air condition INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2744 of 3061

SE-72

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

Check continuity between ADP steering wheel tilt switch connector

M16 terminal 1 and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Replace or replace harness.

Front Door Switch LH Circuit InspectionINFOID:0000000003533203

1.CHECK FUNCTION

With CONSULT-II

Touch "BCM" with “DOOR SW-DR” on the DATA MONITOR, check

ON/OFF operation when the front door is open and closed.

*:Refer to SE-32, "CONSULT-II Function (AUTO DRIVE POS.)".

Without CONSULT-II

GO TO 2.

OK or NG

OK >> Front door switch LH circuit is OK.

NG >> GO TO 2.

2.CHECK FRONT DOOR SWITCH LH

1. Turn ignition switch OFF.

2. Disconnect front door switch LH.

3. Check continuity between front door switch LH terminal 2 and

exposed metal of switch while pressing and releasing switch.

OK or NG

OK >> GO TO 3.

NG >> Replace front door switch LH.

3.CHECK HARNESS CONTINUITY

1. Disconnect BCM.

2. Check continuity between BCM connector M19 terminal 47 and

front door switch LH connector B8 terminal 2.

3. Check continuity between BCM connector M19 terminal 47 and

ground.

OK or NG

OK >> Front door switch LH circuit is OK.

NG >> Repair or replace harness.1 - Ground : Continuity should exist.

LIIA0490E

Monitor item [OPERATION

or UNIT]Contents

DOOR SW DR*“ON/

OFF”Door open (ON)/door closed (OFF) status judged

from the front door switch is displayed.

PIIA0291E

Terminals Condition Continuity

2GroundWith the front door switch LH pressed No

With the front door switch LH released Yes

LIIA2377E

47 - 2 : Continuity should exist.

47 - Ground : Continuity should not exist.

