service INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1913 of 3061

FFD-14

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

ASSEMBLY INSPECTION AND ADJUSTMENT

• Drain the differential gear oil before inspection and adjustment. Refer to FFD-7.

• Remove and install the carrier cover as necessary for inspection and adjustment. Refer to FFD-11

.

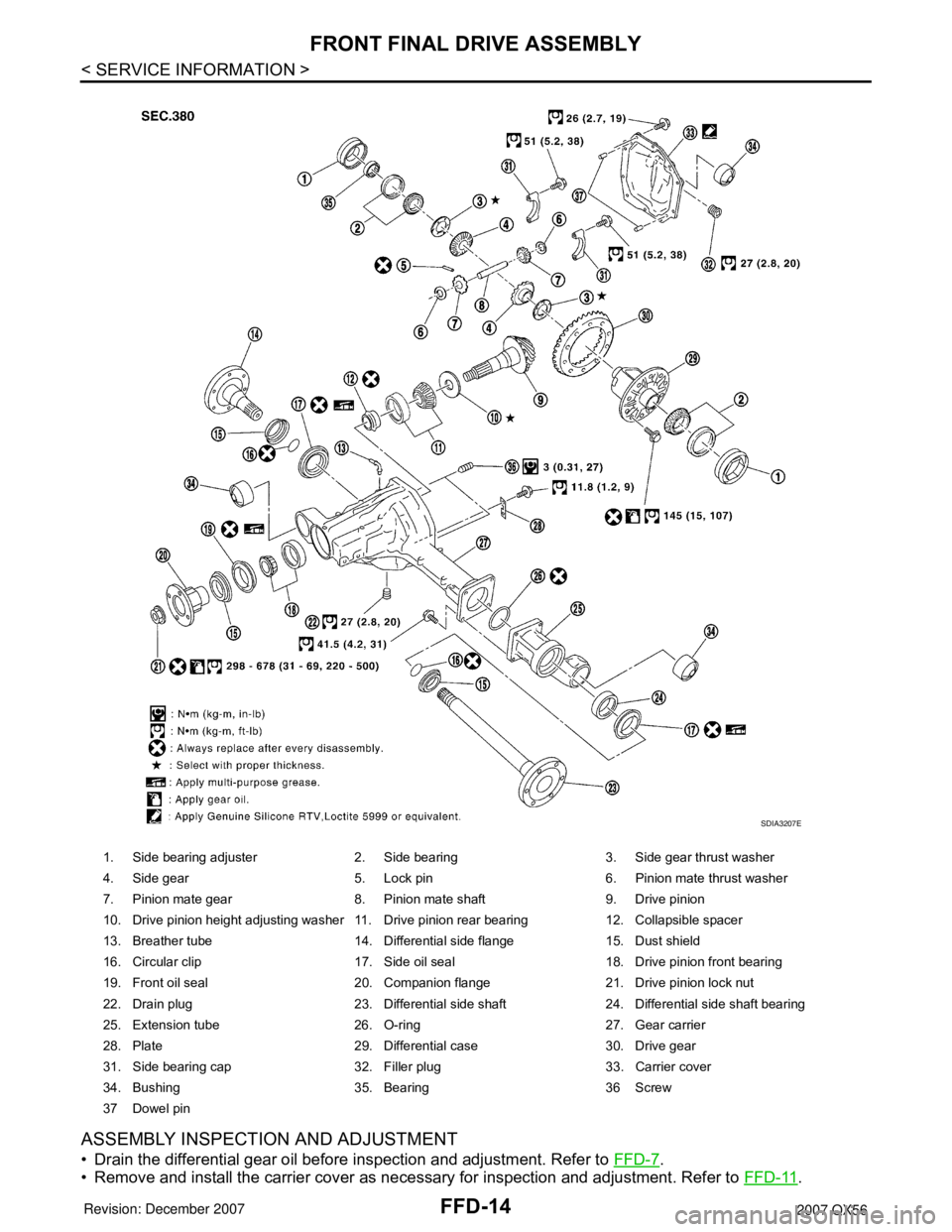

1. Side bearing adjuster 2. Side bearing 3. Side gear thrust washer

4. Side gear 5. Lock pin 6. Pinion mate thrust washer

7. Pinion mate gear 8. Pinion mate shaft 9. Drive pinion

10. Drive pinion height adjusting washer 11. Drive pinion rear bearing 12. Collapsible spacer

13. Breather tube 14. Differential side flange 15. Dust shield

16. Circular clip 17. Side oil seal 18. Drive pinion front bearing

19. Front oil seal 20. Companion flange 21. Drive pinion lock nut

22. Drain plug 23. Differential side shaft 24. Differential side shaft bearing

25. Extension tube 26. O-ring 27. Gear carrier

28. Plate 29. Differential case 30. Drive gear

31. Side bearing cap 32. Filler plug 33. Carrier cover

34. Bushing 35. Bearing 36 Screw

37 Dowel pin

SDIA3207E

Page 1914 of 3061

FRONT FINAL DRIVE ASSEMBLY

FFD-15

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FFD

N

O

P Total Preload Torque

1. Install the differential side shaft and differential side flange if necessary.

CAUTION:

The differential side shaft and differential side flange must be installed in order to measure total

preload torque.

