check engine INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2874 of 3061

TF-52

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYSTEM

4. Turn ignition switch “ON”. (Do not start engine.)

5. Check voltage between transfer control unit harness connector

terminals and ground.

OK or NG

OK >> GO TO 2.

NG >> Check the following. If any items are damaged, repair or replace damaged parts.

• 10A fuses No. 26 located in fuse and fusible link box and No. 59 located in the fuse and relay

box. Refer to PG-3

.

• 20A fuse No. 53 located in the IPDM E/R. Refer to PG-3

.

• Harness for short or open between battery and transfer control unit harness connector terminals

47.

• Harness for short or open between battery and transfer control unit harness connector terminal

29.

• Harness for short or open between battery and transfer shut off relay harness connector E69

terminal 1, and 3.

• Harness for short or open between transfer shut off relay harness connector E69 terminal 2 and

transfer control unit harness connector terminal 30.

• Harness for short or open between transfer shut off relay harness connector E69 terminal 5 and

transfer control unit harness connector terminals 16 and 22.

• Battery and ignition switch. Refer to PG-3

.

• Transfer shut off relay. Refer to "COMPONENT INSPECTION" .

2.CHECK GROUND CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector.

3. Check continuity between transfer control unit harness connec-

tor E142 terminals 3, 6, E143 terminal 45 and ground.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

3.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer to TF-35, "

Transfer Control Unit Input/Output Signal Ref-

erence Value".

OK or NG

OK >> GO TO 4.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

4.CHECK DTC

Perform the self-diagnosis, after driving a vehicle for a while.

OK or NG

OK >> Inspection End.

NG >> Replace transfer control unit. Refer to TF-115, "

Removal and Installation".

Connector Terminal Voltage (Approx.)

E14216 - Ground

Battery voltage 22 - Ground

E14329 - Ground

30 - Ground 0V

47 - Ground Battery voltage

WDIA0166E

Continuity should exist.

