air condition INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1273 of 3061

EC-190

< SERVICE INFORMATION >

DTC P0101 MAF SENSOR

Diagnosis Procedure

INFOID:0000000003531686

1.INSPECTION START

Which malfunction (A or B) is duplicated?

A or B

A>>GO TO 3.

B>>GO TO 2.

2.CHECK INTAKE SYSTEM

Check the following for connection.

• Air duct

• Vacuum hoses

• Intake air passage between air duct to intake manifold

OK or NG

OK >> GO TO 3.

NG >> Reconnect the parts.

3.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer to EC-143, "

Ground Inspection".

OK or NG

OK >> GO TO 4.

NG >> Repair or replace ground connections.

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

51 W Mass air flow sensor[Engine is running]

•Warm-up condition

• Idle speed1.0 - 1.3V

[Engine is running]

•Warm-up condition

• Engine speed: 2,500 rpm.1.7 - 2.1V

67 B Sensor ground[Engine is running]

•Warm-up condition

• Idle speedApproximately 0V

111 W / BECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF0 - 1.5V

[Ignition switch: OFF]

• More than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

11 9

120BR

BRPower supply for ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

BBIA0354E

Page 1275 of 3061

EC-192

< SERVICE INFORMATION >

DTC P0101 MAF SENSOR

Refer to EC-204, "Component Inspection".

OK or NG

OK >> GO TO 9.

NG >> Replace intake air temperature sensor.

9.CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

Refer to EC-394, "

Component Inspection".

OK or NG

OK >> GO TO 10.

NG >> Replace EVAP control system pressure sensor.

10.CHECK MASS AIR FLOW SENSOR

Refer to EC-192, "

Component Inspection".

OK or NG

OK >> GO TO 11.

NG >> Replace mass air flow sensor.

11 .CHECK INTERMITTENT INCIDENT

Refer to EC-138

.

>>INSPECTION END

Component InspectionINFOID:0000000003531687

MASS AIR FLOW SENSOR

With CONSULT-II

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Connect CONSULT-II and select “DATA MONITOR” mode.

4. Select “MAS A/F SE-B1” and check indication under the follow-

ing conditions.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

5. If the voltage is out of specification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following.

• Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system parts

b. If NG, repair or replace malfunctioning part and perform step 2 to 4 again.

If OK, go to next step.

6. Turn ignition switch OFF.

7. Disconnect mass air flow sensor harness connector and reconnect it again.

8. Perform step 2 to 4 again.

9. If NG, clean or replace mass air flow sensor.

Without CONSULT-II

Condition MAS A/F SE-B1 (V)

Ignition switch ON (Engine stopped.) Approx. 0.4

Idle (Engine is warmed-up to normal

operating temperature.)1.0 - 1.3

2,500 rpm (Engine is warmed-up to

normal operating temperature.)1.7 - 2.1

Idle to about 4,000 rpm 1.0 - 1.3 to Approx. 2.4*

PBIB2371E

Page 1276 of 3061

DTC P0101 MAF SENSOR

EC-193

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Check voltage between ECM terminal 51 (Mass air flow sensor

signal) and ground.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

4. If the voltage is out of specification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following.

• Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system parts

b. If NG, repair or replace malfunctioning part and perform step 2 and 3 again.

If OK, go to next step.

5. Turn ignition switch OFF.

6. Disconnect mass air flow sensor harness connector and reconnect it again.

7. Perform step 2 and 3 again.

8. If NG, clean or replace mass air flow sensor.

Removal and InstallationINFOID:0000000003531688

MASS AIR FLOW SENSOR

Refer to EM-15.

Condition MAS A/F SE-B1 (V)

Ignition switch ON (Engine stopped.) Approx. 0.4

Idle (Engine is warmed-up to normal

operating temperature.)1.0 - 1.3

2,500 rpm (Engine is warmed-up to

normal operating temperature.)1.7 - 2.1

Idle to about 4,000 rpm 1.0 - 1.3 to Approx. 2.4*

PBIB1106E

Page 1277 of 3061

EC-194

< SERVICE INFORMATION >

DTC P0102, P0103 MAF SENSOR

DTC P0102, P0103 MAF SENSOR

Component DescriptionINFOID:0000000003531689

The mass air flow sensor is placed in the stream of intake air. It mea-

sures the intake flow rate by measuring a part of the entire intake

flow. The mass air flow sensor controls the temperature of the hot

wire to a certain amount. The heat generated by the hot wire is

reduced as the intake air flows around it. The more air, the greater

the heat loss.

