check oil INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1842 of 3061

EM-72

< SERVICE INFORMATION >

CYLINDER HEAD

VALVE SEAT CONTACT

• After confirming that the dimensions of the valve guides and valves

are within specifications, perform this procedure.

• Apply prussian blue (or white lead) onto the contacting surface of

the valve seat to check the condition of the valve contact on the

surface.

• Check if the contact area band is continuous all around the circum-

ference.

• If not, grind to adjust the valve fit and check again. If the contacting

surface still has NG conditions even after the re-check, replace the

valve seat.

VALVE SEAT REPLACEMENT

When the valve seat is removed, replace it with oversized (0.5 mm, 0.020 in) valve seat.

1. Bore out the old seat until it collapses. Boring should not continue beyond the bottom face of the seat

recess in the cylinder head. Set the machine depth stop to ensure this.

2. Ream the cylinder head recess diameter for service valve seat.

• Be sure to ream in circles concentric to the valve guide center.

• This will enable valve seat to fit correctly.

3. Heat the cylinder head to 110° to 130°C (230° to 266°F) by

soaking it in heated oil.

4. Cool the valve seats well with dry ice. Force fit the valve seat into the cylinder head.

CAUTION:

• Avoid directly touching cold valve seats.

• Cylinder head contains heat. When working, wear protective equipment to avoid getting burned.

5. Finish the seat to the specified dimensions using suitable tool.

Refer to EM-103, "

Standard and Limit".

CAUTION:

When using valve seat cutter, firmly grip the cutter handle

with both hands. Then, press on the contacting surface all

around the circumference to cut in a single drive. Improper

pressure on the cutter or cutting many different times may

result in stage valve seat.

SBIA0322E

Oversize [0.5 mm (0.020 in)] (Service):

Intake : 38.500 - 38.516 mm (1.5157 - 1.5164 in)

Exhaust : 32.700 - 32.716 mm (1.2874 - 1.2880 in)

