sunroof INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 603 of 3061

TELEPHONE

AV-63

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

AV

N

O

P

CAUTION:

To avoid damage use care when removing console finisher.

• Sunroof switch (2).

• Microphone (3).

• Front personal/map lamp LH (4).

• Interior lamp switch (5).

• Front personal/map lamp RH (6).

1. Remove console assembly, roof finisher.

2. Release Bluetooth ON indicator tabs.

3. Disconnect Bluetooth ON indicator connector.

4. Remove Bluetooth ON indicator (1).

Installation

Installation is in the reverse order of removal.

MICROPHONE

Removal

CAUTION:

To avoid damage use care when removing console finisher.

• Bluetooth on indicator (1).

• Sunroof switch (2).

• Front personal/map lamp LH (4).

• Interior lamp switch (5).

• Front personal/map lamp RH (6).

1. Remove console assembly, roof finisher.

2. Release microphone tabs.

3. Disconnect microphone connector.

4. Remove microphone (3).

Installation

Installation is in the reverse order of removal.

LKIA0667E

LKIA0667E

Page 693 of 3061

BCS-6

< SERVICE INFORMATION >

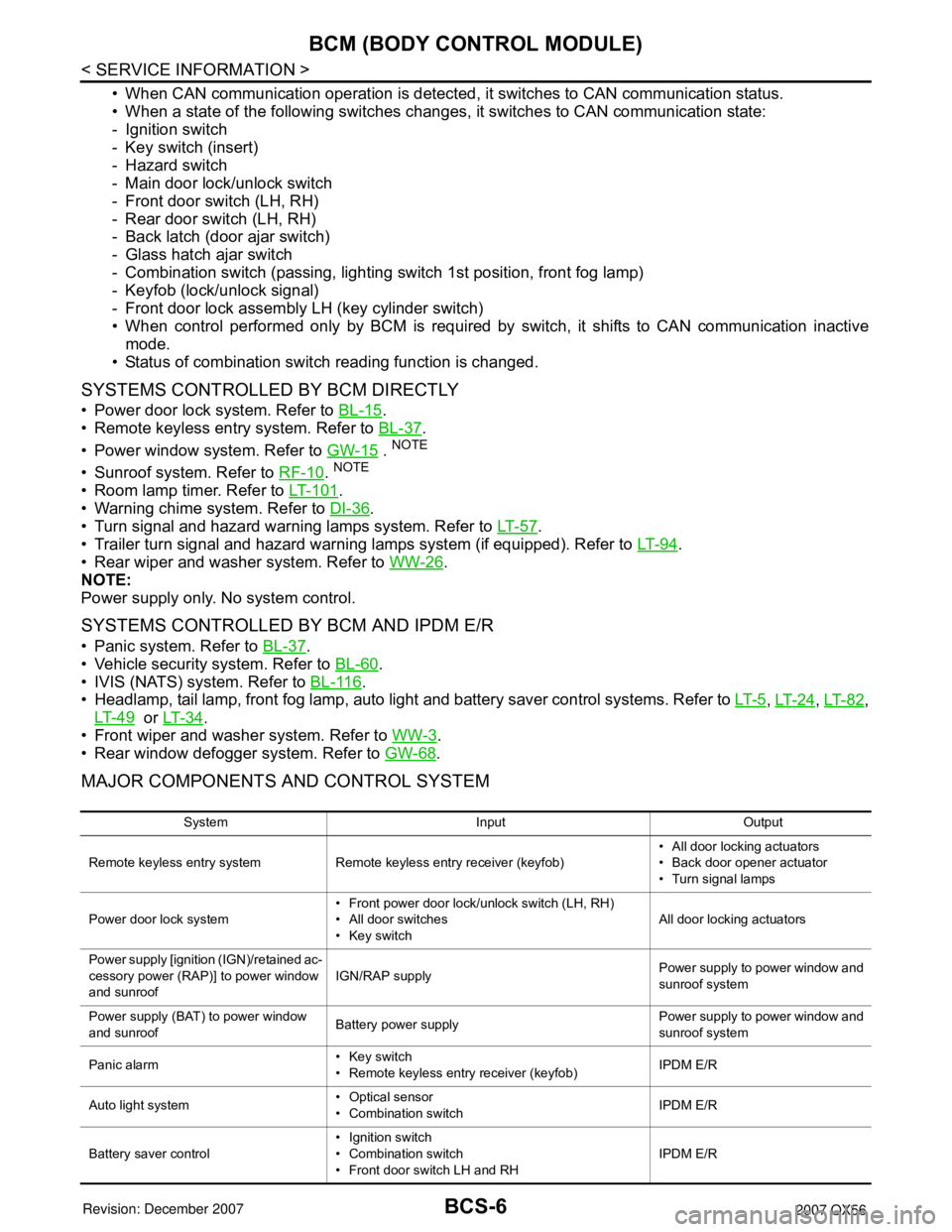

BCM (BODY CONTROL MODULE)

• When CAN communication operation is detected, it switches to CAN communication status.

