ignition INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1033 of 3061

DI-22

< SERVICE INFORMATION >

COMPASS AND THERMOMETER

COMPASS AND THERMOMETER

System DescriptionINFOID:0000000003533500

This unit displays the following items:

• Earth magnetism and heading direction of vehicle.

• Outside air temperature.

• Caution for frozen road surfaces.

OUTSIDE TEMPERATURE DISPLAY

Push the mode (N) switch when the ignition switch is in the ON position. The outside temperature will be dis-

played in “°F”. To change the indication from “°F” to “°C”, push and hold the mode (N) switch for about 3 sec-

onds until the display begins to flash. Press the mode (N) switch again to toggle between “°F” and “°C”.

DIRECTION DISPLAY

Push the mode (N) switch when the ignition switch is in the ON position. The direction will be displayed.

LKIA0447E

Page 1035 of 3061

DI-24

< SERVICE INFORMATION >

COMPASS AND THERMOMETER

1. Turn the ignition switch to the ON position.

2. Cool down ambient sensor 2 with water or ice.

Does the indicated temperature drop?

YES >> GO TO 2.

NO >> The system is malfunctioning. Check the system following “INSPECTION/COMPASS AND THER-

MOMETER”. Refer to "INSPECTION/COMPASS AND THERMOMETER".

2.WARM UP CHECK

1. Leave the vehicle for 10 minutes.

2. With the ignition switch in the ON position, disconnect and reconnect ambient sensor 2 connector.

Does the indicated temperature rise?

YES >> The system is OK.

NO >> The system is malfunctioning. Check the system following “INSPECTION/COMPASS AND THER-

MOMETER”. Refer to "INSPECTION/COMPASS AND THERMOMETER".

INSPECTION/COMPASS AND THERMOMETER

Calibration Procedure for CompassINFOID:0000000003533503

The difference between magnetic North and geographical North can sometimes be great enough to cause

false compass readings. In order for the compass to operate accurately in a particular zone, it must be cali-

brated using the following procedure.

