check transmission fluid INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 71 of 3061

AT-1

TRANSMISSION/TRANSAXLE

D

E

F

G

H

I

J

K

L

M

SECTION AT

A

B

AT

N

O

P

CONTENTS

AUTOMATIC TRANSMISSION

SERVICE INFORMATION ............................6

INDEX FOR DTC .................................................6

Alphabetical Index .....................................................6

DTC No. Index ..........................................................6

PRECAUTIONS ...................................................8

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

8

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine .....................................................

8

Precaution .................................................................8

Service Notice or Precaution .....................................9

PREPARATION ..................................................11

Special Service Tool ...............................................11

Commercial Service Tool ........................................12

A/T FLUID ...........................................................13

Changing Automatic Transmission Fluid (ATF) ......13

Checking Automatic Transmission Fluid (ATF) .......13

A/T Fluid Cooler Cleaning .......................................15

A/T CONTROL SYSTEM ....................................19

Cross-Sectional View (2WD models) ......................19

Cross-Sectional View (4WD models) ......................20

Shift Mechanism ......................................................20

TCM Function ..........................................................31

CAN Communication ...............................................32

Input/Output Signal of TCM .....................................33

Line Pressure Control .............................................33

Shift Control ............................................................35

Lock-up Control .......................................................36

Engine Brake Control ..............................................37

Control Valve ...........................................................37

ON BOARD DIAGNOSTIC (OBD) SYSTEM ......39

Introduction .............................................................39

OBD-II Function for A/T System ..............................39

One or Two Trip Detection Logic of OBD-II ............39

OBD-II Diagnostic Trouble Code (DTC) ..................39

Malfunction Indicator Lamp (MIL) ............................41

TROUBLE DIAGNOSIS ....................................43

DTC Inspection Priority Chart ..................................43

Fail-Safe ..................................................................43

How To Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

44

A/T Electrical Parts Location ...................................50

Circuit Diagram ........................................................51

Inspections Before Trouble Diagnosis .....................51

Check Before Engine Is Started ..............................55

Check at Idle ............................................................55

Cruise Test - Part 1 .................................................56

Cruise Test - Part 2 .................................................58

Cruise Test - Part 3 .................................................59

Vehicle Speed When Shifting Gears .......................59

Vehicle Speed When Performing and Releasing

Complete Lock-up ...................................................

60

Vehicle Speed When Performing and Releasing

Slip Lock-up .............................................................

60

Symptom Chart ........................................................60

TCM Input/Output Signal Reference Value .............82

CONSULT-II Function (A/T) ....................................83

DTC U1000 CAN COMMUNICATION LINE .....91

Description ...............................................................91

On Board Diagnosis Logic .......................................91

Possible Cause ........................................................91

DTC Confirmation Procedure ..................................91

Wiring Diagram - AT - CAN .....................................92

Diagnosis Procedure ...............................................93

DTC P0615 START SIGNAL CIRCUIT .............94

Description ...............................................................94

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................

94

On Board Diagnosis Logic .......................................94

Possible Cause ........................................................94

DTC Confirmation Procedure ..................................94

Wiring Diagram - AT - STSIG ..................................95

Diagnosis Procedure ...............................................95

Page 74 of 3061

AT-4

DTC Confirmation Procedure ................................152

Diagnosis Procedure .............................................152

DTC P1845 ATF PRESSURE SWITCH 5 ........154

Description .............................................................154

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

154

On Board Diagnosis Logic .....................................154

Possible Cause ......................................................154

DTC Confirmation Procedure ................................154

Diagnosis Procedure .............................................154

DTC P1846 ATF PRESSURE SWITCH 6 ........156

Description .............................................................156

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

156

On Board Diagnosis Logic .....................................156

Possible Cause ......................................................156

DTC Confirmation Procedure ................................156

Diagnosis Procedure .............................................156

MAIN POWER SUPPLY AND GROUND CIR-

CUIT .................................................................

158

Wiring Diagram - AT - MAIN ..................................158

Diagnosis Procedure .............................................159

CLOSED THROTTLE POSITION AND WIDE

OPEN THROTTLE POSITION CIRCUIT .........

161

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

161

Diagnosis Procedure .............................................161

BRAKE SIGNAL CIRCUIT ..............................162

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

162

Diagnosis Procedure .............................................162

TOW MODE SWITCH ......................................163

Description .............................................................163

Wiring Diagram - AT - TMSW ................................163

Diagnosis Procedure .............................................164

TROUBLE DIAGNOSIS FOR SYMPTOMS .....165

Wiring Diagram - AT - NONDTC ............................165

A/T Check Indicator Lamp Does Not Come On .....167

Engine Cannot Be Started in "P" or "N" Position ...168

In "P" Position, Vehicle Moves When Pushed .......168

In "N" Position, Vehicle Moves ..............................169

Large Shock ("N" to "D" Position) ..........................170

Vehicle Does Not Creep Backward in "R" Position ..172

Vehicle Does Not Creep Forward in "D" Position ..175

Vehicle Cannot Be Started from D1 .......................177

A/T Does Not Shift: D1→ D2 ..................................179

A/T Does Not Shift: D2→ D3 ..................................181

A/T Does Not Shift: D3→ D4 ..................................183

A/T Does Not Shift: D4→ D5 ..................................185

A/T Does Not Perform Lock-up .............................187

A/T Does Not Hold Lock-up Condition ...................189

Lock-up Is Not Released .......................................190

Engine Speed Does Not Return to Idle .................191

A/T Does Not Shift: 5th gear → 4th gear ..............192

A/T Does Not Shift: 4th gear → 3rd gear ..............194

A/T Does Not Shift: 3rd gear → 2nd gear .............196

A/T Does Not Shift: 2nd gear → 1st gear .............197

Vehicle Does Not Decelerate By Engine Brake ....199

A/T SHIFT LOCK SYSTEM ..............................202

Description ............................................................202

Shift Lock System Electrical Parts Location ..........202

Wiring Diagram - AT - SHIFT ................................203

Shift Lock Control Unit Reference Value ..............204

Component Inspection ..........................................204

SHIFT CONTROL SYSTEM .............................207

Control Device Removal and Installation ..............207

Adjustment of A/T Position ....................................208

Checking of A/T Position .......................................208

ON-VEHICLE SERVICE ...................................209

Oil Pan ..................................................................209

Control Valve with TCM and A/T Fluid Tempera-

ture Sensor 2 ........................................................

