wiring INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2823 of 3061

TF-1

DRIVELINE/AXLE

C

E

F

G

H

I

J

K

L

M

SECTION TF

A

B

TF

N

O

P

CONTENTS

TRANSFER

SERVICE INFORMATION ............................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for Transfer Assembly and Transfer

Control Unit Replacement .........................................

3

Precaution .................................................................4

Service Notice ...........................................................4

PREPARATION ...................................................6

Special Service Tool .................................................6

Commercial Service Tool ..........................................9

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ............................

10

NVH Troubleshooting Chart ....................................10

TRANSFER FLUID .............................................11

Replacement ...........................................................11

Inspection ................................................................11

ALL-MODE 4WD SYSTEM ................................12

Cross-Sectional View ..............................................12

Power Transfer ........................................................12

System Description .................................................14

Schematic ...............................................................19

CAN Communication ...............................................20

TROUBLE DIAGNOSIS .....................................21

How to Perform Trouble Diagnosis .........................21

Location of Electrical Parts ......................................22

Circuit Diagram .......................................................23

Wiring Diagram - T/F - .............................................24

Inspections Before Trouble Diagnosis ....................31

Trouble Diagnosis Chart by Symptom ....................34

Transfer Control Unit Input/Output Signal Refer-

ence Value ..............................................................

35

CONSULT-II Function (ALL MODE AWD/4WD) .....42

Self-Diagnosis Procedure .......................................48

TROUBLE DIAGNOSIS FOR SYSTEM ............51

Power Supply Circuit for Transfer Control Unit ........51

Transfer Control Unit ...............................................53

Output Shaft Revolution Signal (TCM) ....................53

Vehicle Speed Sensor (ABS) ..................................54

Neutral-4LO Switch .................................................54

4WD Shift Switch .....................................................57

Wait Detection Switch ..............................................60

PNP Switch Signal (TCM) .......................................63

Actuator Motor .........................................................64

Actuator Position Switch ..........................................69

Transfer Control Device ...........................................72

Engine Speed Signal (ECM) ....................................76

Clutch Pressure Solenoid ........................................76

2-4WD Solenoid ......................................................80

Transfer Motor .........................................................84

Transfer Fluid Temperature .....................................90

Clutch Pressure Switch ...........................................92

Line Pressure Switch ...............................................94

Throttle Position Signal (ECM) ................................97

ABS Operation Signal (ABS) ...................................97

VDC Operation Signal (ABS) ...................................98

TCS Operation Signal (ABS) ...................................98

CAN Communication Line .......................................99

ATP Switch ..............................................................99

TROUBLE DIAGNOSIS FOR SYMPTOMS ....102

4WD Shift Indicator Lamp and 4LO Indicator

Lamp Do Not Turn ON ...........................................

102

4WD Warning Lamp Does Not Turn ON ...............104

4WD Shift Indicator Lamp or 4LO Indicator Lamp

Does Not Change ..................................................

107

ATP Warning Lamp Turns ON ...............................109

4LO Indicator Lamp Repeats Flashing ..................110

4WD Warning Lamp Flashes Rapidly ....................111

4WD Warning Lamp Flashes Slowly .....................112

Heavy Tight-corner Braking Symptom Occurs ......113

4WD System Does Not Operate ............................114

TRANSFER CONTROL UNIT .........................115

Removal and Installation .......................................115

Page 2825 of 3061

PRECAUTIONS

TF-3

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003532506

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Transfer Assembly and Transfer Control Unit ReplacementINFOID:0000000003532507

When replacing transfer assembly or transfer control unit, check the 4WD shift indicator lamp as follows.

1. Turn ignition switch “ON”.

2. Check 4WD shift indicator lamp is turned ON for approx. 1 second.

• If OK, the position between transfer assembly and transfer control unit is correct.

• If NG, the position is different between transfer assembly and transfer control unit.

Adjust the position between transfer assembly and transfer control unit. Refer to "METHOD FOR POSITION

ADJUSTMENT".

METHOD FOR POSITION ADJUSTMENT

1. Start engine. Run the engine for at least 10 seconds.

2. Stop vehicle and move A/T selector lever to “N” position with brake pedal depressed. Stay in "N" for at

least 2 seconds.

3. Turn 4WD shift switch to “2WD” position. Stay in "2WD" for at least 2 seconds.

4. Turn ignition switch “OFF”.

5. Start engine.

6. Erase self-diagnosis. Refer to TF-42, "

CONSULT-II Function (ALL MODE AWD/4WD)" (with CONSULT-II)

or TF-48, "

Self-Diagnosis Procedure" (without CONSULT-II).

7. Check 4WD shift indicator lamp. Refer to TF-31, "

Inspections Before Trouble Diagnosis".

If 4WD shift indicator lamp does not indicate "2WD", install new transfer control unit and retry the above

check.

