air condition INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1065 of 3061

DI-54

< SERVICE INFORMATION >

REAR SONAR SYSTEM

Symptom Chart

INFOID:0000000003533533

Symptom Repair order

When the rear sonar system OFF switch is OFF, the indicator

lamp does not light and the buzzer does not sound.1. Check rear sonar system OFF switch for malfunction. Refer

to DI-55, "

Component Inspection".

2. Check rear sonar system OFF switch ground circuit.

3. Check harness and connections between rear sonar system

OFF switch and sonar control unit.

4. Replace sonar control unit. Refer to DI-55, "

Removal and In-

stallation".

When the rear sonar system OFF switch is OFF, the indicator

lamp does not light but buzzer sounds.1. Check rear sonar system OFF indicator for malfunction. Re-

fer to DI-55, "

Component Inspection".

2. Check harness and connections between rear sonar system

OFF indicator and sonar control unit.

3. Replace sonar control unit. Refer to DI-55, "

Removal and In-

stallation".

When the rear sonar system OFF switch is OFF, the sonar buzzer

does not sound but indicator lamp illuminates.1. Check sonar buzzer. Refer to DI-55, "

Component Inspec-

tion".

2. Check harness and connections between sonar buzzer and

sonar control unit.

3. Replace sonar control unit. Refer to: DI-55, "

Removal and

Installation".

When rear sonar system OFF switch is ON, the rear sonar system

OFF indicator lamp lights up and the sonar buzzer sounds inter-

mittently (for about 4 seconds).1. Check harness between rear sonar sensors and sonar con-

trol unit for an open condition.

2. Check rear sonar sensors for malfunction.

3. Replace sonar control unit. Refer to DI-55, "

Removal and In-

stallation".

The rear sonar system operates with the rear sonar system OFF

switch OFF.1. Check rear sonar system OFF switch for malfunction. Refer

to DI-55, "

Component Inspection".

2. Check rear sonar system OFF switch ground circuit.

3. Check harness and connections between rear sonar system

OFF switch and sonar control unit.

4. Replace sonar control unit. Refer to DI-55, "

Removal and In-

stallation".

When the transmission gear selector lever is in the R position and

the rear sonar system OFF switch is OFF, the sonar system does

not operate.1. Check for PNP switch failure. Refer to AT- 8 3 , "

CONSULT-II

Function (A/T)".

2. Check harness and connections between sonar control unit

and PNP/reverse lamp circuits.

3. Replace sonar control unit. Refer to DI-55, "

Removal and In-

stallation".

When the rear sonar system OFF switch is OFF, the indicator

lamp lights up and buzzer sounds although there is no obstacle

within the detection range.1. Check for adhesion of snow, mud, or other foreign objects to

rear sonar sensors; dew condensation; etc. Refer to DI-51,

"Pre-diagnosis Inspection".

2. Check that the rear sonar sensor is properly aligned

(bumper is not misaligned, no deformation in sensor mount-

ing area

3. Check harness and connections between rear sonar sen-

sors and sonar control unit.

4. Check rear sonar sensors for malfunction.

5. Replace sonar control unit. Refer to DI-55, "

Removal and In-

stallation".

The rear sonar sensors do not operate according to the distance

between each sensor and the obstacle. (There is a large error in

the obstacle detection distance.1. Check rear sonar sensors for malfunction.

2. Replace sonar control unit. Refer to DI-55, "

Removal and In-

stallation".

3. Check for adhesion of snow, mud, or other foreign objects to

rear sonar sensors; dew condensation; etc. Refer to DI-51,

"Pre-diagnosis Inspection".

4. Check that the rear sonar sensor is properly aligned

(bumper is not misaligned, no deformation in sensor mount-

ing area

Page 1084 of 3061

EC-1

ENGINE

C

D

E

F

G

H

I

J

K

L

M

SECTION EC

A

EC

N

O

P

CONTENTS

ENGINE CONTROL SYSTEM

SERVICE INFORMATION ............................9

INDEX FOR DTC .................................................9

DTC No. Index ..........................................................9

Alphabetical Index ...................................................12

PRECAUTIONS ..................................................17

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

17

On Board Diagnosis (OBD) System of Engine and

A/T ...........................................................................

