heater INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 372 of 3061

ATC-2

Removal and Installation .......................................126

INTAKE SENSOR ............................................127

Removal and Installation ..................................... ..127

BLOWER MOTOR ...........................................128

Component .......................................................... ..128

Removal and Installation .......................................128

IN-CABIN MICROFILTER ................................130

Removal and Installation ..................................... ..130

HEATER & COOLING UNIT ASSEMBLY .......132

Component .......................................................... ..132

Removal and Installation .......................................133

HEATER CORE ...............................................135

Component .......................................................... ..135

Removal and Installation .......................................136

DEFROSTER DOOR MOTOR .........................138

Removal and Installation ..................................... ..138

INTAKE DOOR MOTOR ..................................139

Removal and Installation ..................................... ..139

MODE DOOR MOTOR ....................................140

Removal and Installation ..................................... ..140

AIR MIX DOOR MOTOR ..................................141

Component .......................................................... ..141

Removal and Installation .......................................141

VARIABLE BLOWER CONTROL ...................143

Removal and Installation ..................................... ..143

REAR BLOWER MOTOR RESISTOR ............144

Removal and Installation ..................................... ..144

DUCTS AND GRILLES ....................................145

Component .......................................................... .145

Removal and Installation .......................................148

REFRIGERANT LINES ................................... ..150

HFC-134a (R-134a) Service Procedure ............... .150

Component ...........................................................152

Removal and Installation for Compressor .............154

Removal and Installation for Compressor Clutch ..155

Removal and Installation for Low-Pressure Flexi-

ble Hose ............................................................... .

158

Removal and Installation for High-pressure Flexi-

ble Hose ............................................................... .

158

Removal and Installation for High-pressure Pipe ..158

Removal and Installation for Low-Pressure Pipe ..159

Removal and Installation for Rear High- and Low-

Pressure A/C and Heater Core Pipes .................. .

159

Removal and Installation for Underfloor Rear

High- and Low-Pressure A/C and Heater Core

Pipes .................................................................... .

160

Removal and Installation for Refrigerant Pressure

Sensor .................................................................. .

161

Removal and Installation for Condenser ...............161

Removal and Installation for Front Evaporator .....163

Removal and Installation for Rear Evaporator ......164

Removal and Installation for Front Expansion

Valve .....................................................................

165

Removal and Installation for Rear Expansion

Valve .................................................................... .

165

Checking of Refrigerant Leaks ..............................166

Checking System for Leaks Using the Fluorescent

Dye Leak Detector ................................................

