ad blue INFINITI QX56 2007 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 629 of 3061

NAVIGATION SYSTEM

AV-89

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

AV

N

O

P

Terminal and Reference Value for NAVI Control UnitINFOID:0000000003533713

Te r m i n a l N o .

(Wire color)

ItemSignal

input/

outputCondition

Vo l ta g e

(Approx.)Example of

symptom

+–Igni-

tion

switchOperation

1 (B) Ground Ground – ON – 0V –

2 (Y) Ground Battery power Input OFF – Battery voltageSystem does not

work properly.

5 (O) Ground ACC signal Input ACC – Battery voltageSystem does not

work properly.

12 (B) 14 (W)Voice guide

signalOutput ONPress the “GUIDE/

VOICE” button.Only route guide

and operation

guide are not

heard.

13 – Shield ground – – – –Audio noise in-

terference.

44 (R) 47RGB signal

(R: red)Output ONSelect “Display Di-

agnosis (NAVI)” of

CONFIRMATION/

ADJUSTMENT

function.NAVI screen

looks bluish.

45 (R/W) 47RGB signal

(G: green)Output ONSelect “Display Di-

agnosis (NAVI)” of

CONFIRMATION/

ADJUSTMENT

function.NAVI screen

looks reddish.

46 (B) 47RGB signal

(B: blue)Output ONSelect “Display Di-

agnosis (NAVI)” of

CONFIRMATION/

ADJUSTMENT

function.NAVI screen

looks yellowish.

47 – Shield ground – – – –Video display in-

terference.

48 (BR) 49RGB syn-

chronizing

signalOutput ONPress the “MAP”

button.NAVI screen is

rolling.

SKIA0171J

SKIA4977E

SKIA4978E

SKIA4979E

SKIA0164E

Page 633 of 3061

NAVIGATION SYSTEM

AV-93

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

AV

N

O

P

42 (W/L) GroundAudio RX

communica-

tion signalInput ONOperate audio

volume.Audio does not

operate properly.

43 (W) 41RGB syn-

chronizing

signalInput ONPress the “MAP”

button.NAVI screen is

rolling.

44 (R/L) 45RGB signal

(R: red)Input ONSelect “Display Di-

agnosis (NAVI)” of

CONFIRMATION/

ADJUSTMENT

function.NAVI screen

looks bluish.

45 – Shield ground – – – – –

46 (R/W) 45RGB signal

(G: green)Input ONSelect “Display Di-

agnosis (NAVI)” of

CONFIRMATION/

ADJUSTMENT

function.NAVI screen

looks reddish.

47 – Shield ground – – – – –

48 (B) 45RGB signal

(B: blue)Input ONSelect “Display Di-

agnosis (NAVI)” of

CONFIRMATION/

ADJUSTMENT

function.NAVI screen

looks yellowish.

49 – Shield ground – – – – –

50 (R/L) 47RGB signal

(R: red)Output ONSelect “Display Di-

agnosis (DCU)” of

CONFIRMATION/

ADJUSTMENT

function.NAVI screen

looks bluish. Te r m i n a l N o .

(Wire color)

ItemSignal

input/

outputCondition

Vo l ta g e

(Approx.)Example of

symptom

+–Igni-

tion

switchOperation

SKIA4403E

SKIA0164E

SKIA4977E

SKIA4978E

SKIA4979E

SKIA4980E

Page 634 of 3061

AV-94

< SERVICE INFORMATION >

NAVIGATION SYSTEM

51 (B) 49RGB area

(YS) signalOutput ONPress the“TRIP”

button.RGB screen is

not shown.

52 (R/W) 47RGB signal

(G: green)Output ONSelect “Display Di-

agnosis (DCU)” of

CONFIRMATION/

ADJUSTMENT

function.Screen looks

reddish.

53 (W) 49Vertical syn-

chronizing

(VP) signalInput ON –Operating

screen for audio

and A/C is not

displayed when

showing NAVI

screen.

54 (B) 47RGB signal

(B: blue)Output ONSelect “Display Di-

agnosis (DCU)” of

CONFIRMATION/

ADJUSTMENT

function.Screen looks

yellowish.

