warning light INFINITI QX56 2007 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 991 of 3061

CO-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003531562

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Liquid GasketINFOID:0000000003531563

REMOVAL OF LIQUID GASKET SEALING

• After removing the bolts and nuts, separate the mating surface and

remove the old liquid gasket sealing using Tool.

CAUTION:

Do not damage the mating surfaces.

• Tap the seal cutter to insert it.

• In areas where the Tool is difficult to use, lightly tap to slide it.

LIQUID GASKET APPLICATION PROCEDURE

1. Remove the old liquid gasket adhering to the gasket application

surface and the mating surface using suitable tool.

• Remove the liquid gasket completely from the groove of the

liquid gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering

moisture, grease and foreign material.Tool number : KV10111100 (J-37228)

WBIA0566E

PBIC0003E

Page 1012 of 3061

DI-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION DI

A

B

DI

N

O P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION .. ..........................3

PRECAUTION ................................................ .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

PREPARATION ...................................................4

Commercial Service Tool .................................... ......4

COMBINATION METERS ...................................5

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

5

System Description ...................................................5

Arrangement of Combination Meter ..........................7

Internal Circuit ...........................................................8

Wiring Diagram - METER - .......................................9

Combination Meter Harness Connector Terminal

Layout .....................................................................

11

Terminal and Reference Value for Combination

Meter .......................................................................

11

Self-Diagnosis Mode of Combination Meter ........ ....12

How to Proceed with Trouble Diagnosis ............. ....15

Preliminary Check ...................................................15

Symptom Chart .......................................................16

Power Supply and Ground Circuit Inspection .........16

Vehicle Speed Signal Inspection .............................17

Engine Oil Pressure Signal Inspection ....................17

Water Temperature Signal Inspection .....................18

Engine Speed Signal Inspection ......................... ....18

Fuel Level Sensor Unit Inspection ...................... ....18

Fuel Gauge Fluctuates, Indicates Wrong Value, or

Varies .................................................................. ....

20

Fuel Gauge Does Not Move to Full-position ...........20

Electrical Component Inspection ......................... ....21

Removal and Installation of Combination Meter .....21

COMPASS AND THERMOMETER ................ ....22

System Description ............................................. ....22

Wiring Diagram - COMPAS - ..................................23

Trouble Diagnosis ............................................... ....23

Calibration Procedure for Compass .................... ....24

WARNING LAMPS ............................................26

Schematic ............................................................ ....26

Wiring Diagram - WARN - .......................................27

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) .......................................................... ....

32

Oil Pressure Warning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ...................................... ....

33

A/T INDICATOR ................................................34

Wiring Diagram - AT/IND - .......................................34

A/T Indicator Does Not Illuminate ............................34

WARNING CHIME .............................................36

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

36

System Description ..................................................36

CAN Communication System Description ...............37

Wiring Diagram - CHIME - .......................................38

Terminal and Reference Value for BCM ..................39

Terminal and Reference Value for Combination

Meter ................................................................... ....

39

How to Proceed with Trouble Diagnosis ..................40

Preliminary Check ............................................... ....40

CONSULT-II Function (BCM) ..................................40

All Warning Chimes Do Not Operate .......................41

Key Warning Chime and Light Warning Chime Do

Not Operate (Seat Belt Warning Chime Does Op-

erate) .......................................................................

41

Key Warning Chime Does Not Operate ...................42

Light Warning Chime Does Not Operate .................44

Seat Belt Warning Chime Does Not Operate ..........44

REAR SONAR SYSTEM ...................................46

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

46

System Description ..................................................46

Wiring Diagram - SONAR - ......................................48

Sonar Control Unit Harness Connector Terminal

Layout ......................................................................

50

Page 1016 of 3061

COMBINATION METERSDI-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

COMBINATION METERS

Component Parts and Har ness Connector LocationINFOID:0000000003533479

System DescriptionINFOID:0000000003533480

UNIFIED METER CONTROL UNIT

• Speedometer, odometer, tachometer, fuel gauge, oil pressure gauge, voltage gauge, A/T oil temperature

gauge, and water temperature gauge are controlled by the unified meter control unit, which is built into the

combination meter.

• Warning indicators are controlled by signals drawn fr om the CAN communication system, BCM (body control

module), and components connected directly to the combination meter.

