ignition INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 972 of 3061

![INFINITI QX56 2007 Factory Service Manual BRC-44

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

4.ACTIVE BOOSTER SENSOR INSPECTION

1. Reconnect the active booster and ABS actuator and electric unit (control u INFINITI QX56 2007 Factory Service Manual BRC-44

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

4.ACTIVE BOOSTER SENSOR INSPECTION

1. Reconnect the active booster and ABS actuator and electric unit (control u](/img/42/57029/w960_57029-971.png)

BRC-44

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

4.ACTIVE BOOSTER SENSOR INSPECTION

1. Reconnect the active booster and ABS actuator and electric unit (control unit) connectors.

2. Use "DATA MONITOR" to check if the status of "RELEASE SW NO" and "RELEASE SW NC" is normal.

OK or NG

OK >> Inspection End.

NG >> Replace active booster.

Delta Stroke Sensor System InspectionINFOID:0000000003532795

INSPECTION PROCEDURE

1.DISPLAY SELF DIAGNOSIS RESULTS

Check self-diagnosis result display item.

Is the above displayed in the self-diagnosis display items?

YES or NO

YES >> GO TO 2.

NO >> Inspection End.

2.CONNECTOR INSPECTION

1. Turn the ignition switch OFF.

2. Disconnect the delta stroke sensor connector E114 and ABS actuator and electric unit (control unit) con-

nector E125 and inspect the terminals for deformation, disconnection, looseness, or damage.

OK or NG

OK >> GO TO 3.

NG >> Repair connector.

3.DELTA STROKE SENSOR CIRCUIT INSPECTION

1. Measure the continuity between the ABS actuator and electric unit (control unit) connector E125 and delta

stroke sensor connector E114.

2. Measure the continuity between the ABS actuator and electric unit (control unit) connector E125 and body

ground.ConditionData monitor display

RELEASE SW NO RELEASE SW NC

When brake pedal is depressed ON OFF

When brake pedal is released OFF ON

Self-diagnosis results

ABS DELTA S SEN NG

ABS actuator and electric unit

(control unit) connector E125Delta stroke sensor

connector E114Continuity

26 1

Ye s 39 3

40 5

ABS actuator and electric unit (con-

trol unit) connector E125Body ground Continuity

26

—No 39

40

Page 973 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

BRC-45

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness or connector.

4.DELTA S INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

BRC-45

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness or connector.

4.DELTA S](/img/42/57029/w960_57029-972.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

BRC-45

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness or connector.

4.DELTA STROKE SENSOR INSPECTION

1. Reconnect the delta stroke sensor and ABS actuator and electric unit (control unit) connectors.

2. Use "DATA MONITOR" to check if the status of "DELTA S SEN" is normal.

OK or NG

OK >> Inspection End.

NG >> Replace delta stroke sensor.

Pressure Sensor System InspectionINFOID:0000000003532796

FRONT PRESSURE INSPECTION PROCEDURE

1.DISPLAY SELF DIAGNOSIS RESULTS

Check self-diagnosis result display item.

Is the above displayed in the self-diagnosis display items?

YES or NO

YES >> GO TO 2.

NO >> Inspection End.

2.CONNECTOR INSPECTION

1. Turn the ignition switch OFF.

2. Disconnect the front pressure sensor connector E31 and ABS actuator and electric unit (control unit) con-

nector E125 and inspect the terminals for deformation, disconnection, looseness, or damage.

OK or NG

OK >> GO TO 3.

NG >> Repair connector.

3.FRONT PRESSURE SENSOR CIRCUIT INSPECTION

1. Measure the continuity between the ABS actuator and electric unit (control unit) harness connector E125

and front pressure sensor harness connector E31.

2. Measure the continuity between the ABS actuator and electric unit (control unit) harness connector E125

and body ground.ConditionData monitor display (Approx.)

DELTA S SEN

When brake pedal is released 0.00 mm (+0.6/-0.4)

When brake pedal is depressed 1.05–1.80 mm

Self-diagnosis results

PRESS SEN CIRCUIT

ABS actuator and electric unit

(control unit) harness connector

E125Front pressure sensor har-

ness connector E31Continuity

18 3

Ye s 19 1

20 2

Page 974 of 3061

![INFINITI QX56 2007 Factory Service Manual BRC-46

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness or connector.