SEM795A

SEM008A

SEM934C

Page 1845 of 3061

ENGINE ASSEMBLY

EM-75

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

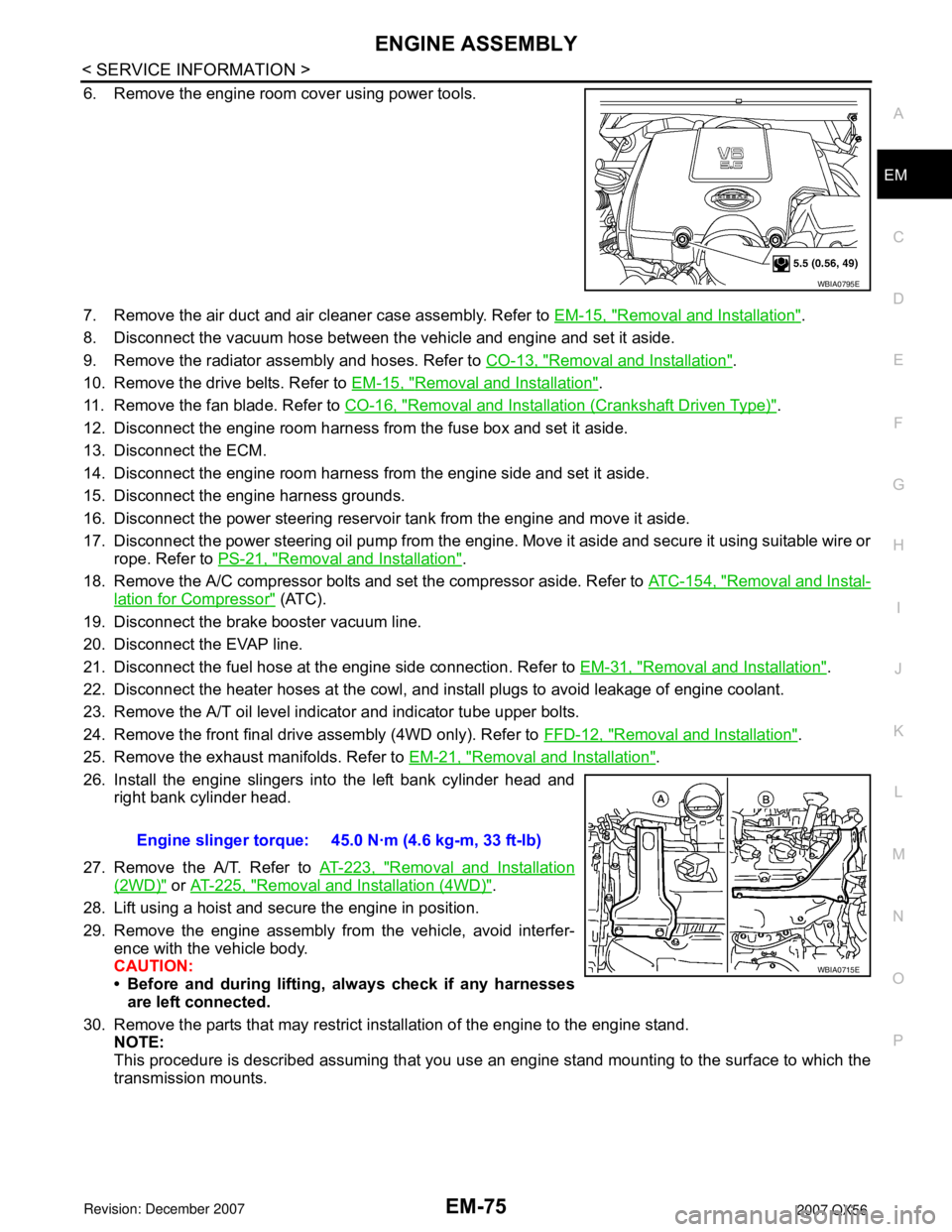

6. Remove the engine room cover using power tools.

7. Remove the air duct and air cleaner case assembly. Refer to EM-15, "

Removal and Installation".

8. Disconnect the vacuum hose between the vehicle and engine and set it aside.

9. Remove the radiator assembly and hoses. Refer to CO-13, "

Removal and Installation".

10. Remove the drive belts. Refer to EM-15, "

Removal and Installation".

11. Remove the fan blade. Refer to CO-16, "

Removal and Installation (Crankshaft Driven Type)".

12. Disconnect the engine room harness from the fuse box and set it aside.

13. Disconnect the ECM.

14. Disconnect the engine room harness from the engine side and set it aside.

15. Disconnect the engine harness grounds.

16. Disconnect the power steering reservoir tank from the engine and move it aside.

17. Disconnect the power steering oil pump from the engine. Move it aside and secure it using suitable wire or

rope. Refer to PS-21, "

Removal and Installation".

18. Remove the A/C compressor bolts and set the compressor aside. Refer to ATC-154, "

Removal and Instal-

lation for Compressor" (ATC).

19. Disconnect the brake booster vacuum line.

20. Disconnect the EVAP line.

21. Disconnect the fuel hose at the engine side connection. Refer to EM-31, "

Removal and Installation".

22. Disconnect the heater hoses at the cowl, and install plugs to avoid leakage of engine coolant.

23. Remove the A/T oil level indicator and indicator tube upper bolts.

24. Remove the front final drive assembly (4WD only). Refer to FFD-12, "

Removal and Installation".

25. Remove the exhaust manifolds. Refer to EM-21, "

Removal and Installation".