210

Rear Oil Seal .........................................................219

AIR BREATHER HOSE ....................................221

Removal and Installation .......................................221

TRANSMISSION ASSEMBLY ..........................223

Removal and Installation (2WD) ...........................223

Removal and Installation (4WD) ...........................225

OVERHAUL ......................................................228

Component ...........................................................228

Oil Channel ...........................................................235

Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ..........................

237

DISASSEMBLY ................................................240

Disassembly ..........................................................240

REPAIR FOR COMPONENT PARTS ..............258

Oil Pump ...............................................................258

Front Sun Gear, 3rd One-Way Clutch ...................260

Front Carrier, Input Clutch, Rear Internal Gear .....262

Mid Sun Gear, Rear Sun Gear, High and Low Re-

verse Clutch Hub ..................................................

267

High and Low Reverse Clutch ..............................272

Direct Clutch .........................................................274

ASSEMBLY ......................................................277

Assembly (1) .........................................................277

Adjustment ............................................................290

Assembly (2) .........................................................292

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

298

General Specification ............................................298

Vehicle Speed When Shifting Gears .....................298

Vehicle Speed When Performing and Releasing

Complete Lock-up .................................................

299

Stall Speed ............................................................299

Page 79 of 3061

PRECAUTIONS

AT-9

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

•After performing each TROUBLE DIAGNOSIS, perform “DTC

(Diagnostic Trouble Code) CONFIRMATION PROCEDURE”.

If the repair is completed the DTC should not be displayed in

the “DTC CONFIRMATION PROCEDURE”.

• Always use the specified brand of ATF. Refer to MA-10

.

• Use paper rags not cloth rags during work.

• After replacing the ATF, dispose of the waste oil using the methods prescribed by law, ordinance, etc.

• Before proceeding with disassembly, thoroughly clean the outside of the transmission. It is important to pre-

vent the internal parts from becoming contaminated by dirt or other foreign matter.

• Disassembly should be done in a clean work area.

• Use lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could interfere

with the operation of the transmission.

• Place disassembled parts in order for easier and proper assembly.

• All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

• Gaskets, seals and O-rings should be replaced any time the transmission is disassembled.

• It is very important to perform functional tests whenever they are indicated.

• The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent springs

and small parts from becoming scattered or lost.

• Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

• Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in place during assembly. Do not use grease.

• Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

• Clean or replace ATF cooler if excessive foreign material is found in oil pan or clogging strainer. Refer to AT-

15, "A/T Fluid Cooler Cleaning".

• After overhaul, refill the transmission with new ATF.

• When the A/T drain plug is removed, only some of the fluid is drained. Old A/T fluid will remain in torque con-

verter and ATF cooling system.

Always follow the procedures under “Changing A/T Fluid” in the AT section when changing A/T fluid. Refer to

AT-13, "

Changing Automatic Transmission Fluid (ATF)", AT-13, "Checking Automatic Transmission Fluid

(ATF)".

Service Notice or PrecautionINFOID:0000000003532221

ATF COOLER SERVICE

If A/T fluid contains frictional material (clutches, bands, etc.), or if an A/T is repaired, overhauled, or replaced,

inspect and clean the A/T fluid cooler mounted in the radiator or replace the radiator. Flush cooler lines using

cleaning solvent and compressed air after repair. For A/T fluid cooler cleaning procedure, refer to AT-15, "

A/T

Fluid Cooler Cleaning". For radiator replacement, refer to CO-13.

CHECKING AND CHANGING A/T FLUID SERVICE

Increase ATF temperature by 80°C (176°F) once, and then check ATF level in 65°C (149°F) when adjusting

ATF level.

NOTE:

JA60 uses both systems of a water-cooling and of an air-cooling. Air-cooling system has a by-pass valve.

When ATF temperature is not over 50°C (122°F) with water-cooling system OFF, it does not flow to air-cooling

system. If ATF level is set without the flow of ATF, the level will be 10mm lower than the standard. Therefore,

piping should be filled with ATF when adjusting level.

OBD-II SELF-DIAGNOSIS

• A/T self-diagnosis is performed by the TCM in combination with the ECM. Refer to the table on AT-83,

"CONSULT-II Function (A/T)" for the indicator used to display each self-diagnostic result.