2. Rotate the drive pinion back and forth 2 to 3 times to check for unusual noise and rotation malfunction.

3. Rotate the drive pinion at least 20 times to check for smooth operation of the bearings.

4. Measure total preload torque using Tool.

NOTE:

Total preload torque = Drive pinion bearing preload torque +

Side bearing preload torque

• If the measured value is out of the specification, check and adjust each part. Adjust the drive pinion

bearing preload torque first, then adjust the side bearing preload torque.

Drive Gear Runout

1. Fit a dial indicator to the drive gear back face.

2. Rotate the drive gear to measure runout.

• If the runout is outside of the limit, check the condition of the drive

gear assembly. Foreign material may be caught between the drive

gear and differential case, or the differential case or drive gear may

be deformed.

CAUTION:

Replace drive gear and drive pinion as a set.

Tooth Contact

Tool number : ST3127S000 (J-25765-A)

Total preload torque:

2.98 - 4.76 N·m (0.31 - 0.48 kg-m, 27 - 42 in-lb)

PDIA0697E

If the total preload torque is greater than specification

On drive pinion bearings: Replace the collapsible spacer.

On side bearings: Loosen the side bearing adjuster by the same amount on each

side.

If the total preload torque is less than specification

On drive pinion bearings: Tighten the drive pinion lock nut.

On side bearings: Tighten the side bearing adjuster by the same amount on each

side.

