brake INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 350 of 3061

AT-280

< SERVICE INFORMATION >

ASSEMBLY

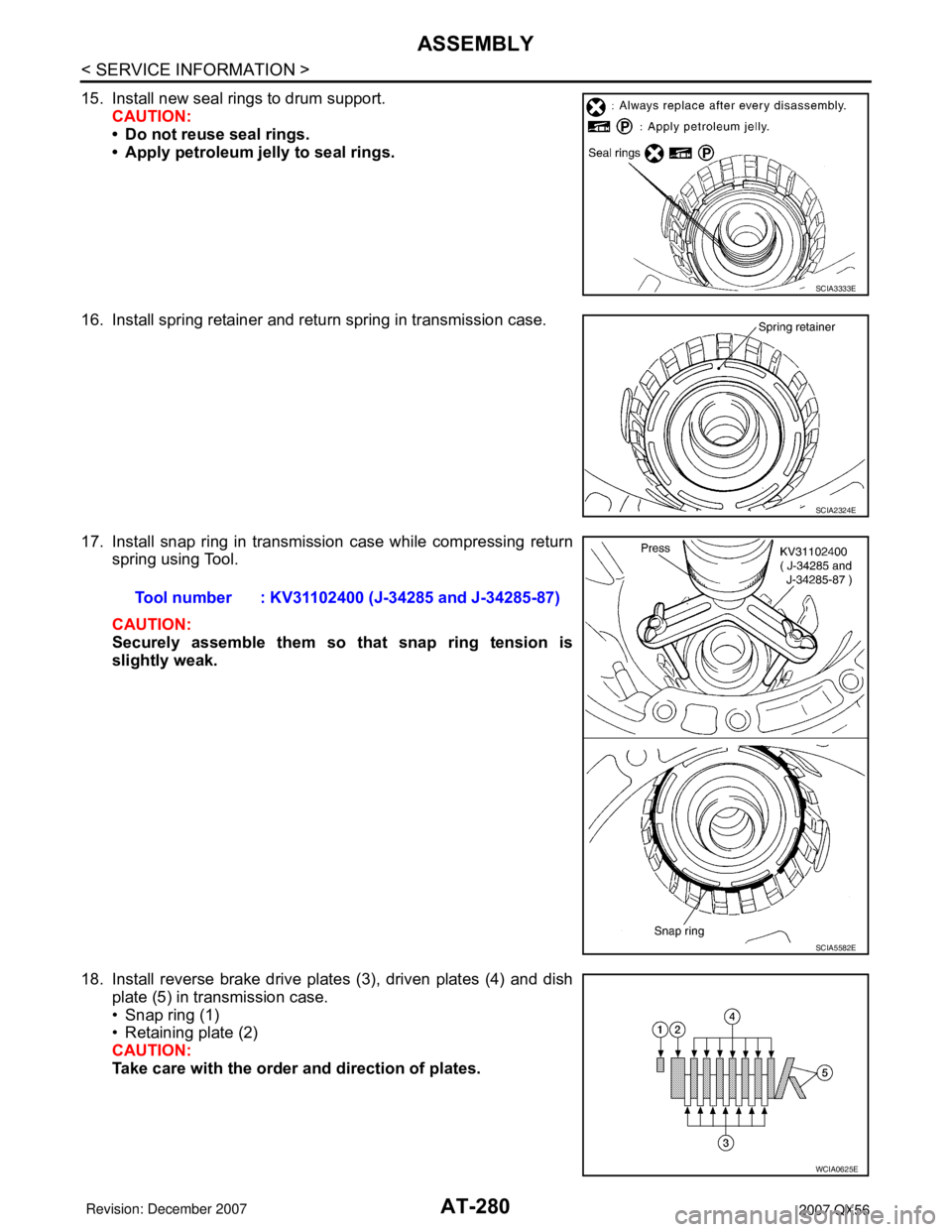

15. Install new seal rings to drum support.

CAUTION:

• Do not reuse seal rings.

• Apply petroleum jelly to seal rings.

16. Install spring retainer and return spring in transmission case.

17. Install snap ring in transmission case while compressing return

spring using Tool.