SDIA2691E

Page 2875 of 3061

TROUBLE DIAGNOSIS FOR SYSTEM

TF-53

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

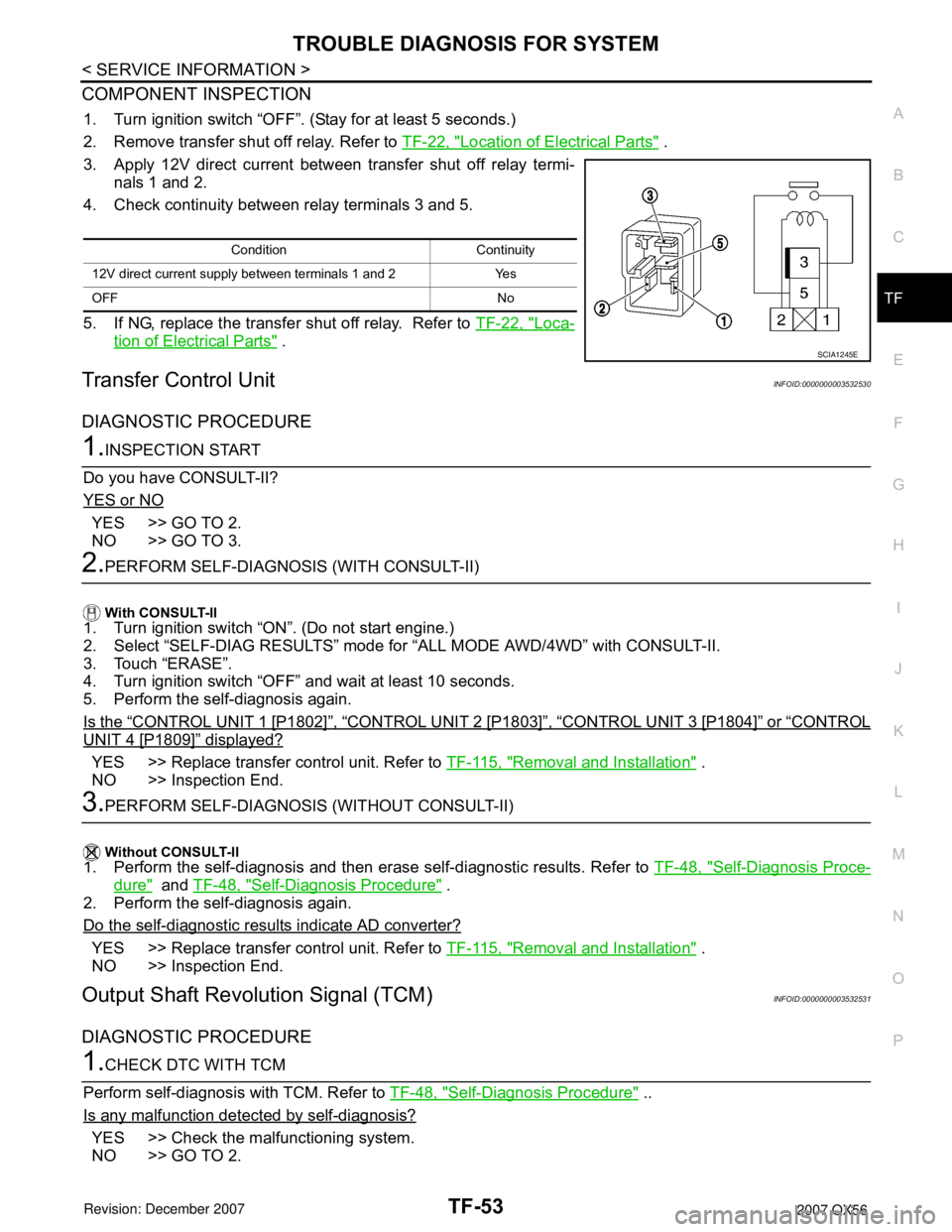

COMPONENT INSPECTION

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Remove transfer shut off relay. Refer to TF-22, "

Location of Electrical Parts" .

3. Apply 12V direct current between transfer shut off relay termi-

nals 1 and 2.

4. Check continuity between relay terminals 3 and 5.

5. If NG, replace the transfer shut off relay. Refer to TF-22, "

Loca-

tion of Electrical Parts" .

Transfer Control UnitINFOID:0000000003532530

DIAGNOSTIC PROCEDURE

1.INSPECTION START

Do you have CONSULT-II?

YES or NO

YES >> GO TO 2.

NO >> GO TO 3.

2.PERFORM SELF-DIAGNOSIS (WITH CONSULT-II)

With CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “SELF-DIAG RESULTS” mode for “ALL MODE AWD/4WD” with CONSULT-II.

3. Touch “ERASE”.

4. Turn ignition switch “OFF” and wait at least 10 seconds.

5. Perform the self-diagnosis again.

Is the

“CONTROL UNIT 1 [P1802]”, “CONTROL UNIT 2 [P1803]”, “CONTROL UNIT 3 [P1804]” or “CONTROL

UNIT 4 [P1809]” displayed?

YES >> Replace transfer control unit. Refer to TF-115, "Removal and Installation" .

NO >> Inspection End.

3.PERFORM SELF-DIAGNOSIS (WITHOUT CONSULT-II)

Without CONSULT-II

1. Perform the self-diagnosis and then erase self-diagnostic results. Refer to TF-48, "Self-Diagnosis Proce-

dure" and TF-48, "Self-Diagnosis Procedure" .

2. Perform the self-diagnosis again.

Do the self-diagnostic results indicate AD converter?

YES >> Replace transfer control unit. Refer to TF-115, "Removal and Installation" .

NO >> Inspection End.

Output Shaft Revolution Signal (TCM)INFOID:0000000003532531

DIAGNOSTIC PROCEDURE

1.CHECK DTC WITH TCM

Perform self-diagnosis with TCM. Refer to TF-48, "

Self-Diagnosis Procedure" ..

Is any malfunction detected by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 2.

Condition Continuity

12V direct current supply between terminals 1 and 2 Yes

OFF No

SCIA1245E

Page 2876 of 3061

TF-54

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYSTEM

2.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer to TF-51, "

Power Supply Circuit for Transfer Control Unit"

.