• Digital meter is adopted for odometer/trip meters*, as well as the A/T position indicator display. *The record of the odometer is kept ev en if the battery cable is disconnected.

• Odometer/trip meters and A/T indicator segments can be checked in diagnosis mode.

• Meters/gauges can be checked in diagnosis mode.

Illumination control

The unified meter control unit outputs the speedometer, odometer/trip meters, tachometer, oil pressure gauge,

voltage meter, A/T indicator, A/T temperature gauge, fuel and temperature gauge lighting when the ignition

switch is turned on. When the lighting switch is turned on, the illumination control switch can be used to adjust

the brightness of the combination meter illuminati on and the odometer/trip meters and meter illumination.

When the ignition switch is turned from the OFF to the ON position, the combination meter dial lighting will

remain off for 0.7 seconds. For additional combination meter illumination control information, refer to LT-120,

"System Description".

1. IPDM E/R E122 2. Combination meter M24 3. Fuel level sensor unit and fuel pump

C5 (view with inspection hole cover

removed)

4. ECM E16 (view with battery re- moved) 5. ABS actuator and electric unit (con-

trol unit) E125 6. Oil pressure switch F4

A. Oil pan (upper)

7. A/T assembly F9

WKIA5718E

Page 1047 of 3061

DI-36

< SERVICE INFORMATION >

WARNING CHIME

WARNING CHIME

Component Parts and Harness Connector LocationINFOID:0000000003533510

System DescriptionINFOID:0000000003533511

FUNCTION

Power is supplied at all times

• through 50A fusible link (letter f, located in the fuse and fusible link box)

• to BCM terminal 70,

• through 10A fuse [No. 19, located in the fuse block (J/B)]

1. Fuse block (J/B) 2. Fuse and fusible link box 3. Fuse and relay box

4. Combination meter M24 5. Combination switch (lighting switch)

M286. BCM M18, M19, M20 (view with in-

strument lower panel LH removed)

7. Front door switch LH B8 8. Key switch and key lock solenoid

M279. Seat belt buckle pre-tensioner as-

sembly LH (seat belt buckle switch)

B74

WKIA4594E

Page 1048 of 3061

WARNING CHIME

DI-37

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

• to key switch and key lock solenoid terminal 3.

With ignition switch in ON or START position, power is supplied

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38.

Ground is supplied

• to BCM terminal 67

• through body grounds M57, M61, and M79.

NOTE:

When ignition key warning chime, light warning chime, and seat belt warning chime are required at the same

time, the priorities for each chime are the following.

1. Light warning chime

2. Ignition key warning chime

3. Seat belt warning chime

IGNITION KEY WARNING CHIME

With the key inserted in the ignition switch, the ignition switch in OFF position, and the driver's door open, the

warning chime will sound.

Power is supplied

• through key switch and key lock solenoid terminal 4

• to BCM terminal 37.

Ground is supplied

• to BCM terminal 47

• through front door switch LH terminal 2.

Front door switch LH is case grounded.

BCM detects key inserted into the ignition switch, and sends key warning signal to combination meter via CAN

communication lines. When the combination meter receives key warning signal, it sounds warning chime.

LIGHT WARNING CHIME

With the key removed from the ignition switch, the driver's door open, and the lighting switch (part of the com-

bination switch) in 1st or 2nd position, the warning chime will sound. [Except when headlamp battery saver

control operates (5 minutes after ignition switch is turned to OFF or ACC position) and headlamps do not illu-

minate.]

Signal is supplied

• from combination switch (lighting switch) terminals 1, 2, 3, 4, 5, 6, 7, 8, 9 and 10

• to BCM terminals 2, 3, 4, 5, 6, 32, 33, 34, 35 and 36.

NOTE:

BCM detected lighting switch in 1st or 2nd position. Refer to LT-72, "

Combination Switch Reading Function".

Ground is supplied

• to BCM terminal 47

• through front door switch LH terminal 2.

Front door switch LH is case grounded.

BCM detects headlamps are illuminated, and sends light warning signal to combination meter CAN communi-

cation lines. When the combination meter receives light warning signal, it sounds warning chime.

SEAT BELT WARNING CHIME

When the ignition switch is turned ON with the seat belt unfastened [seat belt buckle pre-tensioner assembly

LH (seat belt buckle switch) unfastened], warning chime will sound for approximately 6 seconds.