SEF217U

Page 83 of 3061

A/T FLUID

AT-13

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

A/T FLUID

Changing Automatic Transmission Fluid (ATF)INFOID:0000000003532224

1. Drive the vehicle to warm up the ATF to 80° C (176° F).

2. Stop the engine.

3. Remove the ATF level gauge bolt.

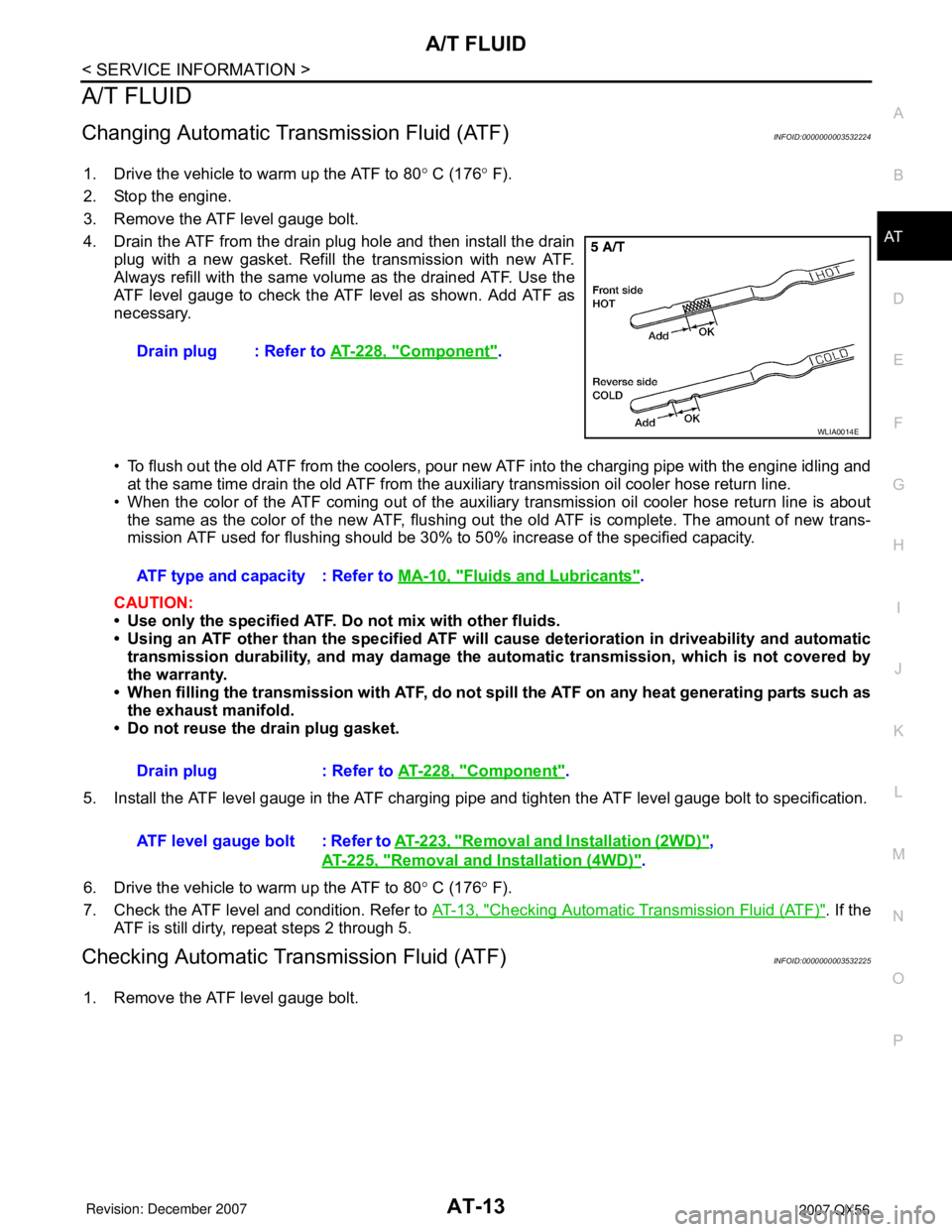

4. Drain the ATF from the drain plug hole and then install the drain

plug with a new gasket. Refill the transmission with new ATF.

Always refill with the same volume as the drained ATF. Use the

ATF level gauge to check the ATF level as shown. Add ATF as

necessary.

• To flush out the old ATF from the coolers, pour new ATF into the charging pipe with the engine idling and

at the same time drain the old ATF from the auxiliary transmission oil cooler hose return line.

• When the color of the ATF coming out of the auxiliary transmission oil cooler hose return line is about

the same as the color of the new ATF, flushing out the old ATF is complete. The amount of new trans-

mission ATF used for flushing should be 30% to 50% increase of the specified capacity.

CAUTION:

• Use only the specified ATF. Do not mix with other fluids.

• Using an ATF other than the specified ATF will cause deterioration in driveability and automatic

transmission durability, and may damage the automatic transmission, which is not covered by

the warranty.

• When filling the transmission with ATF, do not spill the ATF on any heat generating parts such as

the exhaust manifold.

• Do not reuse the drain plug gasket.

5. Install the ATF level gauge in the ATF charging pipe and tighten the ATF level gauge bolt to specification.

6. Drive the vehicle to warm up the ATF to 80° C (176° F).

7. Check the ATF level and condition. Refer to AT-13, "

Checking Automatic Transmission Fluid (ATF)". If the

ATF is still dirty, repeat steps 2 through 5.

Checking Automatic Transmission Fluid (ATF)INFOID:0000000003532225

1. Remove the ATF level gauge bolt.Drain plug : Refer to AT-228, "

Component".

WLIA0014E

ATF type and capacity : Refer to MA-10, "Fluids and Lubricants".

Drain plug : Refer to AT-228, "

Component".

ATF level gauge bolt : Refer to AT-223, "

Removal and Installation (2WD)",

AT-225, "

Removal and Installation (4WD)".