55 (R) 49Horizontal

synchroniz-

ing (HP) sig-

nalInput ON –Operating

screen for audio

and A/C is not

displayed when

showing NAVI

screen.

56 (G) 49RGB syn-

chronizing

signalOutput ONPress the “TRIP”

button.NAVI screen is

rolling. Te r m i n a l N o .

(Wire color)

ItemSignal

input/

outputCondition

Voltag e

(Approx.)Example of

symptom

+–Igni-

tion

switchOperation

SKIA0162E

SKIA4981E

SKIA4983E

SKIA4982E

SKIA4983E

SKIA0164E

Page 636 of 3061

AV-96

< SERVICE INFORMATION >

NAVIGATION SYSTEM

Terminal and Reference Value for AV Switch

INFOID:0000000003533716

18 (B) 7RGB signal

(B: blue)Input ONSelect “Display Di-

agnosis (DCU)” of

CONFIRMATION/

ADJUSTMENT

function.Screen looks

yellowish.

19 (G) 21RGB syn-

chronizing

signalInput ONPress the “TRIP”

button.NAVI screen is

rolling.

20 (W) 21Vertical syn-

chronizing

(VP) signalOutput ON –Operating

screen for audio

and A/C is not

displayed when

showing NAVI

screen.

21 – Shield ground – – – – –

22 (L) 23Display com-

munication

signal

(DSP-DCU)Output ON –Though a screen

is displayed, it is

impossible to ad-

just brightness.

23 – Shield ground – – – – – Terminal No. (Wire

color)

ItemSignal

input/

outputCondition

Voltag e

(Approx.)Example of

symptom

+–Igni-

tion

switchOperation

SKIA4982E

SKIA0164E

SKIA4983E

SKIA4363E

Te r m i n a l N o .

(Wire color)

ItemSignal

input/

outputCondition

Vo l ta g e

(Approx.)Example of

symptom

+–Ignition

switchOperation

1 (Y) Ground Battery power Input OFF - Battery voltageSystem does not

work properly.

2 (V) Ground ACC signal Input ACC - Battery voltageSystem does not

work properly.

3 (R/L) GroundIllumination

signalInput OFFLighting switch is

ON (position 1).Battery voltageAV switch illumi-

nation does not

come on when

lighting switch is

ON (position 1). Turn lighting switch

OFF.3.0V or less

Page 644 of 3061

AV-104

< SERVICE INFORMATION >

NAVIGATION SYSTEM

5. When “Confirmation/Adjustment” is selected on the initial self-

diagnosis screen, the operation will enter the CONFIRMATION/

ADJUSTMENT mode. In this mode, check and adjustment of

each item will become possible.

6. The initial trouble diagnosis screen will be shown, and items

“Display Diagnosis”, “Vehicle Signals”, “Auto Climate Control”

and “Navigation” will become selective.

7. Select each switch on “CONFIRMATION/ADJUSTMENT”

screen to display the relevant diagnosis screen.

DISPLAY DIAGNOSIS

• When RGB signal error occurred in the RGB system, tone of the color bar will change as follows.

• When the color of the screen looks unusual, refer to AV-125, "

Color of RGB Image Is Not Proper (Only NAVI

Screen Looks Bluish)", AV-129, "Color of RGB Image Is Not Proper (All Screens Look Reddish)" and AV-

129, "Color of RGB Image Is Not Proper (All Screens Look Yellowish)".

VEHICLE SIGNALS

• A comparison check can be made of each actual vehicle signal

and the signals recognized by the system.

CAUTION:

In case of confirming light signal, set D/N mode to ON/OFF of

lighting switch (normal setting).

• OFF: D (Day mode)

• ON: N (Night mode)

Unless above setting, light signal (ON/OFF) may not be accu-

rately displayed.

SKIA4220E

WKIA4316E

R (red) signal error : Screen looks bluish

G (green) signal error : Screen looks reddish

B (blue) signal error : Screen looks yellowish

WKIA4306E

Diagnosis item Display Condition Remarks

Vehicle speedON Vehicle speed > 0 km/h (0 MPH)

Changes in indication may be delayed by ap-

prox. 1.5 seconds. This is normal. OFF Vehicle speed = 0 km/h (0 MPH)

– Ignition switch in ACC position

Page 645 of 3061

NAVIGATION SYSTEM

AV-105

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

AV

N

O

P

• If vehicle speed is NG, refer to AV-115, "Vehicle Speed Signal Inspection for Display Control Unit".