CAUTION:

Securely assemble them so that snap ring tension is

slightly weak.

18. Install reverse brake drive plates (3), driven plates (4) and dish

plate (5) in transmission case.

• Snap ring (1)

• Retaining plate (2)

CAUTION:

Take care with the order and direction of plates.

SCIA3333E

SCIA2324E

Tool number : KV31102400 (J-34285 and J-34285-87)

SCIA5582E

WCIA0625E

Page 351 of 3061

ASSEMBLY

AT-281

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

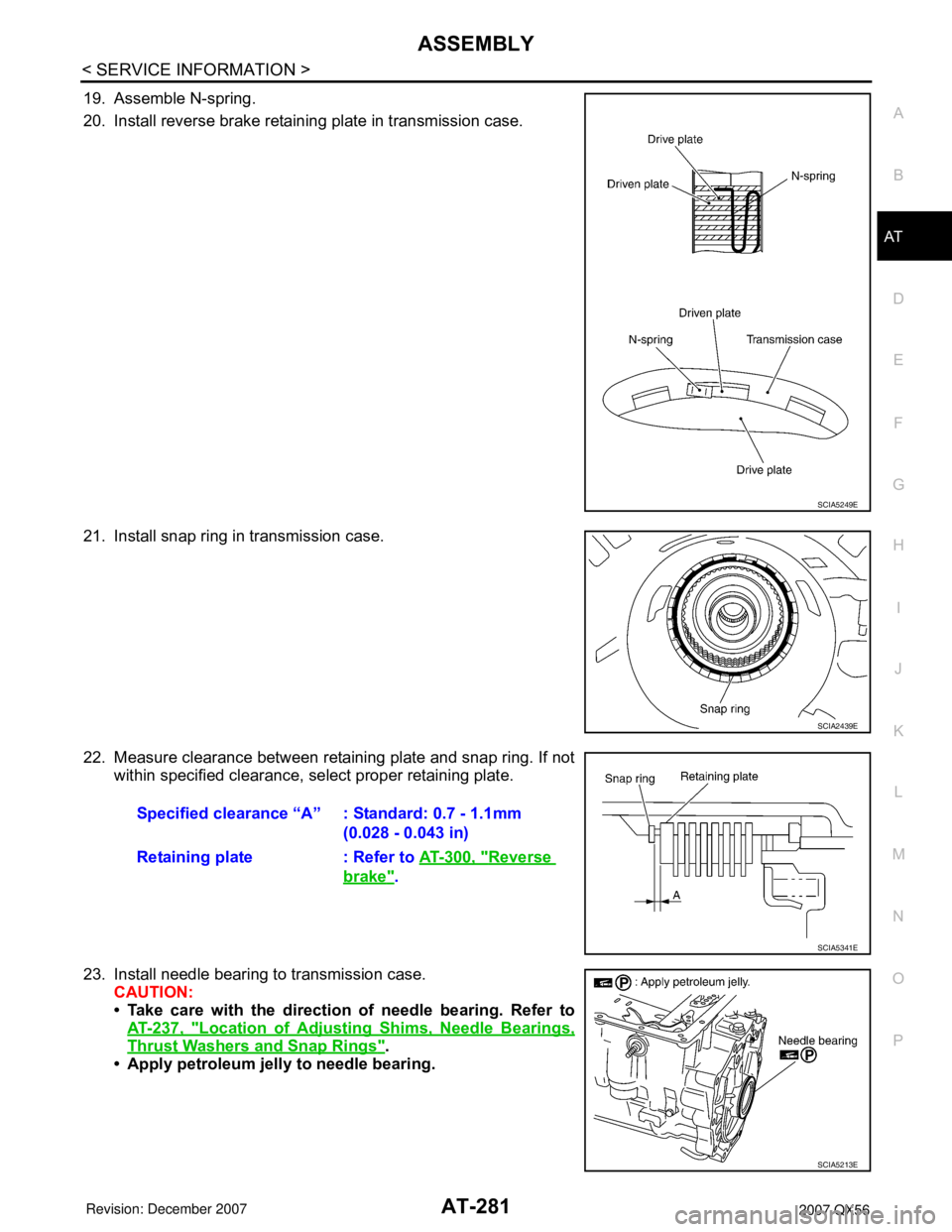

19. Assemble N-spring.

20. Install reverse brake retaining plate in transmission case.

21. Install snap ring in transmission case.

22. Measure clearance between retaining plate and snap ring. If not

within specified clearance, select proper retaining plate.