• When a state of the following switches changes, it switches to CAN communication state:

- Ignition switch

- Key switch (insert)

- Hazard switch

- Main door lock/unlock switch

- Front door switch (LH, RH)

- Rear door switch (LH, RH)

- Back latch (door ajar switch)

- Glass hatch ajar switch

- Combination switch (passing, lighting switch 1st position, front fog lamp)

- Keyfob (lock/unlock signal)

- Front door lock assembly LH (key cylinder switch)

• When control performed only by BCM is required by switch, it shifts to CAN communication inactive

mode.

• Status of combination switch reading function is changed.

SYSTEMS CONTROLLED BY BCM DIRECTLY

• Power door lock system. Refer to BL-15.

• Remote keyless entry system. Refer to BL-37

.

• Power window system. Refer to GW-15

. NOTE

• Sunroof system. Refer to RF-10. NOTE

• Room lamp timer. Refer to LT-101.

• Warning chime system. Refer to DI-36

.

• Turn signal and hazard warning lamps system. Refer to LT- 5 7

.

• Trailer turn signal and hazard warning lamps system (if equipped). Refer to LT- 9 4

.

• Rear wiper and washer system. Refer to WW-26

.

NOTE:

Power supply only. No system control.

SYSTEMS CONTROLLED BY BCM AND IPDM E/R

• Panic system. Refer to BL-37.

• Vehicle security system. Refer to BL-60

.

• IVIS (NATS) system. Refer to BL-116

.

• Headlamp, tail lamp, front fog lamp, auto light and battery saver control systems. Refer to LT- 5

, LT- 2 4, LT- 8 2,

LT- 4 9

or LT- 3 4.

• Front wiper and washer system. Refer to WW-3

.

• Rear window defogger system. Refer to GW-68

.

MAJOR COMPONENTS AND CONTROL SYSTEM

System Input Output

Remote keyless entry system Remote keyless entry receiver (keyfob)• All door locking actuators

• Back door opener actuator

• Turn signal lamps

Power door lock system• Front power door lock/unlock switch (LH, RH)

• All door switches

• Key switchAll door locking actuators

Power supply [ignition (IGN)/retained ac-

cessory power (RAP)] to power window

and sunroofIGN/RAP supplyPower supply to power window and

sunroof system

Power supply (BAT) to power window

and sunroofBattery power supplyPower supply to power window and

sunroof system

Panic alarm• Key switch

• Remote keyless entry receiver (keyfob)IPDM E/R

Auto light system• Optical sensor

• Combination switchIPDM E/R

Battery saver control• Ignition switch

• Combination switch

• Front door switch LH and RHIPDM E/R

Page 719 of 3061

BL-8

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lense loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 851 of 3061

BL-140

< SERVICE INFORMATION >

BODY REPAIR

5. Front pillar hinge brace (RH, LH)

6. Center pillar hinge brace

7. Outer front pillar reinforcement (RH, LH)

8. Center inner pillar (RH, LH)

9. Front inner pillar upper (RH, LH)

10. Inner roof side rail (RH, LH)

11. Roof with sunroof opening

12. Roof

13. Front roof rail

14. Sunroof reinforcement

15. Roof 1st bow

16. Roof 2nd bow

17. Roof 3rd bow

18. Roof 4th bow

19. Rear roof rail

20. Main back pillar (RH, LH)

21. Back pillar reinforcement (RH, LH)

22. Rear inner side panel (RH, LH)

23. Rear wheel housing (RH, LH)

24. Rear body side outer (RH, LH)

25. Front body side outer (RH, LH)

26. Front door assembly (RH, LH)

27. Rear door assembly (RH, LH)

28. Lift gate assembly

Page 1736 of 3061

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

EI-7

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

EI

N

O

P

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator installation pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 1766 of 3061

HEADLINING

EI-37

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

EI

N

O

P

HEADLINING

Removal and InstallationINFOID:0000000003533138

1. Headlining (without sunroof) 2. Assist grip bracket 3. Assist grip

4. Sunvisor assembly LH 5. Cap LH 6. Sunvisor holder

7. Front roof console 8. Sunglass bin 9. Sunroof welt

WIIA0969E

Page 1767 of 3061

EI-38

< SERVICE INFORMATION >

HEADLINING

CAUTION:

Disconnect both terminals from battery in advance.