• If light is NG, refer to AV-116, "

Illumination Signal Inspection for Display Control Unit".

• If IGN is NG, refer to AV-117, "

Ignition Signal Inspection for Display Control Unit".

• If reverse is NG, refer to AV-118, "

Reverse Signal Inspection for Display Control Unit".

NAVIGATION

1. The initial confirmation/adjustment screen will be shown, and

items “Display Diagnosis”, “Vehicle Signals”, “Navigation”,

"Error History“ and "Delete Unit Connection Log” will become

selective.

2. Select each switch on “CONFIRMATION/ADJUSTMENT”

screen to display the relevant diagnosis screen.

DISPLAY DIAGNOSIS

• When RGB signal error occurred in the RGB system, tone of the color bar will change as follows.

• When the color of the screen looks unusual, refer to AV-125, "

Color of RGB Image Is Not Proper (Only NAVI

Screen Looks Bluish)", AV-126, "Color of RGB Image Is Not Proper (Only NAVI Screen Looks Reddish)" and

AV-127, "

Color of RGB Image Is Not Proper (Only NAVI Screen Looks Yellowish)".

VEHICLE SIGNALS

LightON Lighting switch ON

–

OFF Lighting switch OFF

IGNON Ignition switch ON

–

OFF Ignition switch ACC

ReverseON Selector lever in R position

Changes in indication may be delayed by ap-

prox. 1.5 seconds. This is normal. OFF Selector lever in other than R position

– Ignition switch in ACC position Diagnosis item Display Condition Remarks

WKIA4311E

WKIA4317E

R (red) signal error : Screen looks bluish

G (green) signal error : Screen looks reddish

B (blue) signal error : Screen looks yellowish

Page 1802 of 3061

EM-32

< SERVICE INFORMATION >

FUEL INJECTOR AND FUEL TUBE

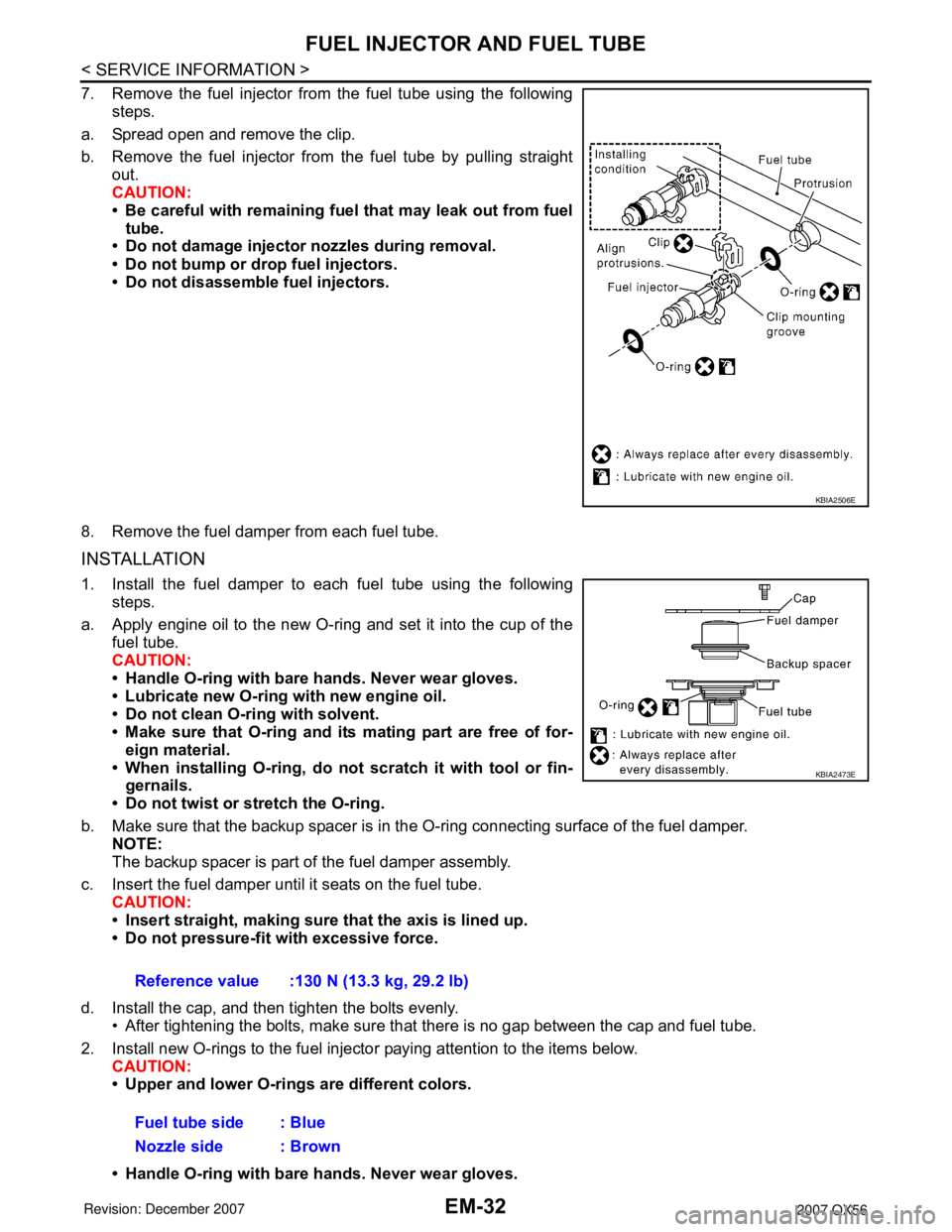

7. Remove the fuel injector from the fuel tube using the followingsteps.

a. Spread open and remove the clip.

b. Remove the fuel injector from the fuel tube by pulling straight out.

CAUTION:

• Be careful with remaining fuel that may leak out from fueltube.

• Do not damage injector nozzles during removal.

• Do not bump or drop fuel injectors.

• Do not disassemble fuel injectors.