17

Precaution ...............................................................17

PREPARATION ..................................................21

Special Service Tool ...............................................21

Commercial Service Tool ........................................22

ENGINE CONTROL SYSTEM ............................24

Schematic ...............................................................24

Multiport Fuel Injection (MFI) System .....................24

Electronic Ignition (EI) System ................................27

Fuel Cut Control (at No Load and High Engine

Speed) .....................................................................

27

AIR CONDITIONING CUT CONTROL ...............29

Input/Output Signal Chart ........................................29

System Description .................................................29

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ...............................................................

30

System Description .................................................30

Component Description ...........................................31

CAN COMMUNICATION ....................................32

System Description .................................................32

EVAPORATIVE EMISSION SYSTEM ................33

Description ..............................................................33

Component Inspection ............................................35

Removal and Installation .........................................37

How to Detect Fuel Vapor Leakage ........................37

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ......................................................

40

System Description ..................................................40

Diagnosis Procedure ...............................................40

Component Inspection .............................................42

POSITIVE CRANKCASE VENTILATION .........45

Description ...............................................................45

Component Inspection .............................................45

IVIS (INFINITI VEHICLE IMMOBILIZER SYS-

TEM-NATS) .......................................................

47

Description ...............................................................47

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....48

Introduction ..............................................................48

Two Trip Detection Logic .........................................48

Emission-related Diagnostic Information .................49

Malfunction Indicator Lamp (MIL) ............................63

OBD System Operation Chart .................................65

BASIC SERVICE PROCEDURE .......................71

Basic Inspection ......................................................71

Idle Speed and Ignition Timing Check .....................75

Procedure After Replacing ECM .............................77

VIN Registration ......................................................77

Accelerator Pedal Released Position Learning .......77

Throttle Valve Closed Position Learning .................77

Idle Air Volume Learning .........................................78

Fuel Pressure Check ...............................................80

TROUBLE DIAGNOSIS ....................................82

Trouble Diagnosis Introduction ................................82

DTC Inspection Priority Chart ..................................87

Fail-Safe Chart ........................................................88

Symptom Matrix Chart .............................................90

Engine Control Component Parts Location .............94

Vacuum Hose Drawing ..........................................100

Circuit Diagram ......................................................101

ECM Harness Connector Terminal Layout ............103

ECM Terminal and Reference Value .....................103

Page 1108 of 3061

ENGINE CONTROL SYSTEM

EC-25

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

*1: This sensor is not used to control the engine system. This is used only for the on board diagnosis.

*2: This signal is sent to the ECM through CAN communication line.

*3: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from both the crankshaft position sensor and the mass air

flow sensor.

VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION

In addition, the amount of fuel injected is compensated to improve engine performance under various operat-

ing conditions as listed below.

• When starting the engine

• During acceleration

• Hot-engine operation

• When selector lever is changed from N to D

• High-load, high-speed operation

• During deceleration

• During high engine speed operation

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

Sensor Input signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Engine speed*

3

Piston position

Fuel injection

& mixture ratio

controlFuel injector Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Air fuel ratio (A/F) sensor 1 Density of oxygen in exhaust gas

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Park/neutral position (PNP) switch Gear position

Knock sensor Engine knocking condition

Battery

Battery voltage*

3

Power steering pressure sensor Power steering operation

Heated oxygen sensor 2*

1Density of oxygen in exhaust gas

ABS actuator and electric unit (control unit)

VDC/TCS operation command*

2

Air conditioner switch

Air conditioner operation*2

Wheel sensor

Vehicle speed*2

PBIB3020E

Page 1109 of 3061

EC-26

< SERVICE INFORMATION >

ENGINE CONTROL SYSTEM

The mixture ratio feedback system provides the best air-fuel mixture ratio for driveability and emission control.

The three way catalyst (manifold) can then better reduce CO, HC and NOx emissions. This system uses air

fuel ratio (A/F) sensor 1 in the exhaust manifold to monitor whether the engine operation is rich or lean. The

ECM adjusts the injection pulse width according to the sensor voltage signal. For more information about air

fuel ratio (A/F) sensor 1, refer to EC-225

. This maintains the mixture ratio within the range of stoichiometric

(ideal air-fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 is located downstream of the three way catalyst (manifold). Even if the switching

characteristics of air fuel ratio (A/F) sensor 1 shift, the air-fuel ratio is controlled to stoichiometric by the signal

from heated oxygen sensor 2.