REMOVAL

1. Disconnect the battery negative and positive cables, then wait at least 3 minutes.

2. Remove body side trim. Refer to EI-34

.

3. Remove luggage floor trim. Refer to EI-39

.

4. Remove sunvisor assemblies.

5. Remove sunvisor clips.

6. Remove sunroof welt (if equipped).

7. Remove front roof console.

• Disconnect harnesses.

8. Remove rear roof console.

• Disconnect harnesses.

9. Remove assist grips.

10. Remove lamp assembly and rear roof finisher.

• Disconnect harness.

11. Remove headlining.

• Remove clips from rear of headlining.

• Disconnect harnesses.

12. Remove rear air control.

• Disconnect harness.

13. Remove rear audio control assembly.

• Disconnect harness.

14. Remove lamp assemblies.

• Disconnect harnesses.

15. Remove air vents.

16. Remove the front roof console bracket.

17. Remove rear roof console front bracket.

18. Remove assist grip brackets from roof.

INSTALLATION

Installation is in the reverse order of removal.

10. Cap RH 11. Sunvisor assembly RH 12. Rear roof console bracket

13. Rear storage bin or DVD display 14. Rear air control 15. Rear audio control assembly

16. Rear roof console 17. Rear roof console finisher 18. Rear storage bin

19. Air vent 20. Lamp assembly 21. Plastic clip

22. Headlining (with sunroof) 23. Rear lamp lens 24. Rear lamp

25. Rear roof finisher 26. Plastic clip 27. Metal clip

⇐Vehicle front

Page 2027 of 3061

GW-8

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINER

Noises in the sunroof/headliner area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lense loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 2051 of 3061

GW-32

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

WORK SUPPORT

DATA MONITOR

Trouble Diagnosis Symptom ChartINFOID:0000000003533036

• Check that other systems using the signal of the following systems operate normally.

Te s t I t e m D e s c r i p t i o n

RETAINED PWRThis test is able to supply RAP signal (power) from BCM (body control module) to power window

system and power sunroof system (if equipped). Those systems can be operated when turning on

“RETAINED PWR” on CONSULT-II screen even if the ignition switch is turned OFF.

NOTE:

During this test, CONSULT-II can be operated with ignition switch in OFF position. “RETAINED

P W R ” s h o u l d b e t u r n e d “ O N ” o r “ O F F ” o n C O N S U LT- I I s c r e e n w h e n i g n i t i o n s w i t c h i s O N . T h e n t u r n

ignition switch OFF to check retained power operation. CONSULT-II might be stuck if “RETAINED

PWR” is turned “ON” or “OFF” on CONSULT-II screen when ignition switch is OFF.

Work item Description

RETAINED PWRRAP signal’s power supply period can be changed by mode setting. Selects RAP signal’s power

supply period between three steps

• MODE1 (45 sec.) / MODE2 (OFF) / MODE 3 (2 min.).

Work item Description

IGN ON SW Indicates (ON/OFF) condition of ignition switch

DOOR SW-DR Indicates (ON/OFF) condition of front door switch driver side

DOOR SW-AS Indicates (ON/OFF) condition of front door switch passenger side

Symptom Repair order Refer to page

None of the power windows can be operated using any switch1. BCM power supply and ground circuit checkBCS-15

2. Main power window and door lock/unlock

power supply and ground circuit checkGW-34

3. Power window serial link check front LH and

RHGW-46

Front power window LH alone does not operate1. Main power window and door lock/unlock

power supply and ground circuit checkGW-342. Front power window motor LH circuit checkGW-36

3. Replace main power window and door lock/

unlock switchEI-31

Front power window RH alone does not operate1. Power window and door lock/unlock switch

RH power supply and ground circuit checkGW-352. Power window serial link check front LH and

