fuse box location INFINITI QX56 2007 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2034 of 3061

POWER WINDOW SYSTEM

GW-15

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

GW

N

O

P

POWER WINDOW SYSTEM

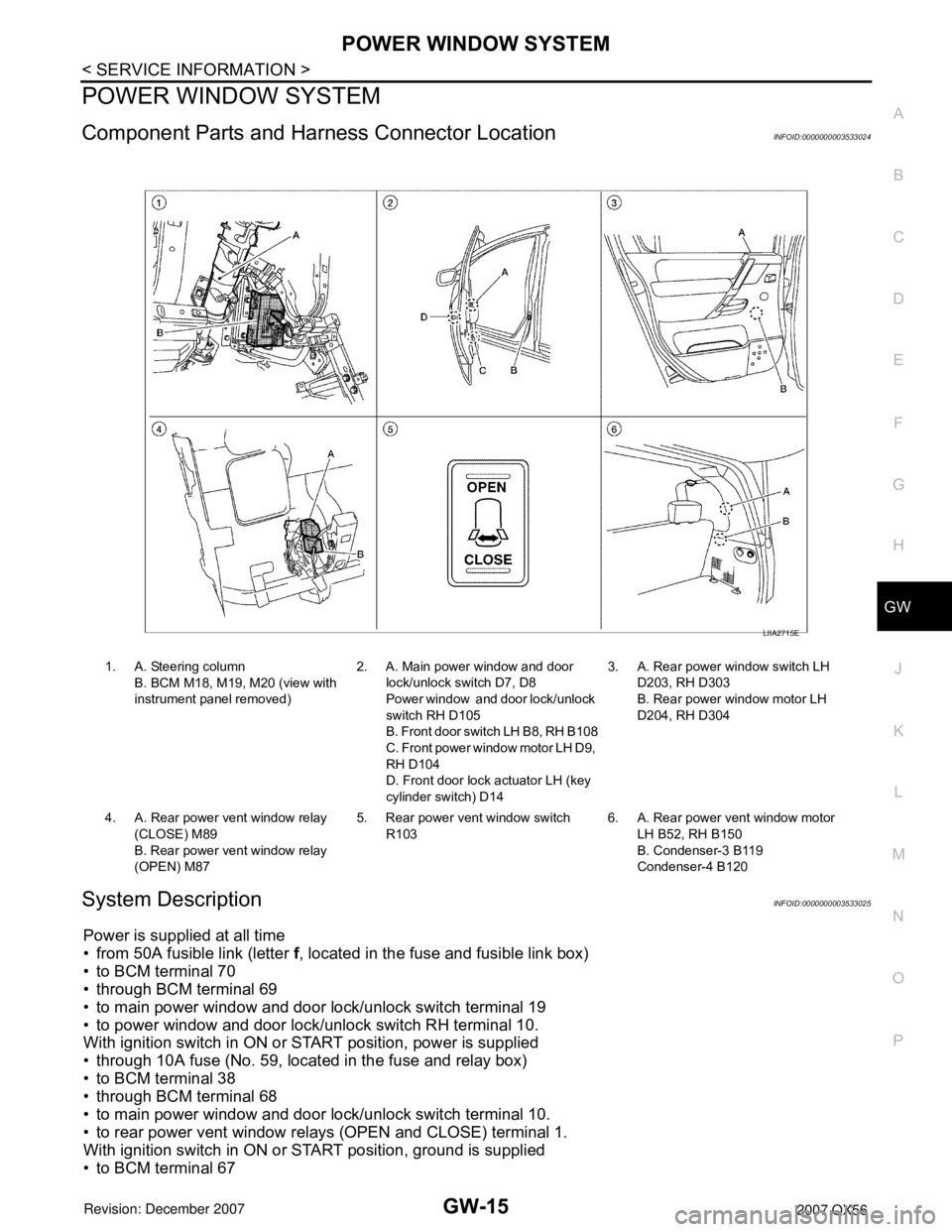

Component Parts and Harness Connector LocationINFOID:0000000003533024

System DescriptionINFOID:0000000003533025

Power is supplied at all time

• from 50A fusible link (letter f, located in the fuse and fusible link box)

• to BCM terminal 70

• through BCM terminal 69

• to main power window and door lock/unlock switch terminal 19

• to power window and door lock/unlock switch RH terminal 10.

With ignition switch in ON or START position, power is supplied

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38

• through BCM terminal 68

• to main power window and door lock/unlock switch terminal 10.

• to rear power vent window relays (OPEN and CLOSE) terminal 1.