Page 84 of 3061

AT-14

< SERVICE INFORMATION >

A/T FLUID

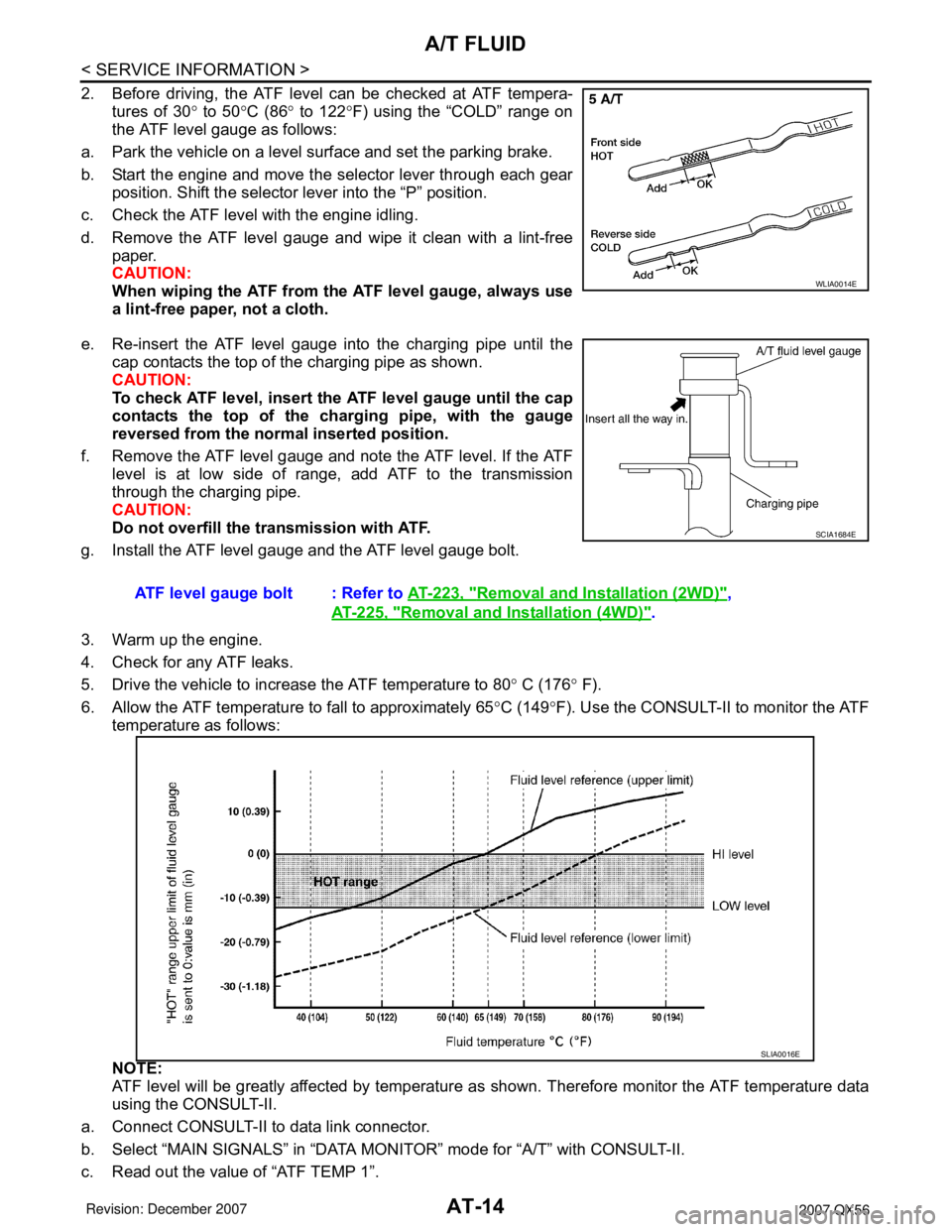

2. Before driving, the ATF level can be checked at ATF tempera-

tures of 30° to 50°C (86° to 122°F) using the “COLD” range on

the ATF level gauge as follows:

a. Park the vehicle on a level surface and set the parking brake.

b. Start the engine and move the selector lever through each gear

position. Shift the selector lever into the “P” position.

c. Check the ATF level with the engine idling.

d. Remove the ATF level gauge and wipe it clean with a lint-free

paper.

CAUTION:

When wiping the ATF from the ATF level gauge, always use

a lint-free paper, not a cloth.

e. Re-insert the ATF level gauge into the charging pipe until the

cap contacts the top of the charging pipe as shown.

CAUTION:

To check ATF level, insert the ATF level gauge until the cap

contacts the top of the charging pipe, with the gauge

reversed from the normal inserted position.

f. Remove the ATF level gauge and note the ATF level. If the ATF

level is at low side of range, add ATF to the transmission

through the charging pipe.

CAUTION:

Do not overfill the transmission with ATF.

g. Install the ATF level gauge and the ATF level gauge bolt.

