heater INFINITI QX56 2007 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1091 of 3061

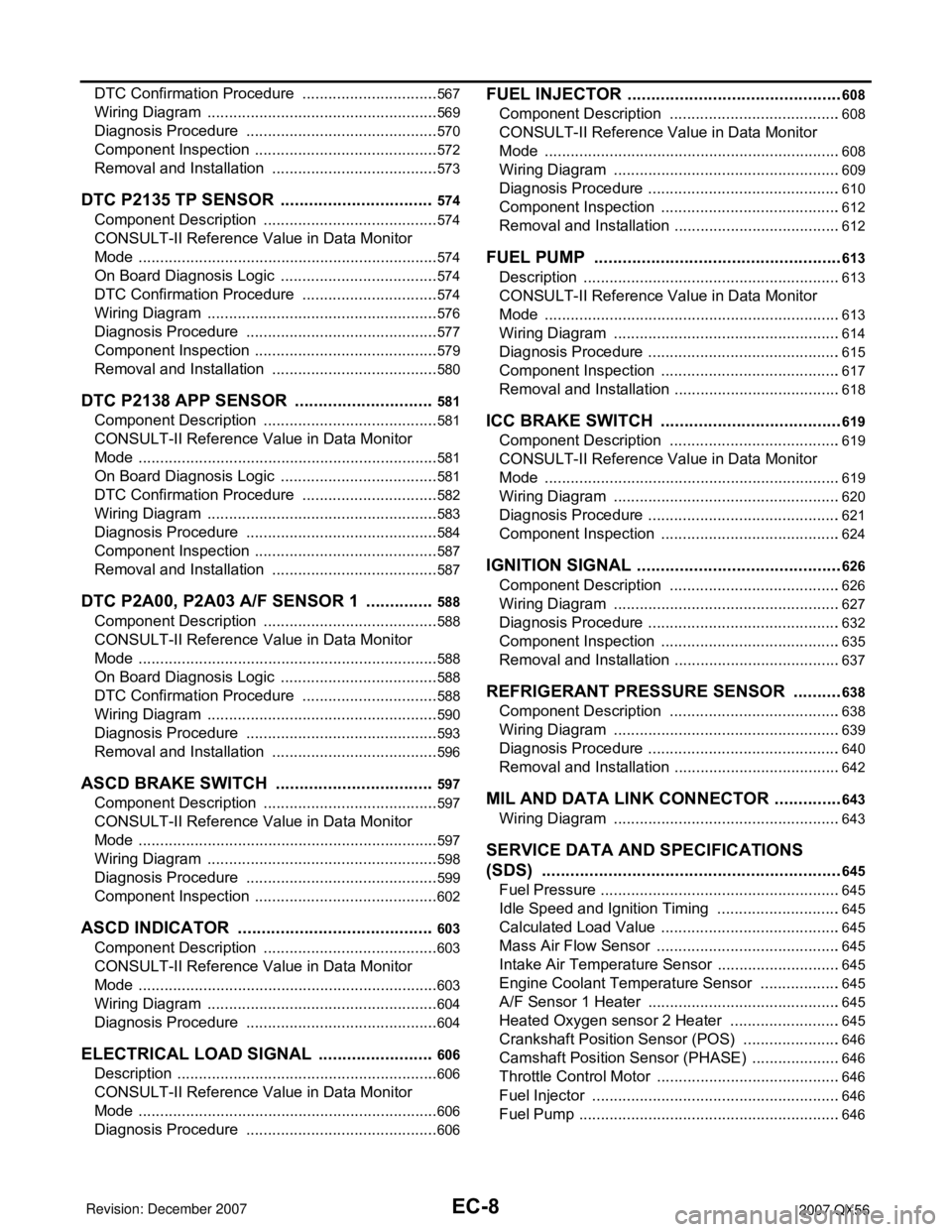

EC-8

DTC Confirmation Procedure ................................567

Wiring Diagram ......................................................569

Diagnosis Procedure .............................................570

Component Inspection ...........................................572

Removal and Installation .......................................573

DTC P2135 TP SENSOR .................................574

Component Description .........................................574

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

574

On Board Diagnosis Logic .....................................574

DTC Confirmation Procedure ................................574

Wiring Diagram ......................................................576

Diagnosis Procedure .............................................577

Component Inspection ...........................................579

Removal and Installation .......................................580

DTC P2138 APP SENSOR ..............................581

Component Description .........................................581

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

581

On Board Diagnosis Logic .....................................581

DTC Confirmation Procedure ................................582

Wiring Diagram ......................................................583

Diagnosis Procedure .............................................584

Component Inspection ...........................................587

Removal and Installation .......................................587

DTC P2A00, P2A03 A/F SENSOR 1 ...............588

Component Description .........................................588

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

588

On Board Diagnosis Logic .....................................588

DTC Confirmation Procedure ................................588

Wiring Diagram ......................................................590

Diagnosis Procedure .............................................593

Removal and Installation .......................................596

ASCD BRAKE SWITCH ..................................597

Component Description .........................................597

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

597

Wiring Diagram ......................................................598

Diagnosis Procedure .............................................599

Component Inspection ...........................................602

ASCD INDICATOR ..........................................603

Component Description .........................................603

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

603

Wiring Diagram ......................................................604

Diagnosis Procedure .............................................604

ELECTRICAL LOAD SIGNAL .........................606

Description .............................................................606

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

606

Diagnosis Procedure .............................................606

FUEL INJECTOR ..............................................608

Component Description ........................................608

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

608

Wiring Diagram .....................................................609

Diagnosis Procedure .............................................610