23. Install needle bearing to transmission case.

CAUTION:

• Take care with the direction of needle bearing. Refer to

AT-237, "

Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings".

• Apply petroleum jelly to needle bearing.

SCIA5249E

SCIA2439E

Specified clearance “A” : Standard: 0.7 - 1.1mm

(0.028 - 0.043 in)

Retaining plate : Refer to AT-300, "

Reverse

brake".

SCIA5341E

SCIA5213E

Page 356 of 3061

AT-286

< SERVICE INFORMATION >

ASSEMBLY

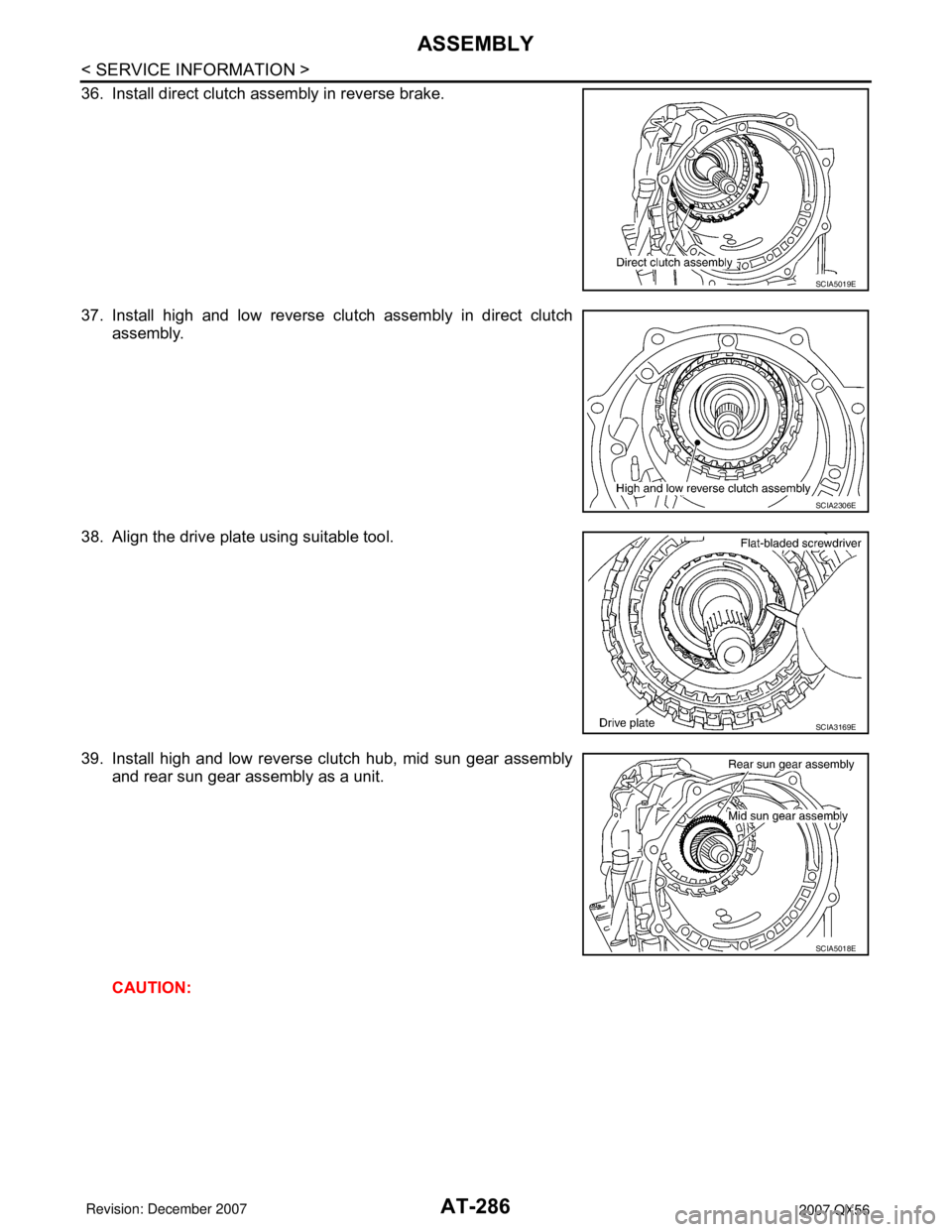

36. Install direct clutch assembly in reverse brake.

37. Install high and low reverse clutch assembly in direct clutch

assembly.

38. Align the drive plate using suitable tool.

39. Install high and low reverse clutch hub, mid sun gear assembly

and rear sun gear assembly as a unit.

CAUTION:

