seat adjustment INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 14 of 3061

ACS-1

ELECTRICAL

C

D

E

F

G

H

I

J

L

M

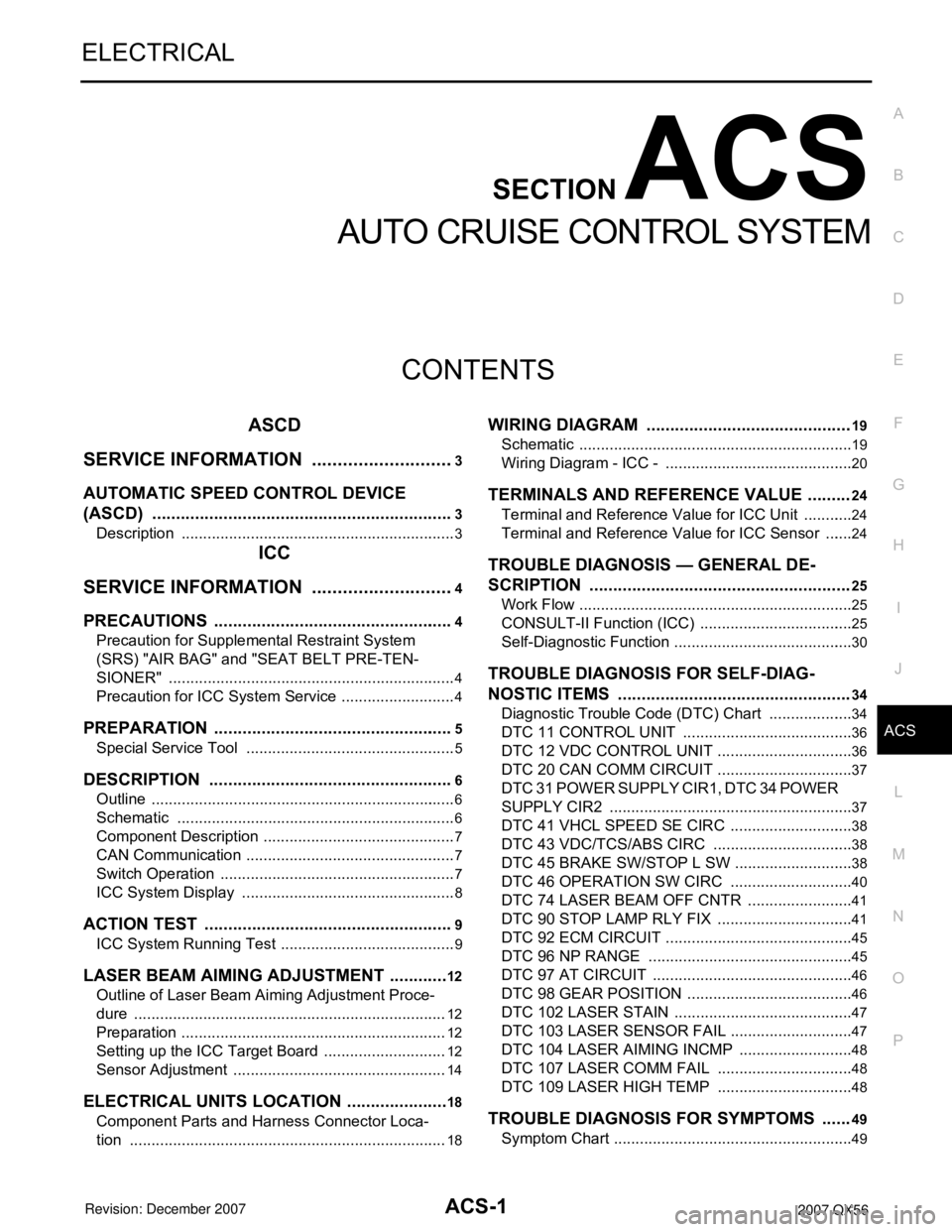

SECTION ACS

A

B

ACS

N

O

P

CONTENTS

AUTO CRUISE CONTROL SYSTEM

ASCD

SERVICE INFORMATION ............................

3

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ................................................................

3

Description ................................................................3

ICC

SERVICE INFORMATION ............................