4.FRONT PRESSURE SENSOR INSPECTION

1. Reco INFINITI QX56 2007 Factory Service Manual BRC-46

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness or connector.

4.FRONT PRESSURE SENSOR INSPECTION

1. Reco](/img/42/57029/w960_57029-973.png)

BRC-46

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness or connector.

4.FRONT PRESSURE SENSOR INSPECTION

1. Reconnect the front pressure sensor and ABS actuator and electric unit (control unit) connectors.

2. Use "DATA MONITOR" to check if the status of "PRESS SENSOR" is normal.

OK or NG

OK >> Inspection End.

NG >> Replace pressure sensor.

REAR PRESSURE INSPECTION PROCEDURE

1.DISPLAY SELF DIAGNOSIS RESULTS

Check self-diagnosis result display item.

Is the above displayed in the self-diagnosis display items?

YES or NO

YES >> GO TO 2.

NO >> Inspection End.

2.CONNECTOR INSPECTION

1. Turn the ignition switch OFF.

2. Disconnect the rear pressure sensor connector E32 and ABS actuator and electric unit (control unit) con-

nector E125 and inspect the terminals for deformation, disconnection, looseness, or damage.

OK or NG

OK >> GO TO 3.

NG >> Repair connector.

3.REAR PRESSURE SENSOR CIRCUIT INSPECTION

1. Measure the continuity between the ABS actuator and electric unit (control unit) connector E125 and rear

pressure sensor connector E32.ABS actuator and electric unit

(control unit) harness connector

E125Body ground Continuity

18

—No 19

20

ConditionData monitor display (Approx.)

PRESS SENSOR

When brake pedal is depressed Positive value

When brake pedal is released 0 bar

Self-diagnosis results

PRESS SEN CIRCUIT

ABS actuator and electric unit (con-

trol unit) connector E125Rear pressure sensor con-

nector E32Continuity

21 1

Ye s 22 3

23 2

Page 976 of 3061

![INFINITI QX56 2007 Factory Service Manual BRC-48

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

When self-diagnostic results show items other than those above, perform repair or replacement for the item

indic INFINITI QX56 2007 Factory Service Manual BRC-48

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

When self-diagnostic results show items other than those above, perform repair or replacement for the item

indic](/img/42/57029/w960_57029-975.png)

BRC-48

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

When self-diagnostic results show items other than those above, perform repair or replacement for the item

indicated and repeat self-diagnosis.

Is the above displayed on self-diagnosis display?

YES >> Erase error memory.

NO >> Inspection End.

CAN Communication System InspectionINFOID:0000000003532798

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn ignition switch OFF, disconnect the ABS actuator and electric unit (control unit) connector, and check

the terminals for deformation, disconnection, looseness, and so on. If there is a malfunction, repair or

replace the terminal.

2. Reconnect connector to perform self-diagnosis.

Is "CAN COMM CIRCUIT" displayed in self-diagnosis display items?

YES >> Print out the self-diagnostic results, and refer to LAN-7.

NO >> Connector terminal is loose, damaged, open, or shorted.

ICC System InspectionINFOID:0000000003532799

INSPECTION PROCEDURE

1.SELF-DIAGNOSIS RESULT CHECK

Perform self-diagnosis of ICC control unit. Refer to ACS-30, "

Self-Diagnostic Function".

Are self-diagnosis result items displayed?

YES >> After checking and repairing the applicable item, perform ICC control unit self-diagnosis again.

NO >> GO TO 2.

2.CONNECTOR INSPECTION

Disconnect the ABS actuator and electric unit (control unit) connector and the ICC control unit connector and

check the terminals for deformation, disconnection, looseness or damage.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace as necessary.

3.ICC CONTROL UNIT CIRCUIT INSPECTION

1. Measure the continuity between ABS actuator and electric unit (control unit) connector E125 and ICC con-

trol unit connector B13.

2. Measure the continuity between ABS actuator and electric unit (control unit) connector E125 and body

ground.

