key INFINITI QX56 2007 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 704 of 3061

BCM (BODY CONTROL MODULE)

BCS-17

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

BCS

N

O

P

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

ITEMS OF EACH PART

NOTE:

CONSULT-II will only display systems the vehicle possesses.

WORK SUPPORT

BCM diagnostic

test itemDiagnostic mode Content

Inspection by partWORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the BCM for

setting the status suitable for required operation, input/output signals are received

from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT

MNTRThe results of transmit/receive diagnosis of CAN communication can be read.

ECU PART NUMBER BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

System and itemCONSULT-II

displayDiagnostic test mode (Inspection by part)

WORK

SUPPORTSELF−

DIAG RE-

SULTSCAN DIAG

SUPPORT

MNTRDATA

MONITORECU

PA R T

NUMBERAC-

TIVE

TESTCON-

FIGU-

RATION

BCM BCM×× × × ×

Power door lock system DOOR LOCK×××

Rear defoggerREAR

DEFOGGER××

Warning chime BUZZER××

Room lamp timer INT LAMP×××

Remote keyless entry

systemMULTI REMOTE

ENT×××

Headlamp HEAD LAMP×××

Wiper (front/rear) WIPER×××

Turn signal lamp

Hazard lampFLASHER××

Blower fan switch signal

Air conditioner switch

signalAIR

CONDITIONER×

Combination switch COMB SW×

IVIS (NATS) IMMU××

Interior lamp battery

saverBATTERY SAV-

ER×××

Back door TRUNK××

Theft alarm THEFT ALM×××

Retained accessory

power controlRETAINED PWR×××

Oil pressure switch SIGNAL BUFFER××

Low tire pressure moni-

tor systemAIR PRESSURE

MONITOR×× × ×

Panic alarm PANIC ALARM×

Page 705 of 3061

BCS-18

< SERVICE INFORMATION >

BCM (BODY CONTROL MODULE)

Display Item List

CAN Communication Inspection Using CONSULT-II (Self-Diagnosis)INFOID:0000000003533603

1.SELF-DIAGNOSTIC RESULT CHECK

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. Connect to CONSULT–II, and select “BCM” on “SELECT SYSTEM” screen.

2. Select “BCM” on “SELECT TEST ITEM” screen, and select “SELF-DIAG RESULTS”.

3. Check display content in self-diagnostic results.

Contents displayed

No malfunction>>Inspection End.

Malfunction in CAN communication system>>After printing the monitor items, go to LAN-7

.

ConfigurationINFOID:0000000003533604

DESCRIPTION

CONFIGURATION has two functions as follows:

• READ CONFIGURATION is the function to confirm vehicle configuration of current BCM.

• WRITE CONFIGURATION is the function to write vehicle configuration on BCM.

CAUTION:

• When replacing BCM, you must perform WRITE CONFIGURATION with CONSULT-II.

• Complete the procedure of WRITE CONFIGURATION in order.

• If you set incorrect WRITE CONFIGURATION, incidents will occur.

• Configuration is different for each vehicle model. Confirm configuration of each vehicle model.

READ CONFIGURATION PROCEDURE

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carries out CAN communication.

1. With ignition switch OFF, connect CONSULT-II and CONSULT-II

CONVERTER to data link connector and turn ignition switch ON.

Item Description

RESET SETTING VALUE Return a value set with WORK SUPPORT of each system to a default value in factory shipment.

CONSULT-II display code Diagnosis item

U1000INITIAL DIAG

TRANSMIT DIAG

ECM

IPDM E/R

METER/M&A

I-KEY

PAIA0070E

Page 711 of 3061

BCS-24

< SERVICE INFORMATION >

BCM (BODY CONTROL MODULE)

14. Touch "OK" on "WRITE CONFIGURATION" screen.

WRITE CONFIGURATION is completed.

BCMINFOID:0000000003533605

REMOVAL AND INSTALLATION

NOTE:

If possible, before removing BCM, retrieve current BCM configuration to use for reference when configuring

brand-new BCM after installation. Refer to BCS-18, "

Configuration".

Removal

1. Disconnect battery negative terminal.

2. Remove instrument lower panel LH. Refer to IP-10

.

3. Remove knee protector. IP-10

.

4. Disconnect BCM electrical connectors.

5. Remove BCM screws and remove BCM.

Installation

Installation is in the reverse order of removal.