Component Inspection ..........................................612

Removal and Installation .......................................612

FUEL PUMP .....................................................613

Description ............................................................613

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

613

Wiring Diagram .....................................................614

Diagnosis Procedure .............................................615

Component Inspection ..........................................617

Removal and Installation .......................................618

ICC BRAKE SWITCH .......................................619

Component Description ........................................619

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

619

Wiring Diagram .....................................................620

Diagnosis Procedure .............................................621

Component Inspection ..........................................624

IGNITION SIGNAL ............................................626

Component Description ........................................626

Wiring Diagram .....................................................627

Diagnosis Procedure .............................................632

Component Inspection ..........................................635

Removal and Installation .......................................637

REFRIGERANT PRESSURE SENSOR ...........638

Component Description ........................................638

Wiring Diagram .....................................................639

Diagnosis Procedure .............................................640

Removal and Installation .......................................642

MIL AND DATA LINK CONNECTOR ...............643

Wiring Diagram .....................................................643

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

645

Fuel Pressure ........................................................645

Idle Speed and Ignition Timing .............................645

Calculated Load Value ..........................................645

Mass Air Flow Sensor ...........................................645

Intake Air Temperature Sensor .............................645

Engine Coolant Temperature Sensor ...................645

A/F Sensor 1 Heater .............................................645

Heated Oxygen sensor 2 Heater ..........................645

Crankshaft Position Sensor (POS) .......................646

Camshaft Position Sensor (PHASE) .....................646

Throttle Control Motor ...........................................646

Fuel Injector ..........................................................646

Fuel Pump .............................................................646

Page 1144 of 3061

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-61

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

HOW TO ERASE EMISSION-RELATED DIAGNOSTIC INFORMATION

How to Erase DTC

WITH CONSULT-II

The emission related diagnostic information in the ECM can be erased by selecting “ERASE” in the “SELF-

DIAG RESULTS” mode with CONSULT-II.

If DTCs are displayed for both ECM and TCM (Transmission control module), they need to be erased individu-

ally from the ECM and TCM (Transmission control module).

NOTE:

If the DTC is not for A/T related items (see EC-9

), skip steps 2 through 4.

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Turn CONSULT-II ON and touch “A/T”.