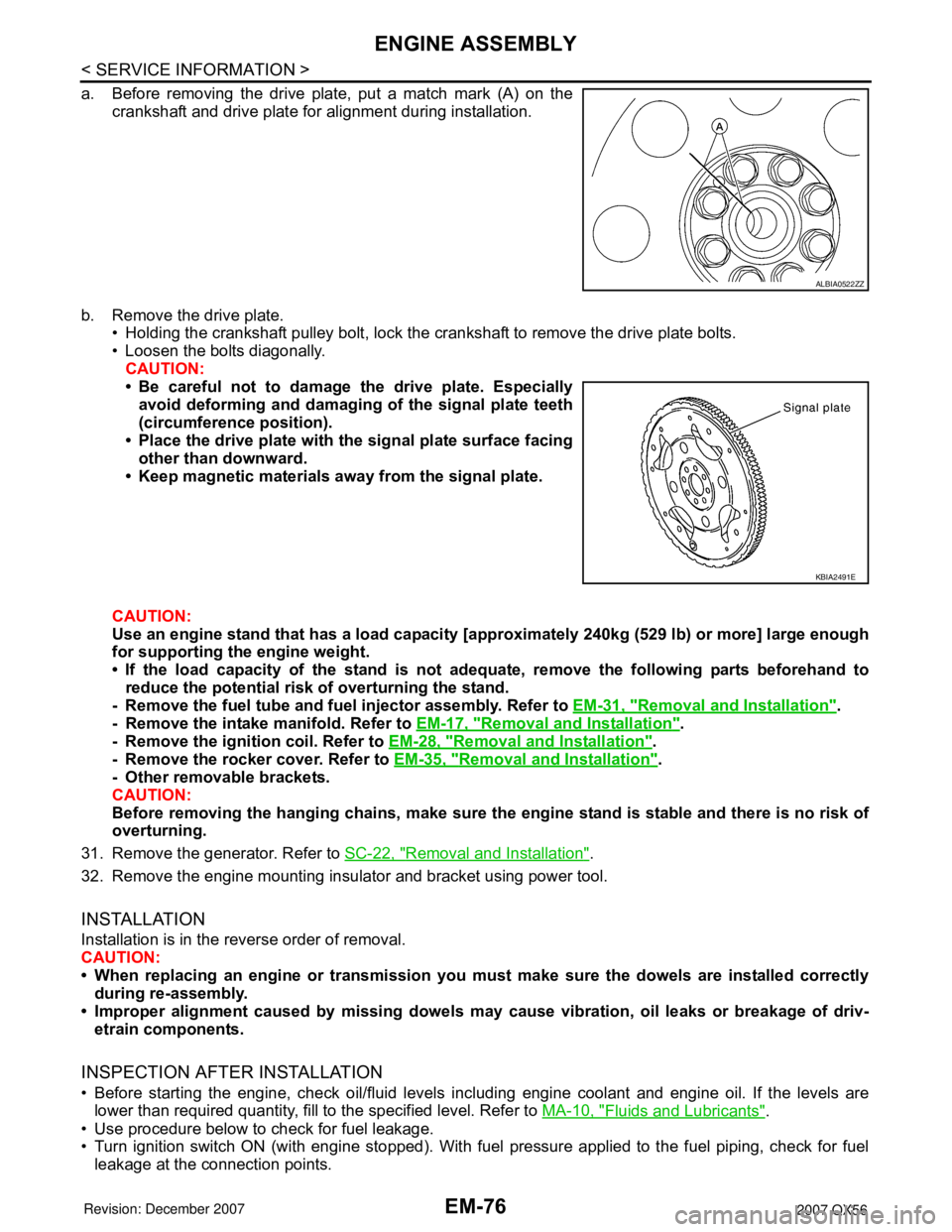

26. Install the engine slingers into the left bank cylinder head and

right bank cylinder head.

27. Remove the A/T. Refer to AT-223, "

Removal and Installation

(2WD)" or AT-225, "Removal and Installation (4WD)".

28. Lift using a hoist and secure the engine in position.

29. Remove the engine assembly from the vehicle, avoid interfer-

ence with the vehicle body.

CAUTION:

• Before and during lifting, always check if any harnesses

are left connected.

30. Remove the parts that may restrict installation of the engine to the engine stand.

NOTE:

This procedure is described assuming that you use an engine stand mounting to the surface to which the

transmission mounts.

WBIA0795E

Engine slinger torque: 45.0 N·m (4.6 kg-m, 33 ft-lb)