LIIA1027E

Page 2776 of 3061

SRS-6

< SERVICE INFORMATION >

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

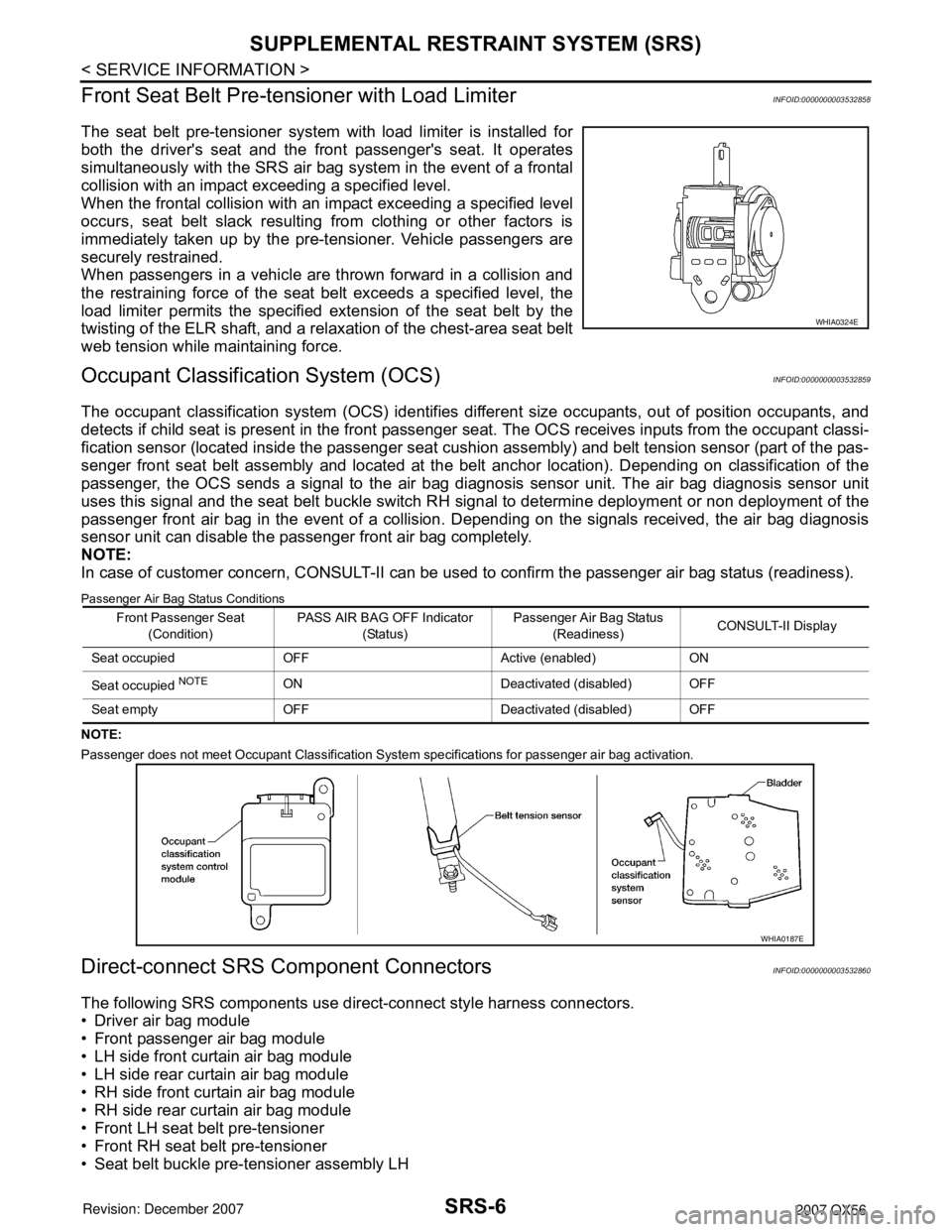

Front Seat Belt Pre-tensioner with Load Limiter

INFOID:0000000003532858

The seat belt pre-tensioner system with load limiter is installed for

both the driver's seat and the front passenger's seat. It operates

simultaneously with the SRS air bag system in the event of a frontal

collision with an impact exceeding a specified level.

When the frontal collision with an impact exceeding a specified level

occurs, seat belt slack resulting from clothing or other factors is

immediately taken up by the pre-tensioner. Vehicle passengers are

securely restrained.

When passengers in a vehicle are thrown forward in a collision and

the restraining force of the seat belt exceeds a specified level, the

load limiter permits the specified extension of the seat belt by the

twisting of the ELR shaft, and a relaxation of the chest-area seat belt

web tension while maintaining force.

Occupant Classification System (OCS)INFOID:0000000003532859

The occupant classification system (OCS) identifies different size occupants, out of position occupants, and

detects if child seat is present in the front passenger seat. The OCS receives inputs from the occupant classi-

fication sensor (located inside the passenger seat cushion assembly) and belt tension sensor (part of the pas-

senger front seat belt assembly and located at the belt anchor location). Depending on classification of the

passenger, the OCS sends a signal to the air bag diagnosis sensor unit. The air bag diagnosis sensor unit

uses this signal and the seat belt buckle switch RH signal to determine deployment or non deployment of the

passenger front air bag in the event of a collision. Depending on the signals received, the air bag diagnosis

sensor unit can disable the passenger front air bag completely.

NOTE:

In case of customer concern, CONSULT-II can be used to confirm the passenger air bag status (readiness).

Passenger Air Bag Status Conditions

NOTE:

Passenger does not meet Occupant Classification System specifications for passenger air bag activation.

Direct-connect SRS Component ConnectorsINFOID:0000000003532860

The following SRS components use direct-connect style harness connectors.

• Driver air bag module

• Front passenger air bag module

• LH side front curtain air bag module

• LH side rear curtain air bag module

• RH side front curtain air bag module

• RH side rear curtain air bag module

• Front LH seat belt pre-tensioner

• Front RH seat belt pre-tensioner

• Seat belt buckle pre-tensioner assembly LH

WHIA0324E

Front Passenger Seat

(Condition)PASS AIR BAG OFF Indicator

(Status)Passenger Air Bag Status

(Readiness)CONSULT-II Display

Seat occupied OFF Active (enabled) ON

Seat occupied

NOTEON Deactivated (disabled) OFF

Seat empty OFF Deactivated (disabled) OFF

WHIA0187E

Page 2778 of 3061

SRS-8

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

Trouble Diagnosis IntroductionINFOID:0000000003532861

CAUTION:

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to do so in

this Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harness con-

nectors.

• Do not attempt to repair, splice or modify SRS wiring harnesses. If a harness is damaged, replace it

with a new one.