Runout limit: 0.08 mm (0.0031 in) or less

SPD886

Page 1915 of 3061

FFD-16

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

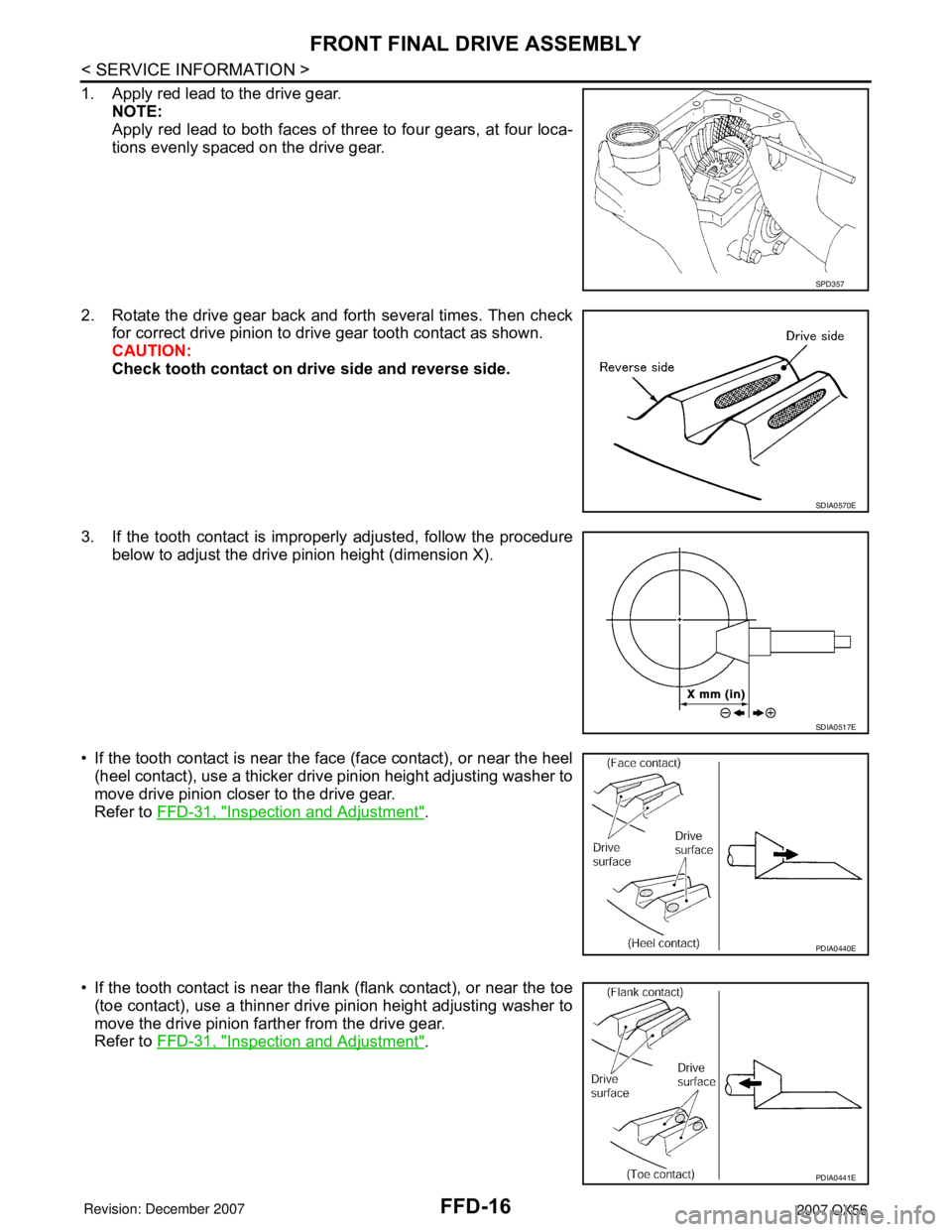

1. Apply red lead to the drive gear.

NOTE:

Apply red lead to both faces of three to four gears, at four loca-

tions evenly spaced on the drive gear.

2. Rotate the drive gear back and forth several times. Then check

for correct drive pinion to drive gear tooth contact as shown.

CAUTION:

Check tooth contact on drive side and reverse side.

3. If the tooth contact is improperly adjusted, follow the procedure

below to adjust the drive pinion height (dimension X).

• If the tooth contact is near the face (face contact), or near the heel

(heel contact), use a thicker drive pinion height adjusting washer to

move drive pinion closer to the drive gear.

Refer to FFD-31, "

Inspection and Adjustment".

• If the tooth contact is near the flank (flank contact), or near the toe

(toe contact), use a thinner drive pinion height adjusting washer to

move the drive pinion farther from the drive gear.

Refer to FFD-31, "

Inspection and Adjustment".

SPD357

SDIA0570E

SDIA0517E

PDIA0440E

PDIA0441E

Page 1916 of 3061

FRONT FINAL DRIVE ASSEMBLY

FFD-17

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FFD

N

O

P Backlash

1. Fit a dial indicator to the drive gear face to measure the back-

lash.

• If the backlash is outside of the specification, adjust each side

bearing adjuster.

CAUTION:

Do not change the side bearing adjusters by different

amounts as it will change the side bearing preload torque.

Companion Flange Runout

1. Rotate companion flange and check for runout on the compan-

ion flange face (inner side of the bolt holes) and companion

flange inner side (socket diameter) using suitable tool.

2. If the runout is outside the runout limit, follow the procedure

below to adjust.

a. Rotate the companion flange on the drive pinion by 90°, 180°

and 270° while checking for the position where the runout is minimum.

b. If the runout is still outside of the runout limit after the companion flange has been rotated on the drive pin-

ion, possible cause could be an assembly malfunction of drive pinion and drive pinion bearing or a mal-

functioning drive pinion bearing.

c. If the runout is still outside of the runout limit after repair of the assembly of drive pinion and drive pinion

bearing or drive pinion bearing, replace the companion flange.

DISASSEMBLY

Differential Assembly

1. Drain the differential gear oil if necessary.Backlash: 0.12 - 0.20 mm (0.0050 - 0.0079 in)

SPD513

If the backlash is greater than specification:

Loosen side bearing adjuster A and tighten side bear-

ing adjuster B by the same amount.

If the backlash is less than specification:

Loosen side bearing adjuster B and tighten side bear-

ing adjuster A by the same amount.

SDIA2262E

Runout limit

Companion flange face: 0.10 mm (0.0039 in)

Companion flange inner side: 0.13 mm (0.0051 in)