8. Remove the fuel damper from each fuel tube.

INSTALLATION

1. Install the fuel damper to each fuel tube using the following steps.

a. Apply engine oil to the new O-ring and set it into the cup of the fuel tube.

CAUTION:

• Handle O-ring with bare hands. Never wear gloves.

• Lubricate new O-ring with new engine oil.

• Do not clean O-ring with solvent.

• Make sure that O-ring and its mating part are free of for-eign material.

• When installing O-ring, do not scratch it with tool or fin-

gernails.

• Do not twist or stretch the O-ring.

b. Make sure that the backup spacer is in the O-ring connecting surface of the fuel damper.

NOTE:

The backup spacer is part of the fuel damper assembly.

c. Insert the fuel damper until it seats on the fuel tube. CAUTION:

• Insert straight, making sure that the axis is lined up.

• Do not pressure-fit with excessive force.

d. Install the cap, and then tighten the bolts evenly. • After tightening the bolts, make sure that there is no gap between the cap and fuel tube.

2. Install new O-rings to the fuel injector paying attention to the items below. CAUTION:

• Upper and lower O-rings are different colors.

• Handle O-ring with bare hands. Never wear gloves.

KBIA2506E

Reference value :130 N (13.3 kg, 29.2 lb)

Fuel tube side : Blue

Nozzle side : Brown

KBIA2473E

Page 1842 of 3061

EM-72

< SERVICE INFORMATION >

CYLINDER HEAD

VALVE SEAT CONTACT

• After confirming that the dimensions of the valve guides and valves

are within specifications, perform this procedure.

• Apply prussian blue (or white lead) onto the contacting surface of

the valve seat to check the condition of the valve contact on the

surface.

• Check if the contact area band is continuous all around the circum-

ference.

• If not, grind to adjust the valve fit and check again. If the contacting

surface still has NG conditions even after the re-check, replace the

valve seat.

VALVE SEAT REPLACEMENT

When the valve seat is removed, replace it with oversized (0.5 mm, 0.020 in) valve seat.