Open Loop Control

The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

• Deceleration and acceleration

• High-load, high-speed operation

• Malfunction of A/F sensor 1 or its circuit

• Insufficient activation of A/F sensor 1 at low engine coolant temperature

• High engine coolant temperature

• During warm-up

• After shifting from N to D

• When starting the engine

MIXTURE RATIO SELF-LEARNING CONTROL

The mixture ratio feedback control system monitors the mixture ratio signal transmitted from A/F sensor 1.

This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio as close to the theoret-

ical mixture ratio as possible. However, the basic mixture ratio is not necessarily controlled as originally

designed. Both manufacturing differences (i.e., mass air flow sensor hot wire) and characteristic changes dur-

ing operation (i.e., injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This is

then computed in terms of “injection pulse duration” to automatically compensate for the difference between

the two ratios.

“Fuel trim” refers to the feedback compensation value compared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

“Short term fuel trim” is the short-term fuel compensation used to maintain the mixture ratio at its theoretical

value. The signal from A/F sensor 1 indicates whether the mixture ratio is RICH or LEAN compared to the the-

oretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is rich, and an increase in

fuel volume if it is lean.

“Long term fuel trim” is overall fuel compensation carried out long-term to compensate for continual deviation

of the short term fuel trim from the central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

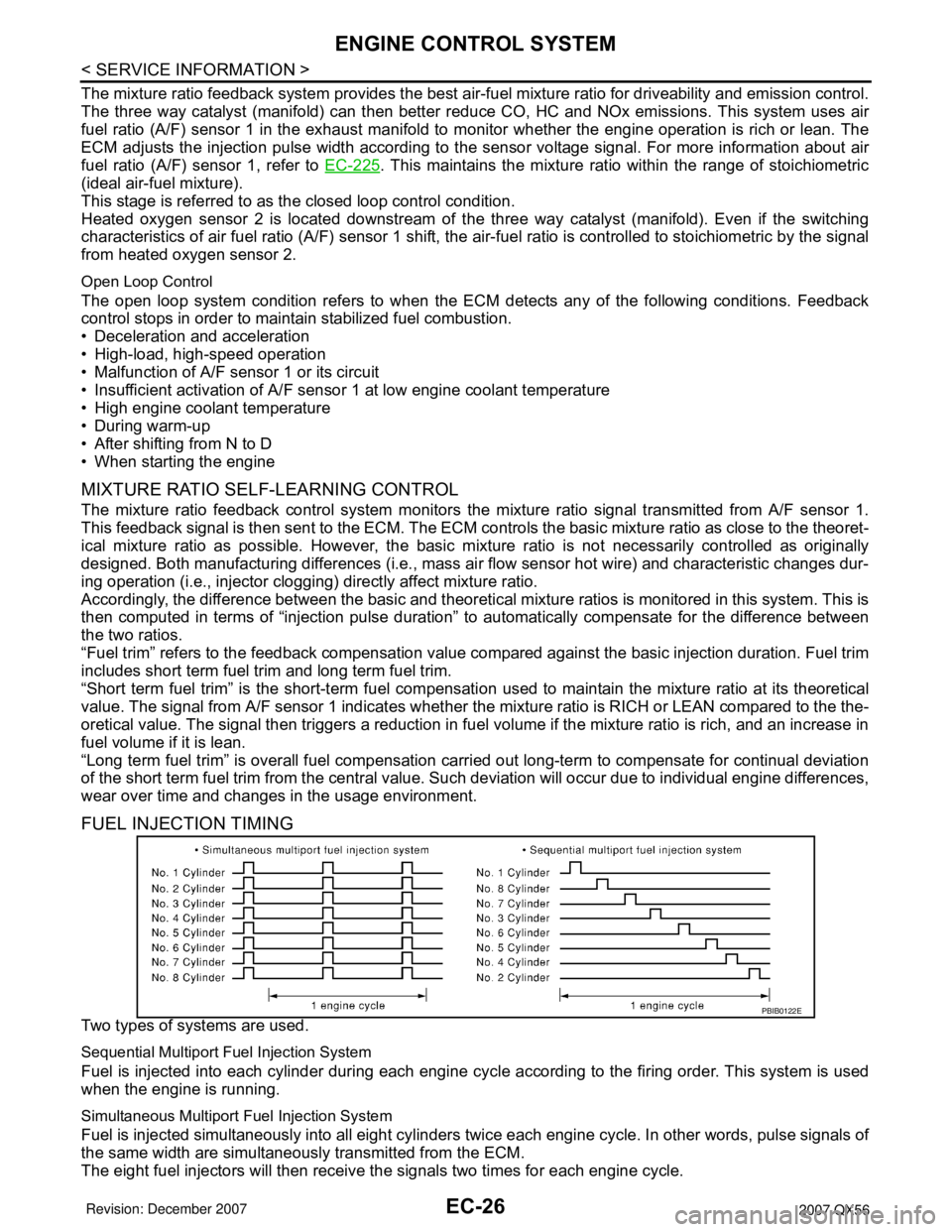

FUEL INJECTION TIMING

Two types of systems are used.