OK or NG

OK >> GO TO 3.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

3.CHECK DTC

Perform the self-diagnosis, after driving a vehicle for a while.

OK or NG

OK >> Inspection End.

NG >> Perform self-diagnosis with TCM again. Refer to TF-48, "

Self-Diagnosis Procedure".

Vehicle Speed Sensor (ABS)INFOID:0000000003532532

DIAGNOSTIC PROCEDURE

1.CHECK DTC WITH ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

Perform self-diagnosis with ABS actuator and electric unit (control unit). Refer to BRC-26, "

CONSULT-II Func-

tion (ABS)".

Is any malfunction detected by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 2.

2.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer to TF-35, "

Transfer Control Unit Input/Output Signal Ref-

erence Value".

OK or NG

OK >> GO TO 3.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

3.CHECK DTC

Perform the self-diagnosis, after driving a vehicle for a while.

OK or NG

OK >> Inspection End.

NG >> Perform self-diagnosis with ABS actuator and electric unit (control unit) again. Refer to BRC-26,

"CONSULT-II Function (ABS)".

Neutral-4LO SwitchINFOID:0000000003532533

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

TRANSFER CONTROL UNIT TERMINALS AND REFERENCE VALUE

Monitored item Content Condition Display value

N POSI SW TF [ON/

OFF]Condition of neutral-4LO

switch• Vehicle stopped

• Engine running

• A/T selector lever “N”

position

• Brake pedal depressed4WD shift switch: 2WD,

AUTO or 4HOFF

4WD shift switch: 4H to

4LO (While actuator mo-

tor is operating.)OFF → ON

4WD shift switch: 4LO to

4H (While actuator motor

is operating.)ON → OFF

4WD shift switch: 4LO ON

Page 2877 of 3061

TROUBLE DIAGNOSIS FOR SYSTEM

TF-55

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

Data are reference value and are measured between each terminal and ground.

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.

DIAGNOSTIC PROCEDURE

1.CHECK 4LO POSITION SWITCH SIGNAL

With CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode for “ALL MODE AWD/4WD” with CONSULT-II.

3. Read out the value of “N POSI SW TF”.

Without CONSULT-II

1. Start engine.

2. Check voltage between transfer control unit harness connector

terminal and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK HARNESS BETWEEN TRANSFER CONTROL UNIT AND NEUTRAL-4LO SWITCH

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector and the neutral-4LO switch harness connector.

Te r m i n a lWire

colorItem Condition Data (Approx.)

25 V Neutral-4LO switch• Vehicle stopped

• Engine running

• A/T selector le-

ver “N” position

• Brake pedal de-

pressed4WD shift switch: 2WD, AUTO or 4H Battery voltage

4WD shift switch: 4H to 4LO (While actua-

tor motor is operating.)Battery voltage

→ 0V

4WD shift switch: 4LO to 4H (While actua-

tor motor is operating.)0V → Battery

voltage

4WD shift switch: 4LO 0V

Condition Display value

• Vehicle stopped

• Engine running

• A/T selector lever “N” position

• Brake pedal depressed4WD shift switch: 2WD,

AUTO or 4HOFF

4WD shift switch: 4H to

4LO (While actuator mo-

tor is operating.)OFF → ON

4WD shift switch: 4LO to

4H (While actuator motor

is operating.)ON → OFF

4WD shift switch: 4LO ON

SDIA2692E

ConnectorTe r m i n a l

(Wire col-

or)ConditionVoltage

(Approx.)

E143 25 -

Ground• Vehicle stopped

• Engine running

• A/T selector lever

“N” position

• Brake pedal de-

pressed4WD shift switch:

2WD, AUTO or 4HBattery

voltage

4WD shift switch: 4H to

4LO (While actuator

motor is operating.)Battery

voltage

→ 0V

4WD shift switch: 4LO

to 4H (While actuator

motor is operating.)0V →

Battery

voltage

4WD shift switch: 4LO 0V

SDIA2693E

Page 2879 of 3061

TROUBLE DIAGNOSIS FOR SYSTEM

TF-57

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

2. Disconnect neutral-4LO switch harness connector.

3. Remove neutral-4LO switch. Refer to TF-22, "

Location of Electrical Parts".