3. Warm up the engine.

4. Check for any ATF leaks.

5. Drive the vehicle to increase the ATF temperature to 80° C (176° F).

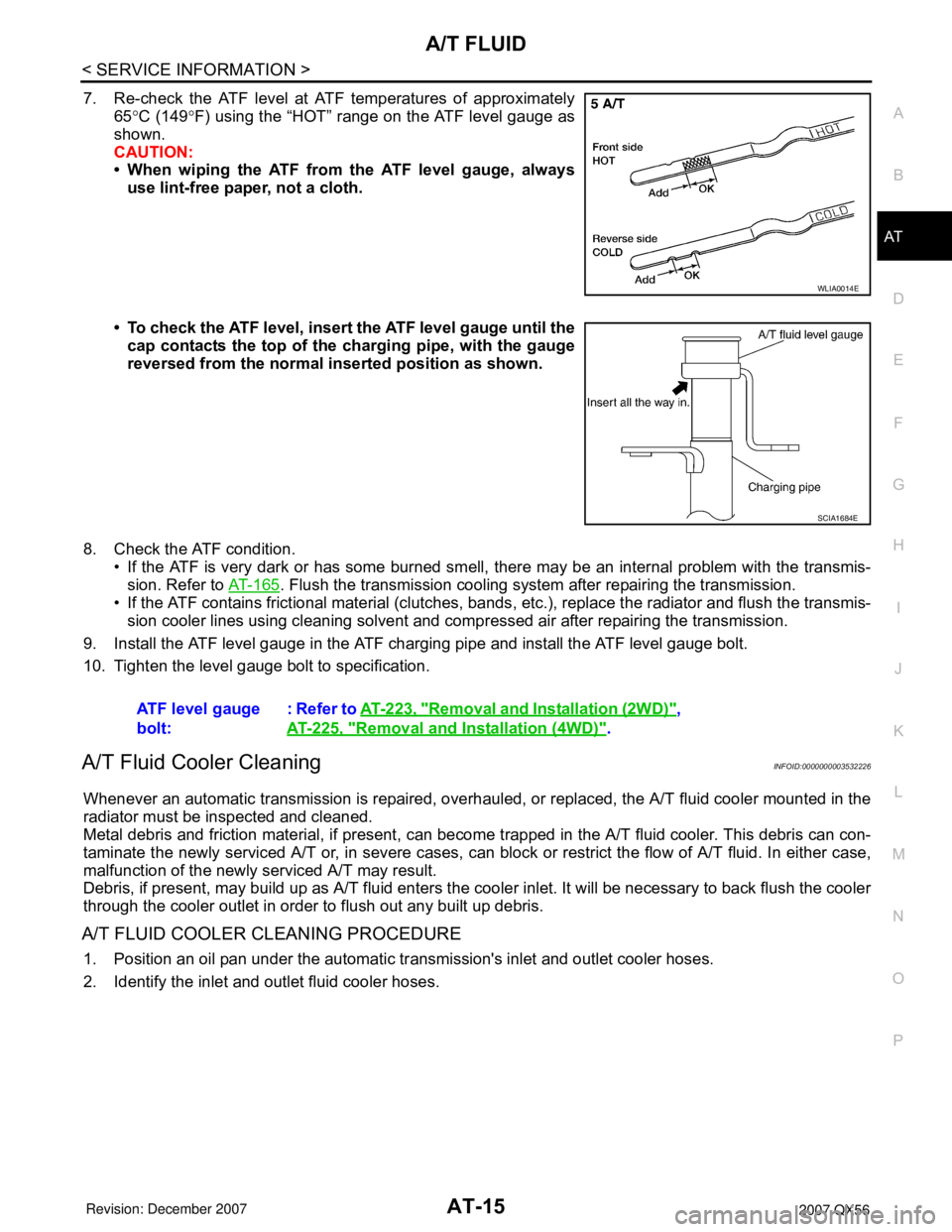

6. Allow the ATF temperature to fall to approximately 65°C (149°F). Use the CONSULT-II to monitor the ATF

temperature as follows:

NOTE:

ATF level will be greatly affected by temperature as shown. Therefore monitor the ATF temperature data

using the CONSULT-II.

a. Connect CONSULT-II to data link connector.

b. Select “MAIN SIGNALS” in “DATA MONITOR” mode for “A/T” with CONSULT-II.

c. Read out the value of “ATF TEMP 1”.

WLIA0014E

ATF level gauge bolt : Refer to AT-223, "Removal and Installation (2WD)",

AT-225, "

Removal and Installation (4WD)".

SCIA1684E

SLIA0016E

Page 85 of 3061

A/T FLUID

AT-15

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

7. Re-check the ATF level at ATF temperatures of approximately

65°C (149°F) using the “HOT” range on the ATF level gauge as

shown.

CAUTION:

• When wiping the ATF from the ATF level gauge, always

use lint-free paper, not a cloth.

• To check the ATF level, insert the ATF level gauge until the

cap contacts the top of the charging pipe, with the gauge

reversed from the normal inserted position as shown.

8. Check the ATF condition.

• If the ATF is very dark or has some burned smell, there may be an internal problem with the transmis-

sion. Refer to AT-165

. Flush the transmission cooling system after repairing the transmission.

• If the ATF contains frictional material (clutches, bands, etc.), replace the radiator and flush the transmis-

sion cooler lines using cleaning solvent and compressed air after repairing the transmission.

9. Install the ATF level gauge in the ATF charging pipe and install the ATF level gauge bolt.

10. Tighten the level gauge bolt to specification.

A/T Fluid Cooler CleaningINFOID:0000000003532226

Whenever an automatic transmission is repaired, overhauled, or replaced, the A/T fluid cooler mounted in the

radiator must be inspected and cleaned.

Metal debris and friction material, if present, can become trapped in the A/T fluid cooler. This debris can con-

taminate the newly serviced A/T or, in severe cases, can block or restrict the flow of A/T fluid. In either case,

malfunction of the newly serviced A/T may result.

Debris, if present, may build up as A/T fluid enters the cooler inlet. It will be necessary to back flush the cooler

through the cooler outlet in order to flush out any built up debris.

A/T FLUID COOLER CLEANING PROCEDURE

1. Position an oil pan under the automatic transmission's inlet and outlet cooler hoses.

2. Identify the inlet and outlet fluid cooler hoses.

WLIA0014E

SCIA1684E

ATF level gauge

bolt:: Refer to AT-223, "Removal and Installation (2WD)",

AT-225, "

Removal and Installation (4WD)".