• Keep ground connections clean.

DIAGNOSIS FUNCTION

The SRS self-diagnosis results can be read by using “AIR BAG” warning lamp and/or CONSULT-II.

The User mode is exclusively prepared for the customer (driver). This mode warns the driver of a system mal-

function through the operation of the “AIR BAG” warning lamp.

The Diagnosis mode allows the technician to locate and inspect the malfunctioning part.

The mode applications for the “AIR BAG” warning lamp and CONSULT-II are as follows:

HOW TO PERFORM TROUBLE DIAGNOSES FOR QUICK AND ACCURATE REPAIR

A good understanding of the malfunction conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a malfunction. It is important to fully understand the symp-

toms or conditions for a customer complaint.

Information From Customer

WHAT - Vehicle model

WHEN - Date, Frequencies

WHERE - Road conditions

HOW - Operating conditions, Symptoms

Preliminary Check

Check that the following parts are in good order.

• Battery (Refer to SC-4, "

How to Handle Battery" .)

• Fuse (Refer to SRS-12, "

Wiring Diagram - SRS -" .)

• System component-to-harness connections

WORK FLOW

User mode Diagnosis mode Display type

“AIR BAG” warning lamp X X ON-OFF operation

CONSULT-II — X Monitoring

Page 2791 of 3061

TROUBLE DIAGNOSIS

SRS-21

< SERVICE INFORMATION >

C

D

E

F

G

I

J

K

L

MA

B

SRS

N

O

P

Warning lamp examples

Trouble Diagnosis with CONSULT-IIINFOID:0000000003532869

DIAGNOSTIC PROCEDURE 2

Refer to GI-36, "CONSULT-II Start Procedure" .

“AIR BAG” warning lamp operation-User mode- SRS condition Reference item

• No malfunction is detected.

• No further action is necessary.—

The system is malfunctioning and

needs to be repaired as indicated.Go to SRS-21, "

Trouble Diagnosis

with CONSULT-II" with CONSULT-

II or SRS-28, "

Trouble Diagnosis

without CONSULT-II" without CON-

SULT-II.

• Air bag is deployed.

• Seat belt pre-tensioner is deployed.

• Seat belt buckle pre-tensioner as-

sembly is deployed.Go to SRS-49

.

• Air bag diagnosis sensor unit is mal-

functioning.

• Air bag power supply circuit is mal-

functioning.

• SRS air bag warning lamp circuit is

malfunctioning.Go to SRS-32, "

Trouble Diagnosis:

"AIR BAG" Warning Lamp Does Not

Turn Off" .

• Air bag diagnosis sensor unit is mal-

functioning.

• Air bag warning lamp circuit is mal-

functioning.Go to SRS-33, "

Trouble Diagnosis:

"AIR BAG" Warning Lamp Does Not

Turn On" .

SHIA0011E

SHIA0012E

SHIA0013E

SHIA0014E

Page 2803 of 3061

TROUBLE DIAGNOSIS

SRS-33

< SERVICE INFORMATION >

C

D

E

F

G

I

J

K

L

MA

B

SRS

N

O

P

1.CHECK CONDITION OF AIR BAG MODULE

Inspect for any deployed air bag modules or seat belt pre-tensioners.

Are any air bag modules or seat belt pre-tensioners deployed?

Yes >> Refer to SRS-49 .

No >> GO TO 2.

2.CHECK THE AIR BAG FUSE

Check 10A fuse [No. 13, located in the fuse block (J/B)].

Refer to PG-3

.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.CHECK AIR BAG FUSE AGAIN

Replace 10A fuse [No. 13, located in the fuse block (J/B)] and turn ignition switch ON.

Does the fuse blow again?

Yes >> Repair harness.

No >> Inspection End.

4.CHECK AIR BAG DIAGNOSIS SENSOR UNIT

Connect CONSULT-II and touch “START”.

Is

“AIR BAG” displayed on CONSULT-II?

Yes >> GO TO 5.

No >> Visually inspect the air bag diagnosis sensor unit har-

ness connections. If the connections are OK, replace

the air bag diagnosis sensor unit. Refer to SRS-47,

"Removal and Installation" .

5.CHECK HARNESS CONNECTION

Check for loose connections between the combination meter and the air bag diagnosis sensor unit.