166

Dye Injection .........................................................166

Electronic Refrigerant Leak Detector ....................167

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

170

Service Data and Specification (SDS) ..................170

Page 377 of 3061

PRECAUTIONSATC-7

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

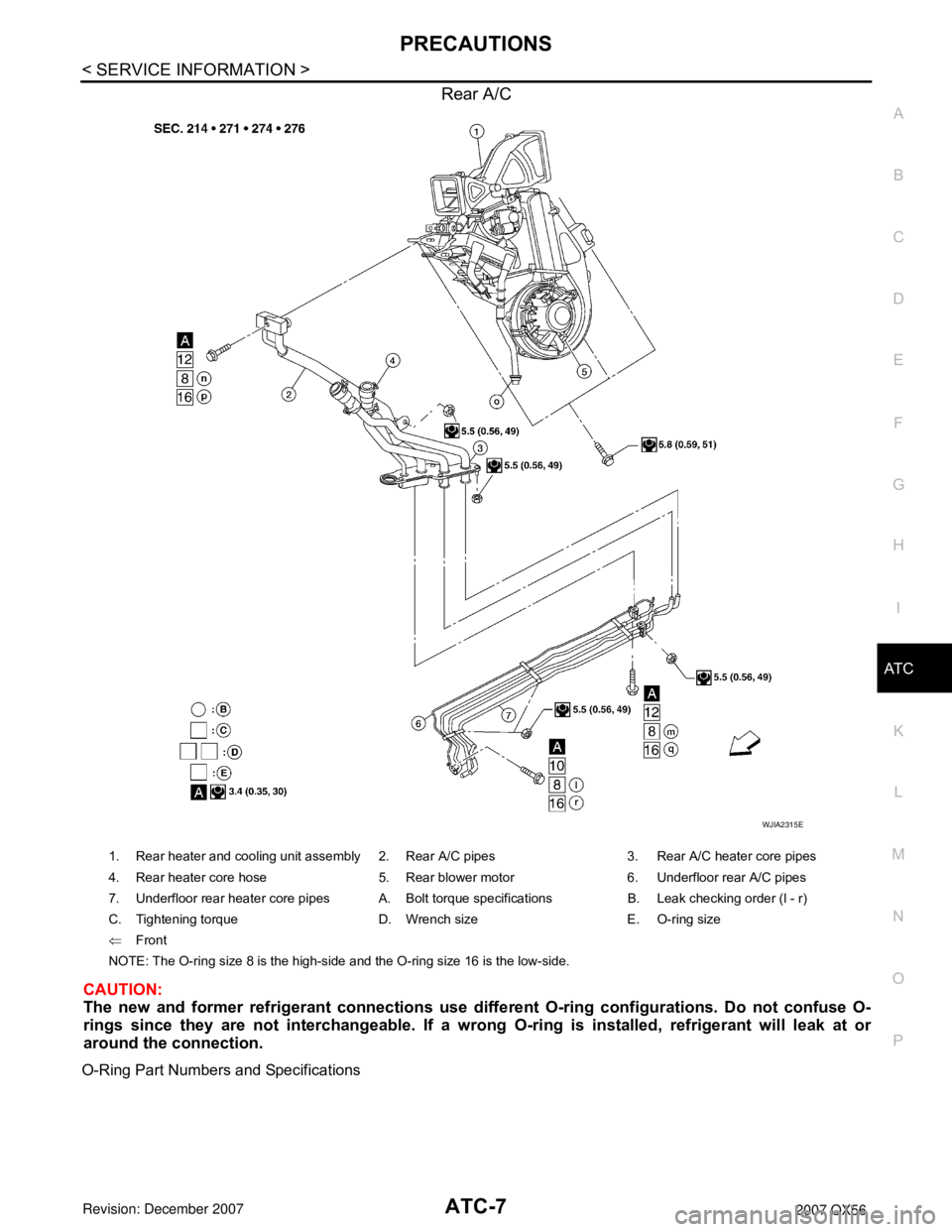

Rear A/C

CAUTION:

The new and former refrigerant connections use diffe rent O-ring configurations. Do not confuse O-

rings since they are not interchangeable. If a wrong O-ring is installed, refrigerant will leak at or

around the connection.

O-Ring Part Numbers and Specifications

WJIA2315E

1. Rear heater and cooling unit assembly 2. Rear A/C pipes 3. Rear A/C heater core pipes

4. Rear heater core hose 5. Rear blower motor 6. Underfloor rear A/C pipes

7. Underfloor rear heater core pipes A. Bolt torque specifications B. Leak checking order (l - r)

C. Tightening torque D. Wrench size E. O-ring size

⇐ Front

NOTE: The O-ring size 8 is the high-side and the O-ring size 16 is the low-side.

Page 388 of 3061

ATC-18

< SERVICE INFORMATION >

REFRIGERATION SYSTEM

REAR REFRIGERATION SYSTEM

1. Defroster nozzle 2. LH side demister duct 3. LH ventilator duct

4. RH side demister duct 5. RH ventilator duct 6. Center ventilator duct

7. Front heater and cooling unit assembly 8. Floor duct 9. Clips

10. Heat duct

WJIA0956E

Page 389 of 3061

REFRIGERATION SYSTEMATC-19

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P1. Rear floor duct 2. Rear heater and cooling unit assembly 3. Rear lower overhead duct

4. Rear upper overhead duct

LJIA0142E

Page 426 of 3061

ATC-56

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Mode Door Control Specification

COMPONENT DESCRIPTION

Mode Door Motor

The mode door motor is attached to the heater & cooling unit. It

rotates so that air is discharged from the outlet as indicated by the

front air control. Motor rotation is conveyed to a link which activates

the mode door.