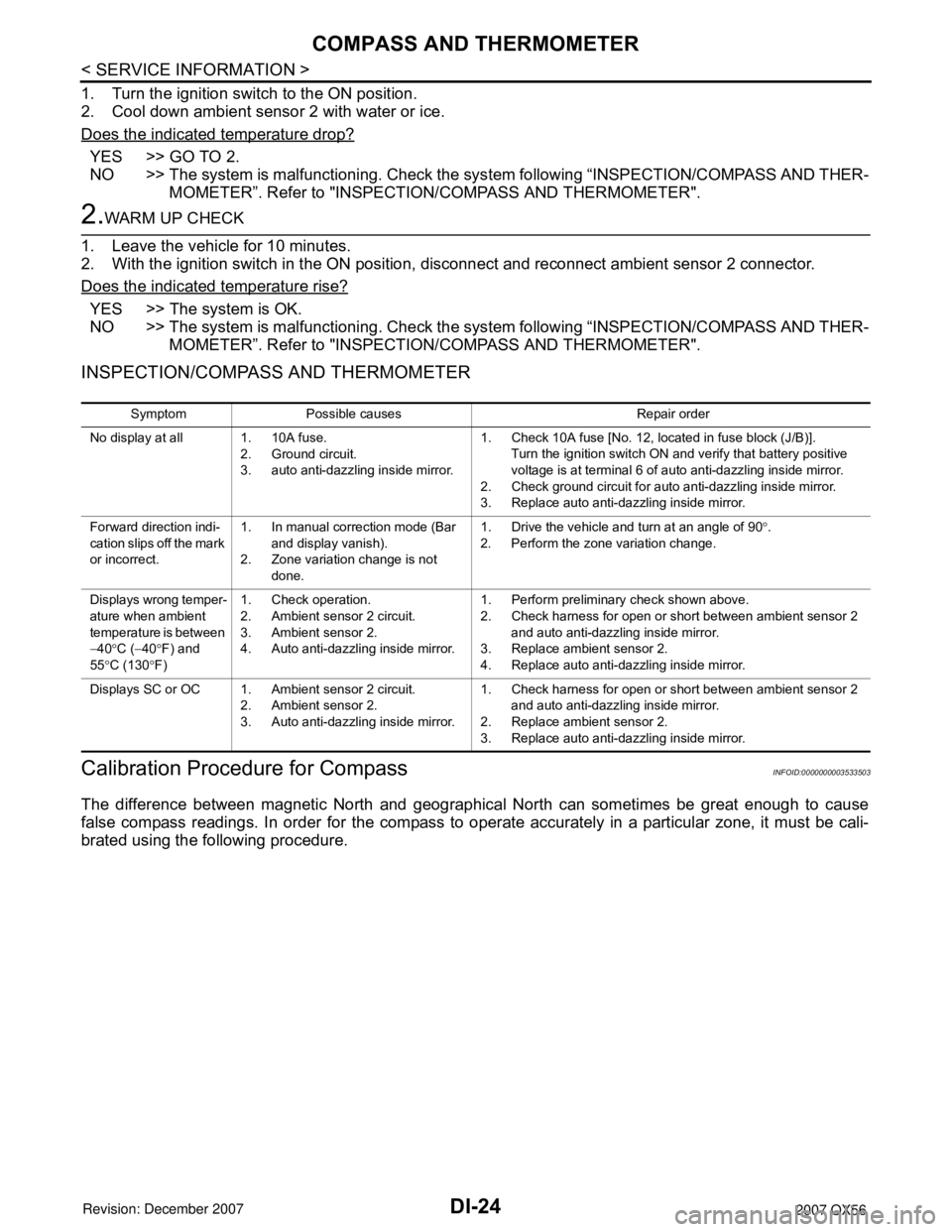

Symptom Possible causes Repair order

No display at all 1. 10A fuse.

2. Ground circuit.

3. auto anti-dazzling inside mirror.1. Check 10A fuse [No. 12, located in fuse block (J/B)].

Turn the ignition switch ON and verify that battery positive

voltage is at terminal 6 of auto anti-dazzling inside mirror.

2. Check ground circuit for auto anti-dazzling inside mirror.

3. Replace auto anti-dazzling inside mirror.

Forward direction indi-

cation slips off the mark

or incorrect.1. In manual correction mode (Bar

and display vanish).

2. Zone variation change is not

done.1. Drive the vehicle and turn at an angle of 90°.

2. Perform the zone variation change.

Displays wrong temper-

ature when ambient

temperature is between

−40°C (−40°F) and

55°C (130°F)1. Check operation.

2. Ambient sensor 2 circuit.

3. Ambient sensor 2.

4. Auto anti-dazzling inside mirror.1. Perform preliminary check shown above.

2. Check harness for open or short between ambient sensor 2

and auto anti-dazzling inside mirror.

3. Replace ambient sensor 2.

4. Replace auto anti-dazzling inside mirror.

Displays SC or OC 1. Ambient sensor 2 circuit.

2. Ambient sensor 2.

3. Auto anti-dazzling inside mirror.1. Check harness for open or short between ambient sensor 2

and auto anti-dazzling inside mirror.

2. Replace ambient sensor 2.

3. Replace auto anti-dazzling inside mirror.

Page 1036 of 3061

COMPASS AND THERMOMETER

DI-25

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

Zone Variation Chart

1. Determine your location on the zone map.

2. Turn the ignition switch to the ON position.

3. Press and hold the mode (N) switch for about 8 seconds. The current zone number will appear in the dis-

play.

4. Press the mode (N) switch repeatedly until the desired number appears in the display.

Once the desired zone number is displayed, stop pressing the mode (N) switch and the display will show a

compass direction after a few seconds.

NOTE:

Use zone number 5 for Hawaii.

CORRECTION FUNCTIONS OF COMPASS

The direction display is equipped with automatic correction function.

If the direction is not shown correctly, carry out initial correction.

INITIAL CORRECTION PROCEDURE FOR COMPASS

1. Pushing the mode (N) switch for about 10 seconds will enter the initial correction mode. The “CAL” icon

will illuminate.

