check oil INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1967 of 3061

GI-1

GENERAL INFORMATION

C

D

E

F

G

H

I

J

K

L

MB

GI

SECTION GI

N

O

P

CONTENTS

GENERAL INFORMATION

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Description ................................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

Precaution for NVIS/IVIS (NISSAN/INFINITI VE-

HICLE IMMOBILIZER SYSTEM - NATS) (If

Equipped) ..................................................................

2

General Precaution ...................................................3

Precaution for Three Way Catalyst ...........................4

Precaution for Fuel (Unleaded Premium Gasoline

Required) ..................................................................

4

Precaution for Multiport Fuel Injection System or

Engine Control System .............................................

5

Precaution for Hoses .................................................5

Precaution for Engine Oils ........................................6

Precaution for Air Conditioning .................................6

HOW TO USE THIS MANUAL ............................7

Description ................................................................7

Terms ........................................................................7

Units ..........................................................................7

Relation between Illustrations and Descriptions .......7

Contents ....................................................................8

Component ................................................................8

How to Follow Trouble Diagnosis ..............................9

How to Read Wiring Diagram ..................................13

Abbreviations ..........................................................20

SERVICE INFORMATION FOR ELECTRICAL

INCIDENT ...........................................................

22

How to Check Terminal ...........................................22

How to Perform Efficient Diagnosis for an Electri-

cal Incident ..............................................................

25

Control Units and Electrical Parts ............................32

CONSULT-II CHECKING SYSTEM ..................35

Description ...............................................................35

Function and System Application ............................35

Nickel Metal Hydride Battery Replacement .............36

Checking Equipment ...............................................36

CONSULT-II Start Procedure ..................................36

CONSULT-II Data Link Connector (DLC) Circuit .....38

LIFTING POINT .................................................40

Pantograph Jack ......................................................40

Garage Jack and Safety Stand ................................40

2-Pole Lift ................................................................40

TOW TRUCK TOWING .....................................42

Tow Truck Towing ...................................................42

Vehicle Recovery (Freeing a stuck vehicle) ............43

TIGHTENING TORQUE OF STANDARD

BOLTS ...............................................................

44

Tightening Torque Table .........................................44

RECOMMENDED CHEMICAL PRODUCTS

AND SEALANTS ...............................................