3. Touch “SELF-DIAG RESULTS”.

HO2SAir fuel ratio (A/F) sensor 1 (Bank 1)P0131 41H 8EH Min. 5mV

P0132 42H 0EH Max. 5mV

P2A00 43H 0EH Max. 0.002

P2A00 44H 8EH Min. 0.002

P0133 45H 8EH Min. 0.002

P0130 46H 0EH Max. 5mV

P0130 47H 8EH Min. 5mV

P0133 48H 8EH Min. 0.002

Air fuel ratio (A/F) sensor 1 (Bank 2)P0151 4CH 8FH Min. 5mV

P0152 4DH 0FH Max. 5mV

P2A03 4EH 0FH Max. 0.002

P2A03 4FH 8FH Min. 0.002

P0153 50H 8FH Min. 0.002

P0150 51H 0FH Max. 5mV

P0150 52H 8FH Min. 5mV

P0153 53H 8FH Min. 0.002

Heated oxygen sensor 2 (Bank 1)P0139 19H 86H Min. 10mV/500 ms

P0137 1AH 86H Min. 10 mV

P0138 1BH 06H Max. 10 mV

P0138 1CH 06H Max. 10mV

Heated oxygen sensor 2 (Bank 2)P0159 21H 87H Min. 10 mV/500 ms

P0157 22H 87H Min. 10 mV

P0158 23H 07H Max. 10 mV

P0158 24H 07H Max. 10mV

HO2S

HTRA/F sensor 1 heater (Bank 1) P0032 57H 10H Max. 5 mV

P0031 58H 90H Min. 5 mV

A/F sensor 1 heater (Bank 2)P0052 59H 11H Max. 5 mV

P0051 5AH 91H Min. 5 mV

Heated oxygen sensor 2 heater (Bank 1)P0038 2DH 0AH Max. 20 mV

P0037 2EH 8AH Min. 20 mV

Heated oxygen sensor 2 heater (Bank 2)P0058 2FH 0BH Max. 20 mV

P0057 30H 8BH Min. 20 mV Item Self-diagnostic test item DTCTest value (GST display)

Test limit Conversion

TID CID

Page 1171 of 3061

EC-88

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Fail-Safe Chart

INFOID:0000000003531619

When the DTC listed below is detected, the ECM enters fail-safe mode and the MIL lights up.

Priority Detected items (DTC)

1 • U1000 U1001 CAN communication line

• U1010 CAN communication

• P0101 P0102 P0103 Mass air flow sensor

• P0112 P0113 P0127 Intake air temperature sensor

• P0117 P0118 P0125 Engine coolant temperature sensor

• P0122 P0123 P0222 P0223 P1225 P1226 P2135 Throttle position sensor

• P0128 Thermostat function

• P0181 P0182 P0183 Fuel tank temperature sensor

• P0327 P0328 P0332 P0333 Knock sensor

• P0335 Crankshaft position sensor (POS)

• P0340 Camshaft position sensor (PHASE)

• P0460 P0461 P0462 P0463 Fuel level sensor

• P0500 Vehicle speed sensor

• P0605 ECM

• P0643 Sensor power supply

• P0700 TCM

• P0705 Park/neutral position (PNP) switch

• P0850 Park/neutral position (PNP) switch

• P1550 P1551 P1552 P1553 P1554 Battery current sensor

• P1610 - P1615 NATS

• P2122 P2123 P2127 P2128 P2138 Accelerator pedal position sensor

2 • P0031 P0032 P0051 P0052 Air fuel ratio (A/F) sensor 1 heater

• P0037 P0038 P0057 P0058 Heated oxygen sensor 2 heater

• P0075 P0081 Intake valve timing control solenoid valve

• P0130 P0131 P0132 P0133 P0150 P0151 P0152 P0153 P2A00 P2A03 Air fuel ratio (A/F) sensor 1

• P0137 P0138 P0139 P0157 P0158 P0159 Heated oxygen sensor 2

• P0441 EVAP control system purge flow monitoring

• P0443 P0444 P0445 EVAP canister purge volume control solenoid valve

• P0447 P0448 EVAP canister vent control valve

• P0451 P0452 P0453 EVAP control system pressure sensor

• P0550 Power steering pressure sensor

• P0603 ECM power supply

• P0710 P0717 P0720 P0740 P0744 P0745 P1730 P1752 P1754 P1757 P1759 P1762 P1764 P1767 P1769 P1772

P1774 A/T related sensors, solenoid valves and switches

• P1217 Engine over temperature (OVERHEAT)

• P1140 P1145 Intake valve timing control position sensor

• P1805 Brake switch

• P2100 P2103 P2118 Electric throttle control actuator

• P2101 Electric throttle control function

3 • P0011 P0021 Intake valve timing control

• P0171 P0172 P0174 P0175 Fuel injection system function

• P0300 - P0308 Misfire

• P0420 P0430 Three way catalyst function

• P0442 EVAP control system (SMALL LEAK)

• P0455 EVAP control system (GROSS LEAK)

• P0456 EVAP control system (VERY SMALL LEAK)

• P0506 P0507 Idle speed control system

• P1148 P1168 Closed loop control

• P1211 TCS control unit

• P1212 TCS communication line

• P1421 Cold start control

• P1564 ICC/ASCD steering switch

• P1568 ICC command value

• P1572 ICC/ASCD brake switch

• P1574 ICC/ASCD vehicle speed sensor

• P2119 Electric throttle control actuator

Page 1186 of 3061

TROUBLE DIAGNOSIS

EC-103

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

ECM Harness Connector Terminal LayoutINFOID:0000000003531624

ECM Terminal and Reference ValueINFOID:0000000003531625

PREPARATION

ECM is located in the engine room passenger side behind battery.