DIAGNOSTIC PROCEDURE FOR MODE DOOR MOTOR

1.CHECK FRONT AIR CONTROL FOR POWER AND GROUND

1. Turn ignition switch ON.

2. Press the mode switch to the B/L ( ) mode.

3. Check voltage between front air control harness connector M49 terminal 5 and terminal 6 while pressing the mode switch to the

floor ( ) mode.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.CHECK MODE DOOR MOTOR CIRCUITS FOR SHORT TO GROUND

1. Turn ignition switch OFF.

2. Disconnect the front air control harness connector.

3. Check continuity between front air control harness connector M49 terminal 5, 6 and ground.

OK or NG

OK >> Replace front air control. Refer to ATC-123, "Removal

and Installation" .

NG >> Repair or replace harness as necessary.

3.CHECK FRONT AIR CONTROL FOR GROUND AND POWER

WJIA0434E

WJIA0587E

Connector Te r m i n a l s

Condition Voltage

(Approx.)

(+) (-)

Front air control: M49 6 5 Press

mode

switch Battery

voltage

WJIA1727E

5 - Ground : Continuity should not exist.

6 - Ground : Continuity should not exist.

WJIA1734E

Page 431 of 3061

TROUBLE DIAGNOSISATC-61

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

Subsequently, HOT/COLD or DEFROST/VENT or FR ESH/RECIRCULATION operation is selected. The new

door position data is returned to the front air control.

Air Mix Door Control Specification

COMPONENT DESCRIPTION

Air Mix Door Motors

The driver (1) and front passenger (2) air mix door motors are

attached to the front heater & cooling unit assembly. The rear air mix

door motor is attached to the rear heater & cooling unit. These

motors rotate so that the air mix door is opened or closed to a posi-

tion set by the front (or rear) air control. Motor rotation is then con-

veyed through a shaft and the air mix door position is then fed back

to the front air control by the PBR built into the air mix door motors.

DIAGNOSTIC PROCEDURE FOR AIR MIX DOOR MOTOR (DRIVER)

1.CHECK FRONT AIR CONTROL FOR POWER AND GROUND

WJIA1244E

WJIA0435E

WJIA2309E

WJIA1245E

Page 445 of 3061

TROUBLE DIAGNOSISATC-75

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

• PBR (Built into defroster door motor)

• In-vehicle sensor

• Ambient sensor

• Optical sensor

• Intake sensor

System Operation

The front air control determines defroster door position based on the position of the defroster switch. When the

defroster switch is depressed, the defroster door moto r rotates directing air to the defroster ducts. When any

mode other than defroster is selected, the defroster moto r rotates in the opposite direction closing off air flow

to the defroster ducts.

In the AUTO mode, the front air control determines defroster door position based on the ambient temperature,

the intake air temperature and the in-vehicle temperature.

COMPONENT DESCRIPTION

Defroster door motor

The defroster door motor is attached to the front heater & cooling

unit assembly. The front air control sends a voltage to rotate to the

defroster door directing the air flow either to the defroster ducts, or to

the floor ducts, depending on which way the voltage and ground are

applied to the motor leads. Motor rotation is conveyed to a lever

which activates the defroster door.

DIAGNOSTIC PROCEDURE FOR DEFROSTER DOOR MOTOR

1.CHECK FRONT AIR CONTROL FOR POWER AND GROUND

1. Turn ignition switch ON.

2. Press the defroster switch ( ).

3. Check voltage between front air control harness connector M49 terminal 20 and terminal 19 and press the defroster switch ( )

again.

WJIA1354E

WJIA0592E

WJIA2277E

Page 479 of 3061

TROUBLE DIAGNOSISATC-109

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

OK >> GO TO 6.

NG >> Check the air mix door motor circuit. Refer to ATC-59, "

Air Mix Door Motor Circuit" .

6.CHECK AIR DUCTS

Check for disconnected or leaking air ducts.

OK or NG

OK >> GO TO 7.

NG >> Repair all disconnected or leaking air ducts.

7.CHECK HEATER HOSE TEMPERATURES

1. Start engine and warm it up to normal operating temperature.

2. Touch both the inlet and outlet heater hoses.

OK or NG

OK >> Hot inlet hose and a warm outlet hose: GO TO 8.