SCIA5019E

SCIA2306E

SCIA3169E

SCIA5018E

Page 359 of 3061

ASSEMBLY

AT-289

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

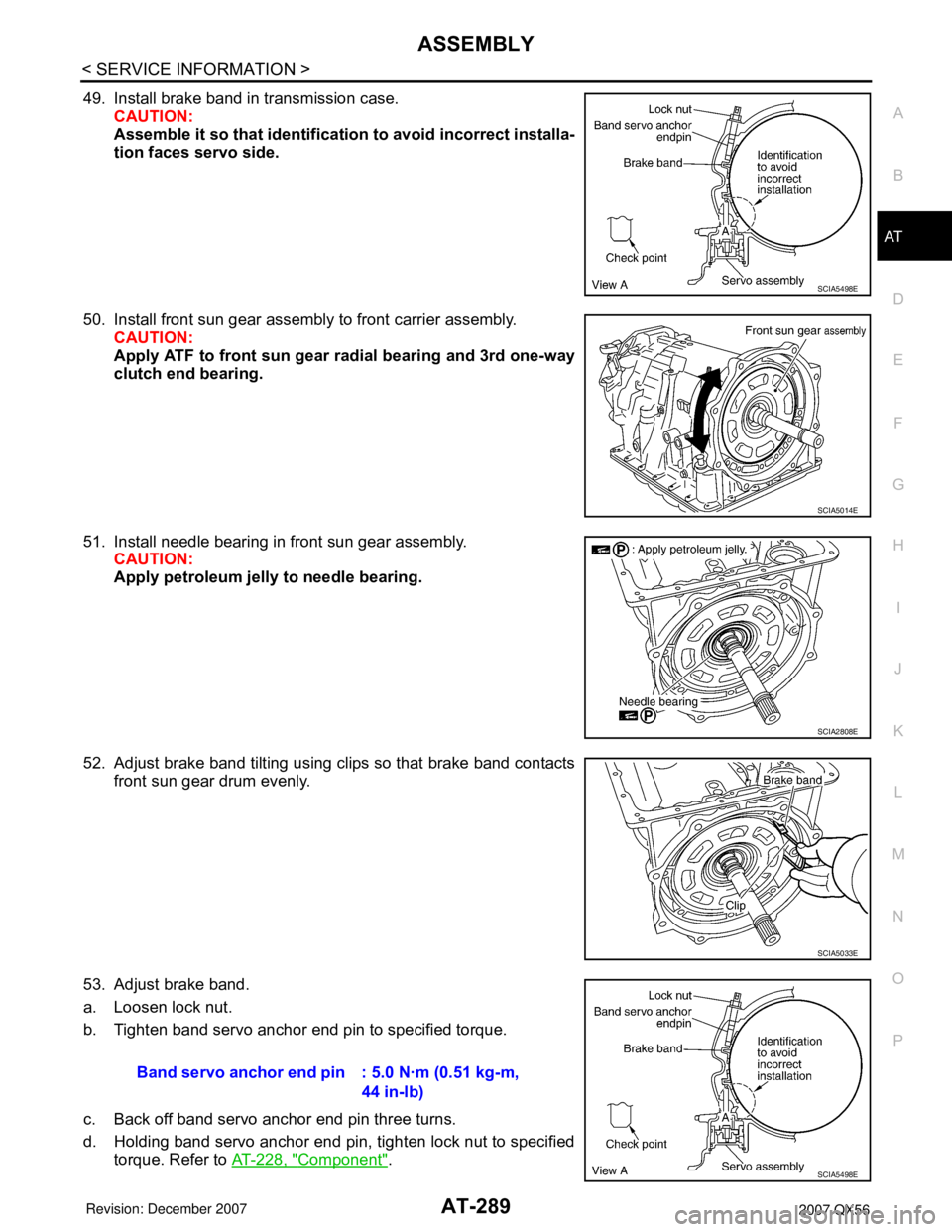

49. Install brake band in transmission case.

CAUTION:

Assemble it so that identification to avoid incorrect installa-

tion faces servo side.

50. Install front sun gear assembly to front carrier assembly.

CAUTION:

Apply ATF to front sun gear radial bearing and 3rd one-way

clutch end bearing.

51. Install needle bearing in front sun gear assembly.

CAUTION:

Apply petroleum jelly to needle bearing.

52. Adjust brake band tilting using clips so that brake band contacts

front sun gear drum evenly.

53. Adjust brake band.

a. Loosen lock nut.

b. Tighten band servo anchor end pin to specified torque.

c. Back off band servo anchor end pin three turns.

d. Holding band servo anchor end pin, tighten lock nut to specified

torque. Refer to AT-228, "

Component".

SCIA5498E

SCIA5014E

SCIA2808E

SCIA5033E

Band servo anchor end pin : 5.0 N·m (0.51 kg-m,

44 in-lb)