Therefore, the electric current supplied to the hot wire is changed to

maintain the temperature of the hot wire as air flow increases. The

ECM detects the air flow by means of this current change.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000003531690

Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000003531691

These self-diagnoses have the one trip detection logic.

FA I L - S A F E M O D E

When the malfunction is detected, the ECM enters fail-safe mode and the MIL lights up.

DTC Confirmation ProcedureINFOID:0000000003531692

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

PROCEDURE FOR DTC P0102

With CONSULT-II

1. Turn ignition switch ON.

BBIA0355E

MONITOR ITEM CONDITION SPECIFICATION

MAS A/F SE-B1 See EC-129

.

CAL/LD VALUE• Engine: After warming up

• Air conditioner switch: OFF

• Selector lever: P or N

•No loadIdle 14% - 33%

2,500 rpm 12% - 25%

MASS AIRFLOW• Engine: After warming up

• Air conditioner switch: OFF

• Selector lever: P or N

•No loadIdle 3.0 - 9.0 g·m/s

2,500 rpm 9.0 - 28.0 g·m/s

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0102

0102Mass air flow sensor circuit

low inputAn excessively low voltage from the sensor is

sent to ECM.• Harness or connectors

(The sensor circuit is open or shorted.)

• Intake air leaks

• Mass air flow sensor

P0103

0103Mass air flow sensor circuit

high inputAn excessively high voltage from the sensor is

sent to ECM.• Harness or connectors

(The sensor circuit is open or shorted.)

• Mass air flow sensor

Detected items Engine operating condition in fail-safe mode

Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.

Page 1280 of 3061

DTC P0102, P0103 MAF SENSOR

EC-197

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Diagnosis ProcedureINFOID:0000000003531694

1.INSPECTION START

Which malfunction (P0102 or P0103) is duplicated?

P0102 or P0103

P0102 >> GO TO 2.

P0103 >> GO TO 3.

2.CHECK INTAKE SYSTEM

Check the following for connection.

• Air duct

• Vacuum hoses

• Intake air passage between air duct to intake manifold

OK or NG

OK >> GO TO 3.

NG >> Reconnect the parts.

3.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer to EC-143, "

Ground Inspection".

OK or NG

OK >> GO TO 4.

NG >> Repair or replace ground connections.

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

51 W Mass air flow sensor[Engine is running]

•Warm-up condition

• Idle speed1.0 - 1.3V

[Engine is running]

•Warm-up condition

• Engine speed: 2,500 rpm.1.7 - 2.1V

67 B Sensor ground[Engine is running]

•Warm-up condition

• Idle speedApproximately 0V

111 W / BECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF0 - 1.5V

[Ignition switch: OFF]

• More than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

11 9

120BR

BRPower supply for ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

BBIA0354E

Page 1282 of 3061

DTC P0102, P0103 MAF SENSOR

EC-199

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Refer to EC-199, "Component Inspection".

OK or NG

OK >> GO TO 9.

NG >> Replace mass air flow sensor.

9.CHECK INTERMITTENT INCIDENT

Refer to EC-138

.

>>INSPECTION END

Component InspectionINFOID:0000000003531695

MASS AIR FLOW SENSOR

With CONSULT-II

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Connect CONSULT-II and select “DATA MONITOR” mode.

4. Select “MAS A/F SE-B1” and check indication under the follow-

ing conditions.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

5. If the voltage is out of specification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following.

• Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system parts

b. If NG, repair or replace malfunctioning part and perform step 2 to 4 again.

If OK, go to next step.

6. Turn ignition switch OFF.

7. Disconnect mass air flow sensor harness connector and reconnect it again.

8. Perform step 2 to 4 again.

9. If NG, clean or replace mass air flow sensor.

Without CONSULT-II

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

Condition MAS A/F SE-B1 (V)

Ignition switch ON (Engine stopped.) Approx. 0.4

Idle (Engine is warmed-up to normal

operating temperature.)1.0 - 1.3

2,500 rpm (Engine is warmed-up to

normal operating temperature.)1.7 - 2.1

Idle to about 4,000 rpm 1.0 - 1.3 to Approx. 2.4*

PBIB2371E

Page 1283 of 3061

EC-200

< SERVICE INFORMATION >

DTC P0102, P0103 MAF SENSOR

3. Check voltage between ECM terminal 51 (Mass air flow sensor

signal) and ground.