NG >> • Inlet hose cold: GO TO 11. • Both hoses warm: GO TO 9.

8.CHECK ENGINE COOLANT SYSTEM

Check engine control temperature sensor. Refer to EC-205

.

OK or NG

OK >> System OK.

NG >> Repair or replace as necessary. Retest.

9.CHECK HEATER HOSES

Check heater hoses for proper installation.

OK or NG

OK >> System OK.

NG >> 1. Back flush heater core. 2. Drain the water from the system.

3. Refill system with new engine coolant. Refer to CO-9, "

Changing Engine Coolant" .

4. GO TO 10 to retest.

10.CHECK HEATER HOSE TEMPERATURES

1. Start engine and warm it up to normal operating temperature.

2. Touch both the inlet and outlet heater hoses.

OK or NG

OK >> System OK.

NG >> Replace heater core. Refer to ATC-135

.

11 .CHECK WATER VALVE

Check the operation of the water valve. Refer to ATC-113, "

Water Valve Circuit".

OK or NG

OK >> System OK.

NG >> Replace water valve.

NoiseINFOID:0000000003533262

SYMPTOM: Noise

INSPECTION FLOW

Page 483 of 3061

TROUBLE DIAGNOSISATC-113

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

Does another symptom exist?

YES >> Refer to ATC-32, "How to Perform Trouble Diagnosis for Quick and Accurate Repair".

NO >> Replace front air control. Refer to ATC-123, "

Removal and Installation".