WBIA0715E

Page 1846 of 3061

EM-76

< SERVICE INFORMATION >

ENGINE ASSEMBLY

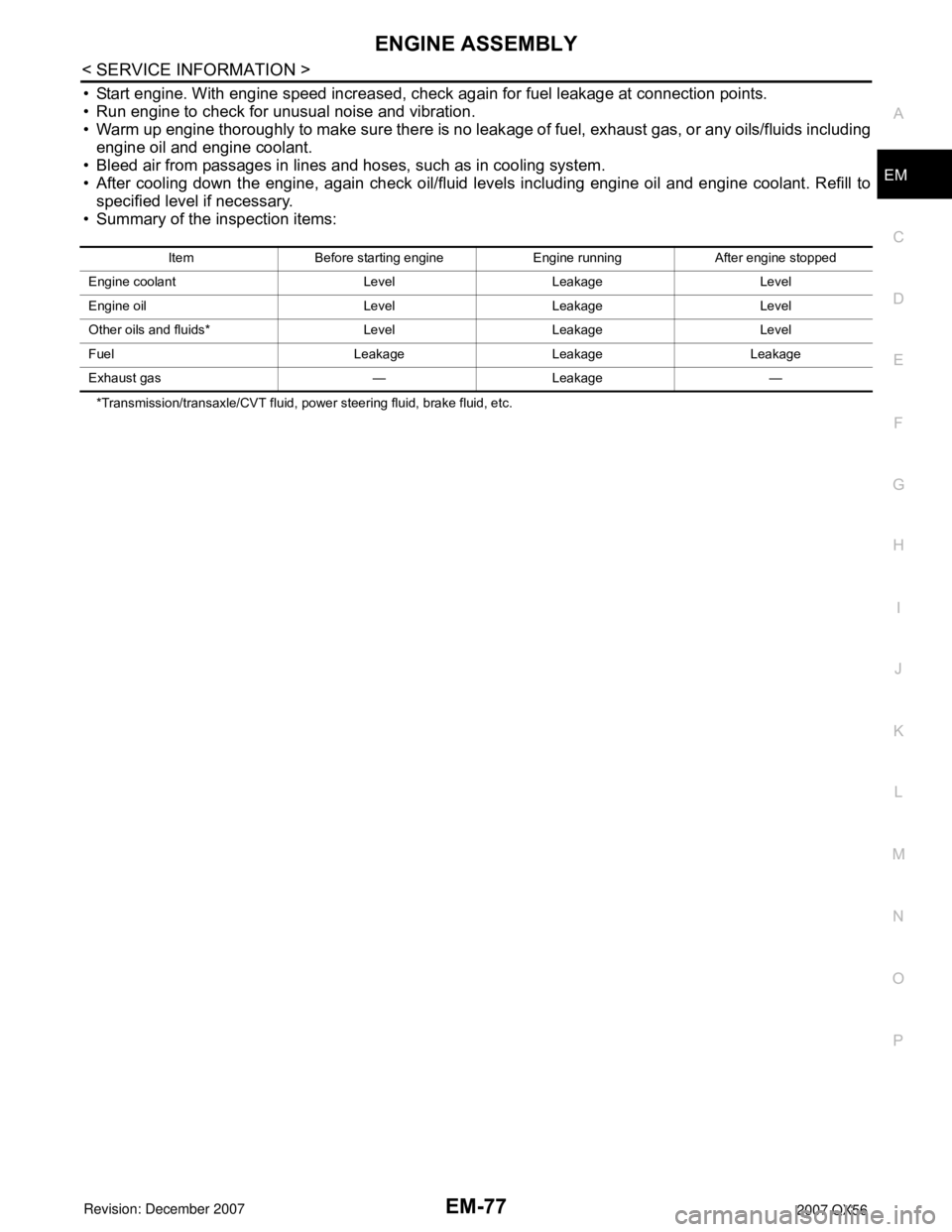

a. Before removing the drive plate, put a match mark (A) on the

crankshaft and drive plate for alignment during installation.

b. Remove the drive plate.

• Holding the crankshaft pulley bolt, lock the crankshaft to remove the drive plate bolts.

• Loosen the bolts diagonally.

CAUTION:

• Be careful not to damage the drive plate. Especially

avoid deforming and damaging of the signal plate teeth

(circumference position).

• Place the drive plate with the signal plate surface facing

other than downward.

• Keep magnetic materials away from the signal plate.

CAUTION:

Use an engine stand that has a load capacity [approximately 240kg (529 lb) or more] large enough

for supporting the engine weight.

• If the load capacity of the stand is not adequate, remove the following parts beforehand to

reduce the potential risk of overturning the stand.

- Remove the fuel tube and fuel injector assembly. Refer to EM-31, "

Removal and Installation".

- Remove the intake manifold. Refer to EM-17, "

Removal and Installation".

- Remove the ignition coil. Refer to EM-28, "

Removal and Installation".

- Remove the rocker cover. Refer to EM-35, "

Removal and Installation".

- Other removable brackets.

CAUTION:

Before removing the hanging chains, make sure the engine stand is stable and there is no risk of

overturning.

31. Remove the generator. Refer to SC-22, "

Removal and Installation".

32. Remove the engine mounting insulator and bracket using power tool.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• When replacing an engine or transmission you must make sure the dowels are installed correctly

during re-assembly.

• Improper alignment caused by missing dowels may cause vibration, oil leaks or breakage of driv-

etrain components.