NOTE:

• When replacing BCM, it must be configured. Refer to BCS-18, "

Configuration".

• When replacing BCM, perform initialization of NATS system and registration of all NATS ignition key IDs.

Refer to BL-116

.

• When replacing BCM, perform ID registration procedure of low tire pressure warning system. Refer to WT-

12, "ID Registration Procedure".

LKIA0400E

LEIA0068E

Page 712 of 3061

BL-1

BODY

C

D

E

F

G

H

J

K

L

M

SECTION BL

A

B

BL

N

O

P

CONTENTS

BODY, LOCK & SECURITY SYSTEM

SERVICE INFORMATION ............................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for work ...................................................3

PREPARATION ...................................................4

Special Service Tool .................................................4

Commercial Service Tool ..........................................4

SQUEAK AND RATTLE TROUBLE DIAGNO-

SIS .......................................................................

5

Work Flow .................................................................5

Generic Squeak and Rattle Troubleshooting ............7

Diagnostic Worksheet ...............................................9

HOOD .................................................................11

Fitting Adjustment ...................................................11

Removal and Installation of Hood Assembly ...........12

Removal and Installation of Hood Lock Control ......13

Hood Lock Control Inspection .................................14

POWER DOOR LOCK SYSTEM ........................15

Component Parts and Harness Connector Loca-

tion ..........................................................................

15

System Description .................................................15

Schematic ...............................................................18

Wiring Diagram - D/LOCK - .....................................19

Terminal and Reference Value for BCM .................23

Work Flow ...............................................................23

CONSULT-II Function (BCM) ..................................24

Trouble Diagnosis Symptom Chart .........................25

BCM Power Supply and Ground Circuit Inspection

....

25

Door Switch Check ..................................................25

Key Switch (Insert) Check .......................................27

Door Lock/Unlock Switch Check .............................28

Glass Hatch Switch Circuit Inspection ....................30

Front Door Lock Assembly LH (Actuator) Check ....32

Front Door Lock Actuator RH Check .......................32

Rear Door Lock Actuator RH/LH Check ..................33

Glass Hatch Lock Actuator Check ...........................34

Front Door Lock Assembly LH (Key Cylinder

Switch) Check ..........................................................

35

REMOTE KEYLESS ENTRY SYSTEM .............37

Component Parts and Harness Connector Loca-

tion ...........................................................................

37

System Description ..................................................37

CAN Communication System Description ...............40

Schematic ................................................................41

Wiring Diagram - KEYLES - ....................................42

Terminal and Reference Value for BCM ..................44

Terminal and Reference Value for IPDM E/R ..........44

CONSULT-II Function (BCM) ..................................45

CONSULT-II Start Procedure ..................................45

CONSULT-II Application Item ..................................45

Trouble Diagnosis Procedure ..................................47

BCM Power Supply and Ground Circuit Inspection

....

47

Trouble Diagnosis ....................................................47

Key Switch (Insert) Check .......................................49

Door Switch Check ..................................................49

Keyfob Battery and Function Check ........................52

Remote Keyless Entry Receiver System Inspec-

tion ...........................................................................

53

ACC Power Check ...................................................54

IPDM E/R Operation Check .....................................54

Check Hazard Function ...........................................55

Check Horn Function ...............................................55

Check Headlamp Function ......................................55

Check Map Lamp Illumination Function ..................56

ID Code Entry Procedure ........................................56

Keyfob Battery Replacement ...................................59

VEHICLE SECURITY (THEFT WARNING)

SYSTEM ............................................................

60

Component Parts and Harness Connector Loca-

tion ...........................................................................