45

Recommended Chemical Product and Sealant .......45

IDENTIFICATION INFORMATION ....................46

Model Variation ........................................................46

Identification Number ...............................................47

Dimensions ..............................................................48

Wheels & Tires ........................................................48

TERMINOLOGY ................................................50

SAE J1930 Terminology List ...................................50

Page 1970 of 3061

GI-4

< SERVICE INFORMATION >

PRECAUTIONS

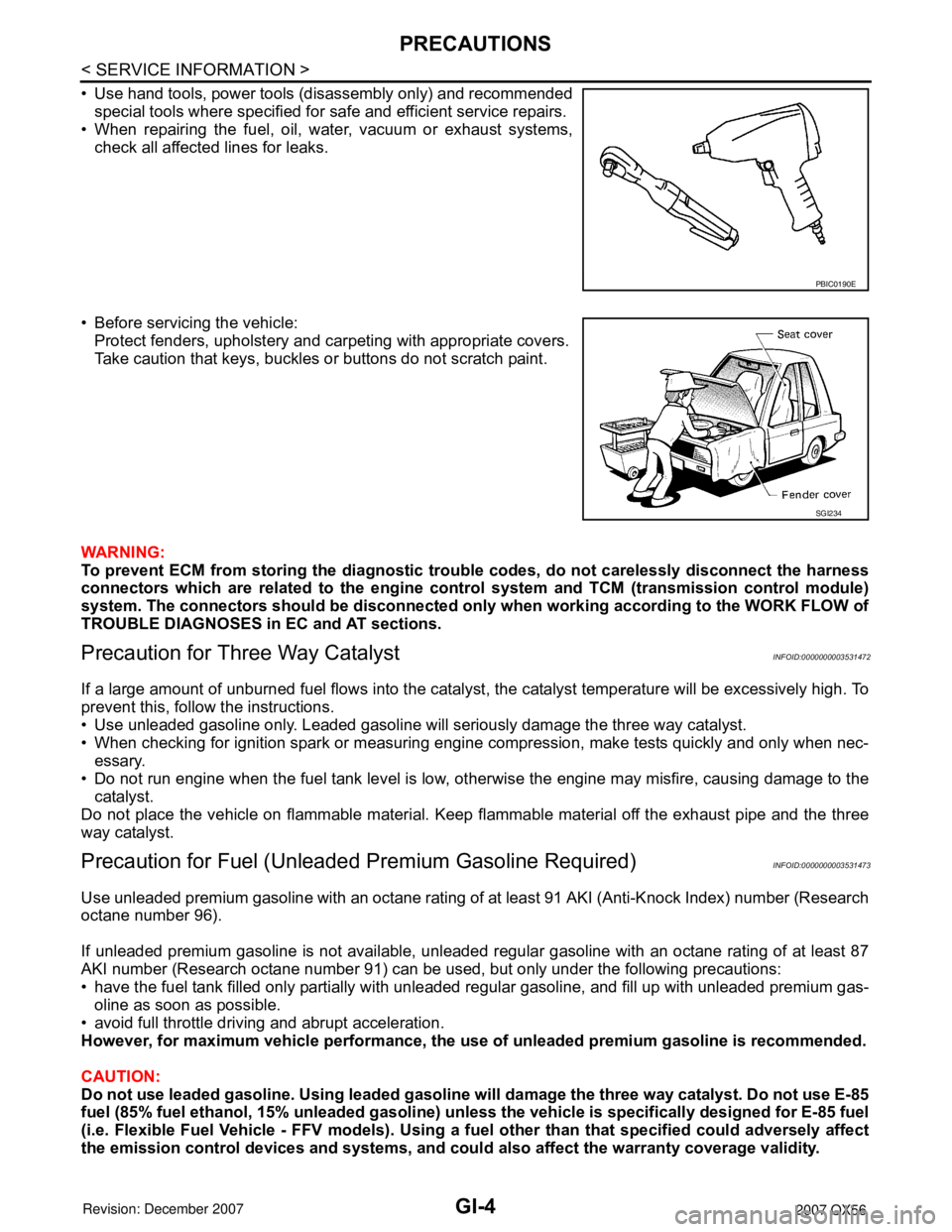

• Use hand tools, power tools (disassembly only) and recommended

special tools where specified for safe and efficient service repairs.

• When repairing the fuel, oil, water, vacuum or exhaust systems,

check all affected lines for leaks.

• Before servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate covers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Precaution for Three Way CatalystINFOID:0000000003531472

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

• Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

• When checking for ignition spark or measuring engine compression, make tests quickly and only when nec-

essary.

• Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to the

catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Precaution for Fuel (Unleaded Premium Gasoline Required)INFOID:0000000003531473

Use unleaded premium gasoline with an octane rating of at least 91 AKI (Anti-Knock Index) number (Research

octane number 96).

If unleaded premium gasoline is not available, unleaded regular gasoline with an octane rating of at least 87

AKI number (Research octane number 91) can be used, but only under the following precautions:

• have the fuel tank filled only partially with unleaded regular gasoline, and fill up with unleaded premium gas-

oline as soon as possible.

• avoid full throttle driving and abrupt acceleration.

However, for maximum vehicle performance, the use of unleaded premium gasoline is recommended.

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will damage the three way catalyst. Do not use E-85

fuel (85% fuel ethanol, 15% unleaded gasoline) unless the vehicle is specifically designed for E-85 fuel

(i.e. Flexible Fuel Vehicle - FFV models). Using a fuel other than that specified could adversely affect

the emission control devices and systems, and could also affect the warranty coverage validity.

PBIC0190E

SGI234

Page 2099 of 3061

GW-80

< SERVICE INFORMATION >

REAR WINDOW DEFOGGER

Check continuity between each door mirror RH terminals 10 and 11.

OK or NG

OK >> Repair or replace harness.

NG >> Replace door mirror RH. Refer to GW-84, "

Door Mirror

Assembly".

Rear Window Defogger Signal InspectionINFOID:0000000003533082

1.CHECK AV COMMUNICATION LINE

AV communication line check is executed. Refer to AV-123, "

CAN Communication Line Check".

OK or NG

OK >> GO TO 2.

NG >> Replace display control unit. Refer to AV-145, "

Removal and Installation".

2.CHECK CAN COMMUNICATION LINE

CAN communication line check is executed. Refer to AV-123, "

CAN Communication Line Check".