With ignition switch in ON or START position, ground is supplied

• to BCM terminal 67

1. A. Steering column

B. BCM M18, M19, M20 (view with

instrument panel removed)2. A. Main power window and door

lock/unlock switch D7, D8

Power window and door lock/unlock

switch RH D105

B. Front door switch LH B8, RH B108

C. Front power window motor LH D9,

RH D104

D. Front door lock actuator LH (key

cylinder switch) D143. A. Rear power window switch LH

D203, RH D303

B. Rear power window motor LH

D204, RH D304

4. A. Rear power vent window relay

(CLOSE) M89

B. Rear power vent window relay

(OPEN) M875. Rear power vent window switch

R1036. A. Rear power vent window motor

LH B52, RH B150

B. Condenser-3 B119

Condenser-4 B120

LIIA2715E

Page 2087 of 3061

GW-68

< SERVICE INFORMATION >

REAR WINDOW DEFOGGER

REAR WINDOW DEFOGGER

Component Parts and Harness Connector LocationINFOID:0000000003533066

System DescriptionINFOID:0000000003533067

The rear window defogger system is controlled by BCM (body control module) and IPDM E/R (intelligent

power distribution module engine room).

The rear window defogger operates only for approximately 15 minutes.

Power is supplied at all times

• through 15A fuses (No. 43, 46, and 47 located in the IPDM E/R)

• to rear window defogger relay and heated mirror relay (located in the IPDM E/R)

• through 50A fusible link (letter f, located in the fuse and fusible link box)

• to BCM terminal 70.

With the ignition switch turned to ON or START position, power is supplied

• through ignition switch

• to rear window defogger relay (located in the IPDM E/R)

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38

• through 10A fuse [No. 8, located in the fuse block (J/B)]

• to front air control terminal 14.

Ground is supplied

• to BCM terminal 67

• to front air control terminal 1

• through body grounds M57, M61 and M79

1. A. Steering column

B. BCM M18, M20 (view with instru-

ment panel removed)2. Front air control M49, M50 3. A. Rear window defogger ground

connector D604

B. Rear window defogger connector

D406

4. IPDM E/R, E120, E122, E124 5. Door mirror LH (door mirror defog-

ger) D4

Door mirror RH (door mirror defog-

ger) D107

LIIA2716E

Page 2108 of 3061

IDX-4

ALPHABETICAL INDEX

Duct and grilles .............................................. ATC-170

DVD - Wiring Diagram ....................................... AV-75

DVD Entertainment System ............................... AV-72

DVD Player ........................................................ AV-73

E

ECM input/output signal ..................... EC-109

, EC-133

ECM power supply ............................. EC-150, EC-475

ECM relay ........................................................ EC-150

ECM/PW - Wiring diagram ............................... EC-476

ECTS - Wiring diagram .................................... EC-220

Electric sunroof .................................................. RF-10

Electric throttle control actuator ......... EC-595, EC-606

Electrical load signal circuit .............................. EC-657

Electrical units location ...................................... PG-65

Electronic ignition (EI) system ........................... EC-27

Engine control circuit diagram ......................... EC-107

Engine control component parts location ........... EC-98

Engine control module (ECM) .......................... EC-479

Engine control system diagram ......................... EC-24

Engine coolant .................................................. CO-10

Engine coolant temperature sensor (ECTS) ... EC-218,

EC-231

Engine fail-safe system ...................................... EC-93

Engine oil ............................................................. LU-8

Engine oil filter replacement ............................. MA-17

Engine oil precautions .......................................... GI-7

Engine oil replacement ..................................... MA-17

Engine removal ................................................. EM-74

Engine room cover ............................................ EM-12

Engine serial number .......................................... GI-50

ETC1 - Wiring diagram .................................... EC-596

ETC2 - Wiring diagram .................................... EC-591

ETC3 - Wiring diagram .................................... EC-602

EVAP canister .................................................... EC-36

EVAP canister purge volume control solenoid valve ....