60

System Description ..................................................61

Page 713 of 3061

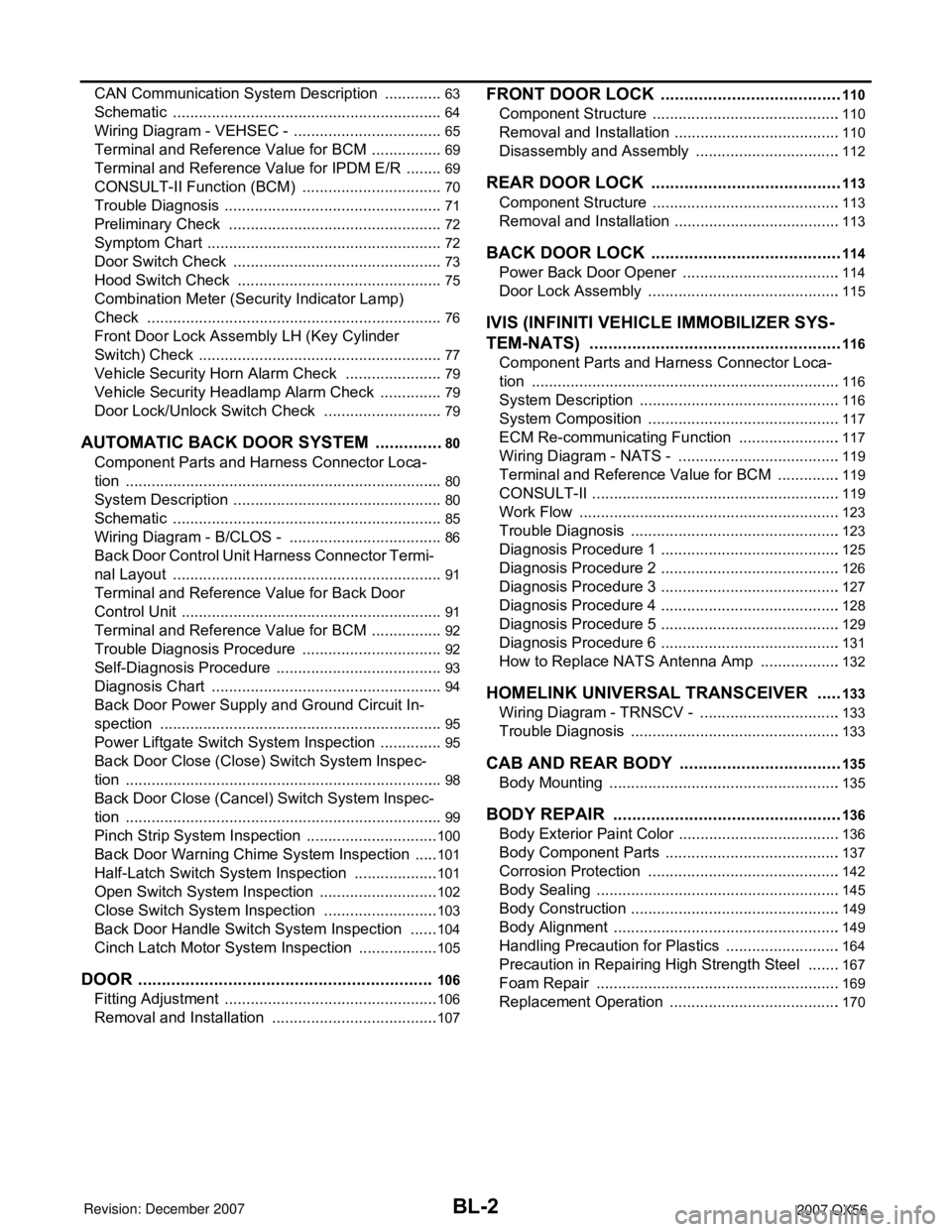

BL-2

CAN Communication System Description ..............63

Schematic ...............................................................64

Wiring Diagram - VEHSEC - ...................................65

Terminal and Reference Value for BCM .................69

Terminal and Reference Value for IPDM E/R .........69

CONSULT-II Function (BCM) .................................70

Trouble Diagnosis ...................................................71

Preliminary Check ..................................................72

Symptom Chart .......................................................72

Door Switch Check .................................................73

Hood Switch Check ................................................75

Combination Meter (Security Indicator Lamp)

Check .....................................................................

76

Front Door Lock Assembly LH (Key Cylinder

Switch) Check .........................................................

77

Vehicle Security Horn Alarm Check .......................79

Vehicle Security Headlamp Alarm Check ...............79

Door Lock/Unlock Switch Check ............................79

AUTOMATIC BACK DOOR SYSTEM ...............80

Component Parts and Harness Connector Loca-

tion ..........................................................................

80

System Description .................................................80

Schematic ...............................................................85

Wiring Diagram - B/CLOS - ....................................86

Back Door Control Unit Harness Connector Termi-

nal Layout ...............................................................

91

Terminal and Reference Value for Back Door

Control Unit .............................................................

91

Terminal and Reference Value for BCM .................92

Trouble Diagnosis Procedure .................................92

Self-Diagnosis Procedure .......................................93

Diagnosis Chart ......................................................94

Back Door Power Supply and Ground Circuit In-

spection ..................................................................