SDIA2078E

Page 1917 of 3061

FFD-18

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

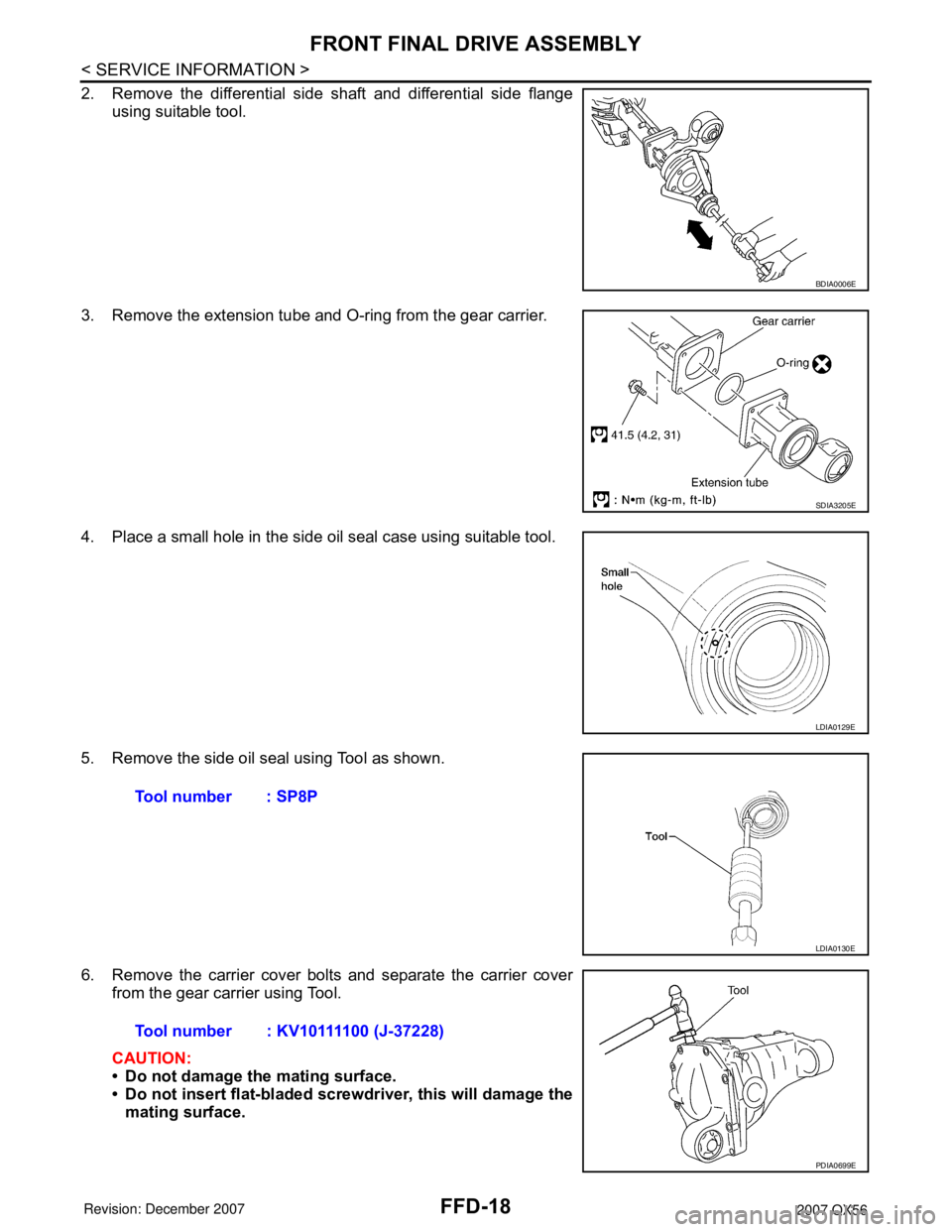

2. Remove the differential side shaft and differential side flange

using suitable tool.

3. Remove the extension tube and O-ring from the gear carrier.

4. Place a small hole in the side oil seal case using suitable tool.

5. Remove the side oil seal using Tool as shown.

6. Remove the carrier cover bolts and separate the carrier cover

from the gear carrier using Tool.

CAUTION:

• Do not damage the mating surface.

• Do not insert flat-bladed screwdriver, this will damage the

mating surface.

BDIA0006E

SDIA3205E

LDIA0129E

Tool number : SP8P

LDIA0130E

Tool number : KV10111100 (J-37228)