4. Push and release neutral-4LO switch and check continuity

between neutral-4LO switch terminals 12 and 13.

5. If NG, replace the neutral-4LO switch. Refer to TF-22, "

Location

of Electrical Parts".

4WD Shift SwitchINFOID:0000000003532534

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

TRANSFER CONTROL UNIT TERMINALS AND REFERENCE VALUE

Data are reference value and are measured between each terminal and ground.

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.

DIAGNOSTIC PROCEDURE

1.CHECK 4WD SHIFT SWITCH SIGNAL

With CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

Terminal Condition Continuity

12 - 13Push neutral-4LO switch Yes

Release neutral-4LO switch No

SDIA2696E

Monitored item [Unit] Content Condition Display value

2WD SWITCH [ON/OFF]Input condition from 4WD

shift switch4WD shift switch: 2WD ON

4WD shift switch: AUTO, 4H or 4LO OFF

AUTO SWITCH [ON/

OFF]Input condition from 4WD

shift switch4WD shift switch: AUTO ON

4WD shift switch: 2WD, 4H or 4LO OFF

LOCK SWITCH [ON/

OFF]Input condition from 4WD

shift switch4WD shift switch: 4H ON

4WD shift switch: 2WD, AUTO or 4LO OFF

4L SWITCH [ON/OFF]Input condition from 4WD

shift switch4WD shift switch: 4LO ON

4WD shift switch: 2WD, AUTO or 4H OFF

4WD MODE [AUTO/

LOCK/2WD/4L]Control status of 4WD

(Output condition of 4WD

shift indicator lamp and

4LO indicator lamp)• Vehicle stopped

• Engine running

• A/T selector lever “N”

position

• Brake pedal depressed4WD shift switch: 2WD 2WD

4WD shift switch: AUTO AUTO

4WD shift switch: 4H LOCK

4WD shift switch: 4LO 4L

Te r m i n a lWire

colorItem Condition Data (Approx.)

9G/W4WD shift switch

(2WD)Ignition switch: ON4WD shift switch: 2WD Battery voltage

4WD shift switch: AUTO, 4H or 4LO 0V

18 O4WD shift switch

(4H)Ignition switch: ON4WD shift switch: 4H Battery voltage

4WD shift switch: 2WD, AUTO or 4LO 0V

23 R4WD shift switch

(4LO)Ignition switch: ON4WD shift switch: 4LO Battery voltage

4WD shift switch: 2WD, AUTO or 4H 0V

24 LG/R4WD shift switch

(AUTO)Ignition switch: ON4WD shift switch: AUTO Battery voltage

4WD shift switch: 2WD, 4H or 4LO 0V

Page 2880 of 3061

TF-58

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYSTEM

2. Select “DATA MONITOR” mode for “ALL MODE AWD/4WD” with CONSULT-II.

3. Read out ON/OFF switching action of the “2WD SWITCH”,

“AUTO SWITCH”, “LOCK SWITCH”, “4L SWITCH” with operat-

ing 4WD shift switch.

Without CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Check voltage between transfer control unit harness connector

terminals and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK 4WD SHIFT SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect 4WD shift switch harness connector.

3. Check voltage between 4WD shift switch harness connector ter-

minal 1 and ground.

4. Turn ignition switch “ON”. (Do not start engine.)

SDIA2697E

Connector Terminal ConditionVoltage (Ap-

prox.)

E1429 - ground4WD shift switch: 2WD Battery voltage

4WD shift switch: AUTO, 4H or 4LO 0V

18 - ground4WD shift switch: 4H Battery voltage

4WD shift switch: 2WD, AUTO or

4LO 0V

23 - ground4WD shift switch: 4LO Battery voltage

4WD shift switch: 2WD, AUTO or 4H 0V

24 - ground4WD shift switch: AUTO Battery voltage

4WD shift switch: 2WD, 4H or 4LO 0V

WDIA0148E

Connector Terminal Voltage (Approx.)