95

Power Liftgate Switch System Inspection ...............95

Back Door Close (Close) Switch System Inspec-

tion ..........................................................................

98

Back Door Close (Cancel) Switch System Inspec-

tion ..........................................................................

99

Pinch Strip System Inspection ...............................100

Back Door Warning Chime System Inspection ......101

Half-Latch Switch System Inspection ....................101

Open Switch System Inspection ............................102

Close Switch System Inspection ...........................103

Back Door Handle Switch System Inspection .......104

Cinch Latch Motor System Inspection ...................105

DOOR ...............................................................106

Fitting Adjustment ..................................................106

Removal and Installation .......................................107

FRONT DOOR LOCK .......................................110

Component Structure ............................................110

Removal and Installation .......................................110

Disassembly and Assembly ..................................112

REAR DOOR LOCK .........................................113

Component Structure ............................................113

Removal and Installation .......................................113

BACK DOOR LOCK .........................................114

Power Back Door Opener .....................................114

Door Lock Assembly .............................................115

IVIS (INFINITI VEHICLE IMMOBILIZER SYS-

TEM-NATS) ......................................................

116

Component Parts and Harness Connector Loca-

tion ........................................................................

116

System Description ...............................................116

System Composition .............................................117

ECM Re-communicating Function ........................117

Wiring Diagram - NATS - ......................................119

Terminal and Reference Value for BCM ...............119

CONSULT-II ..........................................................119

Work Flow .............................................................123

Trouble Diagnosis .................................................123

Diagnosis Procedure 1 ..........................................125

Diagnosis Procedure 2 ..........................................126

Diagnosis Procedure 3 ..........................................127

Diagnosis Procedure 4 ..........................................128

Diagnosis Procedure 5 ..........................................129

Diagnosis Procedure 6 ..........................................131

How to Replace NATS Antenna Amp ...................132

HOMELINK UNIVERSAL TRANSCEIVER ......133

Wiring Diagram - TRNSCV - .................................133

Trouble Diagnosis .................................................133

CAB AND REAR BODY ...................................135

Body Mounting ......................................................135

BODY REPAIR .................................................136

Body Exterior Paint Color ......................................136

Body Component Parts .........................................137

Corrosion Protection .............................................142

Body Sealing .........................................................145

Body Construction .................................................149

Body Alignment .....................................................149

Handling Precaution for Plastics ...........................164

Precaution in Repairing High Strength Steel ........167

Foam Repair .........................................................169

Replacement Operation ........................................170

Page 715 of 3061

BL-4

< SERVICE INFORMATION >

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000003532886

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000003532887

Tool number

(Kent-Moore No.)

Tool nameDescription

—

(J-39570)

Chassis earLocating the noise

—

(J-43980)

NISSAN Squeak and Rat-

tle KitRepairing the cause of noise

—

(J-43241)

Remote Keyless Entry

Te s t e rUsed to test keyfobs

SIIA0993E

SIIA0994E

LEL946A

Tool name

(Kent-Moore No.)Description

Engine ear

(J-39565)Locating the noise

SIIA0995E

Page 727 of 3061

![INFINITI QX56 2007 Factory User Guide BL-16

< SERVICE INFORMATION >

POWER DOOR LOCK SYSTEM

• to BCM terminal 70

• through 15A fuse [No. 22, located in the fuse block (J/B)]

• to BCM terminal 57

• through 10A fuse [No. 19, located INFINITI QX56 2007 Factory User Guide BL-16

< SERVICE INFORMATION >

POWER DOOR LOCK SYSTEM

• to BCM terminal 70

• through 15A fuse [No. 22, located in the fuse block (J/B)]

• to BCM terminal 57

• through 10A fuse [No. 19, located](/img/42/57029/w960_57029-726.png)

BL-16

< SERVICE INFORMATION >

POWER DOOR LOCK SYSTEM

• to BCM terminal 70

• through 15A fuse [No. 22, located in the fuse block (J/B)]

• to BCM terminal 57

• through 10A fuse [No. 19, located in the fuse block (J/B)]

• to key switch and key lock solenoid terminal 3.

With ignition key inserted, power is supplied

• through key switch and key lock solenoid terminal 4

• to BCM terminal 37.

Ground is supplied to terminal 67 of BCM through body grounds M57, M61 and M79.