OK or NG

OK >> Replace ABS actuator and electric unit (control unit). Refer to BRC-58, "Removal and Installation"

NG >> Repair or replace harness or connector.

Inspection for Self-Diagnosis Result "ST ANG SEN SIGNAL"INFOID:0000000003532800

INSPECTION PROCEDURE

ABS actuator and electric unit (con-

trol unit) connector E125ICC control unit connector

B13Continuity

710Yes

ABS actuator and electric unit (con-

trol unit) connector E125Body ground Continuity

7—No

Page 977 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

BRC-49

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

1.DISPLAY SELF-DIAGNOSIS RESULTS

Perform ABS actuator and electric unit (contro INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

BRC-49

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

1.DISPLAY SELF-DIAGNOSIS RESULTS

Perform ABS actuator and electric unit (contro](/img/42/57029/w960_57029-976.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

BRC-49

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

1.DISPLAY SELF-DIAGNOSIS RESULTS

Perform ABS actuator and electric unit (control unit) self-diagnosis.

Do self-diagnosis results indicate anything other than shown above?

YES >> Perform repair or replacement for the item indicated.

NO >> Perform adjustment of steering angle sensor neutral position. GO TO 2.

2.PERFORM SELF-DIAGNOSIS AGAIN

1. Turn the ignition switch to OFF and then to ON and erase self-diagnosis results.

2. Perform ABS actuator and electric unit (control unit) self-diagnosis again.

Are any self-diagnosis results displayed?

YES >> Replace steering angle sensor. Refer to BRC-60, "Removal and Installation".

NO >> Inspection End.

Inspection for Self-Diagnosis Result "DECEL G SEN SET"INFOID:0000000003532801

INSPECTION PROCEDURE

1.PERFORM SELF-DIAGNOSIS

Perform ABS actuator and electric unit (control unit) self-diagnosis.

Do self-diagnosis results indicate anything other than shown above?

YES >> Perform repair or replacement for the item indicated.

NO >> Perform calibration of decel G sensor. Refer to BRC-54, "

Calibration of Decel G Sensor". GO TO

2.

2.PERFORM SELF-DIAGNOSIS AGAIN

1. Turn the ignition switch to OFF and then to ON and erase self-diagnosis results.

2. Perform ABS actuator and electric unit (control unit) self-diagnosis again.

Are any self-diagnosis results displayed?

YES >> Replace yaw rate/side/decel G sensor. Refer to BRC-61, "Removal and Installation".

NO >> Inspection End.

Self-diagnosis results

ST ANG SEN SIGNAL

Self-diagnosis results

DECEL G SEN SET

Page 979 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSES FOR SYMPTOMS

BRC-51

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

3.CHECK CONNECTOR AND BRAKING PERFORMANCE

1. Disable ABS by disconnecting ABS actuator and e INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSES FOR SYMPTOMS

BRC-51

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

3.CHECK CONNECTOR AND BRAKING PERFORMANCE

1. Disable ABS by disconnecting ABS actuator and e](/img/42/57029/w960_57029-978.png)

TROUBLE DIAGNOSES FOR SYMPTOMS

BRC-51

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

3.CHECK CONNECTOR AND BRAKING PERFORMANCE

1. Disable ABS by disconnecting ABS actuator and electric unit (control unit) connector.

2. Drive vehicle and check brake operation.

NOTE:

• Stopping distance may be longer than vehicles without ABS when road condition is slippery.

• Driving the vehicle with the ABS actuator and electric unit (control unit) disconnected may induce DTCs

in electrical control units using CAN communication. After the inspection, clear all DTCs. Refer to LAN-

7.

OK or NG

OK >> GO TO 4.

NG >> Perform Basic Inspection. Refer to BRC-22, "

Basic Inspection".

4.CHECK WHEEL SENSORS

Check the following.

• Wheel sensor mounting for looseness

• Wheel sensors for physical damage

• Wheel sensor connectors for terminal damage or loose connections

OK or NG

OK >> Check ABS actuator and electric unit (control unit) connector terminals for deformation, discon-

nection, looseness or damage. Reconnect ABS actuator and electric unit (control unit) harness

connector. Then retest.