2. Turn the vehicle slowly in an open, safe place. The initial correction is completed in approximately one

and a half turns.

NOTE:

In places where the terrestrial magnetism is extremely disturbed, the initial correction may start automatically.

WKIA4148E

LKIA0447E

Page 1043 of 3061

DI-32

< SERVICE INFORMATION >

WARNING LAMPS

4WD Models

Oil Pressure Warning Lamp Stays Off (Ignition Switch ON)INFOID:0000000003533506

1.CHECK SELF-DIAGNOSTIC RESULTS OF IPDM E/R

Select "IPDM E/R" on CONSULT-II, and perform self-diagnosis of IPDM E/R. Refer to PG-18, "

CONSULT-II

Function (IPDM E/R)".

Self-diagnostic results content

WKWA5140E

Page 1044 of 3061

WARNING LAMPS

DI-33

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

No malfunction detected>>GO TO 2.

Malfunction detected>>GO TO PG-18, "

CONSULT-II Function (IPDM E/R)".

2.CHECK IPDM E/R INPUT SIGNAL

Select "IPDM E/R" on CONSULT-II. Operate ignition switch with "OIL

P SW" of "DATA MONITOR" and check operation status.

OK or NG

OK >> Replace combination meter. Refer to IP-10, "Removal

and Installation".

NG >> GO TO 3.

3.CHECK OIL PRESSURE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector E122 and oil pressure switch

connector F4.

3. Check continuity between IPDM E/R harness connector E122

(A) terminal 42 and oil pressure switch harness connector F4 (B)

terminal 1.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK OIL PRESSURE SWITCH

Check oil pressure switch. Refer to DI-21, "

Electrical Component Inspection".

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and Installation of IPDM E/R".

NG >> Replace oil pressure switch.

Oil Pressure Warning Lamp Does Not Turn Off (Oil Pressure Is Normal)INFOID:0000000003533507

NOTE:

For oil pressure inspection, refer to DI-21, "

Electrical Component Inspection".

1.CHECK ENGINE OIL PRESSURE GAUGE OPERATION

Observe operation of engine oil pressure gauge.

Does engine oil pressure gauge function properly?

YES >> Replace the combination meter. Refer to IP-10, "Removal and Installation".

NO >> GO TO DI-17, "

Engine Oil Pressure Signal Inspection". When ignition switch is in ON

position (Engine stopped): OIL P SW CLOSE

When engine running : OIL P SW OPEN

LKIA0403E

Continuity should exist.

WKIA5607E

Page 1048 of 3061

WARNING CHIME

DI-37

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

• to key switch and key lock solenoid terminal 3.

With ignition switch in ON or START position, power is supplied

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38.

Ground is supplied

• to BCM terminal 67

• through body grounds M57, M61, and M79.

NOTE:

When ignition key warning chime, light warning chime, and seat belt warning chime are required at the same

time, the priorities for each chime are the following.

1. Light warning chime

2. Ignition key warning chime

3. Seat belt warning chime

IGNITION KEY WARNING CHIME

With the key inserted in the ignition switch, the ignition switch in OFF position, and the driver's door open, the

warning chime will sound.

Power is supplied

• through key switch and key lock solenoid terminal 4

• to BCM terminal 37.

Ground is supplied

• to BCM terminal 47

• through front door switch LH terminal 2.

Front door switch LH is case grounded.

BCM detects key inserted into the ignition switch, and sends key warning signal to combination meter via CAN

communication lines. When the combination meter receives key warning signal, it sounds warning chime.

LIGHT WARNING CHIME

With the key removed from the ignition switch, the driver's door open, and the lighting switch (part of the com-

bination switch) in 1st or 2nd position, the warning chime will sound. [Except when headlamp battery saver

control operates (5 minutes after ignition switch is turned to OFF or ACC position) and headlamps do not illu-

minate.]

Signal is supplied

• from combination switch (lighting switch) terminals 1, 2, 3, 4, 5, 6, 7, 8, 9 and 10

• to BCM terminals 2, 3, 4, 5, 6, 32, 33, 34, 35 and 36.