Sequential Multiport Fuel Injection System

Fuel is injected into each cylinder during each engine cycle according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System

Fuel is injected simultaneously into all eight cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The eight fuel injectors will then receive the signals two times for each engine cycle.

PBIB0122E

Page 1110 of 3061

ENGINE CONTROL SYSTEM

EC-27

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

This system is used when the engine is being started and/or if the fail-safe system (CPU) is operating.

FUEL SHUT-OFF

Fuel to each cylinder is cut off during deceleration, operation of the engine at excessively high speeds or oper-

ation of the vehicle at excessively high speed.

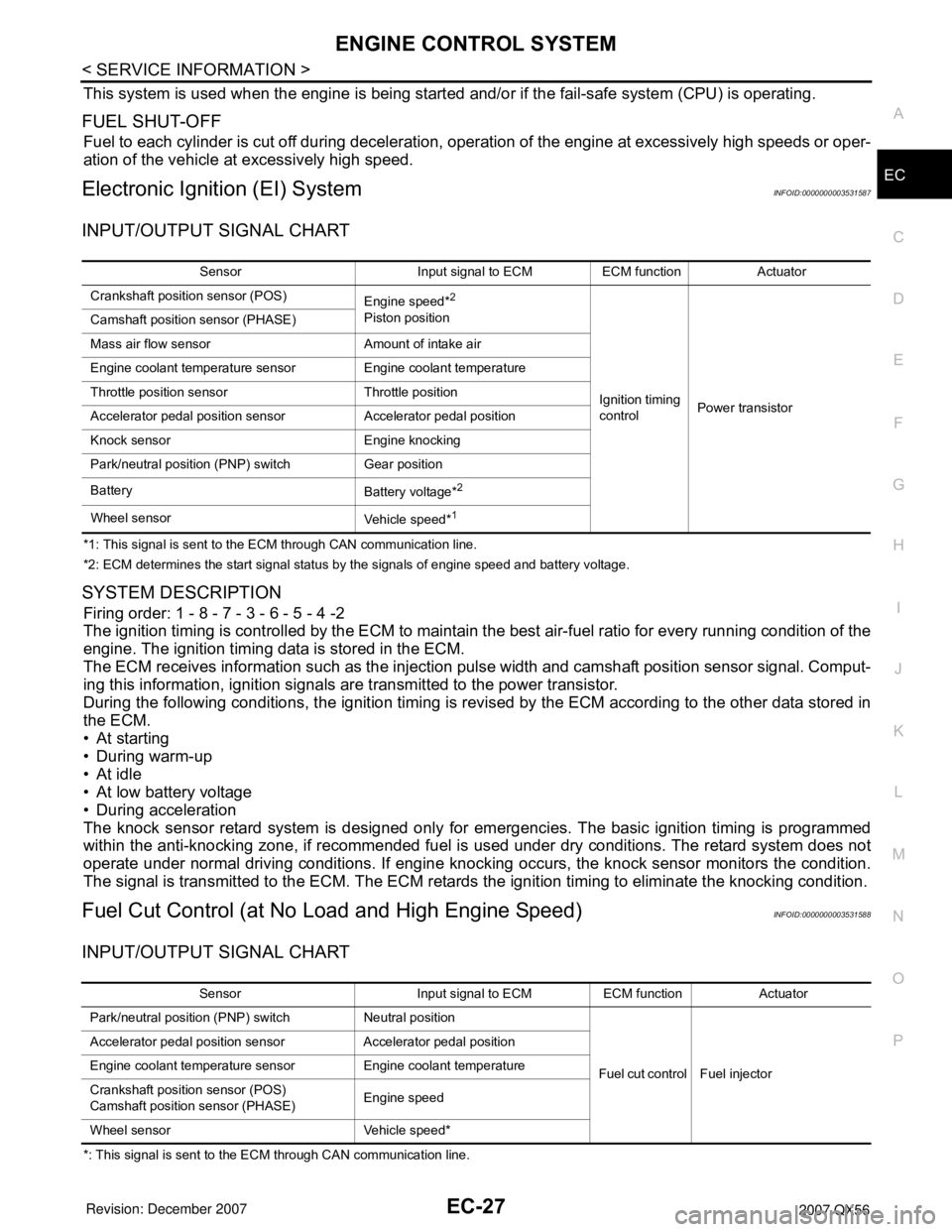

Electronic Ignition (EI) SystemINFOID:0000000003531587

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

Firing order: 1 - 8 - 7 - 3 - 6 - 5 - 4 -2

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of the

engine. The ignition timing data is stored in the ECM.

The ECM receives information such as the injection pulse width and camshaft position sensor signal. Comput-

ing this information, ignition signals are transmitted to the power transistor.

During the following conditions, the ignition timing is revised by the ECM according to the other data stored in

the ECM.

• At starting

• During warm-up

•At idle

• At low battery voltage

• During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions. If engine knocking occurs, the knock sensor monitors the condition.

The signal is transmitted to the ECM. The ECM retards the ignition timing to eliminate the knocking condition.

Fuel Cut Control (at No Load and High Engine Speed)INFOID:0000000003531588

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM through CAN communication line.Sensor Input signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Engine speed*

2

Piston position

Ignition timing

controlPower transistor Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Knock sensor Engine knocking

Park/neutral position (PNP) switch Gear position

Battery

Battery voltage*

2

Wheel sensor

Vehicle speed*1

Sensor Input signal to ECM ECM function Actuator

Park/neutral position (PNP) switch Neutral position

Fuel cut control Fuel injector Accelerator pedal position sensor Accelerator pedal position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed

Wheel sensor Vehicle speed*

Page 1112 of 3061

AIR CONDITIONING CUT CONTROL

EC-29

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

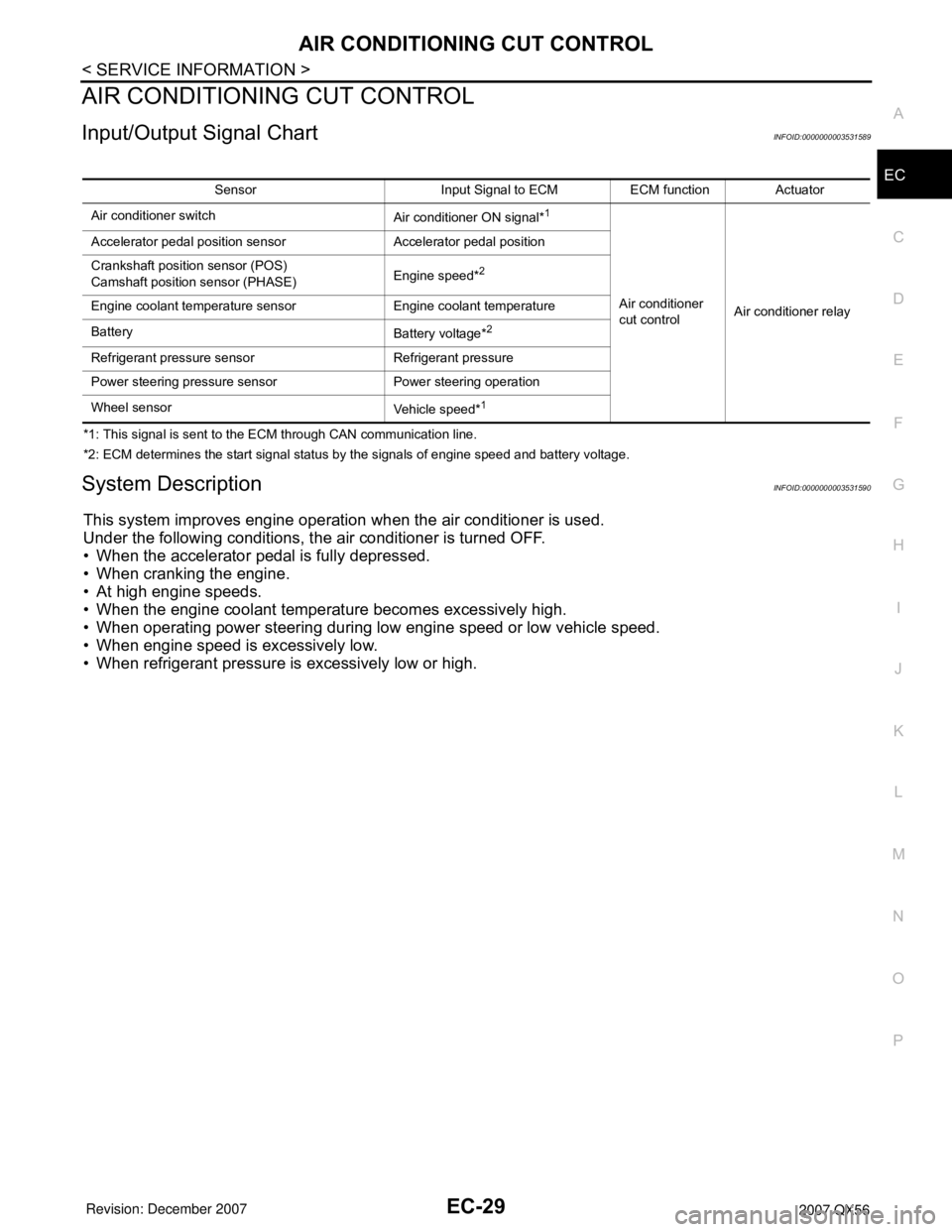

AIR CONDITIONING CUT CONTROL

Input/Output Signal ChartINFOID:0000000003531589

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

System DescriptionINFOID:0000000003531590

This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned OFF.

• When the accelerator pedal is fully depressed.

• When cranking the engine.

• At high engine speeds.

• When the engine coolant temperature becomes excessively high.

• When operating power steering during low engine speed or low vehicle speed.

• When engine speed is excessively low.

• When refrigerant pressure is excessively low or high.

Sensor Input Signal to ECM ECM function Actuator

Air conditioner switch

Air conditioner ON signal*

1

Air conditioner

cut controlAir conditioner relay Accelerator pedal position sensor Accelerator pedal position

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed*

2

Engine coolant temperature sensor Engine coolant temperature

Battery

Battery voltage*

2

Refrigerant pressure sensor Refrigerant pressure

Power steering pressure sensor Power steering operation

Wheel sensor

Vehicle speed*

1

Page 1128 of 3061

POSITIVE CRANKCASE VENTILATION

EC-45

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

POSITIVE CRANKCASE VENTILATION

DescriptionINFOID:0000000003531601

SYSTEM DESCRIPTION

This system returns blow-by gas to the intake manifold.

The positive crankcase ventilation (PCV) valve is provided to conduct crankcase blow-by gas to the intake