ECM INSPECTION TABLE

Specification data are reference values and are measured between each terminal and ground.

Pulse signal is measured by CONSULT-II.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECMs transistor. Use a ground other than ECM terminals, such as the ground.

PBIB3368E

BBIA0386E

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

1 B ECM ground[Engine is running]

• Idle speedBody ground

2 LG/B A/F sensor 1 heater (bank 1)[Engine is running]

•Warm-up condition

• Idle speed

(More than 140 seconds after starting en-

gine)Approximately 2.9 - 8.8V

3LThrottle control motor relay

power supply[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

4 L/W Throttle control motor (Close)[Ignition switch: ON]

• Engine: Stopped

• Selector lever: D

• Accelerator pedal: Fully released0 - 14V

PBIA8148J

PBIB1104E

Page 1189 of 3061

![INFINITI QX56 2007 Factory Workshop Manual EC-106

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

21

22

23

44O/L

BR

GR/W

OFuel injector No. 5

Fuel injector No. 3

Fuel injector No. 1

Fuel injector No. 7[Engine is running]

•Warm-up condition

• Idl INFINITI QX56 2007 Factory Workshop Manual EC-106

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

21

22

23

44O/L

BR

GR/W

OFuel injector No. 5

Fuel injector No. 3

Fuel injector No. 1

Fuel injector No. 7[Engine is running]

•Warm-up condition

• Idl](/img/42/57029/w960_57029-1188.png)

EC-106

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

21

22

23

44O/L

BR

GR/W

OFuel injector No. 5

Fuel injector No. 3

Fuel injector No. 1

Fuel injector No. 7[Engine is running]

•Warm-up condition

• Idle speed

NOTE:

The pulse cycle changes depending on rpm at

idleBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

•Warm-up condition

• Engine speed: 2,000 rpmBATTERY VOLTAGE

(11 - 14V)

24

43GR/G

GR/GA/F sensor 1 heater (bank 2)[Engine is running]

•Warm-up condition

• Idle speed

(More than 140 seconds after starting en-

gine)Approximately 2.9 - 8.8V

25 O/GHeated oxygen sensor 2 heat-

er (bank 2)[Engine is running]

• Engine speed: Below 3,600 rpm after the

following conditions are met.

- Engine: After warming up

- Keeping the engine speed between 3,500

and 4,000 rpm for 1 minute and at idle for 1

minute under no load0 - 1.0V

[Ignition switch: ON]

• Engine: Stopped

[Engine is running]

• Engine speed: Above 3,600 rpmBATTERY VOLTAGE

(11 - 14V)

32 LEVAP control system pres-

sure sensor[Ignition switch: ON]Approximately 1.8 - 4.8V

34 R/B Intake air temperature sensor[Engine is running]Approximately 0 - 4.8V

Output voltage varies with intake

air temperature.

35 BR/R A/F sensor 1 (bank 1)[Engine is running]

•Warm-up condition

• Engine speed: 2,000 rpmApproximately 1.8V

Output voltage varies with air fuel

ratio.

36 W Knock sensor (bank 2)[Engine is running]

• Idle speedApproximately 2.5V TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)SEC984C

SEC985C

PBIA8148J

Page 1196 of 3061

TROUBLE DIAGNOSIS

EC-113

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

X: Applicable

*1: This item includes 1st trip DTCs.

*2: This mode includes 1st trip freeze frame data or freeze frame data. The items appear on CONSULT-II screen in freeze frame data

mode only if a 1st trip DTC or DTC is detected. For details, refer to "Freeze Frame Data and 1st Trip Freeze Frame Data".