NG >> Repair or replace as necessary.

Long Stopping DistanceINFOID:0000000003532804

INSPECTION PROCEDURE

1.CHECK BASE BRAKING SYSTEM PERFORMANCE

1. Disable ABS by disconnecting ABS actuator and electric unit (control unit) connector.

2. Drive vehicle and check brake operation.

NOTE:

• Stopping distance may be longer than vehicles without ABS when road condition is slippery.

• Driving the vehicle with the ABS actuator and electric unit (control unit) disconnected may induce DTCs

in electrical control units using CAN communication. After the inspection, clear all DTCs. Refer to LAN-

7.

OK or NG

OK >> Go to BRC-50, "ABS Works Frequently".

NG >> Perform Basic Inspection. Refer to BRC-22, "

Basic Inspection".

ABS Does Not WorkINFOID:0000000003532805

CAUTION:

The ABS does not operate when the vehicle speed is 10 km/h (6 MPH) or less.

INSPECTION PROCEDURE

1.CHECK WARNING LAMP ACTIVATION

Turn ignition switch ON and check for warning lamp activation.

• Warning lamp should activate for approximately 2 seconds after turning the ignition switch ON.

OK or NG

OK >> Carry out self-diagnosis. Refer to BRC-26, "CONSULT-II Function (ABS)".

NG >> Go to BRC-22, "

Basic Inspection".

Pedal Vibration or ABS Operation NoiseINFOID:0000000003532806

NOTE:

During ABS activation, pedal vibration may be felt and a noise may be heard. This is normal and does not indi-

cate a malfunction.

INSPECTION PROCEDURE

Page 982 of 3061

![INFINITI QX56 2007 Factory Service Manual BRC-54

< SERVICE INFORMATION >[VDC/TCS/ABS]

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

Adjustment of Steering Angle Sensor Neutral PositionINFOID:0000000003532809

After removing/installing or replacing ABS INFINITI QX56 2007 Factory Service Manual BRC-54

< SERVICE INFORMATION >[VDC/TCS/ABS]

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

Adjustment of Steering Angle Sensor Neutral PositionINFOID:0000000003532809

After removing/installing or replacing ABS](/img/42/57029/w960_57029-981.png)

BRC-54

< SERVICE INFORMATION >[VDC/TCS/ABS]

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

Adjustment of Steering Angle Sensor Neutral PositionINFOID:0000000003532809

After removing/installing or replacing ABS actuator and electric unit (control unit), steering angle sensor, steer-

ing and suspension components which affect wheel alignment or after adjusting wheel alignment, be sure to

adjust neutral position of steering angle sensor before running vehicle.

NOTE:

Adjustment of steering angle sensor neutral position requires CONSULT-II.

1. Stop vehicle with front wheels in straight-ahead position.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data

link connector on vehicle, and turn ignition switch ON (do not

start engine).

3. Touch “START (NISSAN BASED VHCL)”, “ABS”, “WORK SUP-

PORT” and “ST ANGLE SENSOR ADJUSTMENT” on CON-

SULT-II screen in this order.

4. Touch “START”.

CAUTION:

Do not touch steering wheel while adjusting steering angle

sensor.

5. After approximately 10 seconds, touch “END”. (After approxi-

mately 60 seconds, it ends automatically.)

6. Turn ignition switch OFF, then turn it ON again.

7. Run vehicle with front wheels in straight-ahead position, then

stop.

8. Select “DATA MONITOR”, “SELECTION FROM MENU”, and

“STR ANGLE SIG” on CONSULT-II screen. Then check that

“STR ANGLE SIG” is within 0±3.5 deg. If value is more than specification, repeat steps 1 to 5.

9. Erase memory of ABS actuator and electric unit (control unit) and ECM.

10. Turn ignition switch to OFF.

Calibration of Decel G SensorINFOID:0000000003532810

After removing/installing or replacing ABS actuator and electric unit (control unit), yaw rate/side/decel G sen-

sor, steering and suspension components which affect wheel alignment or after adjusting wheel alignment, be

sure to calibrate the decel G sensor before running vehicle.

