service INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2551 of 3061

SUNROOF

RF-19

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

RF

N

O

P

1. Disconnect front door switches and BCM.

2. Check continuity between front door switch connector B8 (LH)

or B108 (RH) terminal 2 and BCM connector M18, M19 termi-

nals 12 and 47.

3. Check continuity between front door switch connector B8 (LH)

or B108 (RH) terminal 2 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3.CHECK DOOR SWITCHES

Check continuity between each door switch terminal 2 and body

ground part of door switch.

OK or NG

OK >> GO TO 4.

NG >> Replace malfunctioning door switch.

4.CHECK BCM OUTPUT SIGNAL

1. Connect BCM.

2. Check voltage between BCM connector M18 terminal 12, M19

terminal 47 and ground.

OK or NG

OK >> Check the condition of the harness and the connector.

NG >> Replace BCM. Refer to BCS-24, "

BCM". Front door switch LH

2 - 47 : Continuity should exist.

Front door switch RH

2 - 12 : Continuity should exist.

2 - Ground : Continuity should not exist.

WIIA0235E

Terminal Condition Continuity

2Body ground part

of door switchDoor switch pushed No

Door switch released Yes

LIIA2377E

12 - Ground : Battery voltage

47 - Ground : Battery voltage

WIIA0234E

Page 2552 of 3061

RF-20

< SERVICE INFORMATION >

SUNROOF

Fitting Adjustment

INFOID:0000000003533112

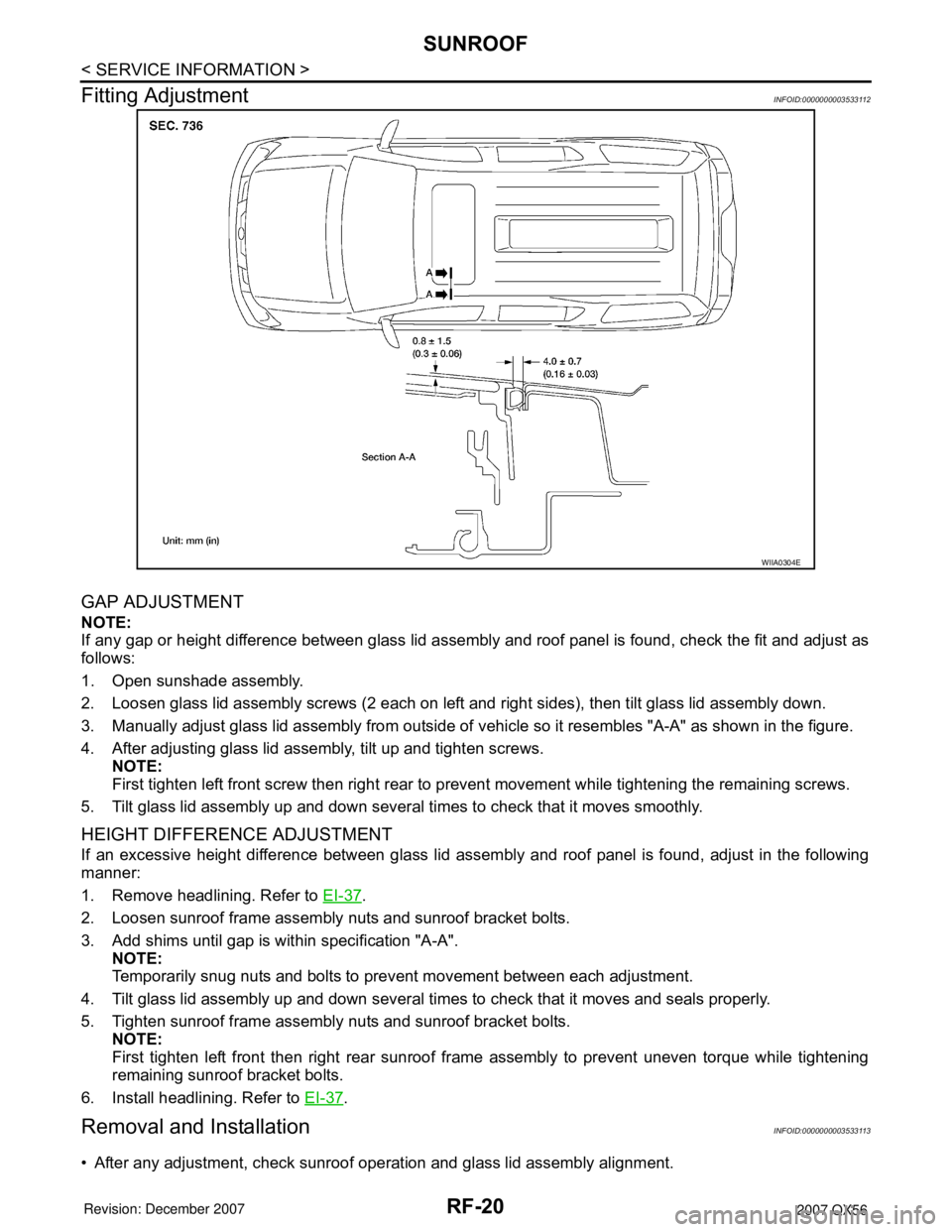

GAP ADJUSTMENT

NOTE:

If any gap or height difference between glass lid assembly and roof panel is found, check the fit and adjust as

follows:

1. Open sunshade assembly.

2. Loosen glass lid assembly screws (2 each on left and right sides), then tilt glass lid assembly down.

3. Manually adjust glass lid assembly from outside of vehicle so it resembles "A-A" as shown in the figure.

4. After adjusting glass lid assembly, tilt up and tighten screws.

NOTE:

First tighten left front screw then right rear to prevent movement while tightening the remaining screws.

5. Tilt glass lid assembly up and down several times to check that it moves smoothly.

HEIGHT DIFFERENCE ADJUSTMENT

If an excessive height difference between glass lid assembly and roof panel is found, adjust in the following

manner:

1. Remove headlining. Refer to EI-37

.

2. Loosen sunroof frame assembly nuts and sunroof bracket bolts.