INSPECTION PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

WORK SUPPORT MODE

Work Item

ENGINE CONTROL COMPONENT PARTS

OUTPUT

Fuel injector×× ×

Power transistor (Ignition timing)×× ×

Throttle control motor relay×××

Throttle control motor×

EVAP canister purge volume con-

trol solenoid valve×××××

Air conditioner relay××

Fuel pump relay××××

Cooling fan relay××××

Air fuel ratio (A/F) sensor 1 heater××××

Heated oxygen sensor 2 heater××××

EVAP canister vent control valve×× ×××

Intake valve timing control solenoid

valve××××

Alternator×× ×

Calculated load value××× ItemDIAGNOSTIC TEST MODE

WORK

SUP-

PORTSELF-DIAGNOSTIC

RESULTS

DATA

MONI-

TORDATA

MONI-

TOR

(SPEC)ACTIVE

TESTDTC & SRT

CONFIRMATION

DTC*1FREEZE

FRAME

DATA*2SRT

STATUSDTC

WORK

SUP-

PORT

WORK ITEM CONDITION USAGE

FUEL PRESSURE RELEASE • FUEL PUMP WILL STOP BY TOUCHING “START” DUR-

ING IDLING.

CRANK A FEW TIMES AFTER ENGINE STALLS.When releasing fuel pressure from

fuel line

IDLE AIR VOL LEARN • THE IDLE AIR VOLUME THAT KEEPS THE ENGINE

WITHIN THE SPECIFIED RANGE IS MEMORIZED IN

ECM.When learning the idle air volume

SELF-LEARNING CONT • THE COEFFICIENT OF SELF-LEARNING CONTROL

MIXTURE RATIO RETURNS TO THE ORIGINAL COEF-

FICIENT.When clearing the coefficient of

self-learning control value

Page 1199 of 3061

![INFINITI QX56 2007 Factory Workshop Manual EC-116

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

FUEL T/TMP SE

[°C] or [°F]ו The fuel temperature (determined by the

signal voltage of the fuel tank tempera-

ture sensor) is displayed.

INT/A T INFINITI QX56 2007 Factory Workshop Manual EC-116

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

FUEL T/TMP SE

[°C] or [°F]ו The fuel temperature (determined by the

signal voltage of the fuel tank tempera-

ture sensor) is displayed.

INT/A T](/img/42/57029/w960_57029-1198.png)

EC-116

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

FUEL T/TMP SE

[°C] or [°F]ו The fuel temperature (determined by the

signal voltage of the fuel tank tempera-

ture sensor) is displayed.

INT/A TEMP SE

[°C] or [°F]×ו The intake air temperature (determined

by the signal voltage of the intake air

temperature sensor) is indicated.

EVAP SYS PRES

[V]ו The signal voltage of EVAP control sys-

tem pressure sensor is displayed.

FUEL LEVEL SE [V]ו The signal voltage of the fuel level sen-

sor is displayed.

START SIGNAL

[ON/OFF]×ו Indicates start signal status [ON/OFF]

computed by the ECM according to the

signals of engine speed and battery volt-

age.• After starting the engine, [OFF] is dis-

played regardless of the starter signal.

CLSD THL POS

[ON/OFF]×ו Indicates idle position [ON/OFF] comput-

ed by ECM according to the accelerator

pedal position sensor signal.

AIR COND SIG

[ON/OFF]×ו Indicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

P/N POSI SW

[ON/OFF]×ו Indicates [ON/OFF] condition from the

park/neutral position (PNP) switch sig-

nal.

PW/ST SIGNAL

[ON/OFF]×ו [ON/OFF] condition of the power steering

system (determined by the signal voltage

of the power steering pressure sensor

signal) is indicated.

LOAD SIGNAL [ON/

OFF]×ו Indicates [ON/OFF] condition from the

electrical load signal.

ON: Rear window defogger switch is ON

and/or lighting switch is in 2nd position.

OFF: Both rear window defogger switch

and lighting switch are OFF.

IGNITION SW

[ON/OFF]ו Indicates [ON/OFF] condition from igni-

tion switch signal.

HEATER FAN SW

[ON/OFF]ו Indicates [ON/OFF] condition from heat-

er fan switch signal.

BRAKE SW

[ON/OFF]ו Indicates [ON/OFF] condition from the

stop lamp switch signal.

INJ PULSE-B1

[msec]×

• Indicates the actual fuel injection pulse

width compensated by ECM according to

the input signals.• When the engine is stopped, a certain

computed value is indicated.

INJ PULSE-B2

[msec]

IGN TIMING [BT-

DC]ו Indicates the ignition timing computed by

ECM according to the input signals.• When the engine is stopped, a certain

value is indicated.

CAL/LD VALUE [%]• “Calculated load value” indicates the val-

ue of the current air flow divided by peak

air flow.