EC-395

, EC-403

EVAP canister vent control valve ....... EC-410, EC-417

EVAP control system (small leak) diagnosis .. EC-387,

EC-441

, EC-449

EVAP control system pressure sensor .... EC-424, EC-

427, EC-433

EVAP control system purge flow monitoring diagnosis

EC-382

EVAP vapor lines inspection ............................. MA-20

Evaporative emission (EVAP) system ............... EC-33

Evaporator ..................................................... ATC-186

Exhaust manifold .............................................. EM-21

Exhaust system ................................................... EX-3

Exhaust system inspection .................................. EX-3

Expansion valve ............................................. ATC-188

F

F/FOG - Wiring diagram ..................................... LT-56

F/PUMP - Wiring diagram ................................ EC-666

Final drive pre-inspection ................................. FFD-15

Final drive removal and installation .. FFD-12, RFD-13

Flow charts .......................................................... GI-27

Fluid temperature sensor (A/T) ........................ AT-123

Fluids ................................................................ MA-11

Fluorescent leak detector .............................. ATC-189

Fog lamp, front ................................................... LT-54

Fog lamp, front, removal and installation ........... LT-62

Foot lamp ......................................................... LT-111

Freeze frame data ............................... EC-55, EC-121

Front brake solenoid valve ................. AT-139, AT-141

Front bumper ...................................................... EI-13

Front case (Transfer) .......................... TF-149, TF-176

Front combination lamp removal and installation LT-25

Front door ............................. BL-117, BL-121, GW-62

Front Door Trim ................................................... EI-32

Front drive shaft (Transfer) ................. TF-149, TF-176

Front fog lamp .................................................... LT-54

Front fog lamp removal and installation ............. LT-62

Front passenger air bag .................................. SRS-43

Front seat ........................................................... SE-89

Front seat belt ...................................................... SB-3

Front seat belt pre-tensioner ............... SRS-3, SRS-50

Front washer ...................................................... WW-4

Front wiper ......................................................... WW-4

FTS - Wiring diagram ....................................... AT-124

FTTS - Wiring diagram ...................... EC-334, EC-339

Fuel cut control (at no load high engine speed) EC-28

Fuel filter replacement ......................................... FL-5

Fuel gauge ............................................................ DI-5

Fuel injection system (Bank 1) .......... EC-311, EC-322

Fuel injection system (Bank 2) .......... EC-311, EC-322

Fuel injector .................................................... EC-659

Fuel injector and fuel tube ................................. EM-31

Fuel level sensor ................. EC-458, EC-460, EC-462

Fuel line inspection .............................................. FL-4

Fuel precautions ................................................... GI-5

Fuel pressure check .......................................... EC-82

Fuel pressure release ....................................... EC-82

Fuel pump ....................................................... EC-665

Fuel pump and gauge .......................................... FL-5

Fuel system .......................................................... FL-4

Fuel tank ............................................................ FL-10

Fuel tank temperature sensor ........... EC-332, EC-338

Fuel tank vacuum relief valve ........................... EC-36

FUELB1 - Wiring diagram ................. EC-313, EC-324

FUELB2 - Wiring diagram ................. EC-315, EC-326

Fuse ...................................................... PG-17, PG-77

Fuse and fusible link box .................................. PG-77

Fuse block ......................................................... PG-76

Fusible link ............................................ PG-17, PG-77

G

Garage jack and safety stand ............................. GI-42

Gauges ................................................................. DI-5

Generator .......................................................... SC-17

Generic scan tool (GST) ................................. EC-131

Glass ...................................... GW-11, GW-62, GW-65

Glove box lamp ................................................ LT-131

GPS antenna ..................................................... AV-82

Page 2212 of 3061

HEADLAMP (FOR USA)

LT-5

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

HEADLAMP (FOR USA)

Component Parts and Harness Connector LocationINFOID:0000000003533332

System DescriptionINFOID:0000000003533333

Control of the headlamp system operation is dependent upon the position of the combination switch (lighting

switch). When the lighting switch is placed in the 2ND position, the BCM (body control module) receives input

requesting the headlamps (and tail lamps) illuminate. This input is communicated to the IPDM E/R (intelligent

power distribution module engine room) across the CAN communication lines. The CPU (central processing

unit) of the IPDM E/R controls the headlamp high and headlamp low relay coils. When energized, these relays

direct power to the respective headlamps, which then illuminate.

OUTLINE

Power is supplied at all times

• to ignition relay, located in the IPDM E/R,

• to headlamp high relay, located in the IPDM E/R,

• to headlamp low relay, located in the IPDM E/R,

• through 20A fuse (No. 53, located in the IPDM E/R)

• to CPU of the IPDM E/R, and

• through 50A fusible link (letter f , located in the fuse and fusible link box)

• to BCM terminal 70.

With the ignition switch in the ON or START position, power is supplied

• to ignition relay, located in the IPDM E/R, and

• through 10A fuse (No. 59, located in the fuse and relay box)

WKIA3463E

Page 2256 of 3061

FRONT FOG LAMP

LT-49

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

FRONT FOG LAMP

Component Parts and Harness Connector LocationINFOID:0000000003533388

System DescriptionINFOID:0000000003533389

Control of the fog lamps is dependent upon the position of the combination switch (lighting switch). The light-

ing switch must be in the 2ND position or AUTO position (LOW beam is ON) for front fog lamp operation.