INSPECTION AFTER INSTALLATION

• Before starting the engine, check oil/fluid levels including engine coolant and engine oil. If the levels are

lower than required quantity, fill to the specified level. Refer to MA-10, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to the fuel piping, check for fuel

leakage at the connection points.

ALBIA0522ZZ

KBIA2491E

Page 1847 of 3061

ENGINE ASSEMBLY

EM-77

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

• Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down the engine, again check oil/fluid levels including engine oil and engine coolant. Refill to

specified level if necessary.

• Summary of the inspection items:

*Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level

Other oils and fluids* Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gas — Leakage —

Page 1849 of 3061

CYLINDER BLOCK

EM-79

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

DISASSEMBLY

NOTE:

Explained here is how to disassemble with engine stand supporting transmission surface. When using differ-

ent type of engine stand, some steps may be different.

1. Remove engine assembly and mount to engine stand. Refer to EM-74, "

Removal and Installation".

CAUTION:

Before removing the hanging chains, make sure engine stand is stable and there is no risk of over-

turning.

2. Drain engine oil. Refer to LU-9, "

Changing Engine Oil".

3. Drain engine coolant by removing the cylinder block drain plugs

“A”, “B”, “C” and “D” as shown.

4. Remove the following components and associated parts (the parts referred to in step 1 are not included

here).

• Oil pan (upper and lower) and oil strainer. Refer to EM-24, "

Removal and Installation".

• Crankshaft pulley, front cover and timing chain. Refer to EM-38, "

Removal and Installation".

• Camshaft. Refer to EM-46, "

Removal and Installation".

• Cylinder head. Refer to EM-65, "

Removal and Installation".

5. Remove knock sensor and sub harness.

CAUTION:

Carefully handle sensor, avoiding shocks.

6. Check connecting rod side clearance. Refer to EM-93, "

Inspection After Disassembly".

7. Remove piston and connecting rod assembly as follows.

a. Position the crankshaft pin corresponding to the connecting rod to be removed onto bottom dead center.

b. Remove connecting rod cap.

22. Drive plate 23. Reinforcement plate 24. Rear oil seal retainer

25. Rear oil seal 26. Transmission 27. O-ring

28. Crankshaft position sensor (POS) 29. Gasket 30. Cylinder block heater

31. Connector cap

WBIA0419E

KBIA2549E

Page 1853 of 3061

CYLINDER BLOCK

EM-83

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

6. Install main bearing caps.

• Align the identification number to the journal position to install.

• Install it with the front mark (indicated by the arrow) facing the

front of engine.

• Tap caps lightly to seat them in the installation position.

7. Follow the steps below to tighten each main bearing cap bolt.

a. Apply engine oil to threads and seating surfaces of bolts, and

tighten all bolts temporarily.

b. Measure tightening angle using Tool.

CAUTION:

Measure tightening angle using Tool. Do not measure visu-

ally.

• Rotate crankshaft by hand after bolts are tightened. Check if it rotates smoothly.

• Check crankshaft side clearance. Refer to EM-93, "

Inspection After Disassembly".

8. Install rear oil seal to rear oil seal retainer.

CAUTION:

Do not damage or scratch outer circumference of oil seal.

• Install new rear oil seal in the direction shown.

KBIA2533E

Main bearing cap bolts in

order of 1 to 10: 39.2 N·m (4.0 kg-m, 29 ft.-lb)

Main bearing cap sub

bolts in order of 11 to 20: 29.4 N·m (3.0 kg-m, 22 ft-lb)

PBIC0090E

Tool number : KV10112100 (BT-8653-A)

Main bearing cap bolts in

order of 1 to 10: 40°

Main bearing cap sub bolts

in order of 11 to 20: 30°

Side bolts in order of 21 to

30: 49 N·m (5.0 kg-m, 36 ft-lb)

WBIA0597E

SEM715A

Page 1855 of 3061

CYLINDER BLOCK

EM-85

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

12. Install the connecting rod bearings to the connecting rod and

connecting rod cap.

• When installing the connecting rod bearings, apply engine oil

to the bearing surface (inside). Do not apply oil to the back

surface, but thoroughly clean it.

• When installing, align the connecting rod bearing stopper pro-

trusion with the cutout of the connecting rod to install.

• Check that the oil holes on the connecting rod and those on

the corresponding bearing are aligned.

13. Install the piston and connecting rod assembly to the crankshaft

using Tool.

• Position the crankshaft pin corresponding to the connecting

rod to be installed onto bottom dead center.