OK or NG

OK >> Check the condition of the harness and the connector.

NG >> In addition, it is necessary to check CAN communication line. Refer to LAN-7

.

Filament CheckINFOID:0000000003533083

1. When measuring voltage, wrap tin foil around the top of the neg-

ative probe.Then press the foil against the wire with your finger.

2. Attach probe circuit tester (in Volt range) to middle portion of

each filament.10 - 11 : Continuity should exist.

LIIA2725E

Is rear window defogger displayed on the display?

SEL122R

SEL263

Page 2106 of 3061

IDX-2

ALPHABETICAL INDEX

Numerics

2-4WD shift solenoid valve ..... TF-93

, TF-154, TF-167

4WD - Wiring diagram ....................................... TF-24

4WD shift switch ................................................ TF-65

4WD solenoid valve ................ TF-89, TF-154, TF-167

4WD system description .................................... TF-15

4WD system diagram ........................................ TF-19

A

A/C air flow ...................................................... ATC-30

A/C compressor clutch removal and installation .. ATC-

180

A/C compressor mounting ............................. ATC-179

A/C compressor precaution ............................. ATC-11

A/C compressor special service tool ................ ATC-14

A/C control operation (auto A/C) ...................... ATC-27

A/C diagnostic work flow (auto A/C) .............. ATC-133

A/C evaporator ............................................... ATC-186

A/C HFC134a (R134a) system identification ..... ATC-6

A/C HFC134a (R134a) system precaution ........ ATC-5

A/C HFC134a (R134a) system service procedure ATC-

175

A/C HFC134a (R134a) system service tools ... ATC-14

A/C HFC134a system service equipment precaution ...