When the lighting switch is placed in the fog lamp position, the BCM (body control module) receives input sig-

nal requesting the fog lamps to illuminate. When the headlamps are illuminated, this input signal is communi-

cated to the IPDM E/R (intelligent power distribution module engine room) across the CAN communication

lines. The CPU (central processing unit) of the IPDM E/R controls the front fog lamp relay coil. When acti-

vated, this relay directs power to the front fog lamps.

OUTLINE

Power is supplied at all times

• to ignition relay, located in the IPDM E/R,

• to front fog lamp relay, located in the IPDM E/R,

• through 20A fuse (No. 53, located in the IPDM E/R)

• to CPU of the IPDM E/R, and

• through 50A fusible link (letter f , located in the fuse and fusible link box)

• to BCM terminal 70.

When the ignition switch is in ON or START position, power is supplied

• to ignition relay, located in the IPDM E/R, and

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38.

Ground is supplied

• to BCM terminal 67

• through grounds M57, M61 and M79, and

• to IPDM E/R terminals 38 and 59

• through grounds E9, E15 and E24.

FOG LAMP OPERATION

The fog lamp switch is built into the combination switch. The lighting switch must be in the 2ND position or

AUTO position (LOW beam is ON) and the fog lamp switch must be ON for fog lamp operation.

WKIA3466E

Page 2264 of 3061

TURN SIGNAL AND HAZARD WARNING LAMPS

LT-57

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

TURN SIGNAL AND HAZARD WARNING LAMPS

Component Parts and Harness Connector LocationINFOID:0000000003533403

System DescriptionINFOID:0000000003533404

OUTLINE

Power is supplied at all times

• through 50A fusible link (letter f , located in the fuse and fusible link box)

• to BCM (body control module) terminal 70, and

• through 10A fuse [No. 19, located in the fuse block (J/B)]

• to combination meter terminal 8.

TURN SIGNAL OPERATION

When the ignition switch is in the ON or START position, power is supplied

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38, and

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal 24.

Ground is supplied

• to BCM terminal 67 and

• to combination meter terminal 17

• through grounds M57, M61 and M79.

LH Turn

When the turn signal switch is moved to the left position, the BCM, interpreting it as turn signal is ON, outputs

turn signal from BCM terminal 60.

The BCM supplies power

• through BCM terminal 60

• to front turn/fog lamp LH terminal 2

• through front turn/fog lamp LH terminal 3

• to grounds E9, E15 and E24,

• to door mirror LH terminal 15

• through door mirror LH terminal 11

• to grounds M57, M61 and M79 and

WKIA3554E

Page 2289 of 3061

LT-82

< SERVICE INFORMATION >

PARKING, LICENSE PLATE AND TAIL LAMPS

PARKING, LICENSE PLATE AND TAIL LAMPS

Component Parts and Harness Connector LocationINFOID:0000000003533434

System DescriptionINFOID:0000000003533435

Control of the parking, license plate, and tail lamp operation is dependent upon the position of the lighting

switch (combination switch). When the lighting switch is placed in the 1ST position, the BCM (body control

module) receives input signal requesting the parking, license plate, side marker and tail lamps to illuminate.

This input signal is communicated to the IPDM E/R (intelligent power distribution module engine room) across

the CAN communication lines. The CPU (central processing unit) of the IPDM E/R controls the tail lamp relay

coil. This relay, when energized, directs power to the parking, license plate and tail lamps, which then illumi-

nate.

Power is supplied at all times

• to ignition relay, located in the IPDM E/R,

• to tail lamp relay, located in the IPDM E/R,

• through 20A fuse (No. 53, located in the IPDM E/R)

• to CPU of the IPDM E/R, and

• through 50A fusible link (letter f , located in the fuse and fusible link box)

• to BCM terminal 70.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38

• to ignition relay, located in the IPDM E/R, and

Ground is supplied

• to BCM terminal 67

• through grounds M57, M61 and M79, and

• to IPDM E/R terminals 38 and 59

• through grounds E9, E15 and E24.

OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST or 2ND position (or if the auto light system is activated), the BCM receives

input signal requesting the parking, license plate, side marker and tail lamps to illuminate. This input signal is

communicated to the IPDM E/R across the CAN communication lines. The CPU of the IPDM E/R controls the

tail lamp relay coil, which when energized, directs power

WKIA3468E

Page 2301 of 3061

LT-94

< SERVICE INFORMATION >

TRAILER TOW

TRAILER TOW

Component Parts and Harness Connector LocationINFOID:0000000003533451

System DescriptionINFOID:0000000003533452

Power is supplied at all times

• to ignition relay, located in the IPDM E/R (intelligent power distribution module engine room),

• through 50A fusible link (letter f , located in the fuse and fusible link box)

• to BCM (body control module) terminal 70,

• through 10A fuse (No. 32, located in the IPDM E/R)

• through IPDM E/R terminal 61

1. Fuse and fusible link box 2. IPDM E/R fuse layout 3. Fuse and relay box

4. IPDM E/R E118, E119, E120, E121,

E122, E123, E1245. A. Steering column

B. Data link connector M22

C. BCM M18, M19, M20

(view with instrument lower panel LH

removed)6. A. Trailer turn relay LH E156

B. Battery

C. Trailer tow relay 2 E140

D. Trailer turn relay RH E157

7. A. Trailer tow relay 1 M51

B. Electric brake (pre-wiring) M76

(view with instrument lower panel LH

removed)8. Trailer connector C2 9. Combination switch (lighting switch)

M28

WKIA4616E

Page 2327 of 3061

LT-120

< SERVICE INFORMATION >

ILLUMINATION

ILLUMINATION

Component Parts and Harness Connector LocationINFOID:0000000003533468

System DescriptionINFOID:0000000003533469

Control of the illumination lamps operation is dependent upon the position of the lighting switch (combination

switch). When the lighting switch is placed in the 1ST or 2ND position (or if the auto light system is activated)

the BCM (body control module) receives input signal requesting the illumination lamps to illuminate. This input

signal is communicated to the IPDM E/R (intelligent power distribution module engine room) across the CAN

communication lines. The CPU (central processing unit) of the IPDM E/R controls the tail lamp relay coil. This

relay, when energized, directs power to the illumination lamps, which then illuminate.

Power is supplied at all times

• to ignition relay, located in the IPDM E/R,

• to tail lamp relay, located in the IPDM E/R,

• through 50A fusible link (letter f , located in the fuse and fusible link box)

• to BCM terminal 70,

• through 20A fuse (No. 53, located in the IPDM E/R)

• to CPU of the IPDM E/R, and

• through 10A fuse [No.19, located in fuse block (J/B)]

• to combination meter terminal 8

With the ignition switch in the ON or START position, power is supplied

• to ignition relay, located in the IPDM E/R,

• through 10A fuse (No. 59, located in the fuse and relay box)

WKIA3471E

Page 2403 of 3061

PG-1

ELECTRICAL

C

D

E

F

G

H

I

J

L

M

SECTION PG

A

B

PG

N

O

P

CONTENTS

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

POWER SUPPLY ROUTING CIRCUIT ...............3

Schematic .................................................................3

Wiring Diagram - POWER - ......................................5

Fuse ........................................................................16

Fusible Link .............................................................16

Circuit Breaker (Built Into BCM) ..............................16

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

17

System Description .................................................17

CAN Communication System Description ...............18

Function of Detecting Ignition Relay Malfunction ....18

CONSULT-II Function (IPDM E/R) ..........................18

Auto Active Test ......................................................20

Terminal and Reference Value for IPDM E/R .........22

IPDM E/R Terminal Arrangement ...........................26

IPDM E/R Power/Ground Circuit Inspection ...........26

Inspection with CONSULT-II (Self-Diagnosis) ........27

Removal and Installation of IPDM E/R ....................28

GROUND CIRCUIT ............................................29

Ground Distribution ..................................................29

HARNESS .........................................................39

Harness Layout .......................................................39

Wiring Diagram Codes (Cell Codes) .......................59

ELECTRICAL UNITS LOCATION ....................63

Electrical Units Location ..........................................63

HARNESS CONNECTOR .................................66

Description ...............................................................66

ELECTRICAL UNITS ........................................68

Terminal Arrangement .............................................68

STANDARDIZED RELAY .................................69

Description ...............................................................69

SUPER MULTIPLE JUNCTION (SMJ) .............71

Terminal Arrangement .............................................71

FUSE BLOCK - JUNCTION BOX (J/B) ............73

Terminal Arrangement .............................................73

FUSE AND FUSIBLE LINK BOX ......................74

Terminal Arrangement .............................................74

FUSE AND RELAY BOX ..................................75

Terminal Arrangement .............................................75