4

PRECAUTIONS ...................................................4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

4

Precaution for ICC System Service ...........................4

PREPARATION ...................................................5

Special Service Tool .................................................5

DESCRIPTION ....................................................6

Outline .......................................................................6

Schematic .................................................................6

Component Description .............................................7

CAN Communication .................................................7

Switch Operation .......................................................7

ICC System Display ..................................................8

ACTION TEST .....................................................9

ICC System Running Test .........................................9

LASER BEAM AIMING ADJUSTMENT .............12

Outline of Laser Beam Aiming Adjustment Proce-

dure .........................................................................

12

Preparation ..............................................................12

Setting up the ICC Target Board .............................12

Sensor Adjustment ..................................................14

ELECTRICAL UNITS LOCATION ......................18

Component Parts and Harness Connector Loca-

tion ..........................................................................

18

WIRING DIAGRAM ...........................................19

Schematic ................................................................19

Wiring Diagram - ICC - ............................................20

TERMINALS AND REFERENCE VALUE .........24

Terminal and Reference Value for ICC Unit ............24

Terminal and Reference Value for ICC Sensor .......24

TROUBLE DIAGNOSIS — GENERAL DE-

SCRIPTION .......................................................

25

Work Flow ................................................................25

CONSULT-II Function (ICC) ....................................25

Self-Diagnostic Function ..........................................30

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS .................................................

34

Diagnostic Trouble Code (DTC) Chart ....................34

DTC 11 CONTROL UNIT ........................................36

DTC 12 VDC CONTROL UNIT ................................36

DTC 20 CAN COMM CIRCUIT ................................37

DTC 31 POWER SUPPLY CIR1, DTC 34 POWER

SUPPLY CIR2 .........................................................

37

DTC 41 VHCL SPEED SE CIRC .............................38

DTC 43 VDC/TCS/ABS CIRC .................................38

DTC 45 BRAKE SW/STOP L SW ............................38

DTC 46 OPERATION SW CIRC .............................40

DTC 74 LASER BEAM OFF CNTR .........................41

DTC 90 STOP LAMP RLY FIX ................................41

DTC 92 ECM CIRCUIT ............................................45

DTC 96 NP RANGE ................................................45

DTC 97 AT CIRCUIT ...............................................46

DTC 98 GEAR POSITION .......................................46

DTC 102 LASER STAIN ..........................................47

DTC 103 LASER SENSOR FAIL .............................47

DTC 104 LASER AIMING INCMP ...........................48

DTC 107 LASER COMM FAIL ................................48

DTC 109 LASER HIGH TEMP ................................48

TROUBLE DIAGNOSIS FOR SYMPTOMS ......49

Symptom Chart ........................................................49

Page 712 of 3061

BL-1

BODY

C

D

E

F

G

H

J

K

L

M

SECTION BL

A

B

BL

N

O

P

CONTENTS

BODY, LOCK & SECURITY SYSTEM

SERVICE INFORMATION ............................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for work ...................................................3

PREPARATION ...................................................4

Special Service Tool .................................................4

Commercial Service Tool ..........................................4

SQUEAK AND RATTLE TROUBLE DIAGNO-

SIS .......................................................................

5

Work Flow .................................................................5

Generic Squeak and Rattle Troubleshooting ............7

Diagnostic Worksheet ...............................................9

HOOD .................................................................11

Fitting Adjustment ...................................................11

Removal and Installation of Hood Assembly ...........12

Removal and Installation of Hood Lock Control ......13

Hood Lock Control Inspection .................................14

POWER DOOR LOCK SYSTEM ........................15

Component Parts and Harness Connector Loca-

tion ..........................................................................

15

System Description .................................................15

Schematic ...............................................................18

Wiring Diagram - D/LOCK - .....................................19

Terminal and Reference Value for BCM .................23

Work Flow ...............................................................23

CONSULT-II Function (BCM) ..................................24

Trouble Diagnosis Symptom Chart .........................25

BCM Power Supply and Ground Circuit Inspection

....

25

Door Switch Check ..................................................25

Key Switch (Insert) Check .......................................27

Door Lock/Unlock Switch Check .............................28

Glass Hatch Switch Circuit Inspection ....................30

Front Door Lock Assembly LH (Actuator) Check ....32

Front Door Lock Actuator RH Check .......................32

Rear Door Lock Actuator RH/LH Check ..................33

Glass Hatch Lock Actuator Check ...........................34

Front Door Lock Assembly LH (Key Cylinder

Switch) Check ..........................................................