NOTE:

BCM detected lighting switch in 1st or 2nd position. Refer to LT-72, "

Combination Switch Reading Function".

Ground is supplied

• to BCM terminal 47

• through front door switch LH terminal 2.

Front door switch LH is case grounded.

BCM detects headlamps are illuminated, and sends light warning signal to combination meter CAN communi-

cation lines. When the combination meter receives light warning signal, it sounds warning chime.

SEAT BELT WARNING CHIME

When the ignition switch is turned ON with the seat belt unfastened [seat belt buckle pre-tensioner assembly

LH (seat belt buckle switch) unfastened], warning chime will sound for approximately 6 seconds.

Ground is supplied

• to combination meter terminal 27

• through seat belt buckle pre-tensioner assembly LH (seat belt buckle switch) terminal 4.

Seat belt buckle pre-tensioner assembly LH (seat belt buckle switch) terminal 3 is grounded through body

grounds B7 and B19.

The combination meter sends seat belt buckle switch LH unfastened signal to BCM via CAN communication

line.

BCM receives seat belt buckle pre-tensioner assembly LH (seat belt buckle switch) unfastened signal from

combination meter via CAN communication line, and sends seat belt warning signal to the combination meter

via CAN communication line. When the combination meter receives the seat belt warning signal, it sounds the

warning chime. The BCM controls the (6 second) duration of the seat belt warning chime.

CAN Communication System DescriptionINFOID:0000000003533512

Refer to LAN-4.

Page 1051 of 3061

DI-40

< SERVICE INFORMATION >

WARNING CHIME

How to Proceed with Trouble Diagnosis

INFOID:0000000003533516

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer to DI-36, "

System Description".

3. Perform the preliminary check. Refer to DI-40, "

Preliminary Check".

4. Check symptom and repair or replace the cause of malfunction.

5. Does the warning chime operate properly? If so, go to 6. If not, go to 3.

6. Inspection End.

Preliminary CheckINFOID:0000000003533517

INSPECTION FOR POWER SUPPLY AND GROUND CIRCUIT

Refer to BCS-15, "BCM Power Supply and Ground Circuit Inspection".