• Apply engine oil sufficiently to the cylinder bore, piston, and

crankshaft pin.

• Match the cylinder position with the cylinder No. on the con-

necting rod to install.

• Install the piston with the front mark on the piston crown facing

the front of the engine.

CAUTION:

Be careful not to damage the crankshaft pin, resulting from an interference of the connecting rod

big end.

14. Install connecting rod cap.

• Match the stamped cylinder number marks on the connecting

rod with those on the cylinder cap to install.

15. Tighten connecting rod bolts using Tool.

• Apply engine oil to threads and seats of connecting rod bolts.

• After tightening bolts, make sure the crankshaft rotates

smoothly.

• Check connecting rod side clearance. Refer to EM-93,

"Inspection After Disassembly".

PBIC0266E

Tool number : EM03470000 (J-8037)

WBIA0626E

KBIA2536E

Tool number : KV10112100 (BT-8653-A)

Connecting rod bolts

Step 1 : 19.6 N·m (1.5 kg-m, 11 ft-lb)

Step 2 : 90° clockwise

WBIA0627E

Page 1865 of 3061

CYLINDER BLOCK

EM-95

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

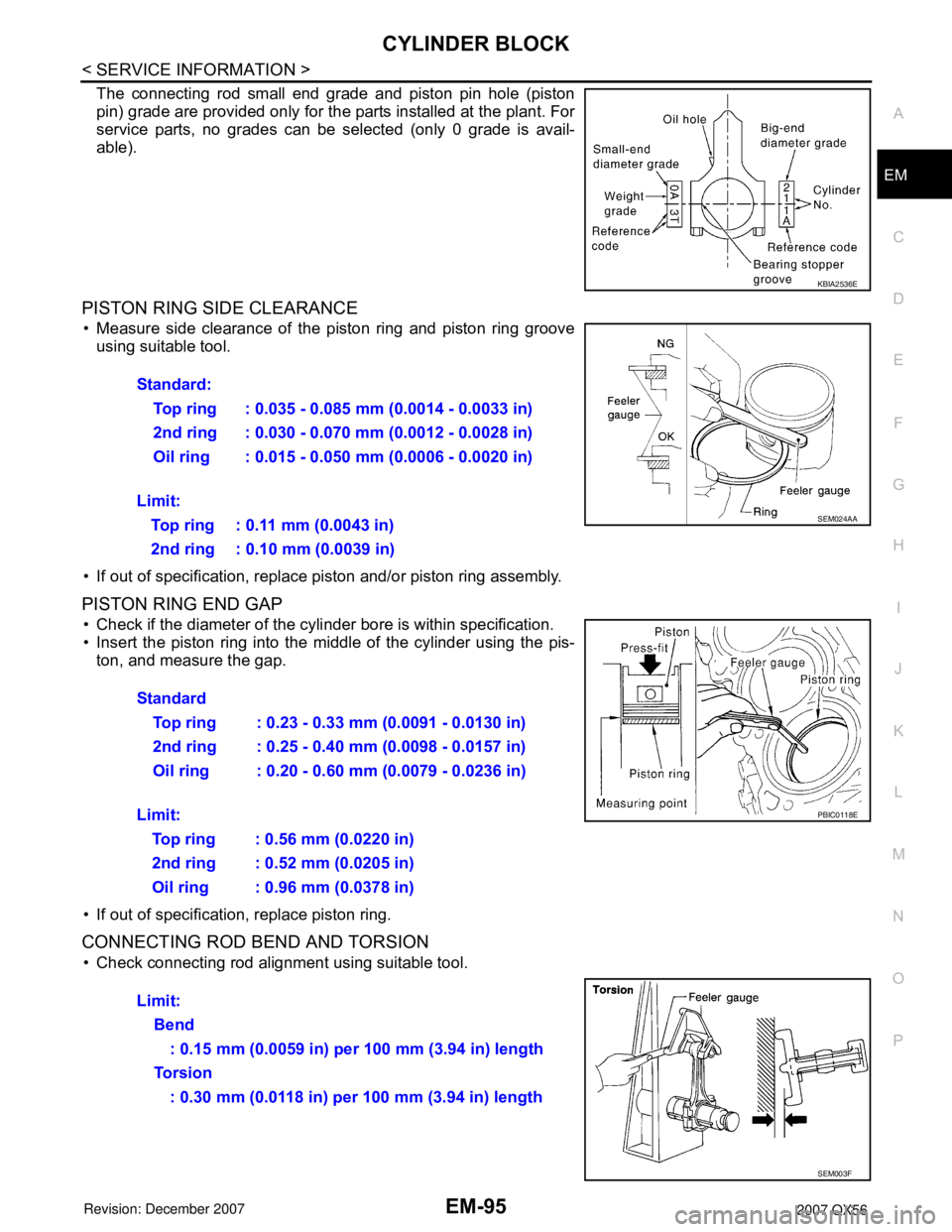

The connecting rod small end grade and piston pin hole (piston

pin) grade are provided only for the parts installed at the plant. For

service parts, no grades can be selected (only 0 grade is avail-

able).

PISTON RING SIDE CLEARANCE

• Measure side clearance of the piston ring and piston ring groove

using suitable tool.

• If out of specification, replace piston and/or piston ring assembly.

PISTON RING END GAP

• Check if the diameter of the cylinder bore is within specification.

• Insert the piston ring into the middle of the cylinder using the pis-

ton, and measure the gap.

• If out of specification, replace piston ring.

CONNECTING ROD BEND AND TORSION

• Check connecting rod alignment using suitable tool.

KBIA2536E

Standard:

Top ring : 0.035 - 0.085 mm (0.0014 - 0.0033 in)

2nd ring : 0.030 - 0.070 mm (0.0012 - 0.0028 in)

Oil ring : 0.015 - 0.050 mm (0.0006 - 0.0020 in)

Limit:

Top ring : 0.11 mm (0.0043 in)

2nd ring : 0.10 mm (0.0039 in)

SEM024AA

Standard

Top ring : 0.23 - 0.33 mm (0.0091 - 0.0130 in)

2nd ring : 0.25 - 0.40 mm (0.0098 - 0.0157 in)

Oil ring : 0.20 - 0.60 mm (0.0079 - 0.0236 in)

Limit:

Top ring : 0.56 mm (0.0220 in)

2nd ring : 0.52 mm (0.0205 in)

Oil ring : 0.96 mm (0.0378 in)

PBIC0118E

Limit:

