in the IPDM E/R)

• to trailer tow relay 2 terminal 1.

Ground is supplied

• to BCM terminal 67

• to electric brake (pre-wiring) terminal 1,

• through grounds M57, M61 and M79,

• to IPDM E/R terminals 38 and 59

• to trailer tow relay 1 terminal 2

• to trailer tow relay 2 terminal 2, and

• to trailer connector terminal 2

• to trailer turn relay LH and RH terminal 2

• through grounds E9, E15 and E24.

TRAILER TAIL LAMP OPERATION

The trailer tail lamps are controlled by the trailer tow relay 1.

With the lighting switch in the parking and tail lamp ON (1ST) position, AUTO position (and the auto light sys-

tem is activated) or headlamp ON (2ND) position, power is supplied

• through the tail lamp relay, located in the IPDM E/R

• through 10A fuse (No. 36, located in the IPDM E/R)

• through IPDM E/R terminal 49

• to trailer tow relay 1 terminal 1.

When energized, trailer tow relay 1 supplies tail lamp power to trailer connector terminal 6.

TRAILER TURN SIGNAL AND HAZARD LAMP OPERATION

The trailer turn signal and hazard lamps are controlled by the BCM through trailer turn relays (LH and RH). If

either turn signal or the hazard lamps are turned on, the BCM supplies voltage to the trailer turn relays (LH

and RH) to make them cycle on and off.

Trailer turn relay LH output is supplied

• through BCM terminal 52

• to trailer turn relay LH terminal 1.

Trailer turn relay RH output is supplied

• through BCM terminal 51

• to trailer turn relay RH terminal 1.

Left turn signal and hazard lamp output is supplied

• through trailer turn relay LH terminal 3

• to trailer connector terminal 1.

Right turn signal and hazard lamp output is supplied

• through trailer turn relay RH terminal 3

• to trailer connector terminal 4.

TRAILER STOP LAMP OPERATION

The trailer stop lamps are controlled by the electric brake. The electric brake receives stop lamp switch signal

when the brake pedal is pressed.

When the brake pedal is pressed, power is supplied

• through electric brake (pre-wiring) terminal 3

• to trailer connector terminal 3.

TRAILER POWER SUPPLY OPERATION

The trailer power supply is controlled by the trailer tow relay 2.

When the ignition switch is in the ON or START position, power is supplied

• through 10A fuse (No. 51, located in the IPDM E/R)