1. Bore out the old seat until it collapses. Boring should not continue beyond the bottom face of the seat

recess in the cylinder head. Set the machine depth stop to ensure this.

2. Ream the cylinder head recess diameter for service valve seat.

• Be sure to ream in circles concentric to the valve guide center.

• This will enable valve seat to fit correctly.

3. Heat the cylinder head to 110° to 130°C (230° to 266°F) by

soaking it in heated oil.

4. Cool the valve seats well with dry ice. Force fit the valve seat into the cylinder head.

CAUTION:

• Avoid directly touching cold valve seats.

• Cylinder head contains heat. When working, wear protective equipment to avoid getting burned.

5. Finish the seat to the specified dimensions using suitable tool.

Refer to EM-103, "

Standard and Limit".

CAUTION:

When using valve seat cutter, firmly grip the cutter handle

with both hands. Then, press on the contacting surface all

around the circumference to cut in a single drive. Improper

pressure on the cutter or cutting many different times may

result in stage valve seat.

SBIA0322E

Oversize [0.5 mm (0.020 in)] (Service):

Intake : 38.500 - 38.516 mm (1.5157 - 1.5164 in)

Exhaust : 32.700 - 32.716 mm (1.2874 - 1.2880 in)

SEM795A

SEM008A

SEM934C

Page 1862 of 3061

EM-92

< SERVICE INFORMATION >

CYLINDER BLOCK

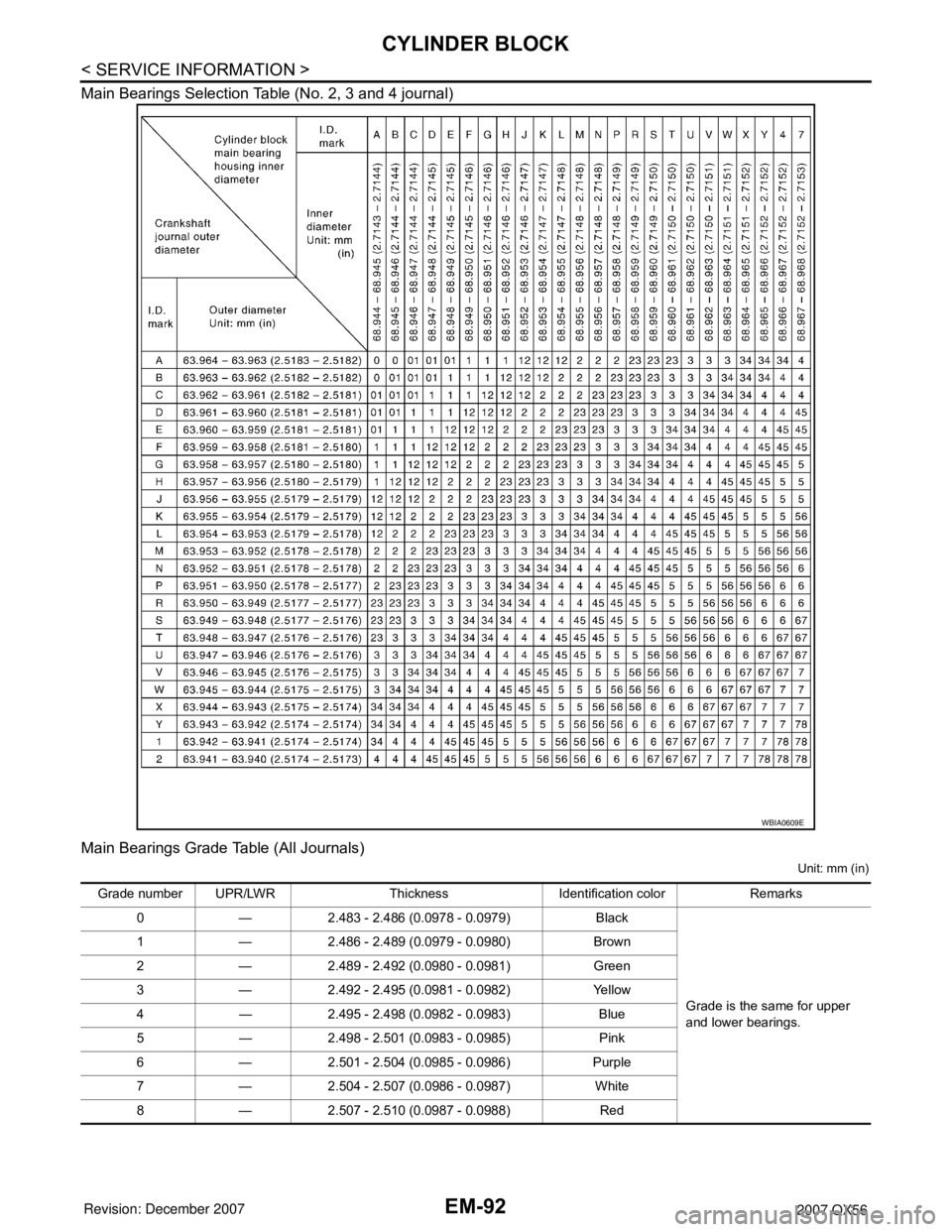

Main Bearings Selection Table (No. 2, 3 and 4 journal)

Main Bearings Grade Table (All Journals)

Unit: mm (in)