Bend

: 0.15 mm (0.0059 in) per 100 mm (3.94 in) length

To r s i o n

: 0.30 mm (0.0118 in) per 100 mm (3.94 in) length

SEM003F

Page 1893 of 3061

DRIVE SHAFT

FAX-7

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

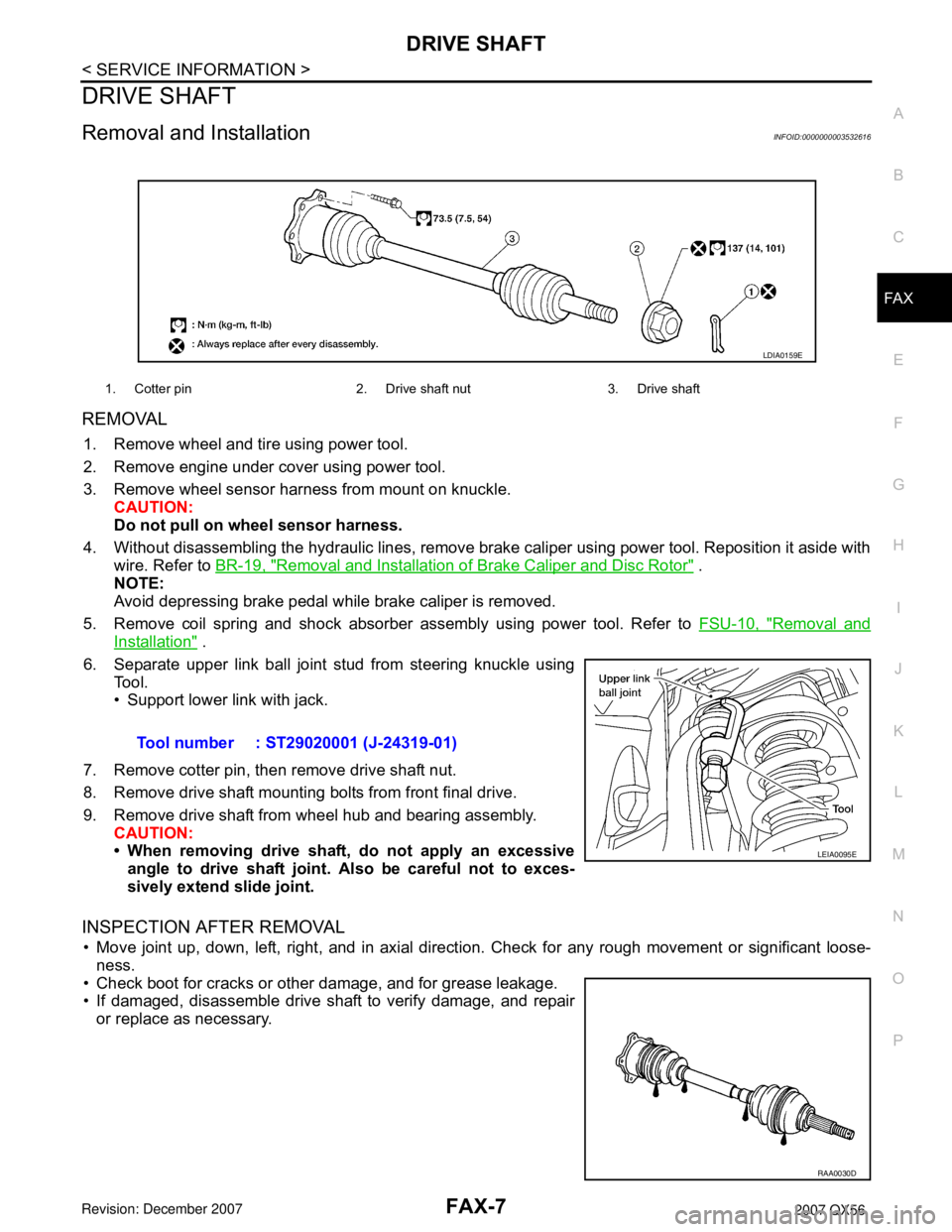

DRIVE SHAFT

Removal and InstallationINFOID:0000000003532616

REMOVAL

1. Remove wheel and tire using power tool.

2. Remove engine under cover using power tool.

3. Remove wheel sensor harness from mount on knuckle.

CAUTION:

Do not pull on wheel sensor harness.

4. Without disassembling the hydraulic lines, remove brake caliper using power tool. Reposition it aside with

wire. Refer to BR-19, "

Removal and Installation of Brake Caliper and Disc Rotor" .

NOTE:

Avoid depressing brake pedal while brake caliper is removed.

5. Remove coil spring and shock absorber assembly using power tool. Refer to FSU-10, "

Removal and

Installation" .

6. Separate upper link ball joint stud from steering knuckle using

Tool.

• Support lower link with jack.

7. Remove cotter pin, then remove drive shaft nut.

8. Remove drive shaft mounting bolts from front final drive.

9. Remove drive shaft from wheel hub and bearing assembly.

CAUTION:

• When removing drive shaft, do not apply an excessive

angle to drive shaft joint. Also be careful not to exces-

sively extend slide joint.

INSPECTION AFTER REMOVAL

• Move joint up, down, left, right, and in axial direction. Check for any rough movement or significant loose-

ness.

• Check boot for cracks or other damage, and for grease leakage.

• If damaged, disassemble drive shaft to verify damage, and repair

or replace as necessary.

1. Cotter pin 2. Drive shaft nut 3. Drive shaft

LDIA0159E

Tool number : ST29020001 (J-24319-01)

LEIA0095E

RAA0030D

Page 1900 of 3061

FFD-1

DRIVELINE/AXLE

C

E

F

G

H

I

J

K

L

M

SECTION FFD

A

B

FFD

N

O

P

CONTENTS

FRONT FINAL DRIVE

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Servicing Front Final Drive ................2

PREPARATION ...................................................3

Special Service Tool .................................................3

Commercial Service Tool ..........................................5

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

6

NVH Troubleshooting Chart ......................................6

DIFFERENTIAL GEAR OIL .................................7

Changing Differential Gear Oil ..................................7

Checking Differential Gear Oil ...................................7

FRONT OIL SEAL ..............................................8

Removal and Installation ..........................................8

SIDE OIL SEAL .................................................10

Removal and Installation .........................................10

CARRIER COVER .............................................11

Removal and Installation .........................................11

FRONT FINAL DRIVE ASSEMBLY ..................12

Removal and Installation .........................................12

Disassembly and Assembly .....................................13

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

31

General Specification ..............................................31

Inspection and Adjustment ......................................31