Page 2354 of 3061

ENGINE OIL

LU-9

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

LU

N

P O

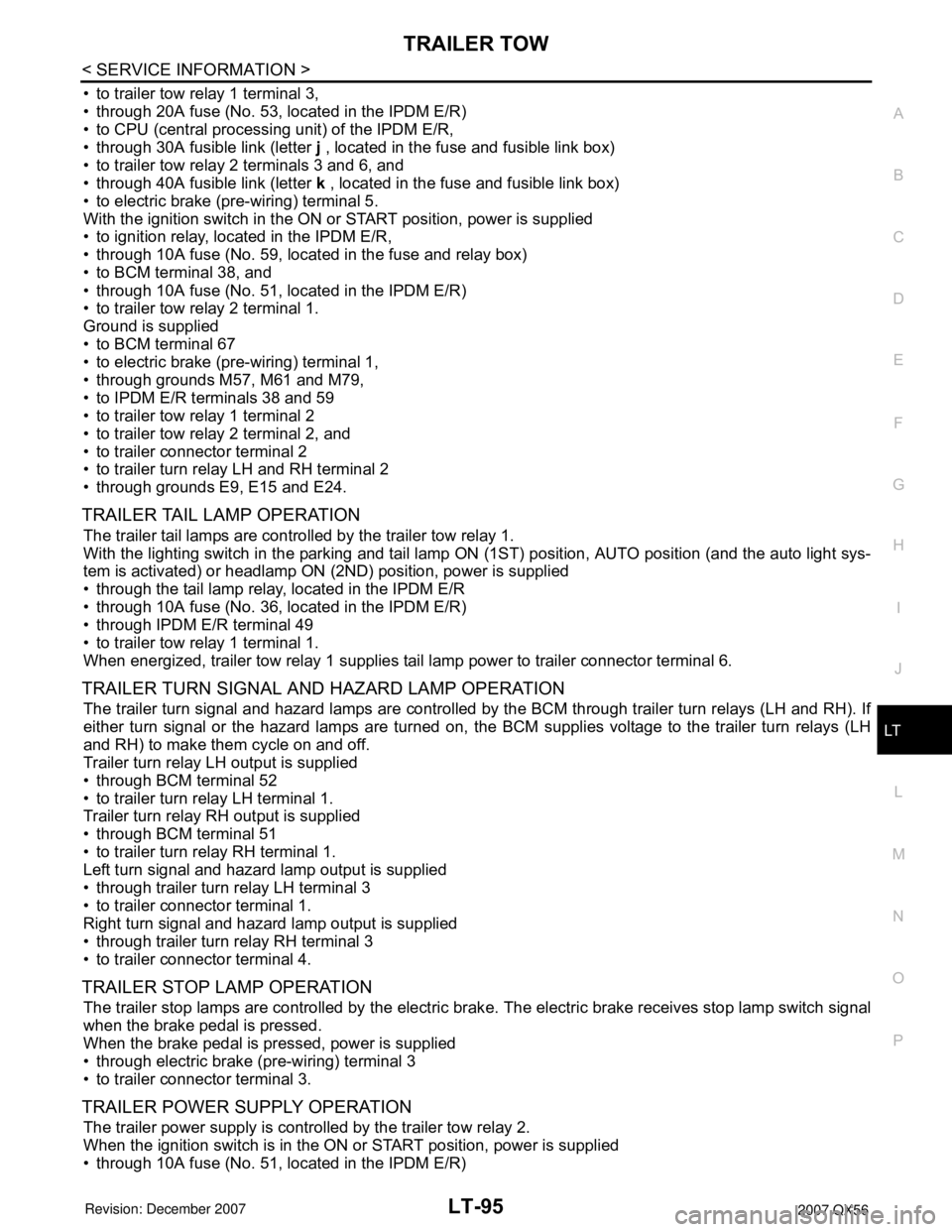

5. Install Tools.

6. Start the engine and warm it up to normal operating temperature.

7. Check the engine oil pressure with engine running under no-load.

Engine oil pressure [Engine oil temperature at 80°C (175°F)]

Unit: kPa (kg/cm2

, psi)

CAUTION:

If the difference is extreme, check the oil passages and oil pump for leaks and blockages.

8. After the inspections, install oil pressure switch as follows:

a. Remove old liquid gasket adhering to oil pressure switch and engine.

b. Apply liquid gasket and tighten oil pressure switch to the specification.

Use Genuine RTV Silicone Sealant or equivalent. Refer to GI-45, "

Recommended Chemical Prod-

uct and Sealant".

c. After warming up engine, make sure there is no leakage of engine oil with engine running.

Changing Engine OilINFOID:0000000003531556

CAUTION:

• Be careful not to burn yourself, as the engine oil is hot.

• Prolonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with used

engine oil. If skin contact is made, wash thoroughly with soap

or hand cleaner as soon as possible.

1. Remove engine front undercover using power tool.

2. Warm up engine, and check for oil leakage from engine compo-

nents. Refer to LU-8, "

Inspection".

3. Stop engine and wait for 10 minutes.

4. Loosen oil filler cap, then remove drain plug.

5. Drain engine oil.

6. Install drain plug with new washer.

CAUTION:

• Be sure to clean drain plug and install with new washer.

7. Refill with new engine oil. Refer to MA-10, "

Fluids and Lubricants".