*: Check for linear voltage rise in response to engine being increased to about 4,000 rpm.

4. If the voltage is out of specification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following.

• Crushed air ducts

• Malfunctioning seal of air cleaner element

• Uneven dirt of air cleaner element

• Improper specification of intake air system parts

b. If NG, repair or replace malfunctioning part and perform step 2 and 3 again.

If OK, go to next step.

5. Turn ignition switch OFF.

6. Disconnect mass air flow sensor harness connector and reconnect it again.

7. Perform step 2 and 3 again.

8. If NG, clean or replace mass air flow sensor.

Removal and InstallationINFOID:0000000003531696

MASS AIR FLOW SENSOR

Refer to EM-15.

Condition MAS A/F SE-B1 (V)

Ignition switch ON (Engine stopped.) Approx. 0.4

Idle (Engine is warmed-up to normal

operating temperature.)1.0 - 1.3

2,500 rpm (Engine is warmed-up to

normal operating temperature.)1.7 - 2.1

Idle to about 4,000 rpm 1.0 - 1.3 to Approx. 2.4*

PBIB1106E

Page 1284 of 3061

DTC P0112, P0113 IAT SENSOR

EC-201

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P0112, P0113 IAT SENSOR

Component DescriptionINFOID:0000000003531697

The intake air temperature sensor is built-into mass air flow sensor.

The sensor detects intake air temperature and transmits a signal to

the ECM.

The temperature sensing unit uses a thermistor which is sensitive to

the change in temperature. Electrical resistance of the thermistor

decreases in response to the temperature rise.

*: This data is reference value and is measured between ECM terminal 34 (Intake air

temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output

voltage. Doing so may result in damage to the ECM's transistor.

Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis LogicINFOID:0000000003531698

DTC Confirmation ProcedureINFOID:0000000003531699

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If 1st trip DTC is detected, go to EC-202, "

Diagnosis Procedure".

WITH GST

BBIA0355E

Intake air temperature

°C (°F)Voltage* V Resistance kΩ

25 (77) 3.3 1.800 - 2.200

80 (176) 1.2 0.283 - 0.359

SEF012P

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0112

0112Intake air temperature

sensor circuit low inputAn excessively low voltage from the sensor is

sent to ECM.• Harness or connectors

(The sensor circuit is open or shorted.)

• Intake air temperature sensor P0113

0113Intake air temperature

sensor circuit high inputAn excessively high voltage from the sensor is

sent to ECM.

SEF058Y

Page 1287 of 3061

EC-204

< SERVICE INFORMATION >

DTC P0112, P0113 IAT SENSOR

5.CHECK INTERMITTENT INCIDENT

Refer to EC-138

.