OK or NG

OK >> Replace air bag diagnosis sensor unit. Refer to SRS-47, "Removal and Installation" .

NG >> Properly connect the combination meter and air bag diagnosis sensor unit harness connectors. If

“AIR BAG” warning lamp still does not turn off, replace the wiring harness.

Trouble Diagnosis: "AIR BAG" Warning Lamp Does Not Turn OnINFOID:0000000003532872

DIAGNOSTIC PROCEDURE 8

1.CHECK METER FUSE

Check the 10A fuse [No. 14, located in the fuse block (J/B)] .

Refer to PG-3

.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.REPLACE METER FUSE AND CHECK AGAIN

Replace 10A fuse [No. 14, located in the fuse block (J/B)] and turn ignition switch ON.

Does the fuse blow again?

Yes >> Replace harness.

No >> Inspection End.

BCIA0030E

Page 2857 of 3061

TROUBLE DIAGNOSIS

TF-35

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

• Heavy tight-corner braking symptom occurs when vehicle is driven in the following conditions: 4WD shift

switch is "4H" or "4LO", steering wheel is turned fully to either side.

Transfer Control Unit Input/Output Signal Reference ValueINFOID:0000000003532526

TRANSFER CONTROL UNIT INSPECTION TABLE

Specifications with CONSULT-II

Monitored item [Unit] Content Condition Display value

VHCL/S SEN·FR [km/h]

or [mph]Front wheel speedVehicle stopped 0 km/h (0 MPH)

Vehicle running

CAUTION:

Check air pressure of tire under standard condition.Approximately

equal to the indica-

tion on speedome-

ter (Inside of

±10%)

VHCL/S SEN·RR [km/h]

or [mph]Rear wheel speedVehicle stopped 0 km/h (0 MPH)

Vehicle running

CAUTION:

Check air pressure of tire under standard condition.Approximately

equal to the indica-

tion on speedome-

ter (Inside of

±10%)

ENGINE SPEED [rpm] Engine speedEngine stopped

(Engine speed: Less than 400 rpm)0 rpm

Engine running

(Engine speed: 400 rpm or more)Approximately

equal to the indica-

tion on tachometer

THRTL POS SEN [V]Accelerator pedal posi-

tion (APP) sensor signal

voltageAccelerator pedal: Release Approx. 0.5V

Accelerator pedal: Fully depressed Approx. 4.0V

FLUID TEMP SE [V]Transfer fluid tempera-

ture signal voltageTransfer fluid temperature approx. 20 - 80°C (68 - 176°F) Approx. 1.1 - 0.3V

BATTERY VOLT [V]Power supply voltage for

transfer control unitIgnition switch: ON Battery voltage

2WD SWITCH [ON/OFF]Input condition from 4WD

shift switch4WD shift switch: 2WD ON

4WD shift switch: AUTO, 4H or 4LO OFF

AUTO SWITCH [ON/

OFF]Input condition from 4WD

shift switch4WD shift switch: AUTO ON

4WD shift switch: 2WD, 4H or 4LO OFF

LOCK SWITCH [ON/

OFF]Input condition from 4WD

shift switch4WD shift switch: 4H ON

4WD shift switch: 2WD, AUTO or 4LO OFF

4L SWITCH [ON/OFF]Input condition from 4WD

shift switch4WD shift switch: 4LO ON

4WD shift switch: 2WD, AUTO or 4H OFF

N POSI SW TF [ON/

OFF]Condition of neutral-4LO

switch• Vehicle stopped

• Engine running

• A/T selector lever “N” posi-

tion

• Brake pedal depressed4WD shift switch: 2WD,

AUTO or 4HOFF

4WD shift switch: 4H to

4LO (While actuator mo-

tor is operating.)OFF → ON

4WD shift switch: 4LO to

4H (While actuator motor

is operating.)ON → OFF

4WD shift switch: 4LO ON

Page 2859 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

TF-37

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

VHCL/S COMP [km/h] or

[mph]Vehicle speedVehicle stopped 0 km/h (0 MPH)

Vehicle running

CAUTION:

Check air pressure of t INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

TF-37

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

VHCL/S COMP [km/h] or

[mph]Vehicle speedVehicle stopped 0 km/h (0 MPH)