PDIA0699E

Page 1918 of 3061

FRONT FINAL DRIVE ASSEMBLY

FFD-19

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FFD

N

O

P

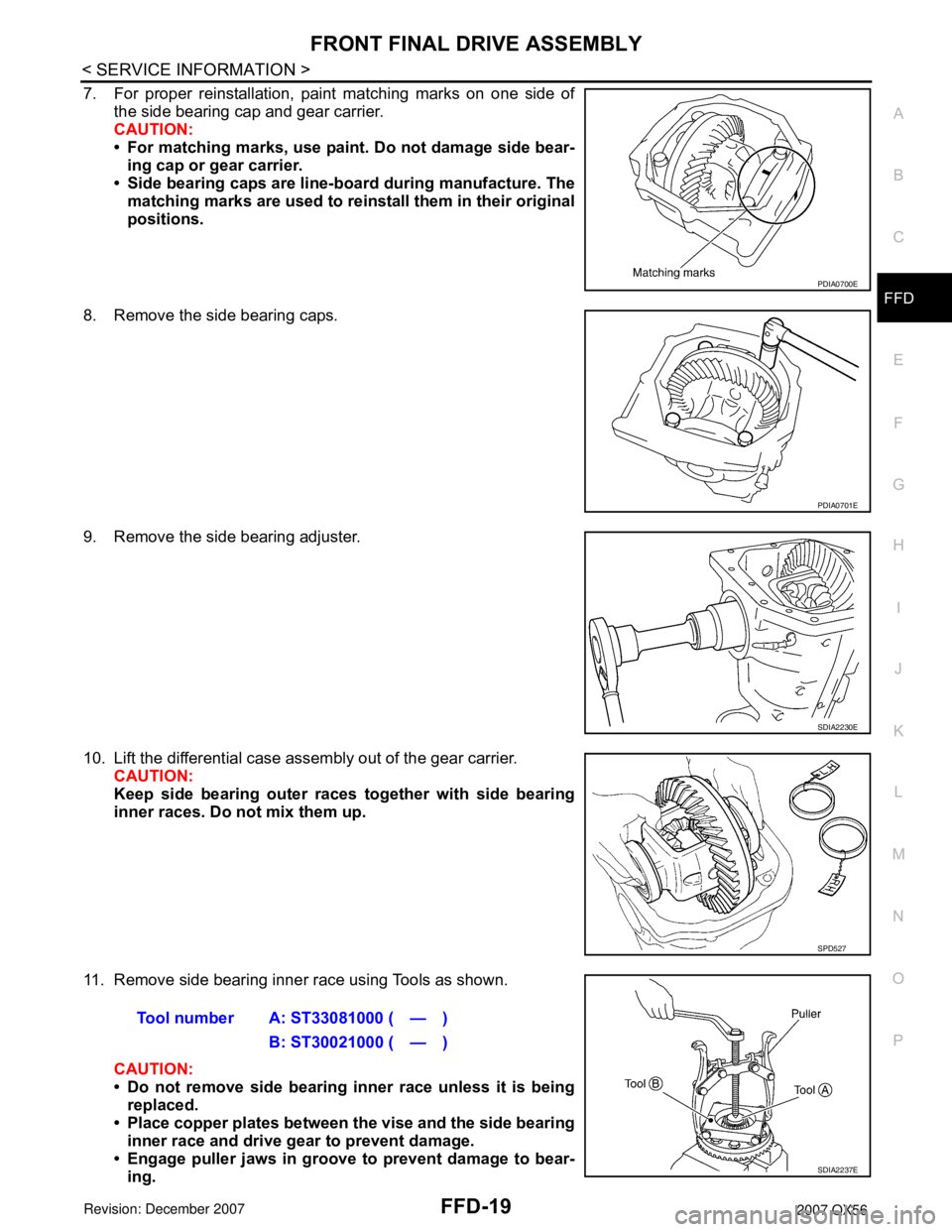

7. For proper reinstallation, paint matching marks on one side of

the side bearing cap and gear carrier.

CAUTION:

• For matching marks, use paint. Do not damage side bear-

ing cap or gear carrier.

• Side bearing caps are line-board during manufacture. The

matching marks are used to reinstall them in their original

positions.

8. Remove the side bearing caps.

9. Remove the side bearing adjuster.

10. Lift the differential case assembly out of the gear carrier.

CAUTION:

Keep side bearing outer races together with side bearing

inner races. Do not mix them up.

11. Remove side bearing inner race using Tools as shown.

CAUTION:

• Do not remove side bearing inner race unless it is being

replaced.

• Place copper plates between the vise and the side bearing

inner race and drive gear to prevent damage.

• Engage puller jaws in groove to prevent damage to bear-

ing.

PDIA0700E

PDIA0701E

SDIA2230E

SPD527

Tool number A: ST33081000 ( — )

B: ST30021000 ( — )