35

REMOTE KEYLESS ENTRY SYSTEM .............37

Component Parts and Harness Connector Loca-

tion ...........................................................................

37

System Description ..................................................37

CAN Communication System Description ...............40

Schematic ................................................................41

Wiring Diagram - KEYLES - ....................................42

Terminal and Reference Value for BCM ..................44

Terminal and Reference Value for IPDM E/R ..........44

CONSULT-II Function (BCM) ..................................45

CONSULT-II Start Procedure ..................................45

CONSULT-II Application Item ..................................45

Trouble Diagnosis Procedure ..................................47

BCM Power Supply and Ground Circuit Inspection

....

47

Trouble Diagnosis ....................................................47

Key Switch (Insert) Check .......................................49

Door Switch Check ..................................................49

Keyfob Battery and Function Check ........................52

Remote Keyless Entry Receiver System Inspec-

tion ...........................................................................

53

ACC Power Check ...................................................54

IPDM E/R Operation Check .....................................54

Check Hazard Function ...........................................55

Check Horn Function ...............................................55

Check Headlamp Function ......................................55

Check Map Lamp Illumination Function ..................56

ID Code Entry Procedure ........................................56

Keyfob Battery Replacement ...................................59

VEHICLE SECURITY (THEFT WARNING)

SYSTEM ............................................................

60

Component Parts and Harness Connector Loca-

tion ...........................................................................

60

System Description ..................................................61

Page 714 of 3061

PRECAUTIONS

BL-3

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003532884

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for workINFOID:0000000003532885

• After removing and installing the opening/closing parts, be sure to carry out fitting adjustments to check their

operation.

• Check the lubrication level, damage, and wear of each part. If necessary, grease or replace it.

Page 719 of 3061

BL-8

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lense loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 899 of 3061

BR-1

BRAKES

C

D

E

G

H

I

J

K

L

M

SECTION BR

A

B

BR

N

O

P

CONTENTS

BRAKE SYSTEM

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

Precaution for Brake System ....................................2

PREPARATION ...................................................3

Special Service Tool .................................................3

Commercial Service Tool ..........................................3

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

4

NVH Troubleshooting Chart ......................................4

BRAKE PEDAL ...................................................5

Inspection and Adjustment ........................................5

Removal and Installation ...........................................6

BRAKE FLUID .....................................................8

On Board Inspection .................................................8

Drain and Refill ..........................................................8

Bleeding Brake System .............................................8

BRAKE PIPING AND HOSE ..............................10

Hydraulic Circuit ......................................................10

Removal and Installation of Front Brake Hose ........10

Removal and Installation of Rear Brake Hose ........11

Inspection After Installation .....................................12

BRAKE MASTER CYLINDER ............................13

On Board Inspection ...............................................13

Removal and Installation .........................................13

Disassembly and Assembly ....................................14

BRAKE BOOSTER ...........................................15

On-Vehicle Service ..................................................15

Removal and Installation .........................................15

VACUUM LINES ...............................................17

Removal and Installation .........................................17

Inspection ................................................................17

FRONT DISC BRAKE .......................................18

On-vehicle Inspection ..............................................18

Component ..............................................................18

Removal and Installation of Brake Pad ...................19

Removal and Installation of Brake Caliper and

Disc Rotor ................................................................

19

Disassembly and Assembly of Brake Caliper ..........20

REAR DISC BRAKE .........................................24

On-vehicle Inspection ..............................................24

Exploded View .........................................................24

Removal and Installation of Brake Pad ...................25

Removal and Installation of Brake Caliper and

Disc Rotor ................................................................

25

Brake Caliper ...........................................................26

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

29

General Specification ..............................................29

Brake Pedal .............................................................29

Brake Booster ..........................................................30

Check Valve ............................................................30

Front Disc Brake ......................................................30

Rear Disc Brake ......................................................30

Page 929 of 3061

BRC-1

BRAKES

C

D

E

G

H

I

J

K

L

M

SECTION BRC

A

B

BRC

N

O

P

CONTENTS

BRAKE CONTROL SYSTEM

VDC/TCS/ABS

SERVICE INFORMATION ............................