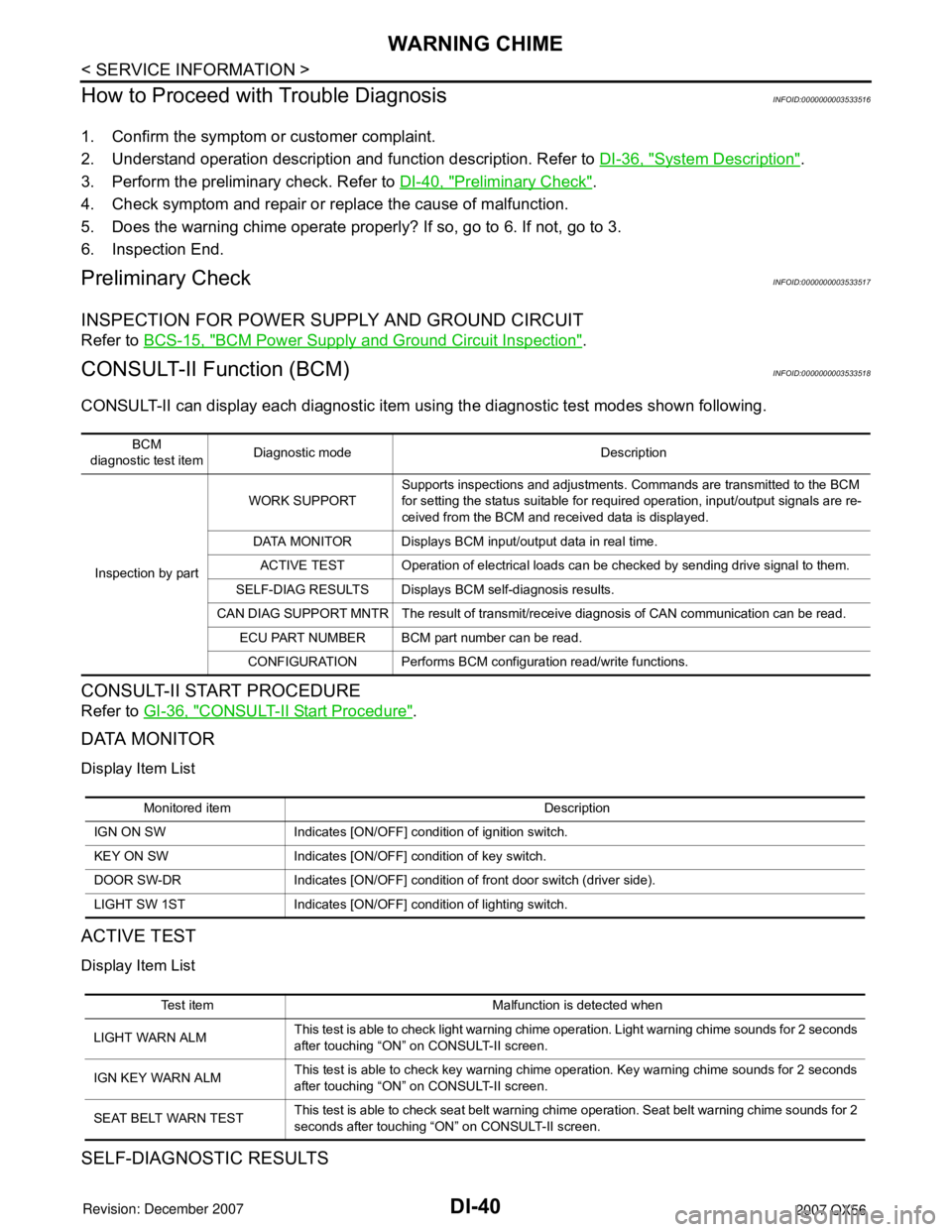

CONSULT-II Function (BCM)INFOID:0000000003533518

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

DATA MONITOR

Display Item List

ACTIVE TEST

Display Item List

SELF-DIAGNOSTIC RESULTS

BCM

diagnostic test itemDiagnostic mode Description

Inspection by partWORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the BCM

for setting the status suitable for required operation, input/output signals are re-

ceived from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ECU PART NUMBER BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

Monitored item Description

IGN ON SW Indicates [ON/OFF] condition of ignition switch.

KEY ON SW Indicates [ON/OFF] condition of key switch.

DOOR SW-DR Indicates [ON/OFF] condition of front door switch (driver side).

LIGHT SW 1ST Indicates [ON/OFF] condition of lighting switch.

Test item Malfunction is detected when

LIGHT WARN ALMThis test is able to check light warning chime operation. Light warning chime sounds for 2 seconds

after touching “ON” on CONSULT-II screen.

IGN KEY WARN ALMThis test is able to check key warning chime operation. Key warning chime sounds for 2 seconds

after touching “ON” on CONSULT-II screen.

SEAT BELT WARN TESTThis test is able to check seat belt warning chime operation. Seat belt warning chime sounds for 2

seconds after touching “ON” on CONSULT-II screen.

Page 1053 of 3061

DI-42

< SERVICE INFORMATION >

WARNING CHIME

1. Turn ignition switch OFF.

2. Disconnect BCM connector M19 and front door switch LH con-

nector B8.

3. Check continuity between BCM harness connector M19 terminal

47 and front door switch LH harness connector B8 terminal 2.

4. Check continuity between BCM harness connector M19 terminal

47 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK FRONT DOOR SWITCH LH

Check continuity between front door switch LH terminal 2 and

exposed metal of switch while pressing and releasing switch.

OK or NG

OK >> Replace the BCM. Refer to BCS-24, "BCM".

NG >> Replace the front door switch LH.

Key Warning Chime Does Not OperateINFOID:0000000003533521

1.CHECK FUSE

Check if the key switch fuse [No. 19, located in the fuse block (J/B)] is blown. Refer to DI-38, "

Wiring Diagram

- CHIME -".

Is the fuse blown?