3. Add shims until gap is within specification "A-A".

NOTE:

Temporarily snug nuts and bolts to prevent movement between each adjustment.

4. Tilt glass lid assembly up and down several times to check that it moves and seals properly.

5. Tighten sunroof frame assembly nuts and sunroof bracket bolts.

NOTE:

First tighten left front then right rear sunroof frame assembly to prevent uneven torque while tightening

remaining sunroof bracket bolts.

6. Install headlining. Refer to EI-37

.

Removal and InstallationINFOID:0000000003533113

• After any adjustment, check sunroof operation and glass lid assembly alignment.

WIIA0304E

Page 2553 of 3061

SUNROOF

RF-21

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

RF

N

O

P

• Handle glass lid assembly with care so not to cause damage.

• For easier installation, mark each point before removal.

CAUTION:

• Always work with a helper.

• Before removal, fully close the glass lid assembly. Then, after removal, do not move the sunroof

motor assembly.

• After installing the sunroof unit and glass lid assembly, operate the mechanism several times to be

sure there is no malfunction.

WIIA0657E

Page 2554 of 3061

RF-22

< SERVICE INFORMATION >

SUNROOF

SUNROOF UNIT

Removal

CAUTION:

• Always work with a helper.

• When taking sunroof unit out, use shop cloths to protect the seats and trim from damage.

• After installing the sunroof unit and glass lid assembly, check gap adjustment to make sure there is

no malfunction.

1. Remove headlining. Refer to EI-37

.

2. Remove the sunroof glass lid assembly. Refer to "GLASS LID ASSEMBLY".

3. Remove overhead console bracket.

4. Disconnect front and rear drain hoses.

5. Remove front sunroof frame assembly bolts.

6. Remove rear sunroof bracket bolts.

7. Remove the sunroof frame assembly side bolts, then the sunroof unit.

Installation

1. Position the sunroof frame assembly and install the side bolts.

2. Install the sunroof brackets and bolts.

3. Install the front sunroof frame assembly bolts.

4. Connect front and rear drain hoses.

5. Install the overhead console bracket.

6. Install the sunroof glass lid assembly. Refer to "GLASS LID ASSEMBLY".

NOTE:

Adjust sunroof glass lid assembly gap and height, refer to RF-20, "

Fitting Adjustment".