3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for Brake System ....................................3

Precaution When Using CONSULT-II .......................3

Precaution for Brake Control .....................................4

Precaution for CAN System ......................................4

PREPARATION ...................................................6

Special Service Tool .................................................6

Commercial Service Tool ..........................................6

SYSTEM DESCRIPTION .....................................7

System Component ...................................................7

ABS Function ............................................................8

EBD Function ............................................................8

TCS Function ............................................................8

VDC Function ............................................................8

Fail-Safe Function .....................................................8

Hydraulic Circuit Diagram .........................................9

CAN COMMUNICATION ....................................10

System Description .................................................10

TROUBLE DIAGNOSIS .....................................11

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ......................................................

11

Component Parts and Harness Connector Loca-

tion ..........................................................................

14

Schematic ...............................................................15

Wiring Diagram - VDC - ..........................................16

Basic Inspection ......................................................22

Warning Lamp and Indicator Timing .......................23

Control Unit Input/Output Signal Standard ..............23

CONSULT-II Function (ABS) ..................................26

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS .................................................

34

Wheel Sensor System Inspection ............................34

Engine System Inspection .......................................35

ABS/TCS/VDC Control Unit Inspection ...................35

Steering Angle Sensor System ................................36

Yaw Rate/Side/Decel G Sensor System Inspec-

tion ...........................................................................

37

Solenoid and VDC Change-Over Valve System

Inspection ................................................................

38

Actuator Motor, Motor Relay, and Circuit Inspec-

tion ...........................................................................

39

Stop Lamp Switch System Inspection .....................40

ABS/TCS/VDC Control Unit Power and Ground

Systems Inspection .................................................

41

Brake Fluid Level Switch System Inspection ...........42

Active Booster System Inspection ...........................43

Delta Stroke Sensor System Inspection ..................44

Pressure Sensor System Inspection .......................45

Steering Angle Sensor Safe Mode Inspection .........47

CAN Communication System Inspection .................48

ICC System Inspection ............................................48

Inspection for Self-Diagnosis Result "ST ANG

SEN SIGNAL" ..........................................................

48

Inspection for Self-Diagnosis Result "DECEL G

SEN SET" ................................................................

49

TROUBLE DIAGNOSES FOR SYMPTOMS .....50

ABS Works Frequently ............................................50

Unexpected Pedal Action ........................................50

Long Stopping Distance ..........................................51

ABS Does Not Work ................................................51

Pedal Vibration or ABS Operation Noise .................51

Vehicle Jerks During TCS/VDC Activation ..............52

Component Inspection .............................................53

ON-VEHICLE SERVICE ....................................54

Adjustment of Steering Angle Sensor Neutral Po-

sition ........................................................................