RHGW-46

3. Front power window motor RH circuit checkGW-37

4. Replace BCMBCS-24

Rear power window LH alone does not operate1. Rear power window control unit LH or RH

power supply and ground circuit checkGW-48

2. Rear power window switch LH or RH power

supply and ground circuit checkGW-49

3. Rear power window motor LH circuit checkGW-50

4. Power window serial link check rear LH and

RHGW-54

5. Replace BCMBCS-24

Page 2108 of 3061

IDX-4

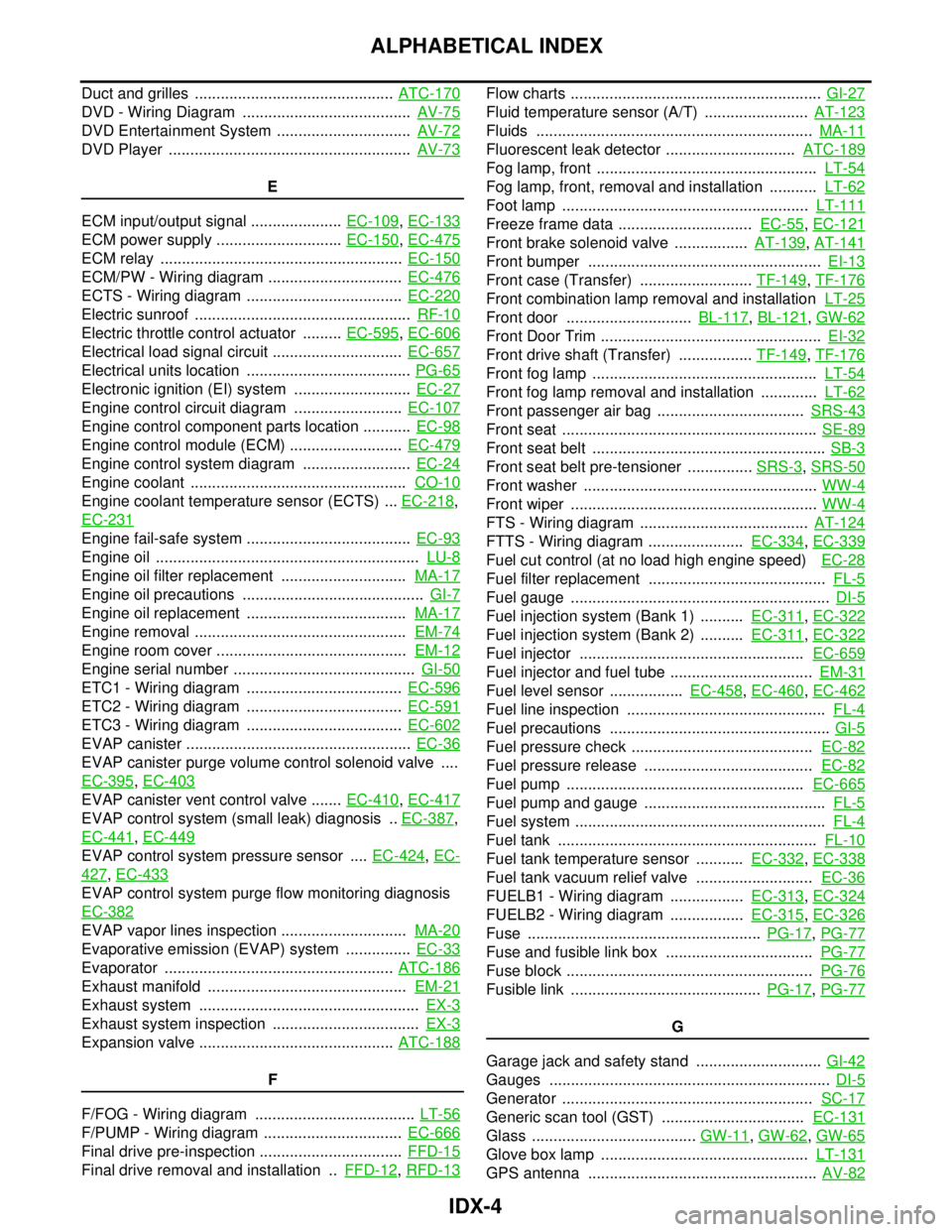

ALPHABETICAL INDEX

Duct and grilles .............................................. ATC-170

DVD - Wiring Diagram ....................................... AV-75

DVD Entertainment System ............................... AV-72

DVD Player ........................................................ AV-73

E

ECM input/output signal ..................... EC-109

, EC-133

ECM power supply ............................. EC-150, EC-475

ECM relay ........................................................ EC-150

ECM/PW - Wiring diagram ............................... EC-476

ECTS - Wiring diagram .................................... EC-220

Electric sunroof .................................................. RF-10

Electric throttle control actuator ......... EC-595, EC-606

Electrical load signal circuit .............................. EC-657

Electrical units location ...................................... PG-65

Electronic ignition (EI) system ........................... EC-27

Engine control circuit diagram ......................... EC-107

Engine control component parts location ........... EC-98

Engine control module (ECM) .......................... EC-479

Engine control system diagram ......................... EC-24

Engine coolant .................................................. CO-10

Engine coolant temperature sensor (ECTS) ... EC-218,

EC-231

Engine fail-safe system ...................................... EC-93

Engine oil ............................................................. LU-8

Engine oil filter replacement ............................. MA-17

Engine oil precautions .......................................... GI-7

Engine oil replacement ..................................... MA-17

Engine removal ................................................. EM-74

Engine room cover ............................................ EM-12

Engine serial number .......................................... GI-50

ETC1 - Wiring diagram .................................... EC-596

ETC2 - Wiring diagram .................................... EC-591

ETC3 - Wiring diagram .................................... EC-602

EVAP canister .................................................... EC-36

EVAP canister purge volume control solenoid valve ....

EC-395

, EC-403

EVAP canister vent control valve ....... EC-410, EC-417

EVAP control system (small leak) diagnosis .. EC-387,

EC-441

, EC-449

EVAP control system pressure sensor .... EC-424, EC-

427, EC-433

EVAP control system purge flow monitoring diagnosis

EC-382

EVAP vapor lines inspection ............................. MA-20

Evaporative emission (EVAP) system ............... EC-33

Evaporator ..................................................... ATC-186

Exhaust manifold .............................................. EM-21

Exhaust system ................................................... EX-3

Exhaust system inspection .................................. EX-3

Expansion valve ............................................. ATC-188

F

F/FOG - Wiring diagram ..................................... LT-56

F/PUMP - Wiring diagram ................................ EC-666

Final drive pre-inspection ................................. FFD-15

Final drive removal and installation .. FFD-12, RFD-13

Flow charts .......................................................... GI-27