SDIA2237E

Page 1919 of 3061

FFD-20

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

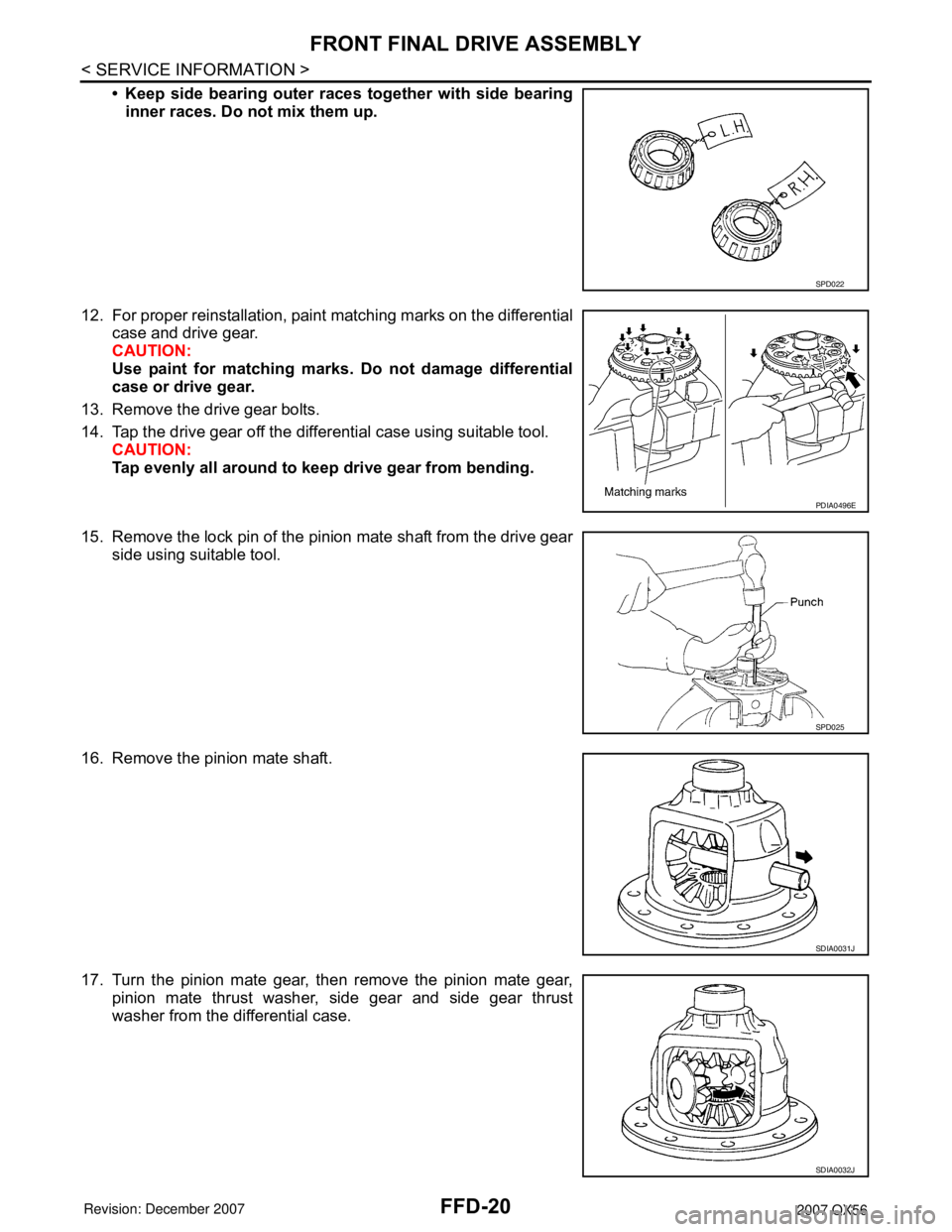

• Keep side bearing outer races together with side bearing

inner races. Do not mix them up.

12. For proper reinstallation, paint matching marks on the differential

case and drive gear.

CAUTION:

Use paint for matching marks. Do not damage differential

case or drive gear.

13. Remove the drive gear bolts.

14. Tap the drive gear off the differential case using suitable tool.

CAUTION:

Tap evenly all around to keep drive gear from bending.

15. Remove the lock pin of the pinion mate shaft from the drive gear

side using suitable tool.

16. Remove the pinion mate shaft.

17. Turn the pinion mate gear, then remove the pinion mate gear,

pinion mate thrust washer, side gear and side gear thrust

washer from the differential case.