54

Calibration of Decel G Sensor .................................54

Page 1051 of 3061

DI-40

< SERVICE INFORMATION >

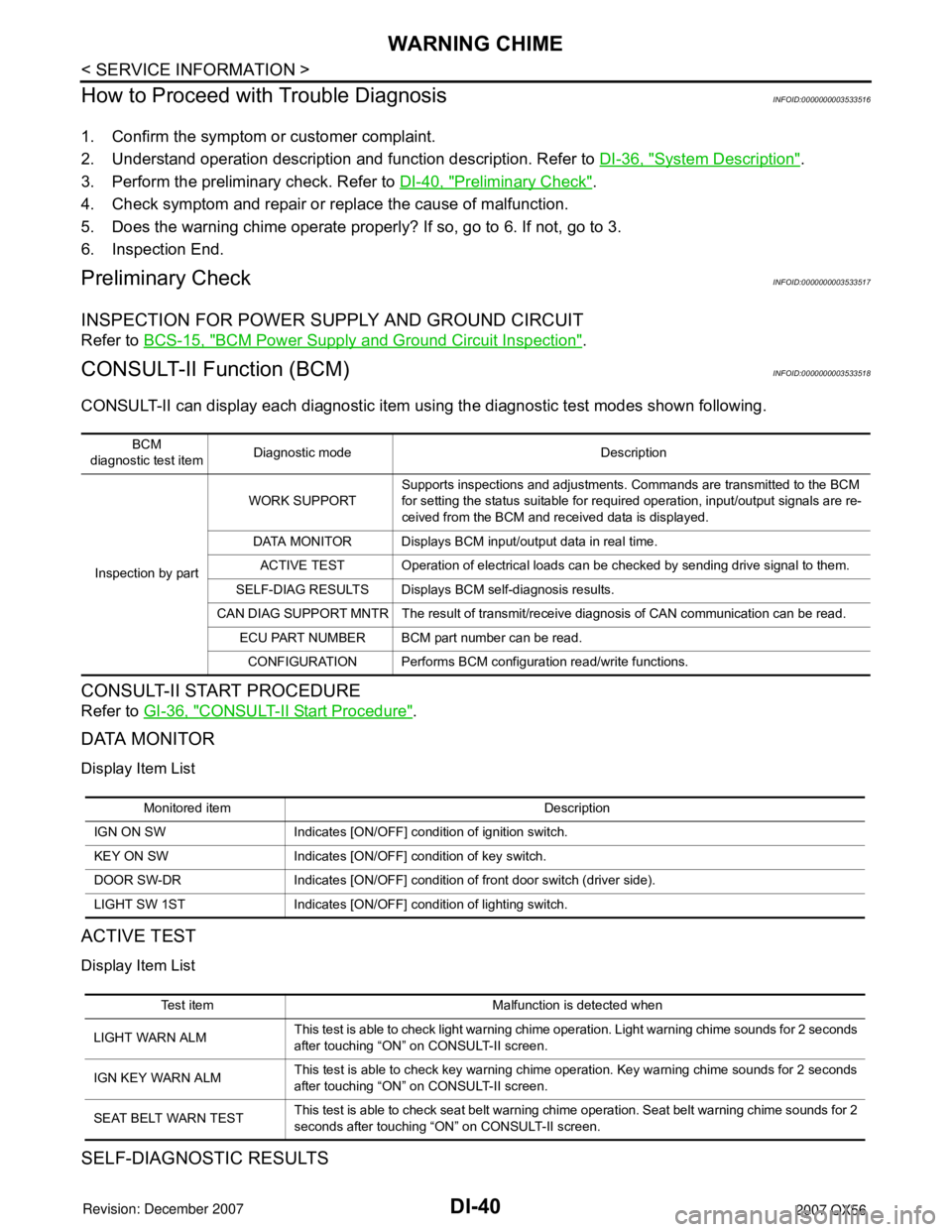

WARNING CHIME

How to Proceed with Trouble Diagnosis

INFOID:0000000003533516

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer to DI-36, "

System Description".

3. Perform the preliminary check. Refer to DI-40, "

Preliminary Check".

4. Check symptom and repair or replace the cause of malfunction.

5. Does the warning chime operate properly? If so, go to 6. If not, go to 3.

6. Inspection End.

Preliminary CheckINFOID:0000000003533517

INSPECTION FOR POWER SUPPLY AND GROUND CIRCUIT

Refer to BCS-15, "BCM Power Supply and Ground Circuit Inspection".

CONSULT-II Function (BCM)INFOID:0000000003533518

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

DATA MONITOR

Display Item List

ACTIVE TEST

Display Item List

SELF-DIAGNOSTIC RESULTS

BCM

diagnostic test itemDiagnostic mode Description

Inspection by partWORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the BCM

for setting the status suitable for required operation, input/output signals are re-

ceived from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ECU PART NUMBER BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

Monitored item Description

IGN ON SW Indicates [ON/OFF] condition of ignition switch.

KEY ON SW Indicates [ON/OFF] condition of key switch.

DOOR SW-DR Indicates [ON/OFF] condition of front door switch (driver side).

LIGHT SW 1ST Indicates [ON/OFF] condition of lighting switch.

Test item Malfunction is detected when

LIGHT WARN ALMThis test is able to check light warning chime operation. Light warning chime sounds for 2 seconds

after touching “ON” on CONSULT-II screen.

IGN KEY WARN ALMThis test is able to check key warning chime operation. Key warning chime sounds for 2 seconds

after touching “ON” on CONSULT-II screen.

SEAT BELT WARN TESTThis test is able to check seat belt warning chime operation. Seat belt warning chime sounds for 2

seconds after touching “ON” on CONSULT-II screen.