When the door is locked or unlocked with main power window and door lock/unlock switch, ground is supplied

• to CPU of main power window and door lock/unlock switch

• through main power window and door lock/unlock switch terminal 17

• through grounds M57, M61 and M79.

Then main power window and door lock/unlock switch operation signal is supplied

• to BCM terminal 22

• through main power window and door lock/unlock switch terminal 14.

When the door is locked or unlocked with power window and door lock/unlock switch RH, ground is supplied

• to CPU of power window and door lock/unlock switch RH

• through power window and door lock/unlock switch RH terminal 11

• through grounds M57, M61 and M79.

Then power window and door lock/unlock switch RH operation signal is supplied

• to BCM terminal 22

• through power window and door lock/unlock switch RH terminal 16.

When the door is locked with front door lock assembly LH (key cylinder switch), ground is supplied

• to main power window and door lock/unlock switch terminal 4

• through front door lock assembly LH (key cylinder switch) terminals 1 and 5

• through grounds M57, M61 and M79.

Then front door lock assembly LH (key cylinder switch) operation signal is supplied

• to BCM terminal 22

• through main power window and door lock/unlock switch terminal 14.

When the door is unlocked with front door lock assembly LH (key cylinder switch), ground is supplied

• to main power window and door lock/unlock switch terminal 6

• through front door lock assembly LH (key cylinder switch) terminals 6 and 5

• through grounds M57, M61 and M79.

Then front door lock assembly LH (key cylinder switch) operation signal is supplied

• to BCM terminal 22

• through main power window and door lock/unlock switch terminal 14.

BCM is connected to main power window and door lock/unlock switch and power window and door lock/unlock

switch RH through a bus.

When the front door switch LH is ON (door is open), ground is supplied

• to BCM terminal 47

• through front door switch LH terminal 2

• through front door switch LH case ground.

When the front door switch RH is ON (door is open), ground is supplied

• to BCM terminal 12

• through front door switch RH terminal 2

• through front door switch RH case ground.

When the rear door switch LH is ON (door is open), ground is supplied

• to BCM terminal 48

• through rear door switch LH terminal 2

• through rear door switch LH case ground.

When the rear door switch RH is ON (door is open), ground is supplied

• to BCM terminal 13

• through rear door switch RH terminal 2

• through rear door switch RH case ground.

When the back door latch (door ajar switch) is ON (door is open), ground is supplied

• to BCM terminal 43

• through back door latch (door ajar switch) terminal 7

• through back door latch (door ajar switch) terminal 8

• through grounds B7 and B19.

OUTLINE

Page 728 of 3061

POWER DOOR LOCK SYSTEM

BL-17

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

NOTE:

The glass hatch switch will be operational only when the front door lock actuator RH is in the unlock position.

Functions available by operating the door lock and unlock switches on driver door and passenger door

• Interlocked with the locking operation of door lock and unlock switch, door lock actuators of all doors and

glass hatch actuator are locked.

• Interlocked with the unlocking operation of door lock and unlock switch, door lock actuators of all doors and

glass hatch actuator are unlocked.

Functions available by operating the front door lock assembly LH (key cylinder switch)

• Interlocked with the locking operation of door key cylinder, door lock actuators of all doors are locked.

• When door key cylinder is unlocked, front door lock assembly LH (actuator) is unlocked.

• When door key cylinder is unlocked for the second time within 5 seconds after the first operation, door lock

actuators on all doors are unlocked.

Key reminder door system

When door lock and unlock switch is operated to lock doors with ignition key in key cylinder and any door

open, all door lock actuators are locked and then unlocked.

Page 735 of 3061

BL-24

< SERVICE INFORMATION >

POWER DOOR LOCK SYSTEM

3. According to the trouble diagnosis chart, repair or replace the cause of the malfunction. Refer to BL-25,

"Trouble Diagnosis Symptom Chart".

4. Does power door lock system operate normally? OK: GO TO 5, NG: GO TO 3.

5. Inspection End.

CONSULT-II Function (BCM)INFOID:0000000003532901

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT–II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

DATA MONITOR

ACTIVE TEST

BCM

diagnostic test itemDiagnostic mode Description

Inspection by partWORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the

BCM for setting the status suitable for required operation, input/output sig-

nals are received from the BCM and received date is displayed.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TESTOperation of electrical loads can be checked by sending drive signal to

them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTRThe result of transmit/receive diagnosis of CAN communication can be

read.