ATC-11

A/C lubricant (R134a) ...................................... ATC-22

A/C lubrication oil ............................................. ATC-22

A/C operational check ....................... ATC-56, ATC-58

A/C self-diagnoses (auto A/C) ........ ATC-54, ATC-133

A/C service data specification ........................ ATC-193

A/C trouble diagnoses (auto A/C) .................... ATC-34

A/C, A - Wiring diagram ................................... ATC-42

A/T fluid checking ...................... AT-12, AT-51, MA-22

A/T fluid cooler cleaning .................................... AT-14

A/T fluid replacement ............................. AT-12, MA-24

A/T fluid temperature sensor ........................... AT-123

A/T IND - Wiring diagram .................................... DI-36

A/T indicator ........................................................ DI-36

A/T shift lock system ........................................ AT-216

A/T trouble diagnoses ........................................ AT-42

ABS - Wiring diagram ..................................... BRC-16

ABS (anti-lock brake system) ........................... BRC-7

Accelerator control system ............................... ACC-3

Accelerator pedal position (APP) sensor . EC-608, EC-

614, EC-628

Accelerator pedal released position learning ..... EC-80

AF1B1-Wiring diagram EC-242, EC-250, EC-258, EC-

267, EC-638

AF1B2-Wiring diagram EC-244, EC-252, EC-260, EC-

269, EC-640

AF1HB1-Wiring diagram .................................. EC-175

AF1HB2-Wiring diagram .................................. EC-177

Aiming adjustment .................................. LT-23, LT-61

Air bag .............................................................. SRS-3

Air bag precautions .............................................. AV-4

Air cleaner and air duct ..................................... EM-15

Air cleaner filter replacement ................ EM-16, MA-16

Air conditioner cut control ................................. EC-29

Air flow meter - See Mass air flow sensor EC-197, EC-

206

Air fuel ratio sensor 1 .. EC-239, EC-248, EC-256, EC-

264, EC-636

Air fuel ratio sensor 1 heater ........................... EC-174

Air mix. door motor .......................................... ATC-69

Ambient sensor ............................. ATC-138, ATC-149

Angular tightening application ............................. EM-4

Antenna .............................................................. AV-58

APPS1 - Wiring diagram ................................. EC-610

APPS2 - Wiring diagram ................................. EC-616

APPS3 - Wiring diagram ................................. EC-630

ASC/BS - Wiring diagram ............................... EC-574

ASC/SW - Wiring diagram .............................. EC-557

ASCBOF - Wiring diagram .............................. EC-648

ASCD ................................................................ EC-30

ASCD (automatic speed control device) ........... ACS-3

ASCD brake switch ........................... EC-572, EC-647

ASCD indicator lamp ....................................... EC-654

ASCD steering switch ..................................... EC-555

ASCIND - Wiring diagram ............................... EC-655

ATP switch ............................ TF-106, TF-109, TF-114

Audio .................................................................... AV-6

AUDIO - Wiring diagram .................................... AV-11

AUT/DP - Wiring diagram .................................. SE-16

Auto air conditioner - Wiring diagram .............. ATC-42

Auto anti-dazzling inside mirror ........... GW-69, GW-70

Autolamp ............................................................ LT-38

Automatic amplifier ......................................... ATC-59

Automatic drive positioner .................................. SE-11

Automatic transmission number .......................... GI-50

B

Back door ........................................................... BL-88

Back door trim ..................................................... EI-32

Back sonar .......................................................... DI-50

BACK/L - Wiring diagram ................................... LT-87

Back-up lamp ..................................................... LT-87

Ball joint (front) ................................................ FSU-15

Basic inspection ................................................ EC-73

Battery ................................................................. SC-4

Battery current sensor . EC-520, EC-527, EC-534, EC-

541

Battery/Starting/Charging System Tester SC-6, SC-12,

SC-20

BCM (Body control module) ................ BCS-3, AV-106

Block heater ...................................................... EM-78

Blower motor ................................... ATC-93, ATC-153

Body alignment ................................................ BL-164

Body component parts ..................................... BL-151

Body construction ............................................ BL-163

Body exterior paint color .................................. BL-150

Body mounting ................................................. BL-149

Body repair ....................................................... BL-150

Body sealing .................................................... BL-160

Bose speaker amp. .............................................. AV-8

Brake booster .................................................... BR-17

Page 2108 of 3061

IDX-4

ALPHABETICAL INDEX

Duct and grilles .............................................. ATC-170

DVD - Wiring Diagram ....................................... AV-75

DVD Entertainment System ............................... AV-72

DVD Player ........................................................ AV-73

E

ECM input/output signal ..................... EC-109

, EC-133

ECM power supply ............................. EC-150, EC-475

ECM relay ........................................................ EC-150

ECM/PW - Wiring diagram ............................... EC-476

ECTS - Wiring diagram .................................... EC-220

Electric sunroof .................................................. RF-10

Electric throttle control actuator ......... EC-595, EC-606

Electrical load signal circuit .............................. EC-657

Electrical units location ...................................... PG-65

Electronic ignition (EI) system ........................... EC-27

Engine control circuit diagram ......................... EC-107

Engine control component parts location ........... EC-98

Engine control module (ECM) .......................... EC-479

Engine control system diagram ......................... EC-24

Engine coolant .................................................. CO-10

Engine coolant temperature sensor (ECTS) ... EC-218,

EC-231

Engine fail-safe system ...................................... EC-93

Engine oil ............................................................. LU-8

Engine oil filter replacement ............................. MA-17

Engine oil precautions .......................................... GI-7

Engine oil replacement ..................................... MA-17

Engine removal ................................................. EM-74

Engine room cover ............................................ EM-12

Engine serial number .......................................... GI-50

ETC1 - Wiring diagram .................................... EC-596

ETC2 - Wiring diagram .................................... EC-591

ETC3 - Wiring diagram .................................... EC-602

EVAP canister .................................................... EC-36

EVAP canister purge volume control solenoid valve ....