NOTE:

Calibration of decel G sensor requires CONSULT-II.

1. Stop vehicle with front wheels in straight-ahead position.

CAUTION:

• The work should be done on a level area with an unloaded vehicle.

• Keep all the tires inflated to the correct pressures. Adjust the tire pressure to the specified pres-

sure value.

2. Connect CONSULT-II with CONSULT-II CONVERTER to data link connector on vehicle, and turn ignition

switch ON (do not start engine).

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carries out CAN communication.

3. Touch “START (NISSAN BASED VHCL)”, "ABS", "WORK SUPPORT" and "DECEL G SEN CALIBRA-

TION" on CONSULT-II screen in this order. Refer to BRC-26, "

CONSULT-II Function (ABS)".

BBIA0369E

WFIA0239E

Page 983 of 3061

![INFINITI QX56 2007 Factory Service Manual ON-VEHICLE SERVICE

BRC-55

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

4. Touch "START".

CAUTION:

Set vehicle as shown in the display.

5. After approximately 10 seconds, touch INFINITI QX56 2007 Factory Service Manual ON-VEHICLE SERVICE

BRC-55

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

4. Touch "START".

CAUTION:

Set vehicle as shown in the display.

5. After approximately 10 seconds, touch](/img/42/57029/w960_57029-982.png)

ON-VEHICLE SERVICE

BRC-55

< SERVICE INFORMATION >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

4. Touch "START".

CAUTION:

Set vehicle as shown in the display.

5. After approximately 10 seconds, touch "END". (After approxi-

mately 60 seconds, it ends automatically.)

6. Turn ignition switch OFF, then turn it ON again.

CAUTION:

Be sure to carry out above operation

7. Run vehicle with front wheels in straight-ahead position, then

stop.

8. Select "DATA MONITOR", "SELECTION FROM MENU", and

"DECEL G SEN" on CONSULT-II screen. Then check that "DECEL G SEN" is within ±0.08G. If value is

more than specification, repeat steps 3 to 7.