Engine oil capacity (Approximate):

Tool number : ST25051001 (J-25695-1)

: ST25052000 (J-25695-2)

WBIA0571E

Engine Speed Approximate Discharge Pressure

Idle speed More than 98 (1.0, 14)

2,000 rpm More than 294 (3.0, 43)

Oil pressure sensor torque : 14.7 N·m (1.5 kg-m, 11 ft-lb)

Oil pan drain plug : 34.3 N·m (3.5 kg-m, 25 ft-lb)

KBIA2498E

Page 2356 of 3061

OIL FILTER

LU-11

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

LU

N

P O

OIL FILTER

Removal and InstallationINFOID:0000000003531557

REMOVAL

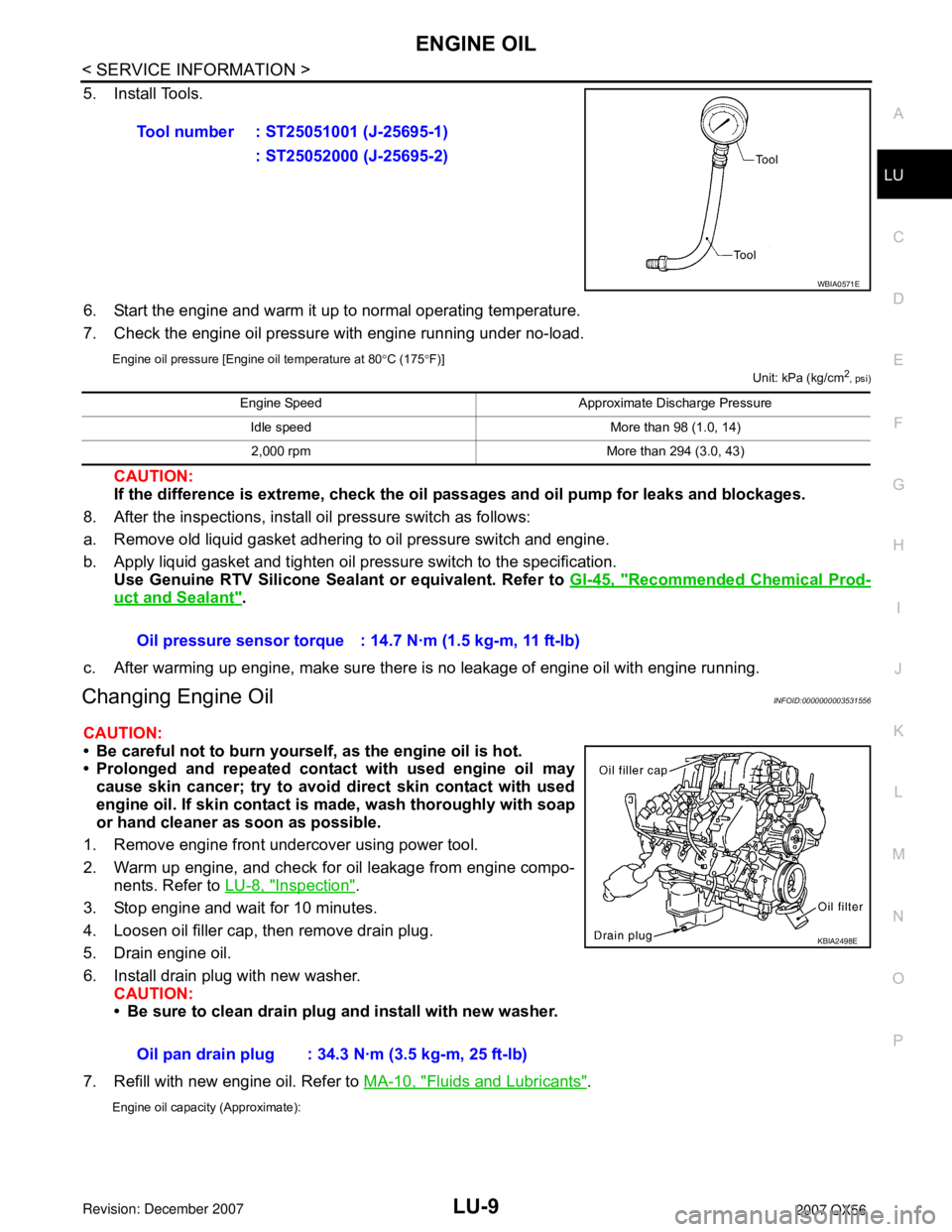

1. Remove the engine front undercover using power tool.

2. Remove the oil filter using Tool.

WARNING:

• The oil filter is provided with a relief valve.