Ground is supplied

• to combination meter terminal 27

• through seat belt buckle pre-tensioner assembly LH (seat belt buckle switch) terminal 4.

Seat belt buckle pre-tensioner assembly LH (seat belt buckle switch) terminal 3 is grounded through body

grounds B7 and B19.

The combination meter sends seat belt buckle switch LH unfastened signal to BCM via CAN communication

line.

BCM receives seat belt buckle pre-tensioner assembly LH (seat belt buckle switch) unfastened signal from

combination meter via CAN communication line, and sends seat belt warning signal to the combination meter

via CAN communication line. When the combination meter receives the seat belt warning signal, it sounds the

warning chime. The BCM controls the (6 second) duration of the seat belt warning chime.

CAN Communication System DescriptionINFOID:0000000003533512

Refer to LAN-4.

Page 1051 of 3061

DI-40

< SERVICE INFORMATION >

WARNING CHIME

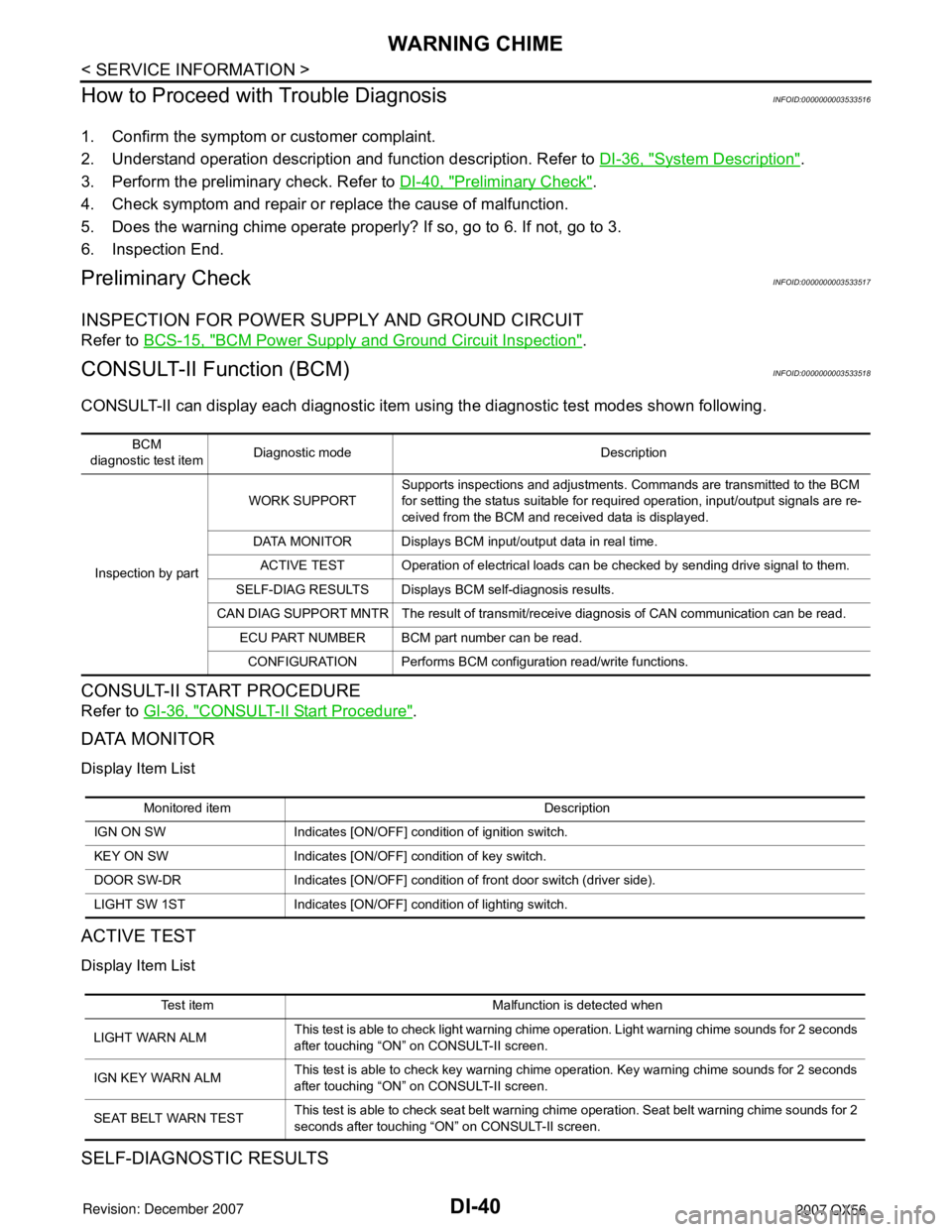

How to Proceed with Trouble Diagnosis

INFOID:0000000003533516

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer to DI-36, "

System Description".