EC-395

, EC-403

EVAP canister vent control valve ....... EC-410, EC-417

EVAP control system (small leak) diagnosis .. EC-387,

EC-441

, EC-449

EVAP control system pressure sensor .... EC-424, EC-

427, EC-433

EVAP control system purge flow monitoring diagnosis

EC-382

EVAP vapor lines inspection ............................. MA-20

Evaporative emission (EVAP) system ............... EC-33

Evaporator ..................................................... ATC-186

Exhaust manifold .............................................. EM-21

Exhaust system ................................................... EX-3

Exhaust system inspection .................................. EX-3

Expansion valve ............................................. ATC-188

F

F/FOG - Wiring diagram ..................................... LT-56

F/PUMP - Wiring diagram ................................ EC-666

Final drive pre-inspection ................................. FFD-15

Final drive removal and installation .. FFD-12, RFD-13

Flow charts .......................................................... GI-27

Fluid temperature sensor (A/T) ........................ AT-123

Fluids ................................................................ MA-11

Fluorescent leak detector .............................. ATC-189

Fog lamp, front ................................................... LT-54

Fog lamp, front, removal and installation ........... LT-62

Foot lamp ......................................................... LT-111

Freeze frame data ............................... EC-55, EC-121

Front brake solenoid valve ................. AT-139, AT-141

Front bumper ...................................................... EI-13

Front case (Transfer) .......................... TF-149, TF-176

Front combination lamp removal and installation LT-25

Front door ............................. BL-117, BL-121, GW-62

Front Door Trim ................................................... EI-32

Front drive shaft (Transfer) ................. TF-149, TF-176

Front fog lamp .................................................... LT-54

Front fog lamp removal and installation ............. LT-62

Front passenger air bag .................................. SRS-43

Front seat ........................................................... SE-89

Front seat belt ...................................................... SB-3

Front seat belt pre-tensioner ............... SRS-3, SRS-50

Front washer ...................................................... WW-4

Front wiper ......................................................... WW-4

FTS - Wiring diagram ....................................... AT-124

FTTS - Wiring diagram ...................... EC-334, EC-339

Fuel cut control (at no load high engine speed) EC-28

Fuel filter replacement ......................................... FL-5

Fuel gauge ............................................................ DI-5

Fuel injection system (Bank 1) .......... EC-311, EC-322

Fuel injection system (Bank 2) .......... EC-311, EC-322

Fuel injector .................................................... EC-659

Fuel injector and fuel tube ................................. EM-31

Fuel level sensor ................. EC-458, EC-460, EC-462

Fuel line inspection .............................................. FL-4

Fuel precautions ................................................... GI-5

Fuel pressure check .......................................... EC-82

Fuel pressure release ....................................... EC-82

Fuel pump ....................................................... EC-665

Fuel pump and gauge .......................................... FL-5

Fuel system .......................................................... FL-4

Fuel tank ............................................................ FL-10

Fuel tank temperature sensor ........... EC-332, EC-338

Fuel tank vacuum relief valve ........................... EC-36

FUELB1 - Wiring diagram ................. EC-313, EC-324

FUELB2 - Wiring diagram ................. EC-315, EC-326

Fuse ...................................................... PG-17, PG-77

Fuse and fusible link box .................................. PG-77

Fuse block ......................................................... PG-76

Fusible link ............................................ PG-17, PG-77

G

Garage jack and safety stand ............................. GI-42

Gauges ................................................................. DI-5

Generator .......................................................... SC-17

Generic scan tool (GST) ................................. EC-131

Glass ...................................... GW-11, GW-62, GW-65

Glove box lamp ................................................ LT-131

GPS antenna ..................................................... AV-82

Page 2211 of 3061

LT-4

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003533330

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

General precautions for service operationsINFOID:0000000003533331

• Never work with wet hands.

• Xenon headlamp includes high voltage generating part. Be sure to

disconnect battery negative cable (negative terminal) or power

fuse before removing, installing, or touching the xenon headlamp

(including lamp bulb).

• Turn the lighting switch OFF before disconnecting and connecting

the connector.

• When turning the xenon headlamp on and while it is illuminated,

never touch the harness, bulb, and socket of the headlamp.

• When checking the headlamp on/off operation, check it on vehicle

and with the power connected to the vehicle-side connector.

• Do not touch the headlamp bulb glass surface with bare hands or

allow oil or grease to get on it. Do not touch the headlamp bulb just after the headlamp is turned off, because

it is very hot.

• Install the xenon headlamp bulb socket correctly. If it is installed

improperly, high-voltage leak or corona discharge may occur that

can melt the bulb, connector, and housing. Do not illuminate the

xenon headlamp bulb out of the headlamp housing. Doing so can

cause fire and harm your eyes.

• When the bulb has burned out, wrap it in a thick vinyl bag and dis-

card. Do not break the bulb.

• Leaving the bulb removed from the headlamp housing for a long

period of time can deteriorate the performance of the lens and

reflector (dirt, clouding). Always prepare a new bulb and have it on

hand when replacing the bulb.

• Do not use organic solvent (paint thinner or gasoline) to clean

lamps and to remove old sealant.