7. Install headlining. Refer to EI-37

.

GLASS LID ASSEMBLY

Removal

1. Open sunshade assembly.

NOTE:

Be sure glass lid assembly is fully closed.

2. Remove side cover LH and RH.

3. Remove the glass lid assembly screws at the sunroof frame

assembly.

4. Remove the glass lid assembly.

Installation

1. Position glass lid assembly to sunroof frame assembly.

2. Install glass lid assembly screws.

NOTE:

First tighten left front screw, then right rear to prevent movement while tightening the remaining screws.

1. Glass lid assembly 2. Wind deflector 3. Rear drain hoses

4. Shade stoppers 5. Sunroof bracket 6. Sunshade assembly

7. Front drain hoses 8. Sunroof motor assembly 9. Sunroof frame assembly

10. Overhead console bracket 11. Side cover LH 12. Side cover RH

WIIA0252E

Page 2555 of 3061

SUNROOF

RF-23

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

RF

N

O

P

3. Adjust the glass lid assembly. Refer to RF-20, "Fitting Adjustment".

4. Install side cover LH and RH.

WIND DEFLECTOR

Removal

1. Open the glass lid assembly.

2. Remove screws from the left, center, and right side wind deflec-

tor holders.

3. Remove the wind deflector from the sunroof frame assembly.

Installation

Installation is in the reverse order of removal.

SUNSHADE ASSEMBLY

Removal

1. Remove the sunroof frame assembly. Refer to "SUNROOF UNIT".

2. Remove the two (2) shade stoppers from the end of the sunroof

frame assembly.

3. Remove the sunshade assembly from the rear end of the sun-

roof frame assembly.

Installation

Installation is in the reverse order of removal.

SUNROOF MOTOR ASSEMBLY

Removal

CAUTION:

• When removing the sunroof motor assembly, be sure the glass lid assembly is in the fully closed

position.

• Never run the removed sunroof motor assembly.

1. Position the glass lid assembly in the fully closed position.

2. Disconnect the negative and positive battery cables, then wait at least 3 minutes.

3. Remove the overhead console assembly. Refer to EI-37

.

LIIA1099E

SBT251A

Page 2556 of 3061

RF-24

< SERVICE INFORMATION >

SUNROOF

4. Disconnect the harness connector (2) from the sunroof motor

assembly.

•⇐: Vehicle front

5. Remove the screws (3) and the sunroof motor assembly (1).

Installation

CAUTION:

Before installing the sunroof motor assembly, be sure to position the link and wire assembly in the

symmetrical and fully closed position.

1. Move the sunroof motor assembly (1) laterally little by little so

that the gear is completely engaged into the wire on the sunroof

unit until surfaces become parallel. Then secure the sunroof

motor assembly with screws.

•⇐: Vehicle front

2. Secure the sunroof motor assembly (1) with screws (3).

3. Connect the harness connector (2) to the sunroof motor assem-

bly.

4. Install the overhead console assembly. Refer to EI-37

.

5. Connect the battery positive and negative cables.

6. Reset the sunroof motor memory. Refer to RF-10, "

System

Description".

DRAIN HOSES

WIIA0772E

WIIA0772E

1. Rear drain hoses 2. Front drain hoses

WIIA0853E

Page 2557 of 3061

SUNROOF

RF-25

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

RF

N

O

P

1. Remove the headlining. Refer to EI-37.

2. Visually check the drain hoses for proper connections, damage or deterioration.

3. Remove each drain hose and check visually for damage, cracks or deterioration.

4. Pour water through the drain hose to check for damage.

• If any damage is found, replace the drain hose.

WEATHERSTRIP

Visually check weatherstrip for any damage, deterioration, or flattening.