3. Perform the preliminary check. Refer to DI-40, "

Preliminary Check".

4. Check symptom and repair or replace the cause of malfunction.

5. Does the warning chime operate properly? If so, go to 6. If not, go to 3.

6. Inspection End.

Preliminary CheckINFOID:0000000003533517

INSPECTION FOR POWER SUPPLY AND GROUND CIRCUIT

Refer to BCS-15, "BCM Power Supply and Ground Circuit Inspection".

CONSULT-II Function (BCM)INFOID:0000000003533518

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

DATA MONITOR

Display Item List

ACTIVE TEST

Display Item List

SELF-DIAGNOSTIC RESULTS

BCM

diagnostic test itemDiagnostic mode Description

Inspection by partWORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the BCM

for setting the status suitable for required operation, input/output signals are re-

ceived from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ECU PART NUMBER BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

Monitored item Description

IGN ON SW Indicates [ON/OFF] condition of ignition switch.

KEY ON SW Indicates [ON/OFF] condition of key switch.

DOOR SW-DR Indicates [ON/OFF] condition of front door switch (driver side).

LIGHT SW 1ST Indicates [ON/OFF] condition of lighting switch.

Test item Malfunction is detected when

LIGHT WARN ALMThis test is able to check light warning chime operation. Light warning chime sounds for 2 seconds

after touching “ON” on CONSULT-II screen.

IGN KEY WARN ALMThis test is able to check key warning chime operation. Key warning chime sounds for 2 seconds

after touching “ON” on CONSULT-II screen.

SEAT BELT WARN TESTThis test is able to check seat belt warning chime operation. Seat belt warning chime sounds for 2

seconds after touching “ON” on CONSULT-II screen.

Page 1052 of 3061

WARNING CHIME

DI-41

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P Display Item List

All Warning Chimes Do Not OperateINFOID:0000000003533519

1.CHECK BCM CHIME OPERATION

Select “BUZZER” on CONSULT-II, and perform “LIGHT WARN

ALM”, "IGN KEY WARN ALM", OR "SEAT BELT WARN TEST"

active test.

Does chime sound?

YES >> Replace the BCM. Refer to BCS-24, "BCM".

NO >> Replace the combination meter. Refer to IP-10,

"Removal and Installation".

Key Warning Chime and Light Warning Chime Do Not Operate (Seat Belt Warning

Chime Does Operate)

INFOID:0000000003533520

1.CHECK BCM INPUT SIGNAL

With CONSULT-II

1. Select "BCM" on CONSULT-II.

2. With "DATA MONITOR" of "BUZZER", confirm "DOOR SW-DR"

changes with the status of front door LH.

Without CONSULT-II

Check voltage between BCM harness connector M19 terminal 47

and ground.

OK or NG

OK >> Replace the BCM. Refer to BCS-24, "BCM".

NG >> GO TO 2.

2.CHECK FRONT DOOR SWITCH LH CIRCUIT

Monitored Item CONSULT-II display Description

CAN communication CAN communication [U1000] Malfunction is detected in CAN communication.

CAN communication system CAN communication system 1 to 6 [U1000] Malfunction is detected in CAN system.

SKIA6331E

When front door LH is

opened: DOOR SW-DR ON

When front door LH is

closed: DOOR SW-DR OFF

LKIA0335E

When front door LH is

opened: Approx. 0V

When front door LH is

closed: Approx. 5V

WKIA1515E

Page 1053 of 3061

DI-42

< SERVICE INFORMATION >

WARNING CHIME

1. Turn ignition switch OFF.

2. Disconnect BCM connector M19 and front door switch LH con-

nector B8.