WKIA0460E

EL-3422D

Page 2353 of 3061

LU-8

< SERVICE INFORMATION >

ENGINE OIL

ENGINE OIL

InspectionINFOID:0000000003531555

OIL LEVEL

• Before starting the engine make sure the vehicle is parked on a flat

and level surface, then check the oil level. If the engine is already

running, turn it off and allow 10 minutes before checking.

• Check that the oil level is within the low (L) and high (H) range as

indicated on the dipstick.

• If the engine oil level is out of range, add oil as necessary. Refer to

GI-45, "

Recommended Chemical Product and Sealant".

OIL APPEARANCE

• Check the engine oil for a white milky appearance or excessive contamination.

• If the engine oil is milky, it is highly probable that it is contaminated with engine coolant. Repair the broken

parts.

OIL LEAKAGE

Check for oil leakage around the following areas:

•Oil pan

• Oil pan drain plug

• Oil pressure switch

• Oil filter

• Oil cooler

• Intake valve timing control cover

• Intake valve timing control solenoid valve

• Front cover

• Mating surface between cylinder block and cylinder head

• Mating surface between cylinder head and rocker cover

• Crankshaft oil seal (front and rear)

OIL PRESSURE CHECK

CAUTION:

• Be careful not to burn yourself, as engine oil may be hot.

• Put the selector lever in the Park “P” position.

1. Check the engine oil level. Refer to LU-8, "

Inspection".