SCIA5498E

Page 363 of 3061

ASSEMBLY

AT-293

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

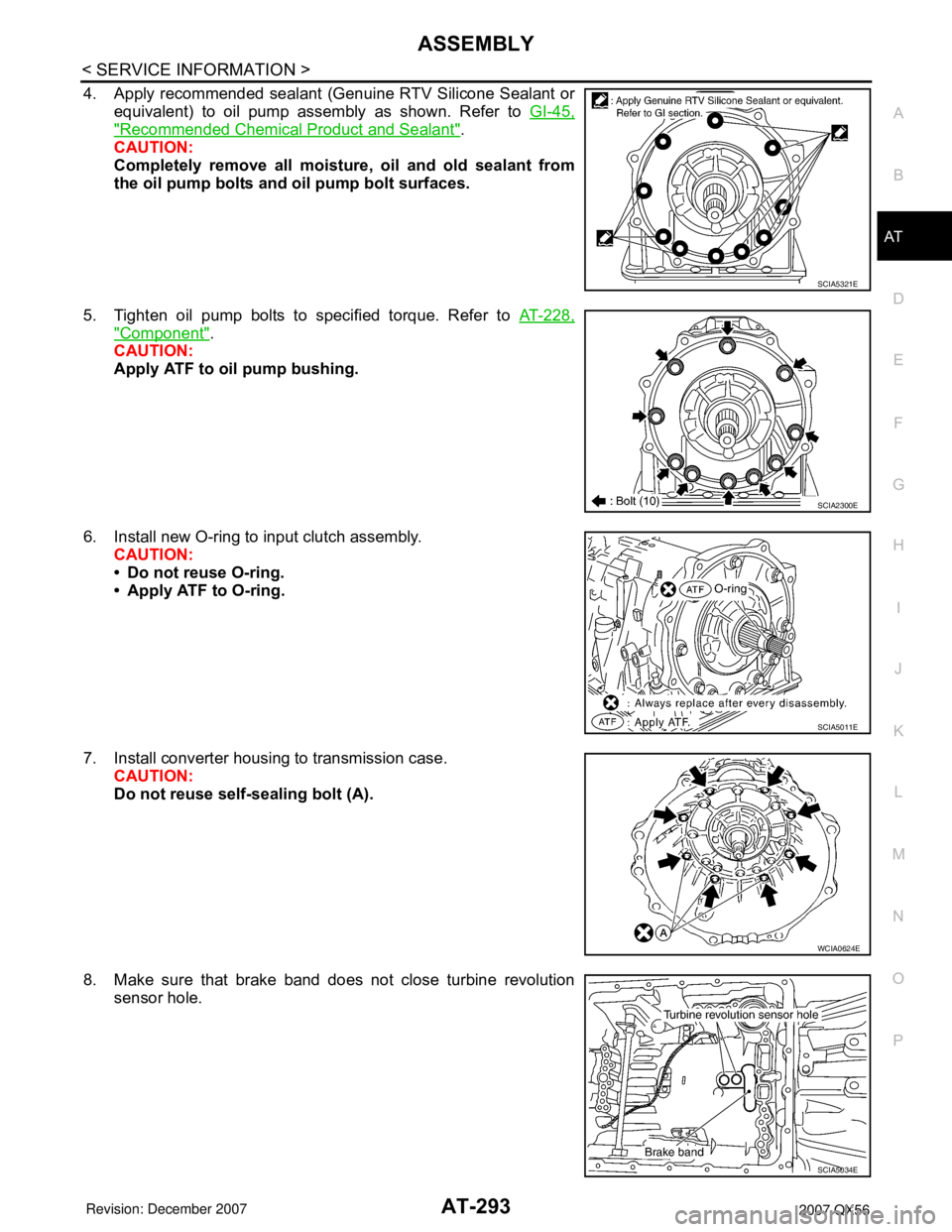

4. Apply recommended sealant (Genuine RTV Silicone Sealant or

equivalent) to oil pump assembly as shown. Refer to GI-45,

"Recommended Chemical Product and Sealant".

CAUTION:

Completely remove all moisture, oil and old sealant from

the oil pump bolts and oil pump bolt surfaces.

5. Tighten oil pump bolts to specified torque. Refer to AT-228,

"Component".

CAUTION:

Apply ATF to oil pump bushing.

6. Install new O-ring to input clutch assembly.

CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

7. Install converter housing to transmission case.

CAUTION:

Do not reuse self-sealing bolt (A).

8. Make sure that brake band does not close turbine revolution

sensor hole.