9. Erase memory of ABS actuator and electric unit (control unit) and ECM.

10. Turn ignition switch to OFF.

SFIA1162E

Page 996 of 3061

OVERHEATING CAUSE ANALYSIS

CO-7

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

Except cool-

ing system

parts mal-

function— Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for ex-

tended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

— Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper —

— Blocked radiator grilleInstalled car brassiere

Mud contamination or paper

clogging

Blocked radiator —

Blocked condenser

Blocked air flow

Installed large fog lamp Symptom Check items

Page 999 of 3061

CO-10

< SERVICE INFORMATION >

ENGINE COOLANT

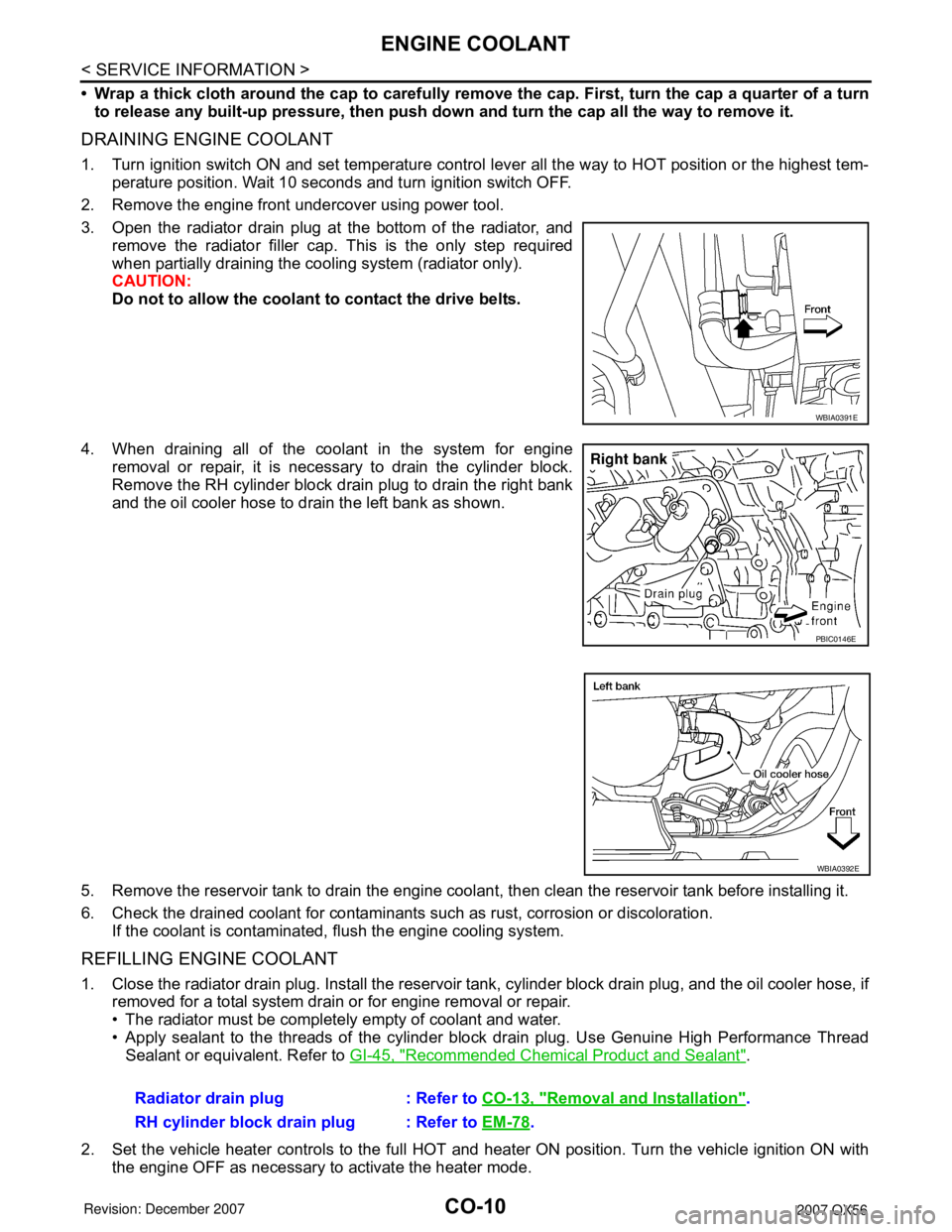

• Wrap a thick cloth around the cap to carefully remove the cap. First, turn the cap a quarter of a turn

to release any built-up pressure, then push down and turn the cap all the way to remove it.

DRAINING ENGINE COOLANT

1. Turn ignition switch ON and set temperature control lever all the way to HOT position or the highest tem-

perature position. Wait 10 seconds and turn ignition switch OFF.

2. Remove the engine front undercover using power tool.

3. Open the radiator drain plug at the bottom of the radiator, and

remove the radiator filler cap. This is the only step required

when partially draining the cooling system (radiator only).

CAUTION:

Do not to allow the coolant to contact the drive belts.

4. When draining all of the coolant in the system for engine

removal or repair, it is necessary to drain the cylinder block.

Remove the RH cylinder block drain plug to drain the right bank

and the oil cooler hose to drain the left bank as shown.

5. Remove the reservoir tank to drain the engine coolant, then clean the reservoir tank before installing it.

6. Check the drained coolant for contaminants such as rust, corrosion or discoloration.

If the coolant is contaminated, flush the engine cooling system.

REFILLING ENGINE COOLANT

1. Close the radiator drain plug. Install the reservoir tank, cylinder block drain plug, and the oil cooler hose, if

removed for a total system drain or for engine removal or repair.

• The radiator must be completely empty of coolant and water.

• Apply sealant to the threads of the cylinder block drain plug. Use Genuine High Performance Thread

Sealant or equivalent. Refer to GI-45, "

Recommended Chemical Product and Sealant".

2. Set the vehicle heater controls to the full HOT and heater ON position. Turn the vehicle ignition ON with

the engine OFF as necessary to activate the heater mode.

WBIA0391E

PBIC0146E

WBIA0392E

Radiator drain plug : Refer to CO-13, "Removal and Installation".

RH cylinder block drain plug : Refer to EM-78

.