M141 1 - Ground 0V

SDIA2383E

Page 2883 of 3061

TROUBLE DIAGNOSIS FOR SYSTEM

TF-61

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

Data are reference value.

TRANSFER CONTROL UNIT TERMINALS AND REFERENCE VALUE

Data are reference value and are measured between each terminal and ground.

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.

DIAGNOSTIC PROCEDURE

1.CHECK WAIT DETECTION SWITCH SIGNAL

With CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode for “ALL MODE AWD/4WD” with CONSULT-II.

3. Read out the value of “WAIT DETCT SW”.

Without CONSULT-II

1. Start engine.

Monitored item Content Condition Display value

WAIT DETCT SW [ON/

OFF]Condition of wait detection

switch• Vehicle stopped

• Engine running

• A/T selector lever “N”

position

• Brake pedal depressed4WD shift switch: 2WD,

AUTO or 4HOFF

4WD shift switch: 4H to

4LO (While actuator mo-

tor is operating.)OFF → ON

4WD shift switch: 4LO to

4H (While actuator motor

is operating.)ON → OFF

4WD shift switch: 4LO ON

Te r m i n a lWire

colorItem Condition Data (Approx.)

43 G/Y Wait detection switch• Vehicle stopped

• Engine running

• A/T selector le-

ver “N” position

• Brake pedal de-

pressed4WD shift switch: 2WD, AUTO or 4H Battery voltage

4WD shift switch: 4H to 4LO (While actua-

tor motor is operating.)Battery voltage

→ 0V

4WD shift switch: 4LO to 4H (While actua-

tor motor is operating.)0V → Battery

voltage

4WD shift switch: 4LO 0V

Condition Display value

• Vehicle stopped

• Engine running

• A/T selector lever “N” position

• Brake pedal depressed4WD shift switch: 2WD, AUTO

or 4HOFF

4WD shift switch: 4H to 4LO

(While actuator motor is operat-

ing.)OFF → ON

4WD shift switch: 4LO to 4H

(While actuator motor is operat-

ing.)ON → OFF

4WD shift switch: 4LO ON

PDIA0221E

Page 2884 of 3061

TF-62

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYSTEM

2. Check voltage between transfer control unit harness connector

terminal and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK HARNESS BETWEEN TRANSFER CONTROL UNIT AND WAIT DETECTION SWITCH

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector and the wait detection switch harness connector.

3. Check continuity between transfer control unit harness connec-

tor E143 terminal 43 and wait detection switch harness connec-

tor F59 terminal 10.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect wait detection switch harness connector.

3. Check continuity between wait detection switch harness con-

nector F59 terminal 11 and ground.

Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

4.CHECK WAIT DETECTION SWITCH

1. Turn ignition switch “OFF”. (Stay for at least 5 seconds.)

2. Disconnect wait detection switch harness connector.

3. Remove wait detection switch. Refer to TF-22, "

Location of Electrical Parts".

Connector Terminal ConditionVoltage

(Approx.)

E14343 -

Ground• Vehicle stopped

• Engine running

• A/T selector lever

“N” position

• Brake pedal de-

pressed4WD shift switch:

2WD, AUTO or 4HBattery

voltage

4WD shift switch: 4H to

4LO (While actuator

motor is operating.)Battery

voltage

→ 0V

4WD shift switch: 4LO

to 4H (While actuator

motor is operating.)0V →

Battery

voltage

4WD shift switch: 4LO 0V

SDIA2701E

Continuity should exist.

SDIA2702E

Continuity should exist.

SDIA2703E

Page 2886 of 3061

TF-64

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYSTEM

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

3.CHECK DTC

Perform the self-diagnosis, after driving a vehicle for a while.

OK or NG

OK >> Inspection End.

NG >> Perform self-diagnosis with TCM again. Refer to AT-83, "

CONSULT-II Function (A/T)".

Actuator MotorINFOID:0000000003532537

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

TRANSFER CONTROL UNIT TERMINALS AND REFERENCE VALUE

Data are reference value and are measured between each terminal and ground.