YES >> Replace the fuse. Be sure to repair the cause of malfunction before installing new fuse.

NO >> GO TO 2.

2.CHECK WARNING CHIME OPERATION

With key removed from the ignition key cylinder and the front door LH open, turn the lighting switch to 1st or

2nd position.

Does warning chime sound?

YES >> GO TO 3.

NO >> Go to DI-41, "

All Warning Chimes Do Not Operate" or DI-41, "Key Warning Chime and Light

Warning Chime Do Not Operate (Seat Belt Warning Chime Does Operate)".

3.CHECK BCM INPUT SIGNAL

With CONSULT-IIContinuity should exist.

Continuity should not exist.

WKIA1516E

When front door switch

LH is released: Continuity should exist.

When front door switch

LH is pressed: Continuity should not exist.

WKIA2023E

Page 1054 of 3061

WARNING CHIME

DI-43

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

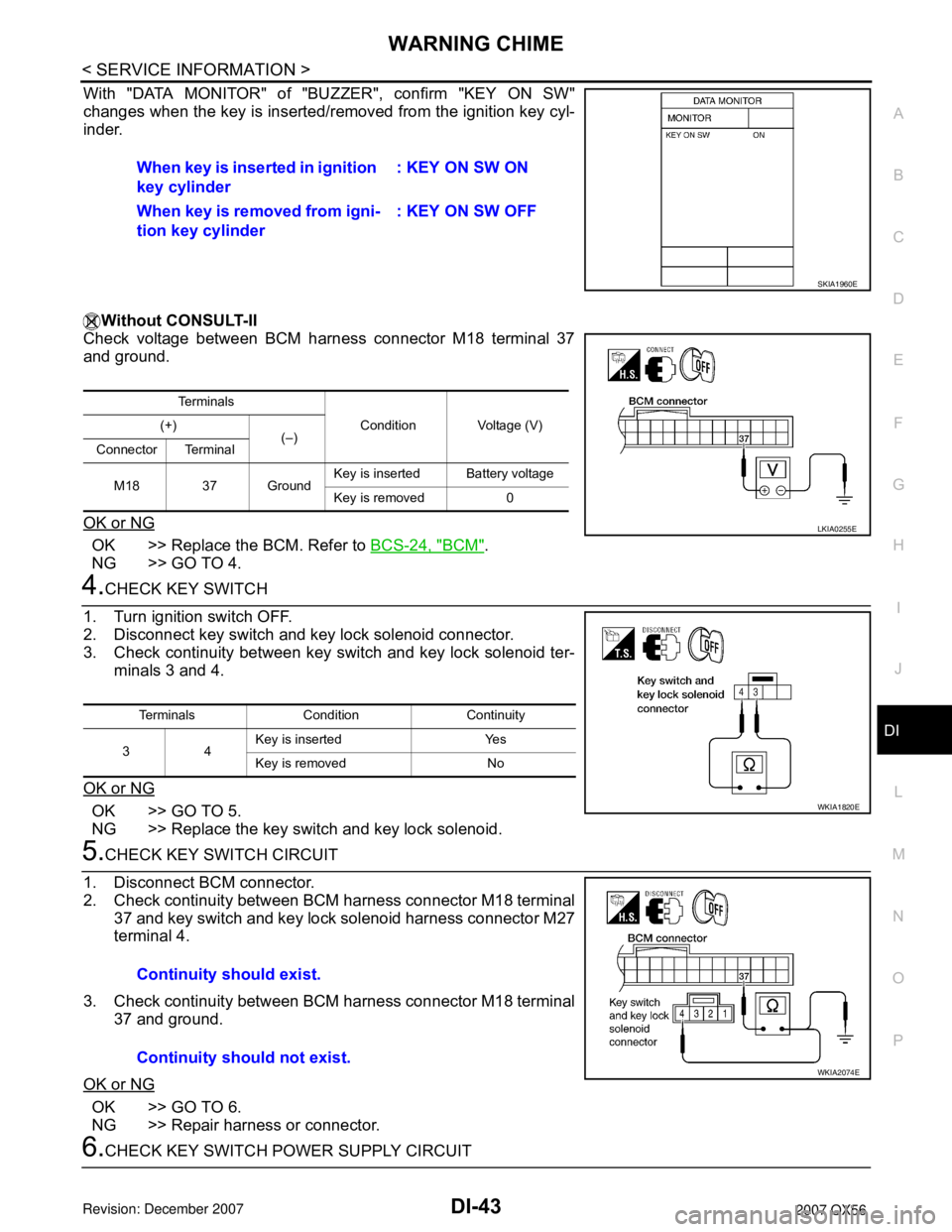

With "DATA MONITOR" of "BUZZER", confirm "KEY ON SW"

changes when the key is inserted/removed from the ignition key cyl-

inder.

Without CONSULT-II

Check voltage between BCM harness connector M18 terminal 37

and ground.

OK or NG

OK >> Replace the BCM. Refer to BCS-24, "BCM".

NG >> GO TO 4.

4.CHECK KEY SWITCH

1. Turn ignition switch OFF.

2. Disconnect key switch and key lock solenoid connector.

3. Check continuity between key switch and key lock solenoid ter-

minals 3 and 4.

OK or NG

OK >> GO TO 5.

NG >> Replace the key switch and key lock solenoid.

5.CHECK KEY SWITCH CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector M18 terminal

37 and key switch and key lock solenoid harness connector M27

terminal 4.

3. Check continuity between BCM harness connector M18 terminal

37 and ground.

OK or NG

OK >> GO TO 6.

NG >> Repair harness or connector.

6.CHECK KEY SWITCH POWER SUPPLY CIRCUITWhen key is inserted in ignition

key cylinder: KEY ON SW ON

When key is removed from igni-

tion key cylinder: KEY ON SW OFF

SKIA1960E

Te r m i n a l s

Condition Voltage (V) (+)

(–)

Connector Terminal

M18 37 GroundKey is insertedBattery voltage

Key is removed 0

LKIA0255E

Terminals Condition Continuity

34Key is inserted Yes

Key is removed No

WKIA1820E

Continuity should exist.

Continuity should not exist.