2. Remove engine front undercover using power tool.

3. Disconnect the oil pressure switch harness connector.

4. Remove the oil pressure switch (A).

SMA954C

WBIA0791E

Page 2354 of 3061

ENGINE OIL

LU-9

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

LU

N

P O

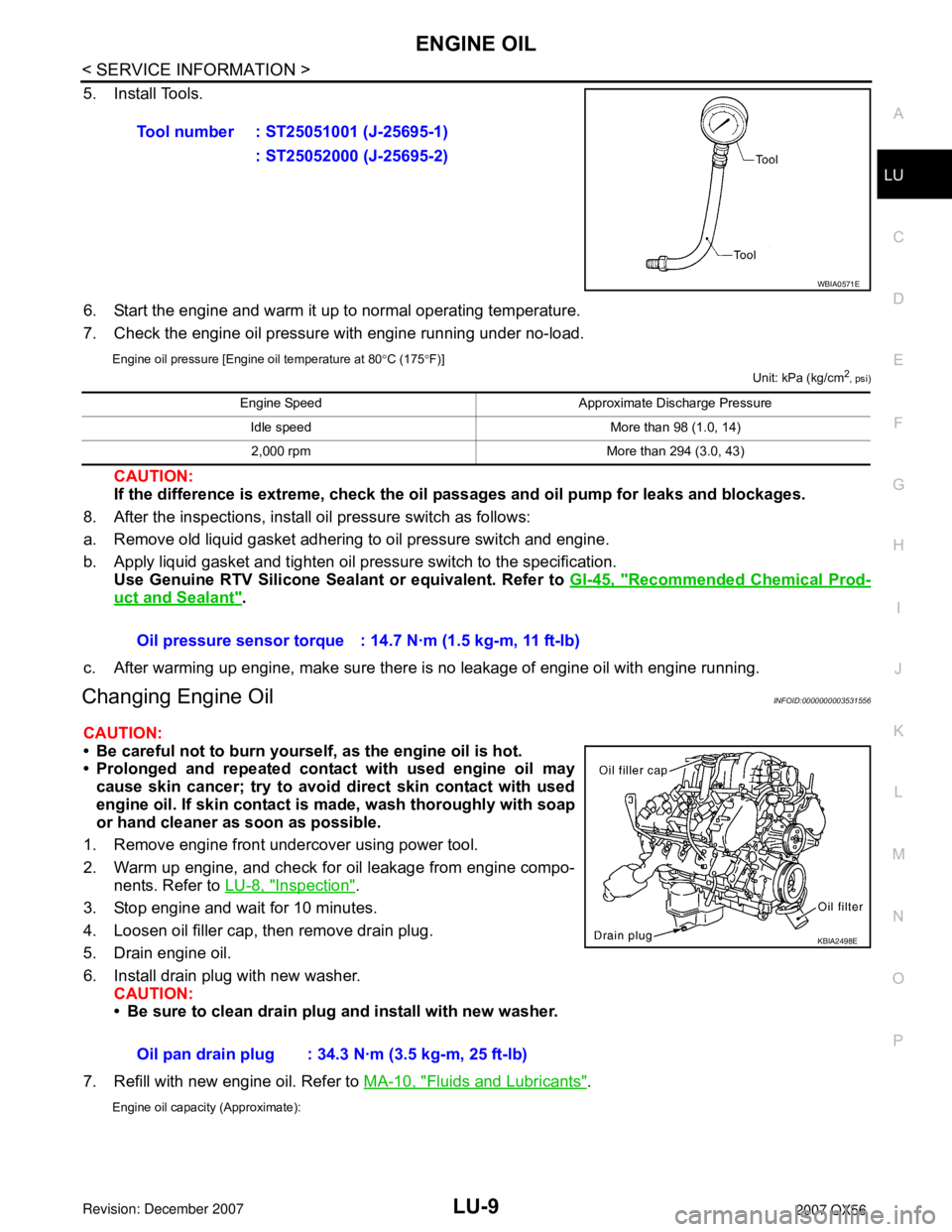

5. Install Tools.

6. Start the engine and warm it up to normal operating temperature.

7. Check the engine oil pressure with engine running under no-load.

Engine oil pressure [Engine oil temperature at 80°C (175°F)]

Unit: kPa (kg/cm2

, psi)

CAUTION:

If the difference is extreme, check the oil passages and oil pump for leaks and blockages.

8. After the inspections, install oil pressure switch as follows:

a. Remove old liquid gasket adhering to oil pressure switch and engine.

b. Apply liquid gasket and tighten oil pressure switch to the specification.

Use Genuine RTV Silicone Sealant or equivalent. Refer to GI-45, "

Recommended Chemical Prod-

uct and Sealant".

c. After warming up engine, make sure there is no leakage of engine oil with engine running.

Changing Engine OilINFOID:0000000003531556

CAUTION:

• Be careful not to burn yourself, as the engine oil is hot.

• Prolonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with used

engine oil. If skin contact is made, wash thoroughly with soap

or hand cleaner as soon as possible.

1. Remove engine front undercover using power tool.

2. Warm up engine, and check for oil leakage from engine compo-

nents. Refer to LU-8, "

Inspection".

3. Stop engine and wait for 10 minutes.

4. Loosen oil filler cap, then remove drain plug.

5. Drain engine oil.

6. Install drain plug with new washer.

CAUTION:

• Be sure to clean drain plug and install with new washer.

7. Refill with new engine oil. Refer to MA-10, "

Fluids and Lubricants".

Engine oil capacity (Approximate):

Tool number : ST25051001 (J-25695-1)

: ST25052000 (J-25695-2)

WBIA0571E

Engine Speed Approximate Discharge Pressure

Idle speed More than 98 (1.0, 14)

2,000 rpm More than 294 (3.0, 43)

Oil pressure sensor torque : 14.7 N·m (1.5 kg-m, 11 ft-lb)

Oil pan drain plug : 34.3 N·m (3.5 kg-m, 25 ft-lb)

KBIA2498E

Page 2355 of 3061

LU-10

< SERVICE INFORMATION >

ENGINE OIL

Unit: (US qt, Imp qt)