MASS AIRFLOW

[g·m/s]• Indicates the mass air flow computed by

ECM according to the signal voltage of

the mass air flow sensor. Monitored item

[Unit]ECM IN-

PUT SIG-

NALSMAIN

SIGNALSDescription Remarks

Page 1200 of 3061

![INFINITI QX56 2007 Factory Workshop Manual TROUBLE DIAGNOSIS

EC-117

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PURG VOL C/V [%]• Indicates the EVAP canister purge vol-

ume control solenoid valve control value

computed by the EC INFINITI QX56 2007 Factory Workshop Manual TROUBLE DIAGNOSIS

EC-117

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PURG VOL C/V [%]• Indicates the EVAP canister purge vol-

ume control solenoid valve control value

computed by the EC](/img/42/57029/w960_57029-1199.png)

TROUBLE DIAGNOSIS

EC-117

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PURG VOL C/V [%]• Indicates the EVAP canister purge vol-

ume control solenoid valve control value

computed by the ECM according to the

input signals.

• The opening becomes larger as the val-

ue increases.

INT/V TIM (B1)

[°CA]

• Indicates [°CA] of intake camshaft ad-

vanced angle.

INT/V TIM (B2)

[°CA]

INT/V SOL (B1) [%] • The control value of the intake valve tim-

ing control solenoid valve (determined by

ECM according to the input signals) is in-

dicated.

• The advance angle becomes larger as

the value increases. INT/V SOL (B2) [%]

AIR COND RLY

[ON/OFF]ו The air conditioner relay control condi-

tion (determined by ECM according to

the input signals) is indicated.

FUEL PUMP RLY

[ON/OFF]ו Indicates the fuel pump relay control con-

dition determined by ECM according to

the input signals.

VENT CONT/V

[ON/OFF]• The control condition of the EVAP canis-

ter vent control valve (determined by

ECM according to the input signals) is in-

dicated.

ON: Closed

OFF: Open

THRTL RELAY [ON/

OFF]ו Indicates the throttle control motor relay

control condition determined by the ECM

according to the input signals.

COOLING FAN

[HI/OFF]ו The control condition of the cooling fan

(determined by ECM according to the in-

put signals) is indicated.

HI: High speed operation

OFF: Stop

HO2S2 HTR (B1)

[ON/OFF]• Indicates [ON/OFF] condition of heated

oxygen sensor 2 heater determined by

ECM according to the input signals. HO2S2 HTR (B2)

[ON/OFF]

I/P PULLY SPD

[rpm]• Indicates the engine speed computed

from the turbine revolution sensor signal.

VEHICLE SPEED

[km/h] or [mph]• Indicates the vehicle speed computed

from the revolution sensor signal.

IDL A/V LEARN

[YET/CMPLT]• Display the condition of idle air volume

learning

YET: Idle Air Volume Learning has not

been performed yet.

CMPLT: Idle Air Volume Learning has al-

ready been performed successfully.

TRVL AFTER MIL

[km] or [mile]• Distance traveled while MIL is activated. Monitored item

[Unit]ECM IN-

PUT SIG-

NALSMAIN

SIGNALSDescription Remarks

Page 1201 of 3061

![INFINITI QX56 2007 Factory Workshop Manual EC-118

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

A/F S1 HTR (B1)

[%]• A/F sensor 1 heater control value com-

puted by ECM according to the input sig-

nals.

• The current flow to the heater become INFINITI QX56 2007 Factory Workshop Manual EC-118

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

A/F S1 HTR (B1)

[%]• A/F sensor 1 heater control value com-

puted by ECM according to the input sig-

nals.

• The current flow to the heater become](/img/42/57029/w960_57029-1200.png)

EC-118

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

A/F S1 HTR (B1)

[%]• A/F sensor 1 heater control value com-

puted by ECM according to the input sig-

nals.

• The current flow to the heater becomes

larger as the value increases. A/F S1 HTR (B2)

[%]

AC PRESS SEN [V]• The signal voltage from the refrigerant

pressure sensor is displayed.

VHCL SPEED SE

[km/h] or [mph]• The vehicle speed computed from the

vehicle speed signal sent from combina-

tion meter is displayed.

SET VHCL SPD

[km/h] or [mph]• The preset vehicle speed is displayed.

MAIN SW

[ON/OFF]• Indicates [ON/OFF] condition from MAIN

switch signal.