WKIA2074E

Page 1055 of 3061

DI-44

< SERVICE INFORMATION >

WARNING CHIME

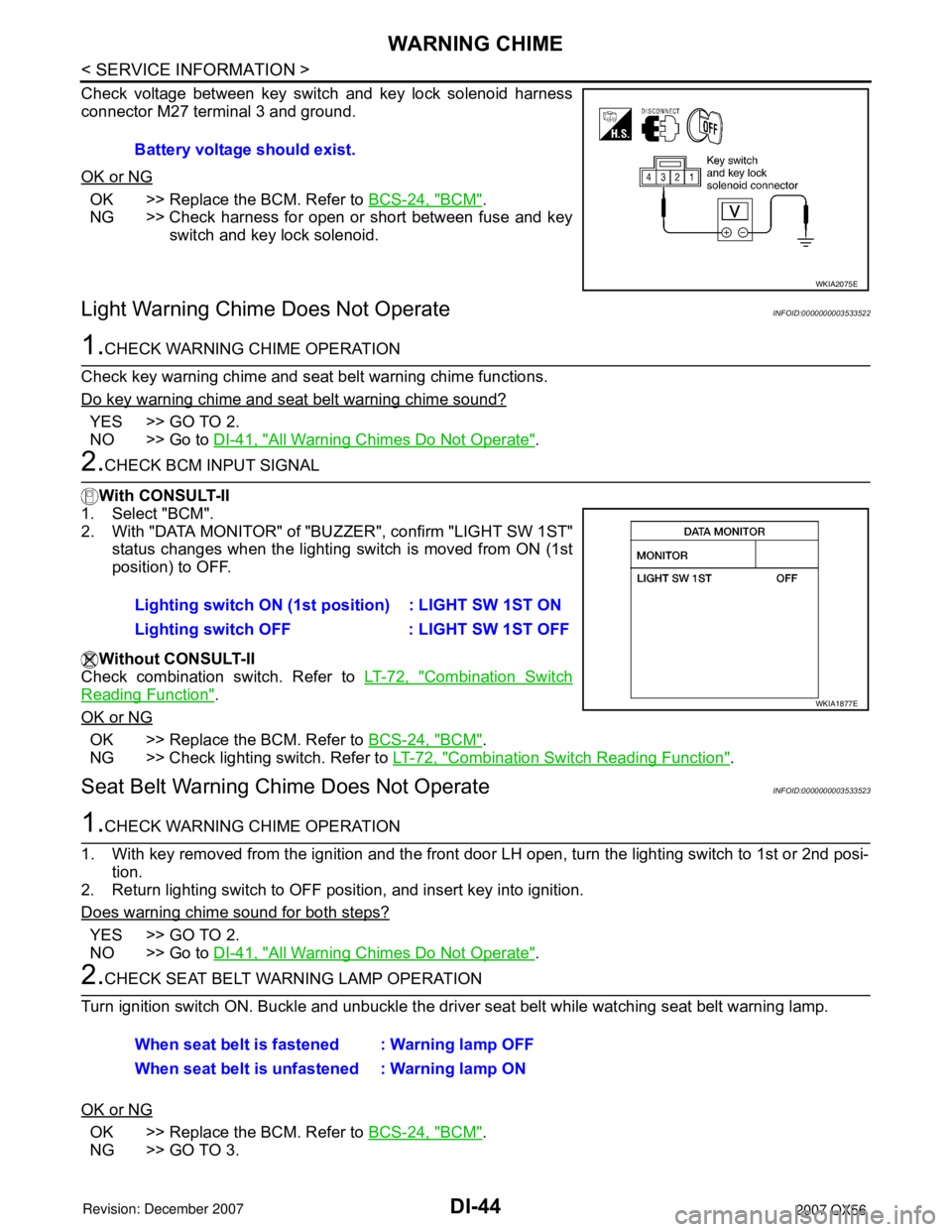

Check voltage between key switch and key lock solenoid harness

connector M27 terminal 3 and ground.

OK or NG

OK >> Replace the BCM. Refer to BCS-24, "BCM".

NG >> Check harness for open or short between fuse and key

switch and key lock solenoid.

Light Warning Chime Does Not OperateINFOID:0000000003533522

1.CHECK WARNING CHIME OPERATION

Check key warning chime and seat belt warning chime functions.

Do key warning chime and seat belt warning chime sound?

YES >> GO TO 2.

NO >> Go to DI-41, "

All Warning Chimes Do Not Operate".

2.CHECK BCM INPUT SIGNAL

With CONSULT-II

1. Select "BCM".

2. With "DATA MONITOR" of "BUZZER", confirm "LIGHT SW 1ST"

status changes when the lighting switch is moved from ON (1st

position) to OFF.

Without CONSULT-II

Check combination switch. Refer to LT-72, "

Combination Switch

Reading Function".

OK or NG

OK >> Replace the BCM. Refer to BCS-24, "BCM".

NG >> Check lighting switch. Refer to LT-72, "

Combination Switch Reading Function".

Seat Belt Warning Chime Does Not OperateINFOID:0000000003533523

1.CHECK WARNING CHIME OPERATION

1. With key removed from the ignition and the front door LH open, turn the lighting switch to 1st or 2nd posi-

tion.

2. Return lighting switch to OFF position, and insert key into ignition.

Does warning chime sound for both steps?

YES >> GO TO 2.

NO >> Go to DI-41, "

All Warning Chimes Do Not Operate".

2.CHECK SEAT BELT WARNING LAMP OPERATION

Turn ignition switch ON. Buckle and unbuckle the driver seat belt while watching seat belt warning lamp.

OK or NG

OK >> Replace the BCM. Refer to BCS-24, "BCM".

NG >> GO TO 3.Battery voltage should exist.

WKIA2075E

Lighting switch ON (1st position) : LIGHT SW 1ST ON

Lighting switch OFF : LIGHT SW 1ST OFF

WKIA1877E

When seat belt is fastened : Warning lamp OFF

When seat belt is unfastened : Warning lamp ON