SPD022

PDIA0496E

SPD025

SDIA0031J

SDIA0032J

Page 1920 of 3061

FRONT FINAL DRIVE ASSEMBLY

FFD-21

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FFD

N

O

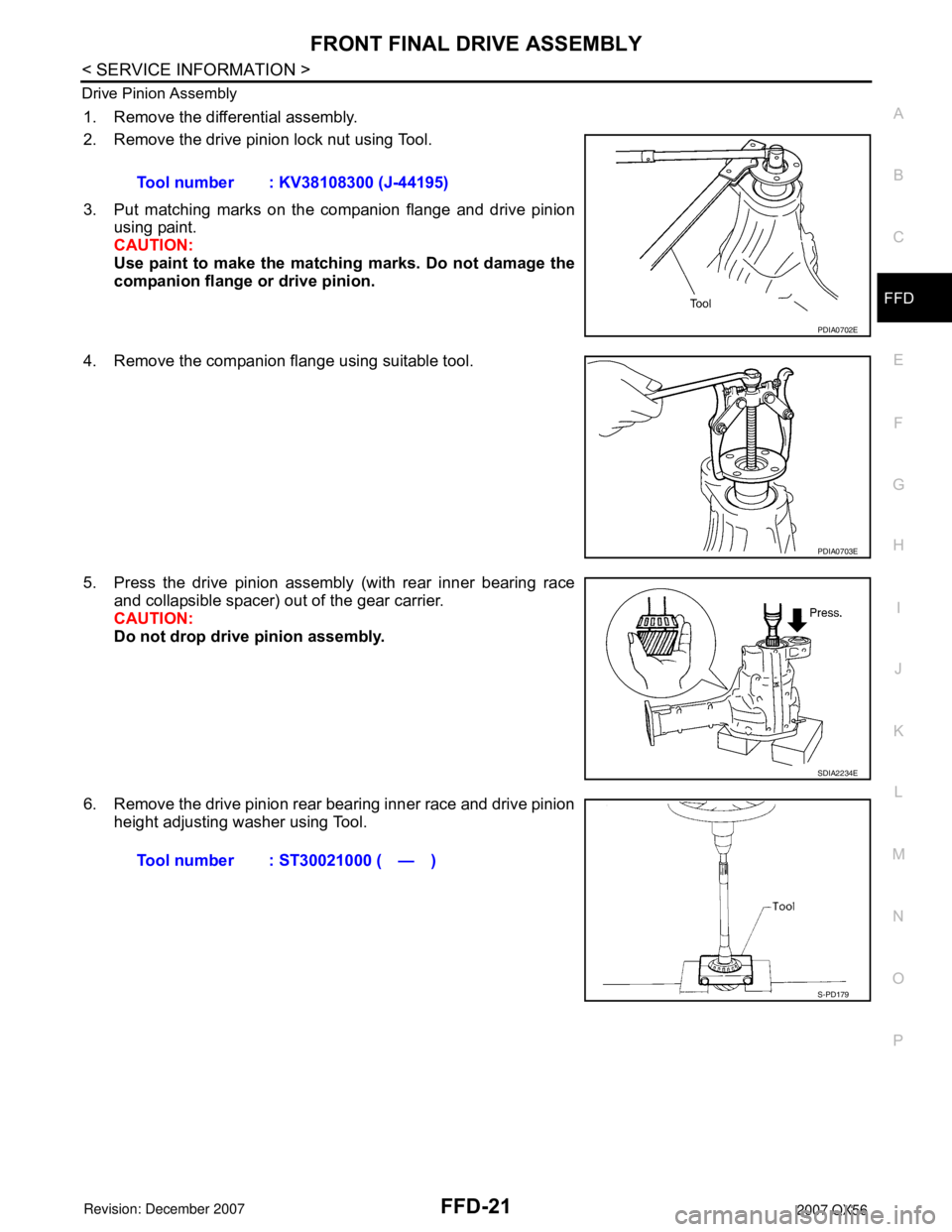

P Drive Pinion Assembly

1. Remove the differential assembly.

2. Remove the drive pinion lock nut using Tool.

3. Put matching marks on the companion flange and drive pinion

using paint.

CAUTION:

Use paint to make the matching marks. Do not damage the

companion flange or drive pinion.

4. Remove the companion flange using suitable tool.

5. Press the drive pinion assembly (with rear inner bearing race

and collapsible spacer) out of the gear carrier.

CAUTION:

Do not drop drive pinion assembly.

6. Remove the drive pinion rear bearing inner race and drive pinion

height adjusting washer using Tool.Tool number : KV38108300 (J-44195)

PDIA0702E

PDIA0703E

SDIA2234E

Tool number : ST30021000 ( — )