Vehicle running

CAUTION:

Check air pressure of t](/img/42/57029/w960_57029-2858.png)

TROUBLE DIAGNOSIS

TF-37

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

VHCL/S COMP [km/h] or

[mph]Vehicle speedVehicle stopped 0 km/h (0 MPH)

Vehicle running

CAUTION:

Check air pressure of tire under standard condition.Approximately

equal to the indica-

tion on speedome-

ter (Inside of

±10%)

COMP CL TORQ [kgm]Condition of control

torque• Vehicle stopped

• Engine running

• A/T selector lever “N” posi-

tion

• Brake pedal depressed4WD shift switch: 2WD 0 kg-m

4WD shift switch: AUTO39 - 1,353 N·m

(4 - 138 kg-m, 29 -

998 ft-lb)

4WD shift switch: 4H or

4LO1,353 N·m

(138 kg-m, 998 ft-

lb)

DUTY SOLENOID [%]Condition of clutch pres-

sure solenoid• Vehicle stopped

• Engine running

• A/T selector lever “N” posi-

tion

• Brake pedal depressed4WD shift switch: 2WD 4%

4WD shift switch: AUTO 96 - 4%

4WD shift switch: 4H or

4LO4%

2-4WD SOL [ON/OFF]Condition of 2-4WD shift

solenoid valve• Vehicle stopped

• Engine running

• A/T selector lever “N” posi-

tion

• Brake pedal depressed4WD shift switch: 2WD OFF

4WD shift switch: AUTO

ON 4WD shift switch: 4H

4WD shift switch: 4LO

4WD shift switch: AUTO

(“Wait” function is operat-

ing.)OFF

4WD shift switch: 4H

(“Wait” function is operat-

ing.)OFF

2-4WD SOL MON [ON/

OFF]Check signal for transfer

control unit signal output• Vehicle stopped

• Engine running

• A/T selector lever “N” posi-

tion

• Brake pedal depressed4WD shift switch: 2WD OFF

4WD shift switch: AUTO

ON 4WD shift switch: 4H

4WD shift switch: 4LO

4WD shift switch: AUTO

(“Wait” function is operat-

ing.)OFF

4WD shift switch: 4H

(“Wait” function is operat-

ing.)OFF

MOTOR RELAY [ON/

OFF]Condition of transfer mo-

tor relay• Accelerator pedal de-

pressed

• Vehicle stopped

• Engine running

• Brake pedal depressed4WD shift switch: 2WD OFF

4WD shift switch: AUTO

or 4LO (A/T selector lever

“P” or “N” position)OFF

("ON" for approx. 2

sec. after shifting

to “P” and “N”.)

4WD shift switch: AUTO

or 4LO (Except for A/T se-

lector lever “P” or “N” po-

sition)ON

4WD shift switch: 4H (A/T

selector lever “P” posi-

tion)OFF

("ON" for approx. 2

sec. after shifting

to “P”.)

4WD shift switch: 4H (Ex-

cept for A/T selector lever

“P” position)ON Monitored item [Unit] Content Condition Display value

Page 2876 of 3061

TF-54

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYSTEM

2.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer to TF-51, "

Power Supply Circuit for Transfer Control Unit"

.

OK or NG

OK >> GO TO 3.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

3.CHECK DTC

Perform the self-diagnosis, after driving a vehicle for a while.

OK or NG

OK >> Inspection End.

NG >> Perform self-diagnosis with TCM again. Refer to TF-48, "

Self-Diagnosis Procedure".

Vehicle Speed Sensor (ABS)INFOID:0000000003532532

DIAGNOSTIC PROCEDURE

1.CHECK DTC WITH ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Perform self-diagnosis with ABS actuator and electric unit (control unit). Refer to BRC-26, "

CONSULT-II Func-

tion (ABS)".

Is any malfunction detected by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 2.

2.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer to TF-35, "

Transfer Control Unit Input/Output Signal Ref-

erence Value".

OK or NG

OK >> GO TO 3.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

3.CHECK DTC

Perform the self-diagnosis, after driving a vehicle for a while.

OK or NG

OK >> Inspection End.

NG >> Perform self-diagnosis with ABS actuator and electric unit (control unit) again. Refer to BRC-26,

"CONSULT-II Function (ABS)".