Use Genuine NISSAN oil filter or equivalent.

• When removing, prepare a shop cloth to absorb any

engine oil leakage or spillage.

• Do not allow engine oil to adhere to the drive belts.

• Completely wipe off any engine oil that adheres to the

engine and the vehicle.

CAUTION:

• Be careful not to get burned when the engine and engine oil are hot.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply engine oil to the oil seal circumference of the new oil filter.

3. Screw the oil filter manually until it touches the installation sur-

face, then tighten it by 2/3 turn. Or tighten to specification.

4. Inspect the engine for oil leakage. Refer to EM-74, "

Removal

and Installation".

5. Install the engine front undercover using power tool.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to LU-8, "Inspection".

2. Start the engine and check for engine oil leakage.

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level and add engine oil as required.Tool number : KV10115801 (J-38956)

WBIA0388E

SMA010

Oil filter : 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B

Page 2358 of 3061

OIL COOLER

LU-13

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

LU

N

P O

• Confirm that no foreign objects are adhering to the sealing sur-

faces of the oil cooler or oil pan.

• Tighten the connecting bolt after aligning the stopper on the oil pan

side with protrusion of the oil cooler.

INSPECTION AFTER INSTALLATION

1. Check levels and add engine oil and engine coolant. Refer to LU-8, "Inspection".

2. Start the engine, and check for leaks of engine oil and engine coolant.

3. Stop engine and wait for 10 minutes.

4. Check engine oil level and engine coolant level again.

KBIA2500E

Page 2359 of 3061

LU-14

< SERVICE INFORMATION >

OIL PUMP

OIL PUMP

Removal and InstallationINFOID:0000000003531559

REMOVAL

1. Remove front cover. Refer to EM-38, "Removal and Installation".

2. Remove the oil pump drive spacer.

3. Remove the oil pump.

INSTALLATION

Installation is in the reverse order of removal, paying attention of the following:

• When inserting the oil pump drive spacer, align the crankshaft key

and the flat face of the inner rotor.

• If they are not aligned, rotate the oil pump inner rotor by hand.

• Make sure that the each part is aligned and tap lightly until it

reaches the end.

INSPECTION AFTER INSTALLATION

• Start the engine, and check for leaks of engine oil.

• Stop engine and wait 10 minutes.

• Check level and add engine oil as required. Refer to LU-8, "

Inspection".