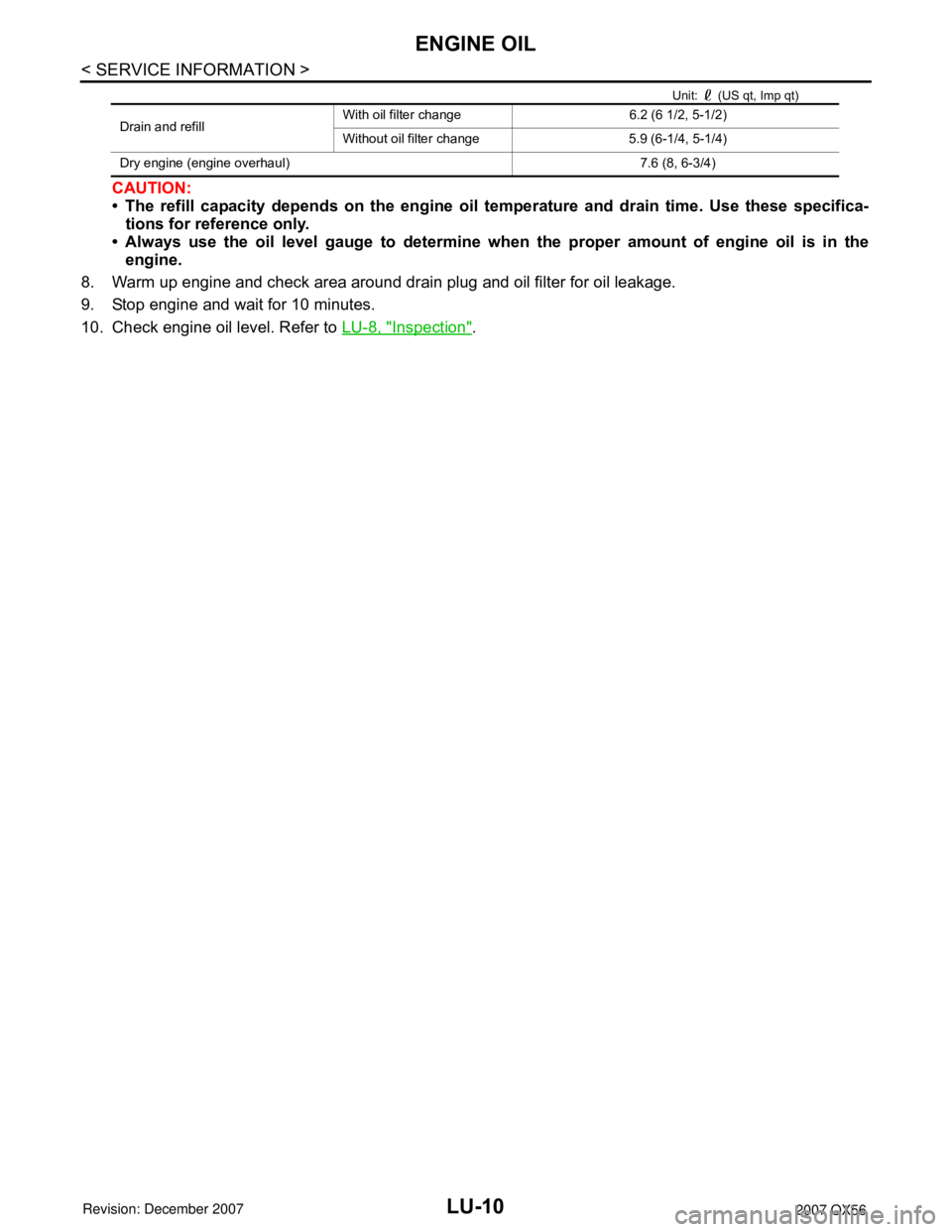

CAUTION:

• The refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

• Always use the oil level gauge to determine when the proper amount of engine oil is in the

engine.

8. Warm up engine and check area around drain plug and oil filter for oil leakage.

9. Stop engine and wait for 10 minutes.

10. Check engine oil level. Refer to LU-8, "

Inspection".

Drain and refillWith oil filter change 6.2 (6 1/2, 5-1/2)

Without oil filter change 5.9 (6-1/4, 5-1/4)

Dry engine (engine overhaul) 7.6 (8, 6-3/4)

Page 2356 of 3061

OIL FILTER

LU-11

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

LU

N

P O

OIL FILTER

Removal and InstallationINFOID:0000000003531557

REMOVAL

1. Remove the engine front undercover using power tool.

2. Remove the oil filter using Tool.

WARNING:

• The oil filter is provided with a relief valve.

Use Genuine NISSAN oil filter or equivalent.

• When removing, prepare a shop cloth to absorb any

engine oil leakage or spillage.

• Do not allow engine oil to adhere to the drive belts.

• Completely wipe off any engine oil that adheres to the

engine and the vehicle.

CAUTION:

• Be careful not to get burned when the engine and engine oil are hot.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply engine oil to the oil seal circumference of the new oil filter.

3. Screw the oil filter manually until it touches the installation sur-

face, then tighten it by 2/3 turn. Or tighten to specification.

4. Inspect the engine for oil leakage. Refer to EM-74, "

Removal

and Installation".

5. Install the engine front undercover using power tool.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to LU-8, "Inspection".

2. Start the engine and check for engine oil leakage.

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level and add engine oil as required.Tool number : KV10115801 (J-38956)

WBIA0388E

SMA010

Oil filter : 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B