S-PD179

Page 1921 of 3061

FFD-22

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

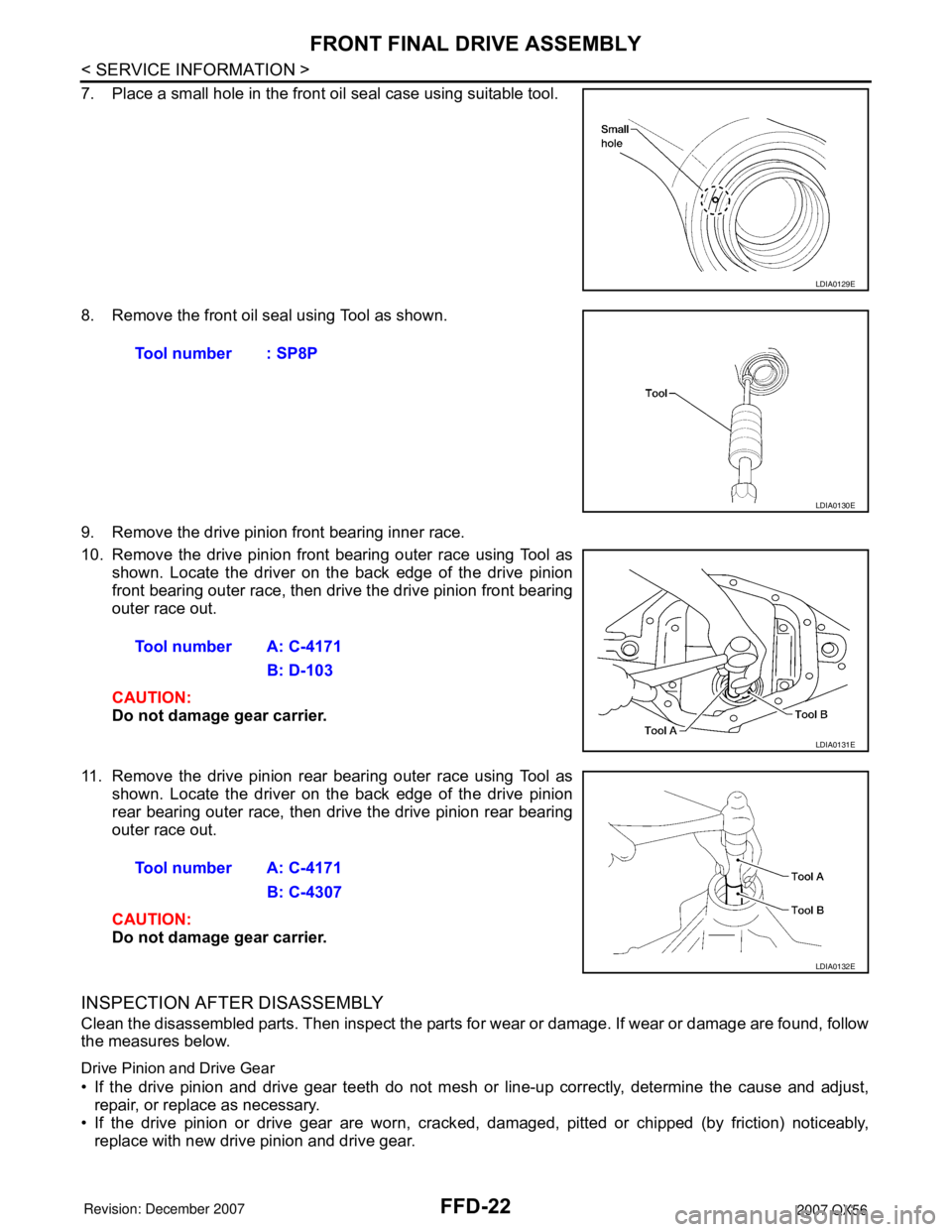

7. Place a small hole in the front oil seal case using suitable tool.

8. Remove the front oil seal using Tool as shown.

9. Remove the drive pinion front bearing inner race.

10. Remove the drive pinion front bearing outer race using Tool as

shown. Locate the driver on the back edge of the drive pinion

front bearing outer race, then drive the drive pinion front bearing

outer race out.

CAUTION:

Do not damage gear carrier.

11. Remove the drive pinion rear bearing outer race using Tool as

shown. Locate the driver on the back edge of the drive pinion

rear bearing outer race, then drive the drive pinion rear bearing

outer race out.

CAUTION:

Do not damage gear carrier.

INSPECTION AFTER DISASSEMBLY

Clean the disassembled parts. Then inspect the parts for wear or damage. If wear or damage are found, follow

the measures below.

Drive Pinion and Drive Gear

• If the drive pinion and drive gear teeth do not mesh or line-up correctly, determine the cause and adjust,

repair, or replace as necessary.

• If the drive pinion or drive gear are worn, cracked, damaged, pitted or chipped (by friction) noticeably,

replace with new drive pinion and drive gear.

LDIA0129E

Tool number : SP8P

LDIA0130E

Tool number A: C-4171

B: D-103

LDIA0131E

Tool number A: C-4171

B: C-4307

LDIA0132E

Page 1922 of 3061

FRONT FINAL DRIVE ASSEMBLY

FFD-23

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FFD

N

O

P

• Drive pinion and drive gear are supplied in matched sets only. Matching numbers on both drive pinion and

drive gear are etched for verification. If a new drive pinion and drive gear set are being used, verify the num-

bers of each drive pinion and drive gear before proceeding with assembly.

Bearing

• If bearings are chipped (by friction), pitted, worn, rusted, scratched, or unusual noise is coming from bearing,

replace with new bearing assembly (as a new set).

• Bearing must be replaced with a new one whenever disassembled.

Side Gear and Pinion Mate Gear

• If any cracks or damage are found on the surface of the teeth, replace with new one.

• If any worn or chipped marks are found on the side of the side gear and pinion mate gear which contact the

thrust washer, replace with new one.

• Replace both side gear and pinion mate gear as a set when replacing side gear or pinion mate gear.

Side Gear Thrust Washer and Pinion Mate Thrust Washer

• If any chips (by friction), damage, or unusual wear are found, replace with new one.

Gear Carrier

• If any wear or cracks are found on the contact sides of gear carrier, replace with new one.

Companion Flange

• If any chips (about 0.1mm, 0.004 in) or other damage on the companion flange surface which contacts the

front oil seal lips are found, replace with new one.

ADJUSTING AND SELECTING WASHERS

Side Gear Back Clearance

• Assemble the differential parts if they are disassembled.

1. Place the differential case straight up so that the side gear to be

measured is upward.

PDIA0460E