Page 2846 of 3061

TF-24

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Wiring Diagram - T/F -

INFOID:0000000003532523

BDWA0166E

Page 2926 of 3061

TF-104

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

3. Check continuity between the following terminals.

- Transfer control unit harness connector E142 terminal 2 and

combination meter harness connector M24 terminal 32.

- Transfer control unit harness connector E142 terminal 11 and

combination meter harness connector M24 terminal 31.

- Transfer control unit harness connector E142 terminal 12 and

combination meter harness connector M24 terminal 33.

- Transfer control unit harness connector E142 terminal 21 and

combination meter harness connector M24 terminal 30.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5.CHECK INDICATOR LAMP CIRCUIT

1. Connect combination meter harness connector.

2. Disconnect transfer control unit harness connector.

3. Turn ignition switch “ON”.

4. Ground the following terminals using suitable wiring.

- Transfer control unit harness connector E142 terminal 2 and

ground.

- Transfer control unit harness connector E142 terminal 11 and

ground.

- Transfer control unit harness connector E142 terminal 12 and

ground.

- Transfer control unit harness connector E142 terminal 21 and

ground.

Do indicator lamps turn on?

OK >> GO TO 6.

NG >> Replace combination meter. Refer to DI-21, "

Removal

and Installation of Combination Meter".

6.SYMPTOM CHECK

Check again.

OK or NG

OK >> Inspection End.

NG >> GO TO 7.

7.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer to TF-35, "

Transfer Control Unit Input/Output Signal Ref-

erence Value".

OK or NG

OK >> Inspection End.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

4WD Warning Lamp Does Not Turn ONINFOID:0000000003532554

SYMPTOM:

Continuity should exist.

WDIA0160E

SDIA2772E

Page 2929 of 3061

TROUBLE DIAGNOSIS FOR SYMPTOMS

TF-107

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

5.CHECK INDICATOR LAMP CIRCUIT

1. Connect combination meter harness connector.

2. Disconnect transfer control unit harness connector.

3. Turn ignition switch “ON”. (Do not start engine.)

4. Ground the following terminal using suitable wiring.

- Transfer control unit harness connector E142 terminal 5 and

ground.

Does 4WD warning lamp turn on?

OK >> GO TO 6.

NG >> Replace combination meter. Refer to DI-21, "

Removal

and Installation of Combination Meter".

6.SYMPTOM CHECK

Check again.

OK or NG

OK >> Inspection End.

NG >> GO TO 7.

7.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer to TF-35, "

Transfer Control Unit Input/Output Signal Ref-

erence Value" .

OK or NG

OK >> Inspection End.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

4WD Shift Indicator Lamp or 4LO Indicator Lamp Does Not ChangeINFOID:0000000003532555

SYMPTOM:

4WD shift indicator lamp or 4LO indicator lamp does not change when switching 4WD shift switch.

DIAGNOSTIC PROCEDURE

1.CONFIRM THE SYMPTOM

Confirm 4WD shift indicator lamp and 4LO indicator lamp turn on when ignition switch is turned to ON.

Do 4WD shift indicator lamp and 4LO indicator lamp turn on?

YES >> GO TO 2.

NO >> Go to "4WD Shift Indicator Lamp or 4LO Indicator Lamp Does Not Change".

2.CHECK SYSTEM FOR 4WD SHIFT SWITCH

Perform trouble diagnosis for 4WD shift switch system. Refer to TF-57, "

4WD Shift Switch".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK SYSTEM FOR WAIT DETECTION SWITCH

Perform trouble diagnosis for wait detection switch system. Refer to TF-60, "

Wait Detection Switch".

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK SYSTEM FOR NEUTRAL-4LO SWITCH

Perform trouble diagnosis for neutral-4LO switch system. Refer to TF-54, "

Neutral-4LO Switch".

SDIA2774E

Page 2932 of 3061

TF-110

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

- Transfer control unit harness connector E142 terminal 40 and

combination meter harness connector M24 terminal 7.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.CHECK ATP WARNING LAMP CIRCUIT

1. A/T selector lever in "P" position.

2. Connect combination meter harness connector and transfer control unit harness connector.

3. Disconnect ATP switch harness connector.

4. Ground the following terminal using suitable wiring.

- ATP switch harness connector F55 terminal 8 and ground.

5. Turn ignition switch “ON”. (Do not start engine.)

Does indicator lamp turn on?

OK >> GO TO 7.

NG >> Replace combination meter. Refer to DI-21, "

Removal

and Installation of Combination Meter".

7.SYMPTOM CHECK

Check again.

OK or NG

OK >> Inspection End.

NG >> GO TO 8.

8.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer to TF-35, "

Transfer Control Unit Input/Output Signal Ref-

erence Value".