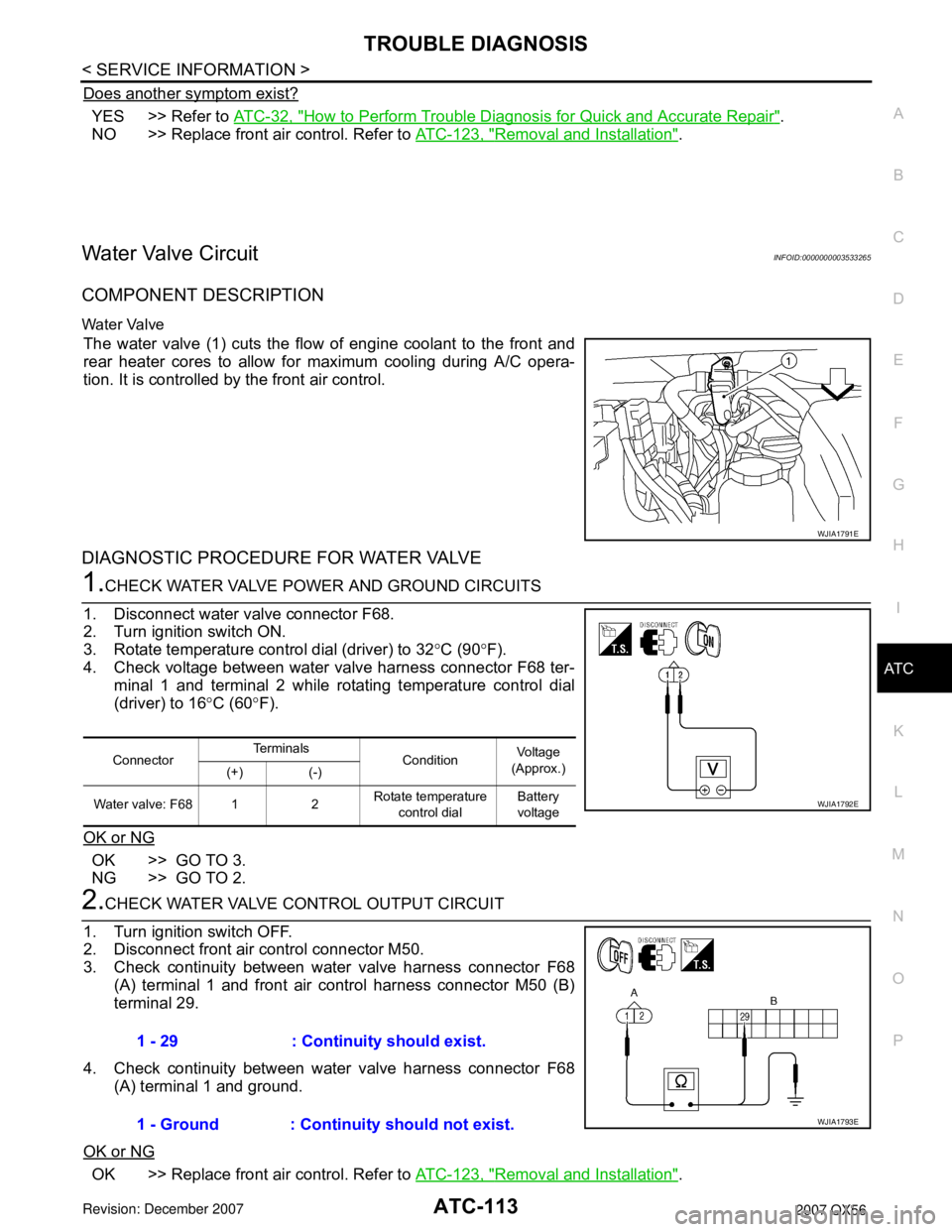

Water Valve CircuitINFOID:0000000003533265

COMPONENT DESCRIPTION

Water Valve

The water valve (1) cuts the flow of engine coolant to the front and

rear heater cores to allow for maximum cooling during A/C opera-

tion. It is controlled by the front air control.

DIAGNOSTIC PROCEDURE FOR WATER VALVE

1.CHECK WATER VALVE POWER AND GROUND CIRCUITS

1. Disconnect water valve connector F68.

2. Turn ignition switch ON.

3. Rotate temperature control dial (driver) to 32 °C (90 °F).

4. Check voltage between water valve harness connector F68 ter- minal 1 and terminal 2 while rotating temperature control dial

(driver) to 16 °C (60 °F).

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.CHECK WATER VALVE CONTROL OUTPUT CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front air control connector M50.

3. Check continuity between water valve harness connector F68 (A) terminal 1 and front air control harness connector M50 (B)

terminal 29.

4. Check continuity between water valve harness connector F68 (A) terminal 1 and ground.

OK or NG

OK >> Replace front air control. Refer to ATC-123, "Removal and Installation".

WJIA1791E

ConnectorTe r m i n a l s

Condition Voltage

(Approx.)

(+) (-)

Water valve: F68 1 2 Rotate temperature

control dial Battery

voltage

WJIA1792E

1 - 29 : Continuity should exist.

1 - Ground : Continuity should not exist.

WJIA1793E

Page 491 of 3061

TROUBLE DIAGNOSISATC-121

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

The intake sensor is located on the heater & cooling unit. It converts

temperature of air after it passes through the evaporator into a resis-

tance value which is then input to the front air control.

DIAGNOSTIC PROCEDURE FOR INTAKE SENSOR

SYMPTOM: Intake sensor circuit is open or shorted. Using the CON-

SULT-II, DTC B2581 or B2582 is di splayed. Without a CONSULT-II,

code 56 or 57 is indicated on front air control as a result of conduct-

ing the front air control self-diagnosis.

1.CHECK VOLTAGE BETWEEN INTAKE SENSOR AND GROUND

1. Disconnect intake sensor connector.

2. Turn ignition switch ON.

3. Check voltage between intake sensor harness connector M146 terminal 2 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2.CHECK CIRCUIT CONTINUITY BETWEEN IN TAKE SENSOR AND FRONT AIR CONTROL

1. Turn ignition switch OFF.

2. Disconnect front air control connector.

3. Check continuity between intake sensor harness connector M146 terminal 1 and front air control harness connector M49 ter-

minal 21.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK INTAKE SENSOR

Refer to "Intake Sensor Circuit".

OK or NG

OK >> 1. Replace front air control. Refer to ATC-123, "Removal and Installation"

2. Go to ATC-48, "A/C System Self-Diagnosis Function" and perform self-diagnosis.

NG >> 1. Replace intake sensor. Refer to ATC-127

.

2. Go to ATC-48, "

A/C System Self-Diagnosis Function" and perform self-diagnosis.

WJIA0571E

WJIA0464E

2 - Ground : Approx. 5V

WJIA1375E

1 - 21 : Continuity should exist.

WJIA1376E