ECU PART NUMBER BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

Monitor item "OPERATION" Content

KEY ON SW "ON/OFF" Indicates [ON/OFF] condition of key switch.

CDL LOCK SW "ON/OFF" Indicates [ON/OFF] condition of lock signal from lock/unlock switch LH and RH.

CDL UNLOCK SW "ON/OFF" Indicates [ON/OFF] condition of unlock signal from lock/unlock switch LH and RH.

KEY CYL LK-SW "ON/OFF" Indicates [ON/OFF] condition of lock signal from key cylinder.

KEY CYL UN-SW "ON/OFF" Indicates [ON/OFF] condition of unlock signal from key cylinder.

IGN ON SW "ON/OFF" Indicates [ON/OFF] condition of ignition switch.

DOOR SW–DR "ON/OFF" Indicates [ON/OFF] condition of front door switch LH.

DOOR SW–AS "ON/OFF" Indicates [ON/OFF] condition of front door switch RH.

DOOR SW–RR "ON/OFF" Indicates [ON/OFF] condition of rear door switch RH.

DOOR SW–RL "ON/OFF" Indicates [ON/OFF] condition of rear door switch LH.

BACK DOOR SW "ON/OFF" Indicates [ON/OFF] condition of back door latch (door ajar switch).

KEYLESS LOCK "ON/OFF" Indicates [ON/OFF] condition of lock signal from keyfob.

KEYLESS UNLOCK "ON/OFF" Indicates [ON/OFF] condition of unlock signal from keyfob.

Test item Content

ALL LOCK/UNLOCKThis test is able to check all door lock actuators lock operation. These actuators lock when "ON"

on CONSULT–II screen is touched.

DR UNLOCKThis test is able to check front door lock assembly LH (actuator) unlock operation.These actu-

ators lock when "ON" on CONSULT–II screen is touched.

OTHER UNLOCKThis test is able to check door lock actuators [except front door lock assembly LH (actuator)]

unlock operation.These actuators unlock when "ON" on CONSULT–II screen is touched.

Page 736 of 3061

POWER DOOR LOCK SYSTEM

BL-25

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

Trouble Diagnosis Symptom ChartINFOID:0000000003532902

BCM Power Supply and Ground Circuit InspectionINFOID:0000000003532903

Refer to BCS-15, "BCM Power Supply and Ground Circuit Inspection".

Door Switch CheckINFOID:0000000003532904

1.CHECK DOOR SWITCHES INPUT SIGNAL

With CONSULT-II

Check door switches ("DOOR SW-DR", "DOOR SW-AS", "DOOR SW-RL", "DOOR SW-RR", "BACK DOOR

SW") in DATA MONITOR mode with CONSULT–II.Refer to BL-24, "

CONSULT-II Function (BCM)".

• When doors are open:

• When doors are closed:

Symptom Repair order Refer to page

Key reminder door function does not operate prop-

erly.1. Door switch checkBL-25

2. Key switch (insert) checkBL-27

3. Replace BCM.BCS-24

Power door lock does not operate with door lock

and unlock switch on main power window and

door lock/unlock switch or power window and door

lock/unlock switch RH.1. Door lock/unlock switch checkBL-28

2. Replace BCM.BCS-24

Front door lock assembly LH (actuator) does not

operate.1. Front door lock assembly LH (Actuator) checkBL-32

Specific door lock actuator does not operate.1. Front door lock actuator RH checkBL-322. Rear door lock actuator RH/LH checkBL-33

Power door lock does not operate with front door

key cylinder LH operation.1. Front door lock assembly LH (key cylinder

switch) checkBL-35

2. Replace BCM.BCS-24

Power door lock does not operate.1. BCM power supply and ground circuit checkBCS-152. Door lock/unlock switch checkBL-28

Back door opener does not operate.1. Back door power supply and ground circuit in-

spectionBL-952. Door switch checkBL-25

3. Power liftgate switch system inspectionBL-95

Glass hatch lock actuator does not operate

(RF door must be unlocked for normal operation).1. Glass hatch switch checkBL-302. Glass hatch lock actuator checkBL-34

3. Replace BCM.BCS-24

DOOR SW-DR : ON

DOOR SW-AS : ON

DOOR SW-RL : ON

DOOR SW-RR : ON

BACK DOOR SW : ON

DOOR SW-DR : OFF

DOOR SW-AS : OFF

DOOR SW-RL : OFF

LIIA0665E