CANCEL SW

[ON/OFF]• Indicates [ON/OFF] condition from CAN-

CEL switch signal.

RESUME/ACC SW

[ON/OFF]• Indicates [ON/OFF] condition from RE-

SUME/ACCELERATE switch signal.

SET SW

[ON/OFF]• Indicates [ON/OFF] condition from SET/

COAST switch signal.

BRAKE SW1

[ON/OFF]• Indicates [ON/OFF] condition from

ASCD brake switch signal.

BRAKE SW2

[ON/OFF]• Indicates [ON/OFF] condition of stop

lamp switch signal.

DIST SW

[ON/OFF]• Indicates [ON/OFF] condition from DIS-

TANCE switch signal.

VHCL SPD CUT

[NON/CUT]• Indicates the vehicle cruise condition.

NON: Vehicle speed is maintained at the

ASCD set speed.

CUT: Vehicle speed increased to exces-

sively high compared with the ASCD set

speed, and ASCD operation is cut off.

LO SPEED CUT

[NON/CUT]• Indicates the vehicle cruise condition.

NON: Vehicle speed is maintained at the

ASCD set speed.

CUT: Vehicle speed decreased to exces-

sively low compared with the ASCD set

speed, and ASCD operation is cut off.

AT O D M O N I T O R

[ON/OFF]• Indicates [ON/OFF] condition of A/T O/D

according to the input signal from the

TCM.

AT O D C A N C E L

[ON/OFF]• Indicates [ON/OFF] condition of A/T O/D

cancel signal sent from the TCM.

CRUISE LAMP

[ON/OFF]• Indicates [ON/OFF] condition of CRUISE

lamp determined by the ECM according

to the input signals.

SET LAMP

[ON/OFF]• Indicates [ON/OFF] condition of SET

lamp determined by the ECM according

to the input signals.

ALT DUTY [%]• Indicates the duty ratio of the power gen-

eration command value. The ratio is cal-

culated by ECM based on the battery

current sensor signal.

BAT CUR SEN [mV]• The signal voltage of battery current sen-

sor is displayed. Monitored item

[Unit]ECM IN-

PUT SIG-

NALSMAIN

SIGNALSDescription Remarks

Page 1208 of 3061

TROUBLE DIAGNOSIS

EC-125

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

AIR COND SIG• Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

P/N POSI SW • Ignition switch: ONSelector lever: P or N ON

Selector lever: Except above OFF

PW/ST SIGNAL• Engine: After warming up, idle the

engineSteering wheel: Not being turned

(Forward direction)OFF

Steering wheel: Being turned ON

LOAD SIGNAL • Ignition switch: ONRear window defogger switch is ON

and/or lighting switch is in 2nd.ON

Rear window defogger switch is OFF

and lighting switch is OFF.OFF

IGNITION SW • Ignition switch: ON → OFF → ON ON → OFF → ON

HEATER FAN SW• Engine: After warming up, idle the

engineHeater fan control switch: ON ON

Heater fan control switch: OFF OFF

BRAKE SW • Ignition switch: ONBrake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

INJ PULSE-B1

INJ PULSE-B2• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle 2.0 - 2.8 msec

2,000 rpm 1.9 - 2.9 msec

IGN TIMING• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle 10° - 20° BTDC

2,000 rpm 25° - 45° BTDC

CAL/LD VALUE• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle 14% - 33%

2,500 rpm 12% - 25%

MASS AIRFLOW• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle 3.0 - 9.0 g·m/s

2,500 rpm 9.0 - 28.0 g·m/s

PURG VOL C/V• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle

(Accelerator pedal: Not depressed

even slightly, after engine starting.)0%

2,000 rpm —

INT/V TIM (B1)

INT/V TIM (B2)• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle−5° - 5°CA

2,000 rpm Approx. 0° - 20°CA

INT/V SOL (B1)

INT/V SOL (B2)• Engine: After warming up

• Selector lever: P or N

• Air conditioner switch: OFF

• No loadIdle 0% - 2%

2,000 rpm Approx. 25% - 50%

AIR COND RLY• Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor: Operates)ON

FUEL PUMP RLY• For 1 second after turning ignition switch ON

• Engine running or crankingON

• Except above conditions OFF

VENT CONT/V • Ignition switch: ON OFF

THRTL RELAY • Ignition switch: ON ONMONITOR ITEM CONDITION SPECIFICATION