WBIA0415E

1. Oil pump body 2. Outer rotor 3. Inner rotor

4. Oil pump cover 5. Oil pump drive spacer 6. Regulator valve

7. Regulator spring 8. Regulator plug

KBIA2512E

KBIA2490E

Page 2379 of 3061

ENGINE MAINTENANCE

MA-17

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

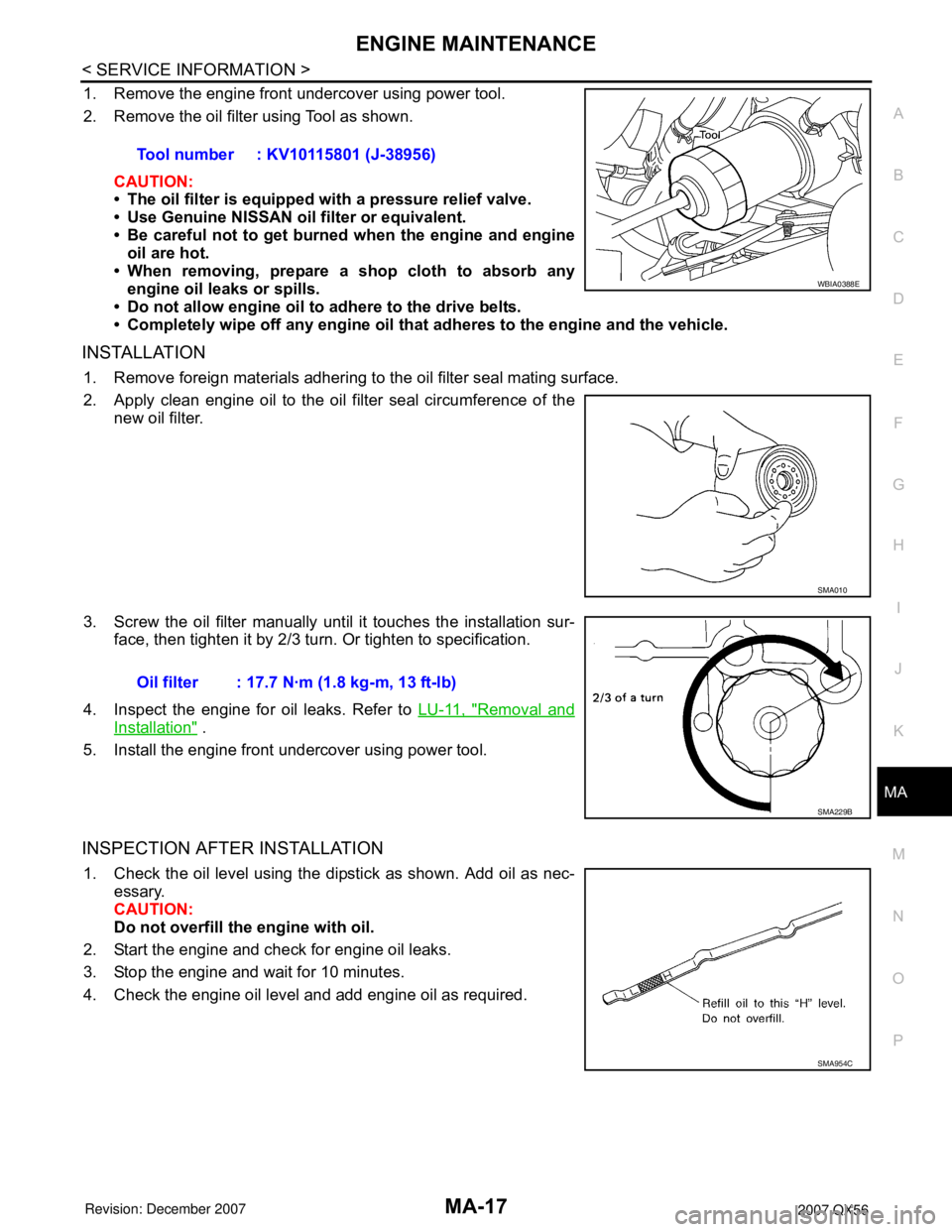

1. Remove the engine front undercover using power tool.

2. Remove the oil filter using Tool as shown.

CAUTION:

• The oil filter is equipped with a pressure relief valve.

• Use Genuine NISSAN oil filter or equivalent.

• Be careful not to get burned when the engine and engine

oil are hot.

• When removing, prepare a shop cloth to absorb any

engine oil leaks or spills.

• Do not allow engine oil to adhere to the drive belts.

• Completely wipe off any engine oil that adheres to the engine and the vehicle.

INSTALLATION

1. Remove foreign materials adhering to the oil filter seal mating surface.

2. Apply clean engine oil to the oil filter seal circumference of the

new oil filter.

3. Screw the oil filter manually until it touches the installation sur-

face, then tighten it by 2/3 turn. Or tighten to specification.

4. Inspect the engine for oil leaks. Refer to LU-11, "

Removal and

Installation" .

5. Install the engine front undercover using power tool.

INSPECTION AFTER INSTALLATION

1. Check the oil level using the dipstick as shown. Add oil as nec-

essary.

CAUTION:

Do not overfill the engine with oil.

2. Start the engine and check for engine oil leaks.

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level and add engine oil as required.Tool number : KV10115801 (J-38956)

WBIA0388E

SMA010

Oil filter : 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B

SMA954C