manifold. During partial throttle operation of the engine, the intake manifold sucks the blow-by gas through the

PCV valve. Normally, the capacity of the valve is sufficient to handle any blow-by and a small amount of venti-

lating air. The ventilating air is then drawn from the air inlet tubes into the crankcase. In this process the air

passes through the hose connecting air inlet tubes to rocker cover. Under full-throttle condition, the manifold

vacuum is insufficient to draw the blow-by flow through the valve. The flow goes through the hose connection

in the reverse direction.

On vehicles with an excessively high blow-by, the valve does not

meet the requirement. This is because some of the flow will go

through the hose connection to the air inlet tubes under all condi-

tions.

Component InspectionINFOID:0000000003531602

PCV (POSITIVE CRANKCASE VENTILATION) VALVE

With engine running at idle, remove PCV valve from rocker cover. A

properly working valve makes a hissing noise as air passes through

it. A strong vacuum should be felt immediately when a finger is

placed over valve inlet.

PCV VALVE VENTILATION HOSE

PBIB0062E

PBIB1588E

PBIB1589E

Page 1132 of 3061

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-49

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Therefore, when electrical controlled throttle and part of ECM related diagnoses are continuously detected as

NG for 5 trips, ECM warns the driver that engine control system malfunctions and MIL circuit is open by means

of operating fail-safe function.

The fail-safe function also operates when above diagnoses except MIL circuit are detected and demands the

driver to repair the malfunction.