WBIA0609E

Grade number UPR/LWR Thickness Identification color Remarks

0 — 2.483 - 2.486 (0.0978 - 0.0979) Black

Grade is the same for upper

and lower bearings. 1 — 2.486 - 2.489 (0.0979 - 0.0980) Brown

2 — 2.489 - 2.492 (0.0980 - 0.0981) Green

3 — 2.492 - 2.495 (0.0981 - 0.0982) Yellow

4 — 2.495 - 2.498 (0.0982 - 0.0983) Blue

5 — 2.498 - 2.501 (0.0983 - 0.0985) Pink

6 — 2.501 - 2.504 (0.0985 - 0.0986) Purple

7 — 2.504 - 2.507 (0.0986 - 0.0987) White

8 — 2.507 - 2.510 (0.0987 - 0.0988) Red

Page 1863 of 3061

CYLINDER BLOCK

EM-93

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

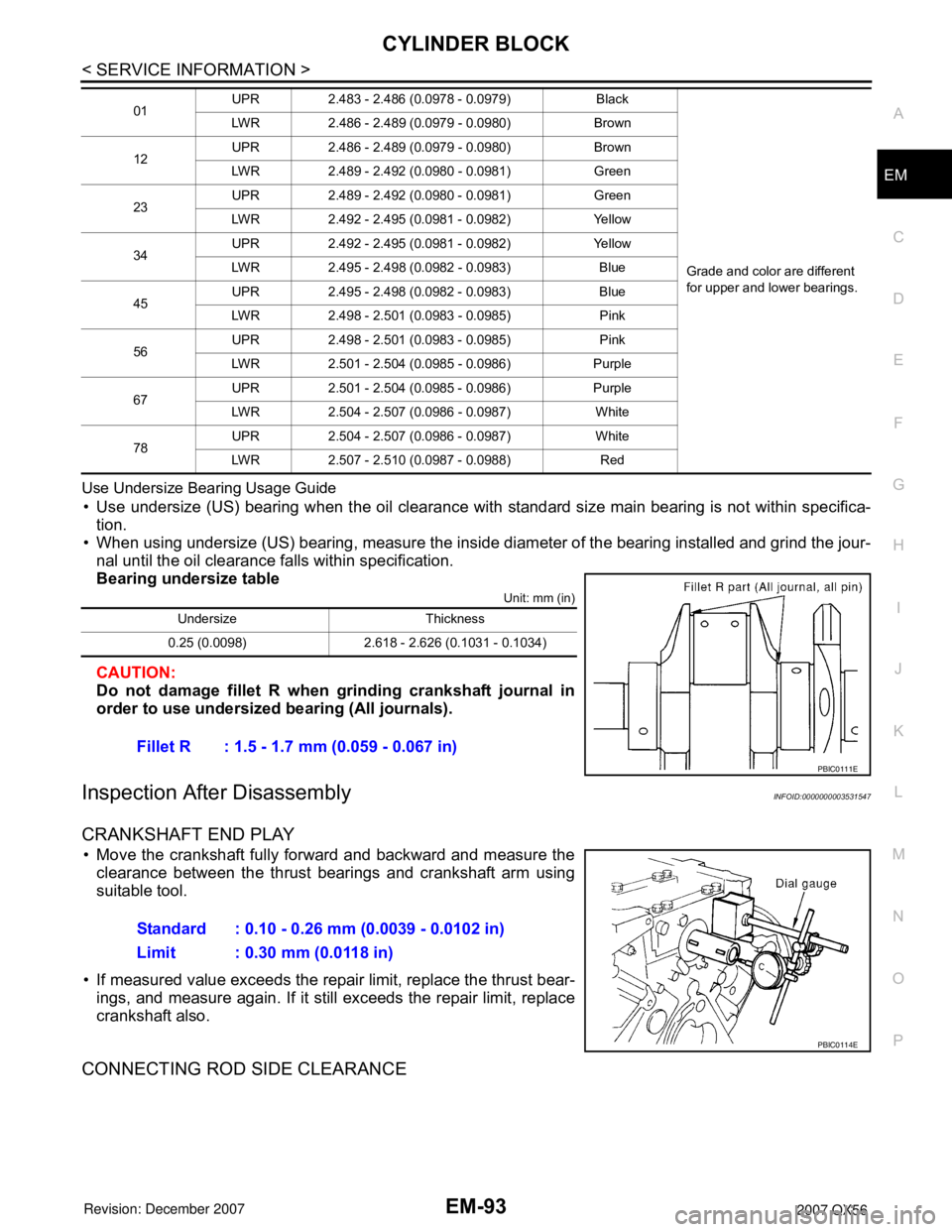

P O Use Undersize Bearing Usage Guide

• Use undersize (US) bearing when the oil clearance with standard size main bearing is not within specifica-

tion.

• When using undersize (US) bearing, measure the inside diameter of the bearing installed and grind the jour-

nal until the oil clearance falls within specification.

Bearing undersize table

Unit: mm (in)

CAUTION:

Do not damage fillet R when grinding crankshaft journal in

order to use undersized bearing (All journals).

Inspection After DisassemblyINFOID:0000000003531547

CRANKSHAFT END PLAY

• Move the crankshaft fully forward and backward and measure the