Page 102 of 3061

AT-32

< SERVICE INFORMATION >

A/T CONTROL SYSTEM

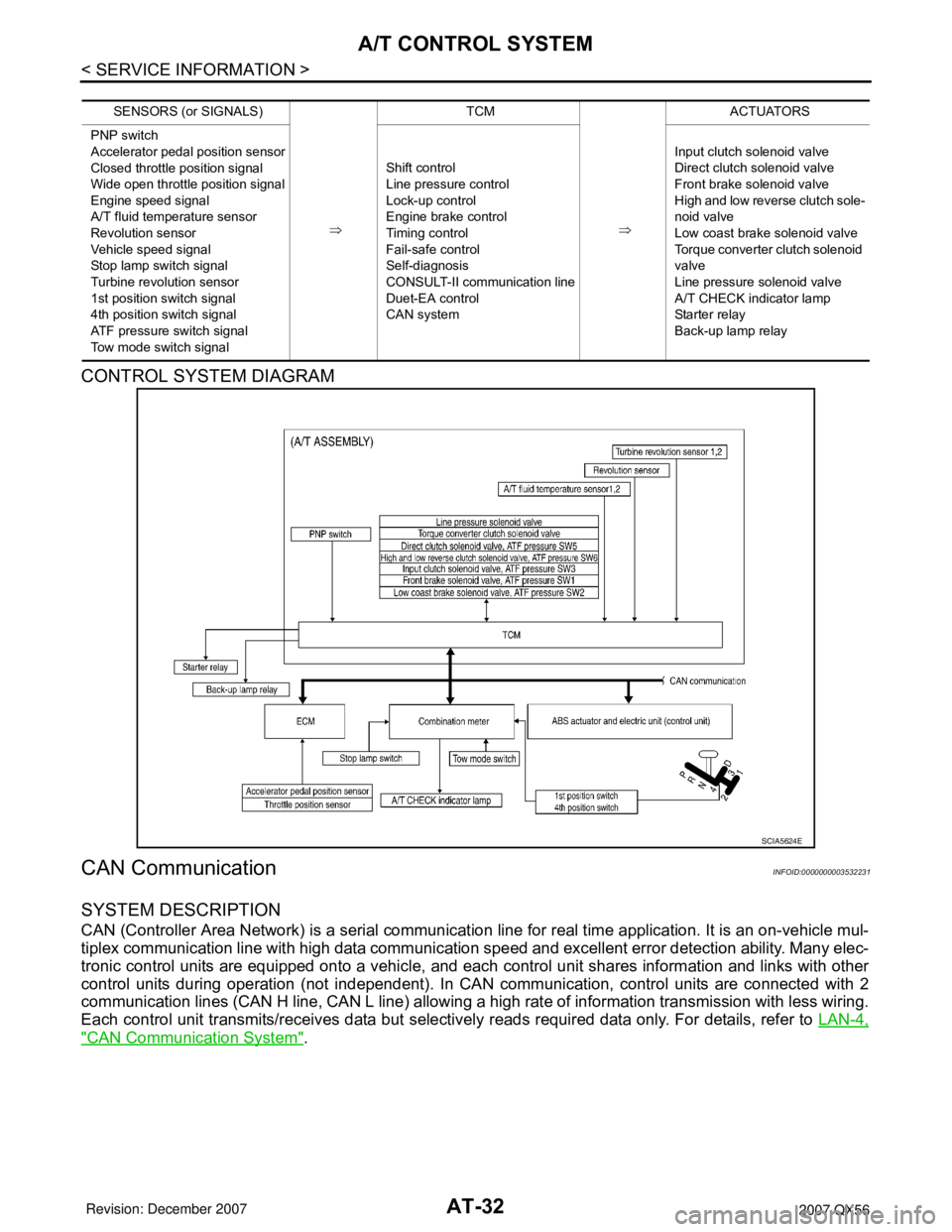

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000003532231

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. For details, refer to LAN-4,

"CAN Communication System".

SENSORS (or SIGNALS)