Emission-related Diagnostic InformationINFOID:0000000003531606

EMISSION-RELATED DIAGNOSTIC INFORMATION ITEMS

×:Applicable —: Not applicable

Engine operating condition in fail-safe mode Engine speed will not rise more than 2,500 rpm due to the fuel cut

Items

(CONSULT-II screen terms)DTC*

1

SRT codeTe s t v a l u e /

Test limit

(GST only)Trip MILRefer-

ence page CONSULT-II

GST*

2ECM*3

CAN COMM CIRCUIT U1000

1000*5—— 1×EC-145

CAN COMM CIRCUIT U1001

1001*5——1 or 2

2*10—EC-145

CONTROL UNIT(CAN) U1010 1010 — — 1×EC-147

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.P0000 0000———

Flashing*7EC-63

INT/V TIM CONT-B1 P0011 0011 — — 2×EC-149

INT/V TIM CONT-B2 P0021 0021 — — 2×EC-149

A/F SEN1 HTR (B1) P0031 0031 —×2×EC-163

A/F SEN1 HTR (B1) P0032 0032 —×2×EC-163

HO2S2 HTR (B1) P0037 0037 —×2×EC-170

HO2S2 HTR (B1) P0038 0038 —×2×EC-170

A/F SEN1 HTR (B2) P0051 0051 —×2×EC-163

A/F SEN1 HTR (B2) P0052 0052 —×2×EC-163

HO2S2 HTR (B2) P0057 0057 —×2×EC-170

HO2S2 HTR (B2) P0058 0058 —×2×EC-170

INT/V TIM V/CIR-B1 P0075 0075 — — 2×EC-178

INT/V TIM V/CIR-B2 P0081 0081 — — 2×EC-178

MAF SEN/CIRCUIT P0101 0101 — — 2×EC-186

MAF SEN/CIRCUIT P0102 0102 — — 1×EC-194

MAF SEN/CIRCUIT P0103 0103 — — 1×EC-194

IAT SEN/CIRCUIT P0112 0112 — — 2×EC-201

IAT SEN/CIRCUIT P0113 0113 — — 2×EC-201

ECT SEN/CIRC P0117 0117 — — 1×EC-205

ECT SEN/CIRC P0118 0118 — — 1×EC-205

TP SEN 2/CIRC P0122 0122 — — 1×EC-210

TP SEN 2/CIRC P0123 0123 — — 1×EC-210

ECT SENSOR P0125 0125 — — 2×EC-217

IAT SENSOR P0127 0127 — — 2×EC-220

THERMSTAT FNCTN P0128 0128 — — 2×EC-223

A/F SENSOR1 (B1) P0130 0130 —×2×EC-225

A/F SENSOR1 (B1) P0131 0131 —×2×EC-234

A/F SENSOR1 (B1) P0132 0132 —×2×EC-242

Page 1137 of 3061

EC-54

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

A sample of CONSULT-II display for DTC and 1st trip DTC is shown below. DTC or 1st trip DTC of a malfunc-

tion is displayed in SELF-DIAGNOSTIC RESULTS mode of CONSULT-II. Time data indicates how many times

the vehicle was driven after the last detection of a DTC.

If the DTC is being detected currently, the time data will be [0].

If a 1st trip DTC is stored in the ECM, the time data will be [1t].

FREEZE FRAME DATA AND 1ST TRIP FREEZE FRAME DATA

The ECM records the driving conditions such as fuel system status, calculated load value, engine coolant tem-

perature, short term fuel trim, long term fuel trim, engine speed, vehicle speed, absolute throttle position, base

fuel schedule and intake air temperature at the moment a malfunction is detected.

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data.

The data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-II or

GST. The 1st trip freeze frame data can only be displayed on the CONSULT-II screen, not on the GST. For

details, see E C - 111 , "

CONSULT-II Function (ENGINE)".

Only one set of freeze frame data (either 1st trip freeze frame data or freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM memory along with the 1st trip DTC. There is no priority

for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MIL on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the fol-

lowing priorities to update the data.

For example, the EGR malfunction (Priority: 2) was detected and the freeze frame data was stored in the 2nd

trip. After that when the misfire (Priority: 1) is detected in another trip, the freeze frame data will be updated

from the EGR malfunction to the misfire. The 1st trip freeze frame data is updated each time a different mal-

function is detected. There is no priority for 1st trip freeze frame data. However, once freeze frame data is

stored in the ECM memory, 1st trip freeze data is no longer stored (because only one freeze frame data or 1st

trip freeze frame data can be stored in the ECM). If freeze frame data is stored in the ECM memory and freeze

frame data with the same priority occurs later, the first (original) freeze frame data remains unchanged in the

ECM memory.