3. Check continuity between BCM harness connector M19 terminal

47 and front door switch LH harness connector B8 terminal 2.

4. Check continuity between BCM harness connector M19 terminal

47 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK FRONT DOOR SWITCH LH

Check continuity between front door switch LH terminal 2 and

exposed metal of switch while pressing and releasing switch.

OK or NG

OK >> Replace the BCM. Refer to BCS-24, "BCM".

NG >> Replace the front door switch LH.

Key Warning Chime Does Not OperateINFOID:0000000003533521

1.CHECK FUSE

Check if the key switch fuse [No. 19, located in the fuse block (J/B)] is blown. Refer to DI-38, "

Wiring Diagram

- CHIME -".

Is the fuse blown?

YES >> Replace the fuse. Be sure to repair the cause of malfunction before installing new fuse.

NO >> GO TO 2.

2.CHECK WARNING CHIME OPERATION

With key removed from the ignition key cylinder and the front door LH open, turn the lighting switch to 1st or

2nd position.

Does warning chime sound?

YES >> GO TO 3.

NO >> Go to DI-41, "

All Warning Chimes Do Not Operate" or DI-41, "Key Warning Chime and Light

Warning Chime Do Not Operate (Seat Belt Warning Chime Does Operate)".

3.CHECK BCM INPUT SIGNAL

With CONSULT-IIContinuity should exist.

Continuity should not exist.

WKIA1516E

When front door switch

LH is released: Continuity should exist.

When front door switch

LH is pressed: Continuity should not exist.