SCIA5321E

SCIA2300E

SCIA5011E

WCIA0624E

SCIA5034E

Page 370 of 3061

AT-300

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

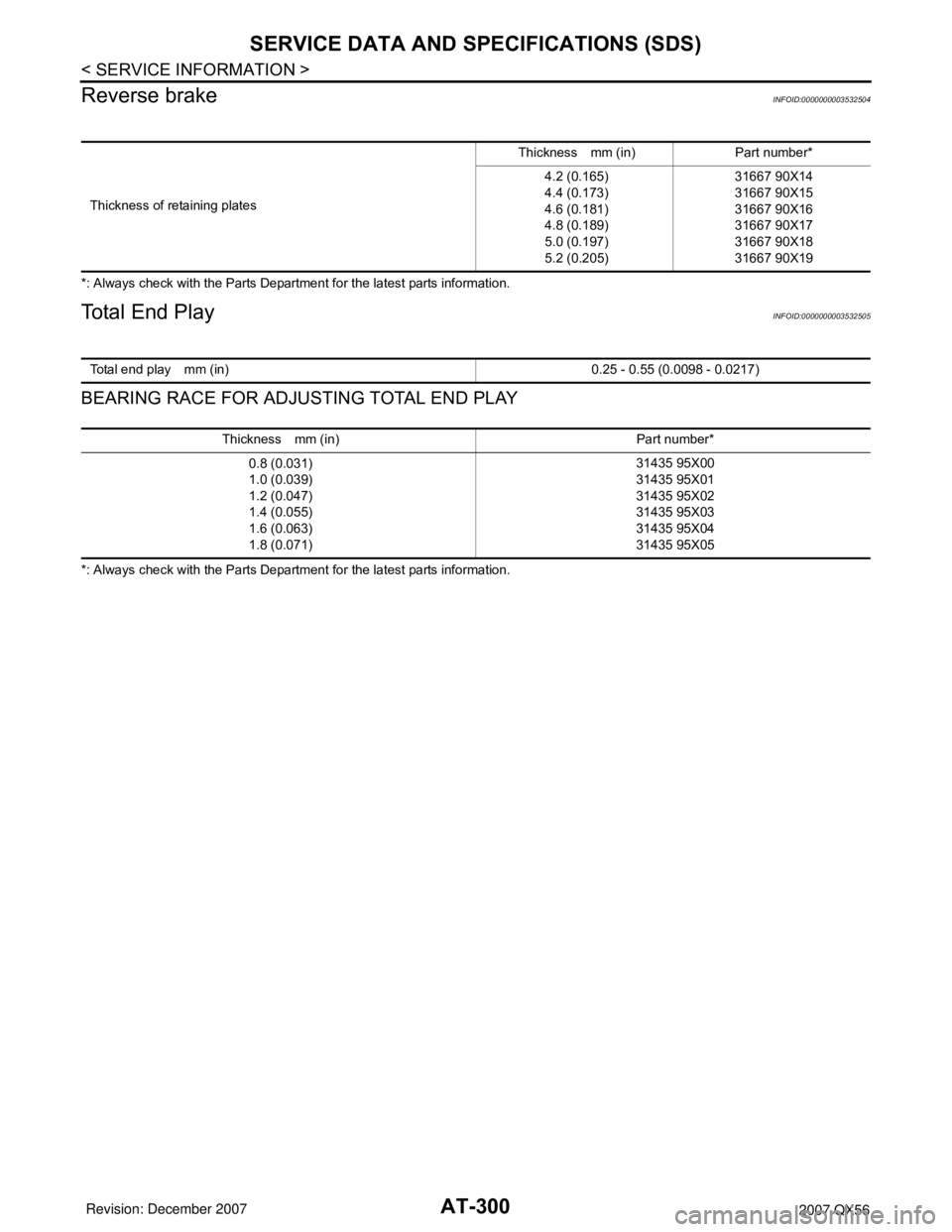

Reverse brake

INFOID:0000000003532504

*: Always check with the Parts Department for the latest parts information.

Total End PlayINFOID:0000000003532505

BEARING RACE FOR ADJUSTING TOTAL END PLAY

*: Always check with the Parts Department for the latest parts information.Thickness of retaining platesThickness mm (in) Part number*

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)

5.2 (0.205) 31667 90X14

31667 90X15

31667 90X16

31667 90X17

31667 90X18

31667 90X19

Total end play mm (in) 0.25 - 0.55 (0.0098 - 0.0217)

Thickness mm (in) Part number*

0.8 (0.031)

1.0 (0.039)

1.2 (0.047)

1.4 (0.055)

1.6 (0.063)

1.8 (0.071)31435 95X00

31435 95X01

31435 95X02

31435 95X03

31435 95X04

31435 95X05

Page 853 of 3061

BL-142

< SERVICE INFORMATION >

BODY REPAIR

6. 2nd crossmember assembly

7. Front upper link mounting bracket RH/LH

8. Panhard rod bracket reinforcement

9. Bound bumper bracket RH/LH

10. Front brake hose bracket RH/LH

11. Panhard rod reinforcement

12. 4th crossmember gusset RH/LH

13. 2nd cab mounting bracket RH/LH

14. 3rd cab mounting bracket RH/LH

15. 4th cab mounting reinforcement RH/LH

16. 4th cab mounting bracket RH/LH

17. Rear suspension mounting bracket RH/LH

18. Rear brake hose bracket

19. Rear shock absorber bracket assembly RH/LH

20. Rear bound bumper bracket RH/LH

21. Rear bracket bumper reinforcement RH/LH

22. Cab mounting bracket assembly RH/LH

23. 9th crossmember assembly

24. Exhaust bracket assembly

25. Canister bracket, LH

26. 7th crossmember reinforcement

27. 7th crossmember assembly

28. 6th crossmember assembly

29. 4th crossmember gusset RH/LH

30. 4th crossmember assembly

31. 3rd crossmember assembly

32. Frame assembly

Corrosion ProtectionINFOID:0000000003533007

DESCRIPTION

To provide improved corrosion prevention, the following anti-corrosive measures have been implemented in

NISSAN production plants. When repairing or replacing body panels, it is necessary to use the same anti-cor-

rosive measures.