⇒TCM

⇒ACTUATORS

PNP switch

Accelerator pedal position sensor

Closed throttle position signal

Wide open throttle position signal

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Vehicle speed signal

Stop lamp switch signal

Turbine revolution sensor

1st position switch signal

4th position switch signal

ATF pressure switch signal

Tow mode switch signalShift control

Line pressure control

Lock-up control

Engine brake control

Timing control

Fail-safe control

Self-diagnosis

CONSULT-II communication line

Duet-EA control

CAN systemInput clutch solenoid valve

Direct clutch solenoid valve

Front brake solenoid valve

High and low reverse clutch sole-

noid valve

Low coast brake solenoid valve

Torque converter clutch solenoid

valve

Line pressure solenoid valve

A/T CHECK indicator lamp

Starter relay

Back-up lamp relay

SCIA5624E

Page 121 of 3061

TROUBLE DIAGNOSIS

AT-51

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

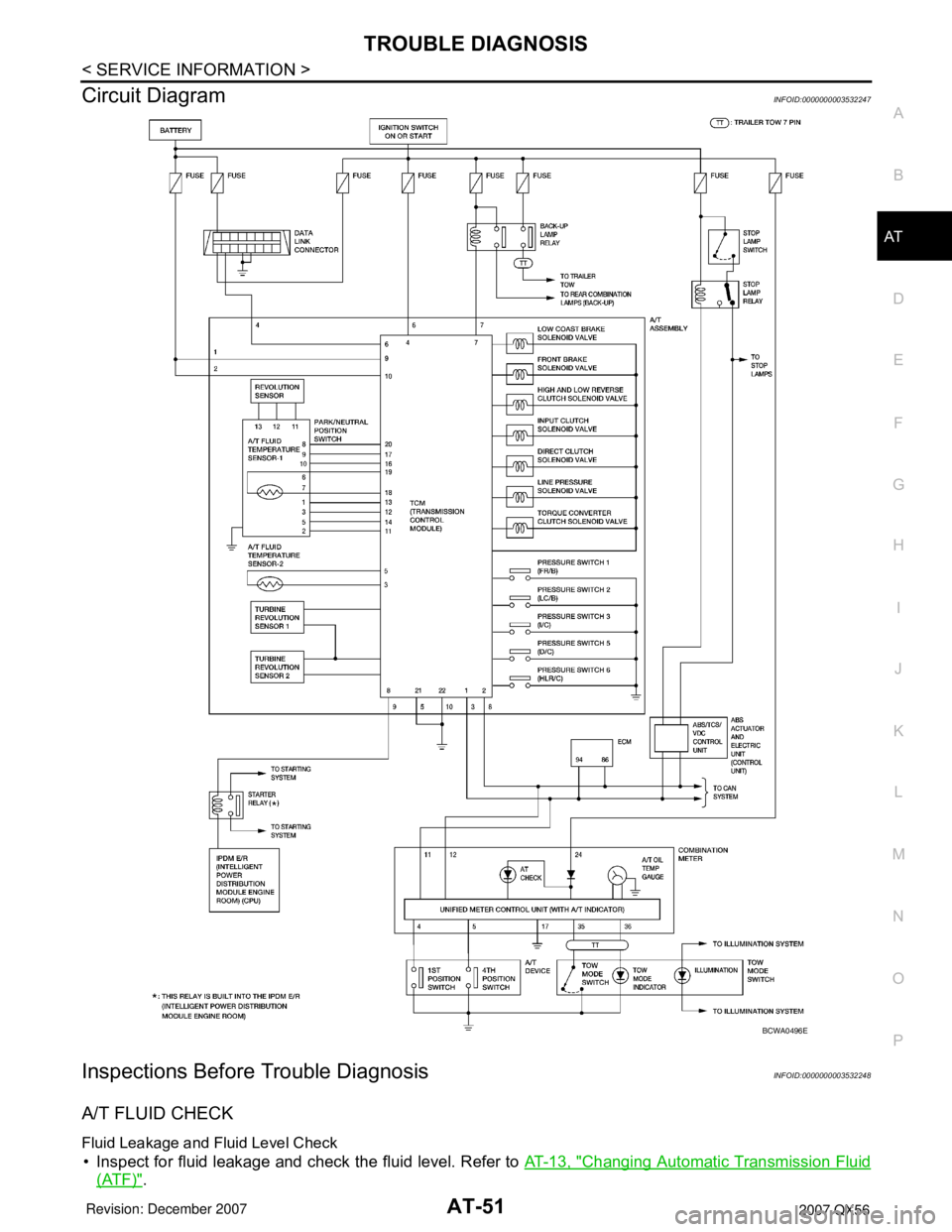

Circuit DiagramINFOID:0000000003532247

Inspections Before Trouble DiagnosisINFOID:0000000003532248

A/T FLUID CHECK

Fluid Leakage and Fluid Level Check

• Inspect for fluid leakage and check the fluid level. Refer to AT-13, "Changing Automatic Transmission Fluid

(ATF)".

BCWA0496E

Page 239 of 3061

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-169

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

Even though the selector lever is set in the “P” position, the parking mechanism is not actuated,

allowing the vehicle to be moved when it is pushed.

DIAGNOSTIC PROCEDURE

1.CHECK PNP SWITCH CIRCUIT

Perform self-diagnosis. Refer to AT-83, "

CONSULT-II Function (A/T)".

Do the self-diagnosis results indicate PNP switch?

YES >> Check the malfunctioning system. Refer to AT- 9 9.

NO >> GO TO 2.

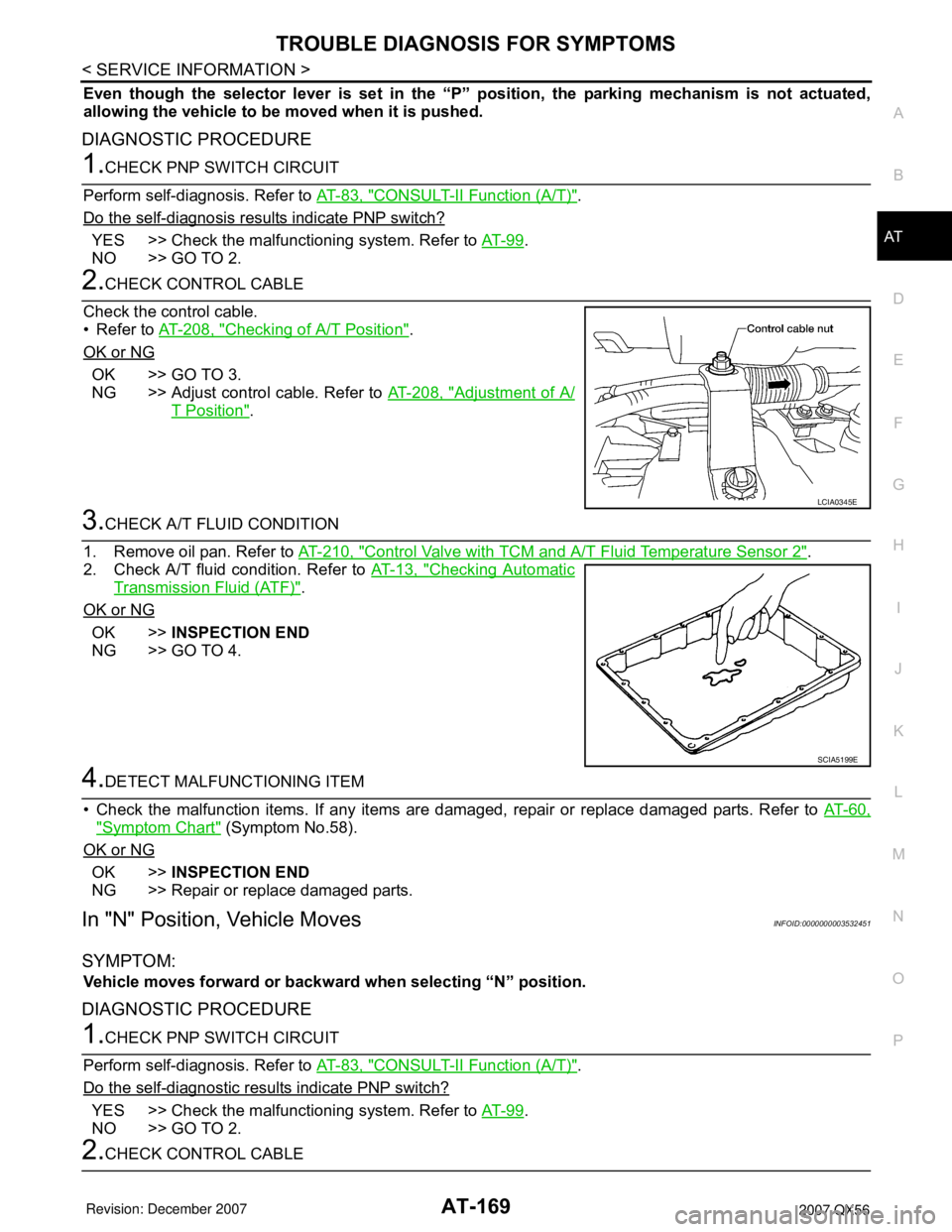

2.CHECK CONTROL CABLE

Check the control cable.

• Refer to AT-208, "

Checking of A/T Position".

OK or NG

OK >> GO TO 3.

NG >> Adjust control cable. Refer to AT-208, "

Adjustment of A/

T Position".