OK or NG

OK >> GO TO 9.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

9.CHECK TRANSFER INNER PARTS

1. Disassemble transfer assembly. Refer to TF-128, "

Disassembly and Assembly".

2. Check transfer inner parts.

OK or NG

OK >> Inspection End.

NG >> Repair or replace damaged parts.

4LO Indicator Lamp Repeats FlashingINFOID:0000000003532557

SYMPTOM:

4LO lamp keeps flashing.

DIAGNOSTIC PROCEDURE

1.CONFIRM THE SYMPTOM

1. Set 4WD shift switch to “2WD”.

2. Move vehicle forward and backward, or drive straight increasing or decreasing under 20 km/h (12 MPH). 40 to 7: Continuity should not exist.

7 to 40: Continuity should exist.

WDIA0150E

SDIA2769E

Page 2990 of 3061

WT-1

SUSPENSION

C

D

F

G

H

I

J

K

L

M

SECTION WT

A

B

WT

N

O

PCONTENTS

ROAD WHEELS & TIRES

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

PREPARATION ...................................................3

Special Service Tool .................................................3

Commercial Service Tool ..........................................3

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

4

NVH Troubleshooting Chart ......................................4

WHEEL ................................................................5

Inspection ..................................................................5

WHEEL AND TIRE ASSEMBLY .........................6

Balancing Wheels .....................................................6

Rotation .....................................................................7

LOW TIRE PRESSURE WARNING SYSTEM .....8

System Component ...................................................8

System Description ...................................................8

CAN COMMUNICATION ....................................10

System Description .................................................10

TROUBLE DIAGNOSIS .....................................11

Wiring Diagram- T/WARN - .....................................11

Terminal and Reference Value (BCM) ....................12

ID Registration Procedure .......................................12

Transmitter Wake Up Operation .............................14

CONSULT-II Function (BCM) ..................................15

Self-Diagnosis .........................................................15

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

17

Preliminary Check ...................................................18

Flash Code/Symptom Chart ....................................18

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS .................................................

20

Data from Transmitter Not Being Received .............20

Transmitter Malfunction ...........................................20

Transmitter Pressure Malfunction ............................21

Vehicle Speed Signal ..............................................21

Ignition Signal ..........................................................22

TROUBLE DIAGNOSIS FOR SYMPTOMS ......23

Low Tire Pressure Warning Lamp Does Not Come

On When Ignition Switch Is Turned On ...................

23

Low Tire Pressure Warning Lamp Stays On When

Ignition Switch Is Turned On ...................................

23

Low Tire Pressure Warning Lamp Flashes When

Ignition Switch Is Turned On ...................................

24

Hazard Warning Lamps Flash When Ignition

Switch Is Turned On ................................................

25

"TIRE PRESSURE" Information in Display Unit

Does Not Exist .........................................................

25

ID Registration Cannot Be Completed ....................25

REMOVAL AND INSTALLATION .....................26

Transmitter (Pressure Sensor) ................................26

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

28

Road Wheel .............................................................28

Tire ..........................................................................28