>>INSPECTION END

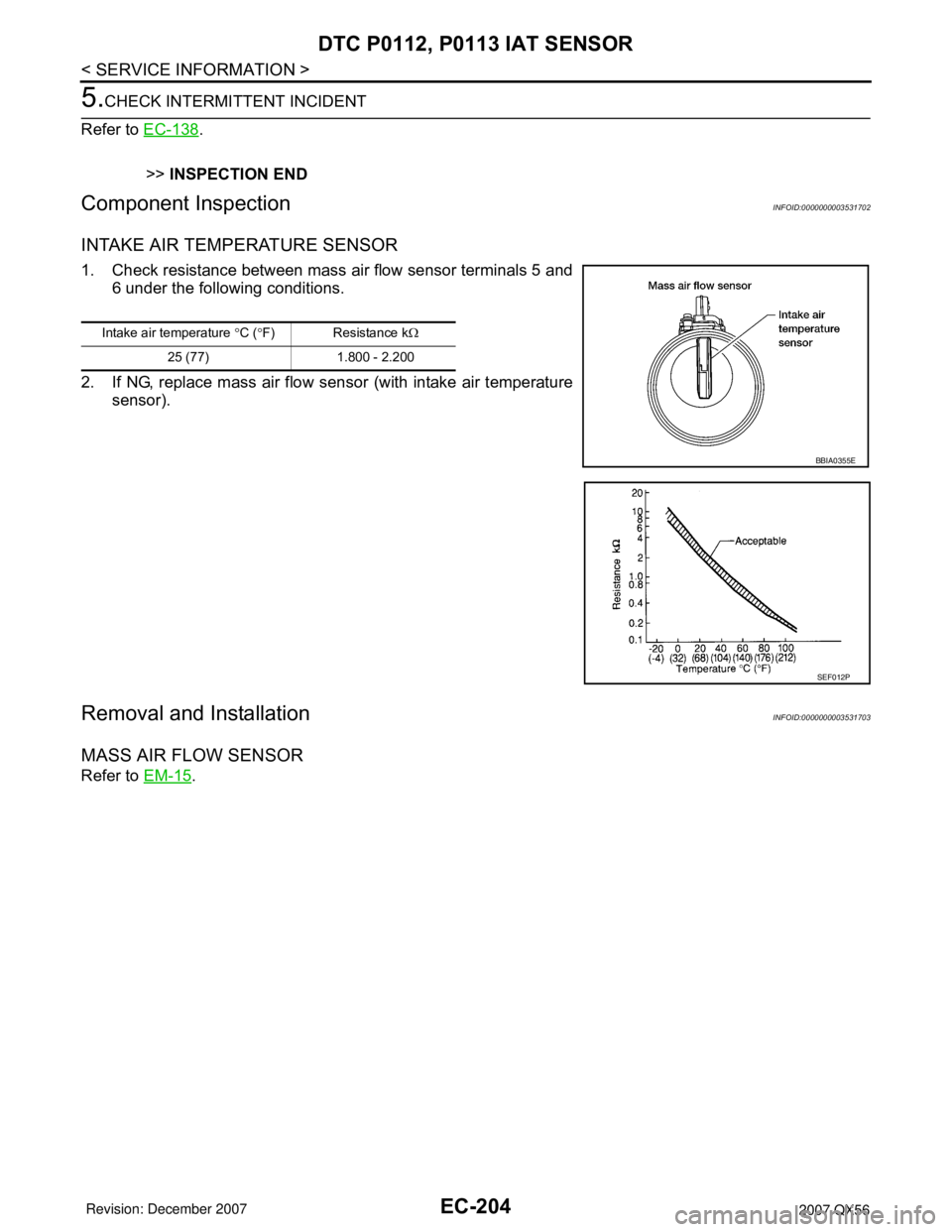

Component InspectionINFOID:0000000003531702

INTAKE AIR TEMPERATURE SENSOR

1. Check resistance between mass air flow sensor terminals 5 and

6 under the following conditions.

2. If NG, replace mass air flow sensor (with intake air temperature

sensor).

Removal and InstallationINFOID:0000000003531703

MASS AIR FLOW SENSOR

Refer to EM-15.

Intake air temperature °C (°F) Resistance kΩ

25 (77) 1.800 - 2.200

BBIA0355E

SEF012P

Page 1296 of 3061

DTC P0122, P0123 TP SENSOR

EC-213

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Diagnosis ProcedureINFOID:0000000003531716

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer to EC-143, "

Ground Inspection" .

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK THROTTLE POSITION SENSOR 2 POWER SUPPLY CIRCUIT-I

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

47 YSensor power supply

(Throttle position sensor)[Ignition switch: ON]Approximately 5V

50 B Throttle position sensor 1[Ignition switch: ON]

• Engine: Stopped

• Selector lever: D

• Accelerator pedal: Fully releasedMore than 0.36V

[Ignition switch: ON]

• Engine: Stopped

• Selector lever: D

• Accelerator pedal: Fully depressedLess than 4.75V

66 RSensor ground

(Throttle position sensor)[Engine is running]

•Warm-up condition

• Idle speedApproximately 0V

69 W Throttle position sensor 2[Ignition switch: ON]

• Engine: Stopped

• Selector lever: D

• Accelerator pedal: Fully releasedLess than 4.75V

[Ignition switch: ON]

• Engine: Stopped

• Selector ever: D

• Accelerator pedal: Fully depressedMore than 0.36V

91 W/RSensor power supply

(APP sensor 2)[Ignition switch: ON]Approximately 5V

BBIA0354E