Fluid temperature sensor (A/T) ........................ AT-123

Fluids ................................................................ MA-11

Fluorescent leak detector .............................. ATC-189

Fog lamp, front ................................................... LT-54

Fog lamp, front, removal and installation ........... LT-62

Foot lamp ......................................................... LT-111

Freeze frame data ............................... EC-55, EC-121

Front brake solenoid valve ................. AT-139, AT-141

Front bumper ...................................................... EI-13

Front case (Transfer) .......................... TF-149, TF-176

Front combination lamp removal and installation LT-25

Front door ............................. BL-117, BL-121, GW-62

Front Door Trim ................................................... EI-32

Front drive shaft (Transfer) ................. TF-149, TF-176

Front fog lamp .................................................... LT-54

Front fog lamp removal and installation ............. LT-62

Front passenger air bag .................................. SRS-43

Front seat ........................................................... SE-89

Front seat belt ...................................................... SB-3

Front seat belt pre-tensioner ............... SRS-3, SRS-50

Front washer ...................................................... WW-4

Front wiper ......................................................... WW-4

FTS - Wiring diagram ....................................... AT-124

FTTS - Wiring diagram ...................... EC-334, EC-339

Fuel cut control (at no load high engine speed) EC-28

Fuel filter replacement ......................................... FL-5

Fuel gauge ............................................................ DI-5

Fuel injection system (Bank 1) .......... EC-311, EC-322

Fuel injection system (Bank 2) .......... EC-311, EC-322

Fuel injector .................................................... EC-659

Fuel injector and fuel tube ................................. EM-31

Fuel level sensor ................. EC-458, EC-460, EC-462

Fuel line inspection .............................................. FL-4

Fuel precautions ................................................... GI-5

Fuel pressure check .......................................... EC-82

Fuel pressure release ....................................... EC-82

Fuel pump ....................................................... EC-665

Fuel pump and gauge .......................................... FL-5

Fuel system .......................................................... FL-4

Fuel tank ............................................................ FL-10

Fuel tank temperature sensor ........... EC-332, EC-338

Fuel tank vacuum relief valve ........................... EC-36

FUELB1 - Wiring diagram ................. EC-313, EC-324

FUELB2 - Wiring diagram ................. EC-315, EC-326

Fuse ...................................................... PG-17, PG-77

Fuse and fusible link box .................................. PG-77

Fuse block ......................................................... PG-76

Fusible link ............................................ PG-17, PG-77

G

Garage jack and safety stand ............................. GI-42

Gauges ................................................................. DI-5

Generator .......................................................... SC-17

Generic scan tool (GST) ................................. EC-131

Glass ...................................... GW-11, GW-62, GW-65

Glove box lamp ................................................ LT-131

GPS antenna ..................................................... AV-82