ANTI-CORROSIVE PRECOATED STEEL (GALVANNEALED STEEL)

To improve repairability and corrosion resistance, a new type of anti-

corrosive precoated steel sheet has been adopted replacing conven-

tional zinc-coated steel sheet.

Galvannealed steel is electroplated and heated to form Zinc-iron

alloy, which provides excellent and long term corrosion resistance

with cationic electrode position primer.

Nissan Genuine Service Parts are fabricated from galvannealed steel. Therefore, it is recommended that

GENUINE NISSAN PARTS or equivalent be used for panel replacement to maintain the anti-corrosive perfor-

mance built into the vehicle at the factory.

PHOSPHATE COATING TREATMENT AND CATIONIC ELECTRODEPOSITION PRIMER

PIIA0093E

Page 899 of 3061

BR-1

BRAKES

C

D

E

G

H

I

J

K

L

M

SECTION BR

A

B

BR

N

O

P

CONTENTS

BRAKE SYSTEM

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

Precaution for Brake System ....................................2

PREPARATION ...................................................3

Special Service Tool .................................................3

Commercial Service Tool ..........................................3

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

4

NVH Troubleshooting Chart ......................................4

BRAKE PEDAL ...................................................5

Inspection and Adjustment ........................................5

Removal and Installation ...........................................6

BRAKE FLUID .....................................................8

On Board Inspection .................................................8

Drain and Refill ..........................................................8

Bleeding Brake System .............................................8

BRAKE PIPING AND HOSE ..............................10

Hydraulic Circuit ......................................................10

Removal and Installation of Front Brake Hose ........10

Removal and Installation of Rear Brake Hose ........11

Inspection After Installation .....................................12

BRAKE MASTER CYLINDER ............................13

On Board Inspection ...............................................13

Removal and Installation .........................................13

Disassembly and Assembly ....................................14

BRAKE BOOSTER ...........................................15

On-Vehicle Service ..................................................15

Removal and Installation .........................................15

VACUUM LINES ...............................................17

Removal and Installation .........................................17

Inspection ................................................................17

FRONT DISC BRAKE .......................................18

On-vehicle Inspection ..............................................18

Component ..............................................................18

Removal and Installation of Brake Pad ...................19

Removal and Installation of Brake Caliper and

Disc Rotor ................................................................

19

Disassembly and Assembly of Brake Caliper ..........20

REAR DISC BRAKE .........................................24

On-vehicle Inspection ..............................................24

Exploded View .........................................................24

Removal and Installation of Brake Pad ...................25

Removal and Installation of Brake Caliper and

Disc Rotor ................................................................

25

Brake Caliper ...........................................................26

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

29

General Specification ..............................................29

Brake Pedal .............................................................29

Brake Booster ..........................................................30

Check Valve ............................................................30

Front Disc Brake ......................................................30

Rear Disc Brake ......................................................30

Page 900 of 3061

BR-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003532717

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Brake SystemINFOID:0000000003532718

• Always use recommended brake fluid. Refer to MA-10 .

• Do not reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas.

• To clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use clean brake fluid.

• Do not use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

• Use flare nut wrench when removing and installing brake tube.

• Always check tightening torque when installing brake lines.

• Before working, turn ignition switch to OFF and disconnect con-

nectors for ABS actuator and electric unit (control unit) or battery

terminals.

• Burnish the brake contact surfaces after refinishing or replacing

drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage.

Refer to BR-20, "

Disassembly and Assembly of Brake Caliper" .

WARNING:

• Clean brake pads and shoes with a waste cloth, then wipe

with a dust collector.

SBR686C

Page 901 of 3061

PREPARATION

BR-3

< SERVICE INFORMATION >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

PREPARATION

Special Service ToolINFOID:0000000003532719

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000003532720

Tool number

(Kent-Moore No.)

Tool nameDescription

—

(J-46532)

Brake and clutch pedal height measure-

ment toolMeasuring brake pedal height

LFIA0227E

Tool nameDescription

1. Flare nut crowfoot

2. Torque wrenchRemoving and installing each brake pip-

ing.

a: 10 mm (0.39 in) / 12 mm (0.47 in)

Power toolRemoving nuts, bolts and screws.

S-NT360

PBIC0190E

PBIC0191E