Both 1st trip freeze frame data and freeze frame data (along with the DTCs) are cleared when the ECM mem-

ory is erased. Procedures for clearing the ECM memory are described in "HOW TO ERASE EMISSION-

RELATED DIAGNOSTIC INFORMATION".

SYSTEM READINESS TEST (SRT) CODE

System Readiness Test (SRT) code is specified in Service $01 of SAE J1979.

As part of an enhanced emissions test for Inspection & Maintenance (I/M), certain states require the status of

SRT be used to indicate whether the ECM has completed self-diagnosis of major emission systems and com-

ponents. Completion must be verified in order for the emissions inspection to proceed.

If a vehicle is rejected for a State emissions inspection due to one or more SRT items indicating “INCMP”, use

the information in this Service Manual to set the SRT to “CMPLT”.

In most cases the ECM will automatically complete its self-diagnosis cycle during normal usage, and the SRT

status will indicate “CMPLT” for each application system. Once set as “CMPLT”, the SRT status remains

“CMPLT” until the self-diagnosis memory is erased.

Occasionally, certain portions of the self-diagnostic test may not be completed as a result of the customer's

normal driving pattern; the SRT will indicate “INCMP” for these items.

PBIB0911E

Priority Items

1Freeze frame data Misfire — DTC: P0300 - P0308

Fuel Injection System Function — DTC: P0171, P0172, P0174, P0175

2 Except the above items (Includes A/T related items)

3 1st trip freeze frame data

Page 1143 of 3061

EC-60

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

• Sea level

• Flat road

• Ambient air temperature: 20 - 30°C (68 - 86°F)

• Diagnosis is performed as quickly as possible under normal conditions.

Under different conditions [For example: ambient air temperature other than 20 - 30°C (68 - 86°F)], diagno-

sis may also be performed.

Pattern 1:

•The engine is started at the engine coolant temperature of −10 to 35°C (14 to 95°F)

(where the voltage between the ECM terminal 73 and ground is 3.0 - 4.3V).

•The engine must be operated at idle speed until the engine coolant temperature is greater than 70°C

(158°F) (where the voltage between the ECM terminal 73 and ground is lower than 1.4V).

•The engine is started at the fuel tank temperature of warmer than 0°C (32°F) (where the voltage

between the ECM terminal 107 and ground is less than 4.1V).

Pattern 2:

• When steady-state driving is performed again even after it is interrupted, each diagnosis can be conducted.

In this case, the time required for diagnosis may be extended.

Pattern 3:

• Operate vehicle following the driving pattern shown in the figure.

• Release the accelerator pedal during decelerating vehicle speed

from 90 km/h (56 MPH) to 0 km/h (0 MPH).

Pattern 4:

• The accelerator pedal must be held very steady during steady-

state driving.

• If the accelerator pedal is moved, the test must be conducted all

over again.

*1: Depress the accelerator pedal until vehicle speed is 90 km/h (56

MPH), then release the accelerator pedal and keep it released for

more than 10 seconds. Depress the accelerator pedal until vehicle

speed is 90 km/h (56 MPH) again.

*2: Checking the vehicle speed with GST is advised.

Suggested Transmission Gear Position

Set the selector lever in the D position with the overdrive switch turned ON.

TEST VALUE AND TEST LIMIT (GST ONLY — NOT APPLICABLE TO CONSULT-II)

The following is the information specified in Service $06 of SAE J1979.

The test value is a parameter used to determine whether a system/circuit diagnostic test is OK or NG while

being monitored by the ECM during self-diagnosis. The test limit is a reference value which is specified as the

maximum or minimum value and is compared with the test value being monitored.

These data (test value and test limit) are specified by Test ID (TID) and Component ID (CID) and can be dis-

played on the GST screen.

PBIB2244E

Item Self-diagnostic test item DTCTest value (GST display)

Test limit Conversion

TID CID

CATALYSTThree way catalyst function (Bank 1)P0420 01H 01H Max. 1/128

P0420 02H 81H Min. 1

Three way catalyst function (Bank 2)P0430 03H 02H Max. 1/128

P0430 04H 82H Min. 1

EVAP

SYSTEMEVAP control system (Small leak) P0442 05H 03H Max.

1/128 mm

2

EVAP control system purge flow monitoring P0441 06H 83H Min. 20 mV

EVAP control system (Very small leak) P0456 07H 03H Max.

1/128 mm

2