clearance between the thrust bearings and crankshaft arm using

suitable tool.

• If measured value exceeds the repair limit, replace the thrust bear-

ings, and measure again. If it still exceeds the repair limit, replace

crankshaft also.

CONNECTING ROD SIDE CLEARANCE

01UPR 2.483 - 2.486 (0.0978 - 0.0979) Black

Grade and color are different

for upper and lower bearings. LWR 2.486 - 2.489 (0.0979 - 0.0980) Brown

12UPR 2.486 - 2.489 (0.0979 - 0.0980) Brown

LWR 2.489 - 2.492 (0.0980 - 0.0981) Green

23UPR 2.489 - 2.492 (0.0980 - 0.0981) Green

LWR 2.492 - 2.495 (0.0981 - 0.0982) Yellow

34UPR 2.492 - 2.495 (0.0981 - 0.0982) Yellow

LWR 2.495 - 2.498 (0.0982 - 0.0983) Blue

45UPR 2.495 - 2.498 (0.0982 - 0.0983) Blue

LWR 2.498 - 2.501 (0.0983 - 0.0985) Pink

56UPR 2.498 - 2.501 (0.0983 - 0.0985) Pink

LWR 2.501 - 2.504 (0.0985 - 0.0986) Purple

67UPR 2.501 - 2.504 (0.0985 - 0.0986) Purple

LWR 2.504 - 2.507 (0.0986 - 0.0987) White

78UPR 2.504 - 2.507 (0.0986 - 0.0987) White

LWR 2.507 - 2.510 (0.0987 - 0.0988) Red

Undersize Thickness

0.25 (0.0098) 2.618 - 2.626 (0.1031 - 0.1034)

Fillet R : 1.5 - 1.7 mm (0.059 - 0.067 in)

PBIC0111E

Standard : 0.10 - 0.26 mm (0.0039 - 0.0102 in)

Limit : 0.30 mm (0.0118 in)

PBIC0114E