• In the case of leakage around glass lid assembly, close and pour water around it to find the damaged or

gaped portion, remove glass lid assembly.

• If any damage is found, replace glass lid assembly.

CAUTION:

Do not remove weatherstrip.

LINK AND WIRE ASSEMBLY

NOTE:

Before replacing any suspect part, be sure it is the source of the noise being experienced.

1. Visually check to determine if a sufficient amount of petroleum jelly has been applied to the wire or rail

groove. If not, add petroleum jelly as required.

2. Check wire and casing for any damage or deterioration. If any damage is found, replace sunroof frame

assembly.

LIIA0272E

Page 2558 of 3061

RFD-1

DRIVELINE/AXLE

C

E

F

G

H

I

J

K

L

M

SECTION RFD

A

B

RFD

N

O

P

CONTENTS

REAR FINAL DRIVE

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Servicing Rear Final Drive .................2

PREPARATION ...................................................3

Special Service Tool .................................................3

Commercial Service Tool ..........................................6

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

7

NVH Troubleshooting Chart ......................................7

DIFFERENTIAL GEAR OIL .................................8

Changing Differential Gear Oil ..................................8

Checking Differential Gear Oil ...................................8

FRONT OIL SEAL ..............................................9

Removal and Installation ..........................................9

SIDE OIL SEAL .................................................11

Removal and Installation .........................................11

CARRIER COVER .............................................13

Removal and Installation .........................................13

REAR FINAL DRIVE ASSEMBLY ....................14

Removal and Installation .........................................14

Disassembly and Assembly .....................................15

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

32

General Specification ..............................................32

Inspection and Adjustment ......................................32

Page 2559 of 3061

RFD-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Servicing Rear Final DriveINFOID:0000000003532597

• Before starting diagnosis of the vehicle, understand the symptoms well. Perform correct and systematic

operations.

• Check for the correct installation status prior to removal or disassembly. When matching marks are required,

be certain they do not interfere with the function of the parts they are applied to.

• Overhaul should be done in a clean work area, a dust proof area is recommended.

• Before disassembly, completely remove sand and mud from the exterior of the unit, preventing them from

entering into the unit during disassembly or assembly.

• Always use shop paper for cleaning the inside of components.

• Avoid using cotton gloves or a shop cloth to prevent the entering of lint.

• Check appearance of the disassembled parts for damage, deformation, and abnormal wear. Replace them

with new ones if necessary.

• Gaskets, seals and O-rings should be replaced any time the unit is disassembled.

• Clean and flush the parts sufficiently and blow them dry.

• Be careful not to damage sliding surfaces and mating surfaces.

• When applying sealant, remove the old sealant from the mating surface; then remove any moisture, oil, and

foreign materials from the application and mating surfaces.

• In principle, tighten nuts or bolts gradually in several steps working diagonally from inside to outside. If a

tightening sequence is specified, observe it.

• During assembly, observe the specified tightening torque.

• Add new differential gear oil, petroleum jelly, or multi-purpose grease, as specified.

Page 2560 of 3061

PREPARATION

RFD-3

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

RFD

N

O

P

PREPARATION

Special Service ToolINFOID:0000000003532598

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool name

Tool number

(Kent-Moore No.)Description

KV40104000

(—)

Flange wrenchRemoving and installing drive pinion nut

a: 85 mm (3.35 in) dia.

b: 65 mm (2.56 in) dia.

KV381054S0

(J-34286)

PullerRemoving front oil seal

ST15310000

(—)

Drift• Installing front oil seal

• Installing drive pinion rear bearing outer

race.

a: 96 mm (3.77 in) dia.

b: 84 mm (3.30 in) dia.

ST36230000

(J-25840-A)

Slide hammer Removing side flange

KV40104100

(—)

Axle stand Removing side flange

ST35271000

(—)

DriftInstalling side oil seal

a: 72 mm (2.83 in) dia.

b: 63 mm (2.48 in) dia.

NT659

ZZA0601D

ZZA0811D

ZZA0803D

ZZA0804D

ZZA1143D