Page 1736 of 3061

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

EI-7

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

EI

N

O

P

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the console panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the console at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator installation pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Page 1908 of 3061

FRONT OIL SEAL

FFD-9

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FFD

N

O

P

INSTALLATION

1. Apply multi-purpose grease to the lips of the new front oil seal.

Then drive the new front oil seal in evenly to the gear carrier

using Tool.

CAUTION:

• Do not reuse front oil seal.

• Do not incline the new front oil seal when installing.

• Apply multi-purpose grease to the lips of the new front oil

seal.

2. Install the companion flange to the drive pinion while aligning the matching marks.

3. Apply anti-corrosive oil to the threads of the drive pinion and the

seating surface of the new drive pinion lock nut. Then adjust the

drive pinion lock nut tightening torque using Tool A, and check

the total preload torque using Tool B.

• The total preload torque should be within the total preload

torque specification. When not replacing the collapsible

spacer, it should also be equal to the measurement taken dur-

ing removal plus an additional 0.56 N·m (0.06 Kg-m, 5 in-lb).

• If the total preload torque is low, tighten the drive pinion lock

nut in 6.8 N·m (0.69 Kg-m, 5ft-lb) increments until the total pre-

load torque is met.

CAUTION:

• Do not reuse drive pinion lock nut.

• Apply anti-corrosive oil to the threads of the drive pinion

and the seating surface of the new drive pinion lock nut.

• Adjust the drive pinion lock nut tightening torque to the

lower limit first. Do not exceed the drive pinion lock nut

specified torque. Refer to FFD-13, "

Disassembly and Assembly".

• Do not loosen drive pinion lock nut to adjust the total preload torque. If the drive pinion lock nut

torque or the total preload torque exceeds the specifications, replace the collapsible spacer and

tighten it again to adjust. Refer to FFD-13, "

Disassembly and Assembly".

• After adjustment, rotate drive pinion back and forth 2 to 3 times to check for unusual noise, rota-

tion malfunction, and other malfunctions.

4. Installation of the remaining components is in the reverse order of removal.

CAUTION:

Check the differential gear oil level after installation. Refer to FFD-7

. Tool number : KV38100500 (J-25273)

BDIA0003E

Tool number A: KV38108300 ( — )

B: ST3127S000 (J-25765-A)

Total preload torque: Refer to FFD-13, "

Disassem-

bly and Assembly".

WDIA0381E

Page 1926 of 3061

FRONT FINAL DRIVE ASSEMBLY

FFD-27

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FFD

N

O

P

10. Apply anti-corrosive oil to the threads of the drive pinion and the

seating surface of the new drive pinion lock nut. Then adjust the

drive pinion lock nut tightening torque using Tool A, and check

the drive pinion bearing preload torque using Tool B.

CAUTION:

• Do not reuse drive pinion lock nut.

• Apply anti-corrosive oil to the threads of the drive pinion

and the seating surface of the new drive pinion lock nut.

• Adjust the drive pinion lock nut tightening torque to the

lower limit first. Do not exceed the drive pinion lock nut

specified torque.

• If the drive pinion bearing preload torque exceeds the

specified value, replace collapsible spacer and tighten it

again to adjust. Do not loosen drive pinion lock nut to

adjust the drive pinion bearing preload torque.

• After adjustment, rotate drive pinion back and forth 2 to 3

times to check for unusual noise, rotation malfunction,

and other malfunctions.

11. Check companion flange runout.

12. Install the differential case assembly.

Differential Assembly

1. Install side gear thrust washers with the same thickness as the

ones installed prior to disassembly, or reinstall the old ones on

the side gears.

2. Install the side gears and side gear thrust washers into the dif-

ferential case.

3. Install the pinion mate thrust washers to the two pinion mate

gears. Then install the pinion mate gears with the pinion mate

thrust washers by aligning them in diagonally opposite positions

and rotating them into the differential case.Tool number A: KV38108300 (J-44195)

B: ST3127S000 (J-25765-A)

Drive pinion bearing preload torque:

2.3 - 3.4 N·m (24 - 34 kg-cm, 21 - 30 in-lb)

WDIA0382E

SDIA0193J

SDIA2025E