WKIA2023E

Page 1055 of 3061

DI-44

< SERVICE INFORMATION >

WARNING CHIME

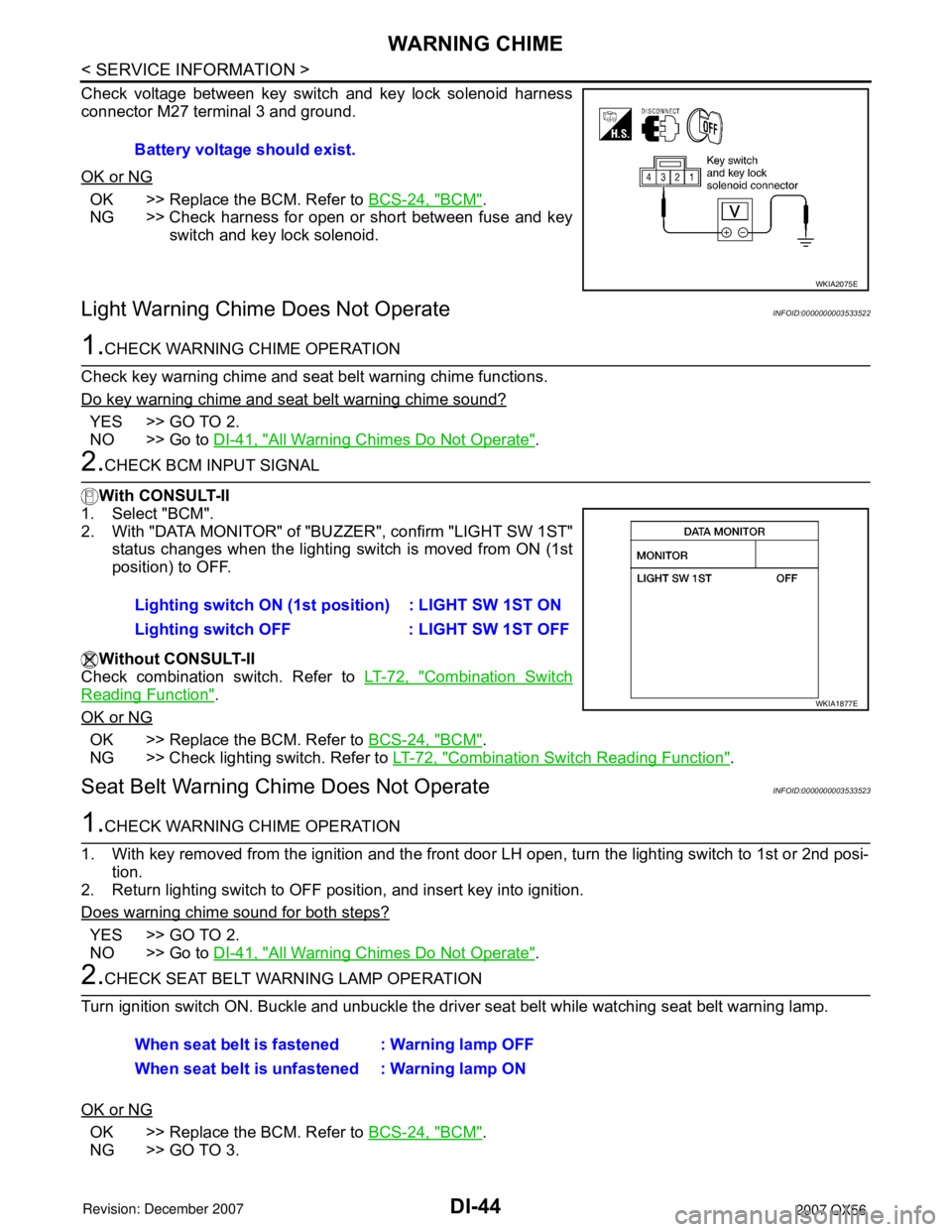

Check voltage between key switch and key lock solenoid harness

connector M27 terminal 3 and ground.

OK or NG

OK >> Replace the BCM. Refer to BCS-24, "BCM".

NG >> Check harness for open or short between fuse and key

switch and key lock solenoid.

Light Warning Chime Does Not OperateINFOID:0000000003533522

1.CHECK WARNING CHIME OPERATION

Check key warning chime and seat belt warning chime functions.

Do key warning chime and seat belt warning chime sound?

YES >> GO TO 2.

NO >> Go to DI-41, "

All Warning Chimes Do Not Operate".

2.CHECK BCM INPUT SIGNAL

With CONSULT-II

1. Select "BCM".

2. With "DATA MONITOR" of "BUZZER", confirm "LIGHT SW 1ST"

status changes when the lighting switch is moved from ON (1st

position) to OFF.

Without CONSULT-II

Check combination switch. Refer to LT-72, "

Combination Switch

Reading Function".

OK or NG

OK >> Replace the BCM. Refer to BCS-24, "BCM".

NG >> Check lighting switch. Refer to LT-72, "

Combination Switch Reading Function".

Seat Belt Warning Chime Does Not OperateINFOID:0000000003533523

1.CHECK WARNING CHIME OPERATION

1. With key removed from the ignition and the front door LH open, turn the lighting switch to 1st or 2nd posi-

tion.

2. Return lighting switch to OFF position, and insert key into ignition.

Does warning chime sound for both steps?

YES >> GO TO 2.

NO >> Go to DI-41, "

All Warning Chimes Do Not Operate".

2.CHECK SEAT BELT WARNING LAMP OPERATION

Turn ignition switch ON. Buckle and unbuckle the driver seat belt while watching seat belt warning lamp.

OK or NG

OK >> Replace the BCM. Refer to BCS-24, "BCM".

NG >> GO TO 3.Battery voltage should exist.

WKIA2075E

Lighting switch ON (1st position) : LIGHT SW 1ST ON

Lighting switch OFF : LIGHT SW 1ST OFF

WKIA1877E

When seat belt is fastened : Warning lamp OFF

When seat belt is unfastened : Warning lamp ON

Page 1100 of 3061

PRECAUTIONS

EC-17

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003531580

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

On Board Diagnosis (OBD) System of Engine and A/TINFOID:0000000003531581

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and disconnect the negative battery cable before any repair

or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc. will

cause the MIL to light up.

• Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Certain systems and components, especially those related to OBD, may use a new style slide-lock-

ing type harness connector. For description and how to disconnect, refer to PG-66

.

• Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MIL to light up due to the short circuit.

• Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to the malfunction of the EVAP system or fuel injection system,

etc.

• Be sure to erase the unnecessary malfunction information (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

PrecautionINFOID:0000000003531582

•Always use a 12 volt battery as power source.

•Do not attempt to disconnect battery cables while engine is

running.

•Before connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative bat-

tery cable. Failure to do so may damage the ECM because

battery voltage is applied to ECM even if ignition switch is

turned OFF.

•Before removing parts, turn ignition switch OFF and then dis-

connect negative battery cable.

SEF289H