Neutral-4LO SwitchINFOID:0000000003532533

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

TRANSFER CONTROL UNIT TERMINALS AND REFERENCE VALUE

Monitored item Content Condition Display value

N POSI SW TF [ON/

OFF]Condition of neutral-4LO

switch• Vehicle stopped

• Engine running

• A/T selector lever “N”

position

• Brake pedal depressed4WD shift switch: 2WD,

AUTO or 4HOFF

4WD shift switch: 4H to

4LO (While actuator mo-

tor is operating.)OFF → ON

4WD shift switch: 4LO to

4H (While actuator motor

is operating.)ON → OFF

4WD shift switch: 4LO ON

Page 2878 of 3061

TF-56

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYSTEM

3. Check continuity between transfer control unit harness connec-

tor E143 terminal 25 and neutral-4LO switch harness connector

F60 terminal 13.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect neutral-4LO switch harness connector.

3. Check continuity between neutral-4LO switch harness connec-

tor F60 terminal 12 and ground.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

4.CHECK 4LO SWITCH

1. Turn ignition switch “OFF”.

2. Disconnect neutral-4LO switch harness connector.

3. Remove neutral-4LO switch. Refer to TF-22, "

Location of Electrical Parts".

4. Push and release neutral-4LO switch and check continuity

between neutral-4LO switch terminals 12 and 13.

OK or NG

OK >> GO TO 5.

NG >> Replace neutral-4LO switch. Refer to TF-22, "

Location

of Electrical Parts".

5.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer to TF-35, "

Transfer Control Unit Input/Output Signal Ref-

erence Value".

OK or NG

OK >> GO TO 6.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

6.CHECK DTC

Perform the self-diagnosis, after driving a vehicle for a while.

OK or NG

OK >> Inspection End.

NG >> Replace transfer control unit. Refer to TF-115, "

Removal and Installation".

COMPONENT INSPECTION

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)Continuity should exist.

SDIA2694E

Continuity should exist.

SDIA2695E

Terminal Condition Continuity

12 - 13Push neutral-4LO switch Yes

Release neutral-4LO switch No

SDIA2696E

Page 2881 of 3061

TROUBLE DIAGNOSIS FOR SYSTEM

TF-59

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

5. Check voltage between 4WD shift switch harness connector ter-

minal 1 and ground.

OK or NG

OK >> GO TO 3.

NG >> Go to TF-51, "

Power Supply Circuit for Transfer Control

Unit".

3.CHECK HARNESS BETWEEN 4WD SHIFT SWITCH AND TRANSFER CONTROL UNIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector and the 4WD shift switch harness connector.

3. Check continuity between the following terminals.

- Transfer control unit harness connector E142 terminal 9 and

4WD shift switch harness connector M141 terminal 2.

- Transfer control unit harness connector E142 terminal 18 and

4WD shift switch harness connector M141 terminal 5.

- Transfer control unit harness connector E142 terminal 23 and

4WD shift switch harness connector M141 terminal 6.

- Transfer control unit harness connector E142 terminal 24 and

4WD shift switch harness connector M141 terminal 3.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Check the following. If any items are damaged, repair or replace damaged parts.

• Harness for short or open between battery and transfer shut off relay harness connector E69

terminal 3.

• Power supply circuit for transfer control unit. Refer to PG-3

.

4.CHECK 4WD SHIFT SWITCH

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect 4WD shift switch harness connector.

3. Operate 4WD shift switch and check continuity between 4WD

shift switch terminals.

Connector Terminal Voltage (Approx.)

M141 1 - Ground Battery voltage

PDIA0210E

Continuity should exist.SDIA2699E

Connector Terminal Condition Continuity

M1411 - 24WD shift switch: 2WD Yes

4WD shift switch: AUTO, 4H and

4LONo

1 - 34WD shift switch: AUTO Yes

4WD shift switch: 2WD, 4H and

4LONo

1 - 44WD shift switch: 2WD No

4WD shift switch: AUTO, 4H and

4LOYe s

1 - 54WD shift switch: 4H Yes

4WD shift switch: 2WD, AUTO,

and 4LONo

1 - 64WD shift switch: 4LO Yes

4WD shift switch: 2WD, AUTO and

4HNo

WDIA0205E