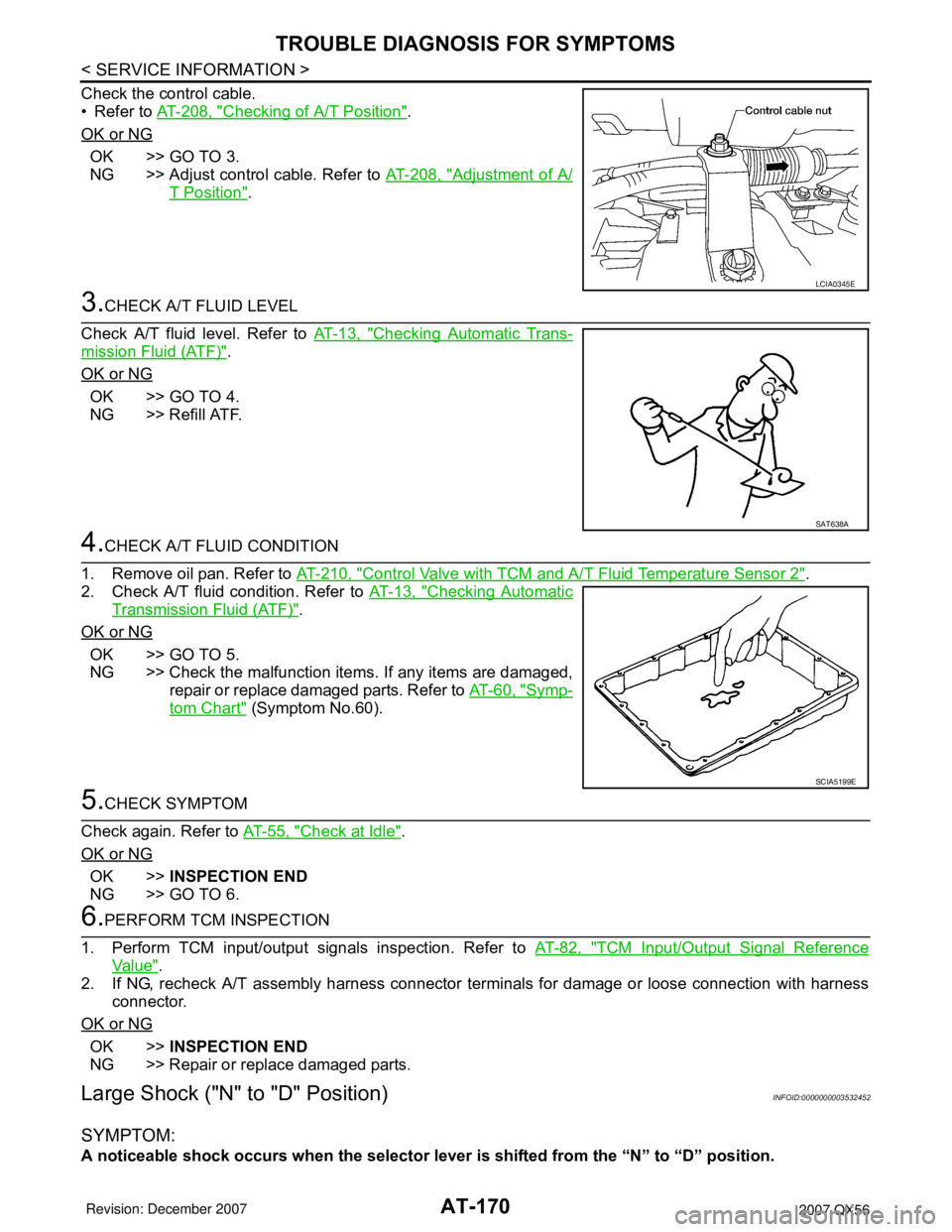

3.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sensor 2".

2. Check A/T fluid condition. Refer to AT-13, "

Checking Automatic

Transmission Fluid (ATF)".

OK or NG

OK >>INSPECTION END

NG >> GO TO 4.

4.DETECT MALFUNCTIONING ITEM

• Check the malfunction items. If any items are damaged, repair or replace damaged parts. Refer to AT-60,

"Symptom Chart" (Symptom No.58).

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

In "N" Position, Vehicle MovesINFOID:0000000003532451

SYMPTOM:

Vehicle moves forward or backward when selecting “N” position.

DIAGNOSTIC PROCEDURE

1.CHECK PNP SWITCH CIRCUIT

Perform self-diagnosis. Refer to AT-83, "

CONSULT-II Function (A/T)".

Do the self-diagnostic results indicate PNP switch?

YES >> Check the malfunctioning system. Refer to AT- 9 9.

NO >> GO TO 2.

2.CHECK CONTROL CABLE

LCIA0345E

SCIA5199E

Page 240 of 3061

AT-170

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

Check the control cable.

• Refer to AT-208, "

Checking of A/T Position".

OK or NG

OK >> GO TO 3.

NG >> Adjust control cable. Refer to AT-208, "

Adjustment of A/

T Position".

3.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT-13, "

Checking Automatic Trans-

mission Fluid (ATF)".

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature Sensor 2".

2. Check A/T fluid condition. Refer to AT-13, "

Checking Automatic

Transmission Fluid (ATF)".

OK or NG

OK >> GO TO 5.

NG >> Check the malfunction items. If any items are damaged,

repair or replace damaged parts. Refer to AT-60, "

Symp-

tom Chart" (Symptom No.60).

5.CHECK SYMPTOM

Check again. Refer to AT-55, "

Check at Idle".

OK or NG

OK >>INSPECTION END

NG >> GO TO 6.

6.PERFORM TCM INSPECTION

1. Perform TCM input/output signals inspection. Refer to AT-82, "

TCM Input/Output Signal Reference

Va l u e".

2. If NG, recheck A/T assembly harness connector terminals for damage or loose connection with harness

connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

Large Shock ("N" to "D" Position)INFOID:0000000003532452

SYMPTOM:

A noticeable shock occurs when the selector lever is shifted from the “N” to “D” position.

LCIA0345E

SAT638A

SCIA5199E