Monitored item Content Condition Display value

SHIFT ACT1 [ON/OFF]Output condition to ac-

tuator motor (High)• Vehicle stopped

• Engine running

• A/T selector lever “N”

position

• Brake pedal depressed4WD shift switch: 4H to

4LO (“Wait” function is op-

erating.)ON

Except the above OFF

SHIFT AC MON1 [ON/OFF]Check signal for trans-

fer control unit signal

output• Vehicle stopped

• Engine running

• A/T selector lever “N”

position

• Brake pedal depressed4WD shift switch: 4H to

4LO (“Wait” function is op-

erating.)ON

Except the above OFF

SHIFT ACT2 [ON/OFF]Output condition to ac-

tuator motor (Low)• Vehicle stopped

• Engine running

• A/T selector lever “N”

position

• Brake pedal depressed4WD shift switch: 4LO to

4H (“Wait” function is op-

erating.)ON

Except the above OFF

SHIFT AC MON2 [ON/OFF]Check signal for trans-

fer control unit signal

output• Vehicle stopped

• Engine running

• A/T selector lever “N”

position

• Brake pedal depressed4WD shift switch: 4LO to

4H (“Wait” function is op-

erating.)ON

Except the above OFF

Te r m i n a lWire

colorItem Condition Data (Approx.)

4 Y/L Transfer shift high relay• Vehicle stopped

• Engine running

• A/T selector le-

ver “N” position

• Brake pedal de-

pressed4WD shift switch: 4H to 4LO (“Wait” func-

tion is operating.)Battery voltage

Except the above 0V

13 G/B Transfer shift low relay• Vehicle stopped

• Engine running

• A/T selector le-

ver “N” position

• Brake pedal de-

pressed4WD shift switch: 4LO to 4H (“Wait” func-

tion is operating.)Battery voltage

Except the above 0V

33 R/LTransfer shift high relay moni-

tor• Vehicle stopped

• Engine running

• A/T selector le-

ver “N” position

• Brake pedal de-

pressed4WD shift switch: 4H to 4LO (“Wait” func-

tion is operating.)Battery voltage

Except the above 0V

Page 2887 of 3061

TROUBLE DIAGNOSIS FOR SYSTEM

TF-65

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

CAUTION:

When using a circuit tester to measure voltage for inspection, be sure not to extend forcibly any connector terminals.

DIAGNOSTIC PROCEDURE

1.CHECK ACTUATOR MOTOR SIGNAL

With CONSULT-II

1. Start engine.

2. Select “DATA MONITOR” mode for “ALL MODE AWD/4WD” with CONSULT-II.

3. Read out the value of “SHIFT ACT1”, “SHIFT AC MON1”,

“SHIFT ACT2” and “SHIFT AC MON2”.

Without CONSULT-II

1. Start engine.

2. Check voltage between transfer control unit harness connector

terminal and ground.

42 P/GTransfer shift low relay moni-

tor• Vehicle stopped

• Engine running

• A/T selector le-

ver “N” position

• Brake pedal de-

pressed4WD shift switch: 4LO to 4H (“Wait” func-

tion is operating.)Battery voltage

Except the above 0V Te r m i n a lWire

colorItem Condition Data (Approx.)

Monitored

itemConditionDisplay

value

SHIFT ACT1• Vehicle stopped

• Engine running

• A/T selector lever “N” posi-

tion

• Brake pedal depressed4WD shift switch: 4H

to 4LO (“Wait” func-

tion is operating.)ON

Except the above OFF

SHIFT AC

MON1• Vehicle stopped

• Engine running

• A/T selector lever “N” posi-

tion

• Brake pedal depressed4WD shift switch: 4H

to 4LO (“Wait” func-

tion is operating.)ON

Except the above OFF

SHIFT ACT2• Vehicle stopped

• Engine running

• A/T selector lever “N” posi-

tion

• Brake pedal depressed4WD shift switch:

4LO to 4H (“Wait”

function is operating.)ON

Except the above OFF

SHIFT AC

MON2• Vehicle stopped

• Engine running

• A/T selector lever “N” posi-

tion

• Brake pedal depressed4WD shift switch:

4LO to 4H (“Wait”

function is operating.)ON

Except the above OFF

PDIA0223E

SDIA2705E