Page 2991 of 3061

WT-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003532685

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Page 3000 of 3061

TROUBLE DIAGNOSIS

WT-11

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

WT

N

O

P

TROUBLE DIAGNOSIS

Wiring Diagram- T/WARN -INFOID:0000000003532695

WEWA0047E

Page 3018 of 3061

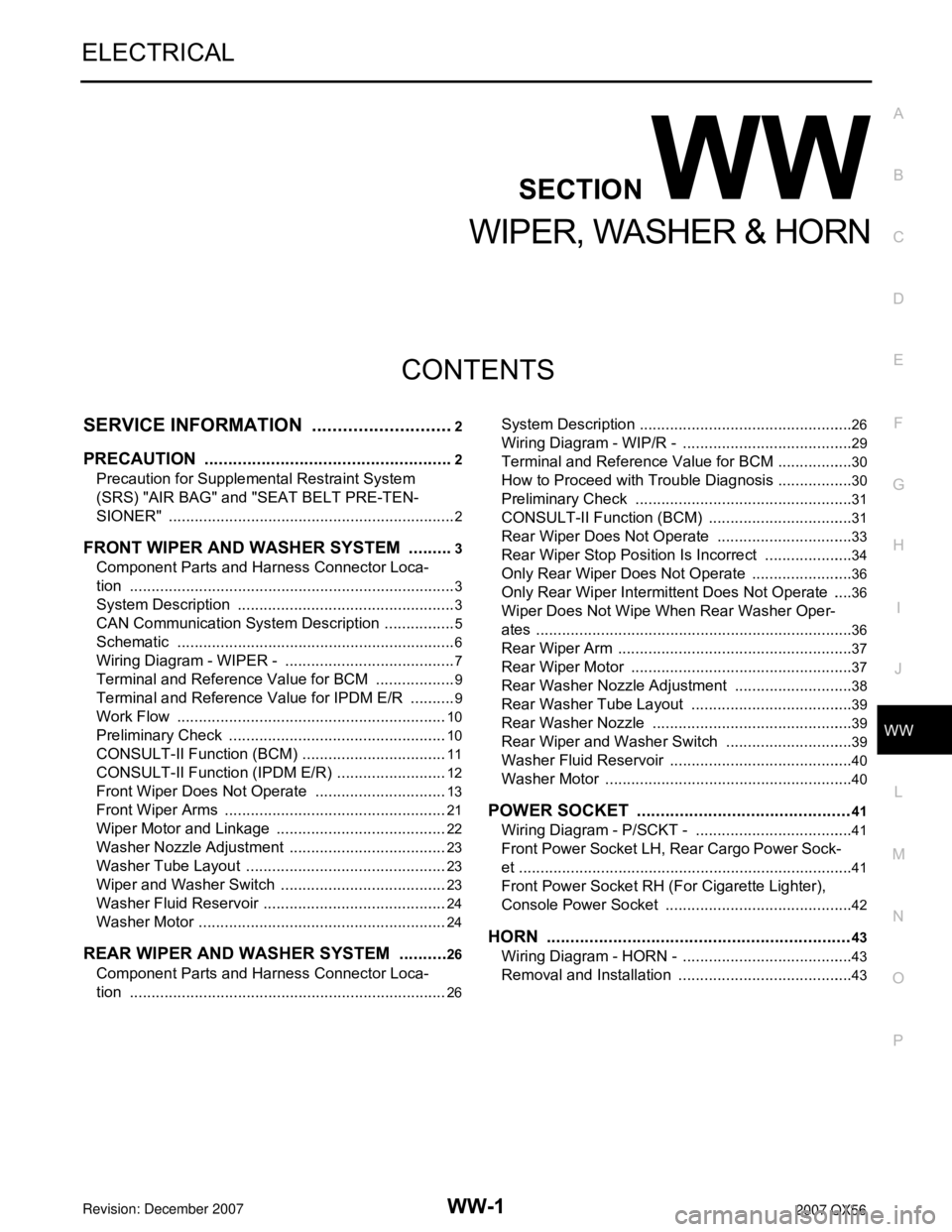

WW-1

ELECTRICAL

C

D

E

F

G

H

I

J

L

M

SECTION WW

A

B

WW

N

O

P

CONTENTS

WIPER, WASHER & HORN

SERVICE INFORMATION ............................2

PRECAUTION .....................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

FRONT WIPER AND WASHER SYSTEM ..........3

Component Parts and Harness Connector Loca-

tion ............................................................................

3

System Description ...................................................3

CAN Communication System Description .................5

Schematic .................................................................6

Wiring Diagram - WIPER - ........................................7

Terminal and Reference Value for BCM ...................9

Terminal and Reference Value for IPDM E/R ...........9

Work Flow ...............................................................10

Preliminary Check ...................................................10

CONSULT-II Function (BCM) ..................................11

CONSULT-II Function (IPDM E/R) ..........................12

Front Wiper Does Not Operate ...............................13

Front Wiper Arms ....................................................21

Wiper Motor and Linkage ........................................22

Washer Nozzle Adjustment .....................................23

Washer Tube Layout ...............................................23

Wiper and Washer Switch .......................................23

Washer Fluid Reservoir ...........................................24

Washer Motor ..........................................................24

REAR WIPER AND WASHER SYSTEM ...........26

Component Parts and Harness Connector Loca-

tion ..........................................................................

26

System Description ..................................................26

Wiring Diagram - WIP/R - ........................................29

Terminal and Reference Value for BCM ..................30

How to Proceed with Trouble Diagnosis ..................30

Preliminary Check ...................................................31

CONSULT-II Function (BCM) ..................................31

Rear Wiper Does Not Operate ................................33

Rear Wiper Stop Position Is Incorrect .....................34

Only Rear Wiper Does Not Operate ........................36

Only Rear Wiper Intermittent Does Not Operate .....36

Wiper Does Not Wipe When Rear Washer Oper-

ates ..........................................................................

36

Rear Wiper Arm .......................................................37

Rear Wiper Motor ....................................................37

Rear Washer Nozzle Adjustment ............................38

Rear Washer Tube Layout ......................................39

Rear Washer Nozzle ...............................................39

Rear Wiper and Washer Switch ..............................39

Washer Fluid Reservoir ...........................................40

Washer Motor ..........................................................40

POWER SOCKET .............................................41

Wiring Diagram - P/SCKT - .....................................41

Front Power Socket LH, Rear Cargo Power Sock-

et ..............................................................................

41

Front Power Socket RH (For Cigarette Lighter),

Console Power Socket ............................................

42

HORN ................................................................43

Wiring Diagram - HORN - ........................................43

Removal and Installation .........................................43