battery INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 11 of 3061

ACCELERATOR CONTROL SYSTEM

ACC-3

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

ACC

N

P O

ACCELERATOR CONTROL SYSTEM

Removal and InstallationINFOID:0000000003532214

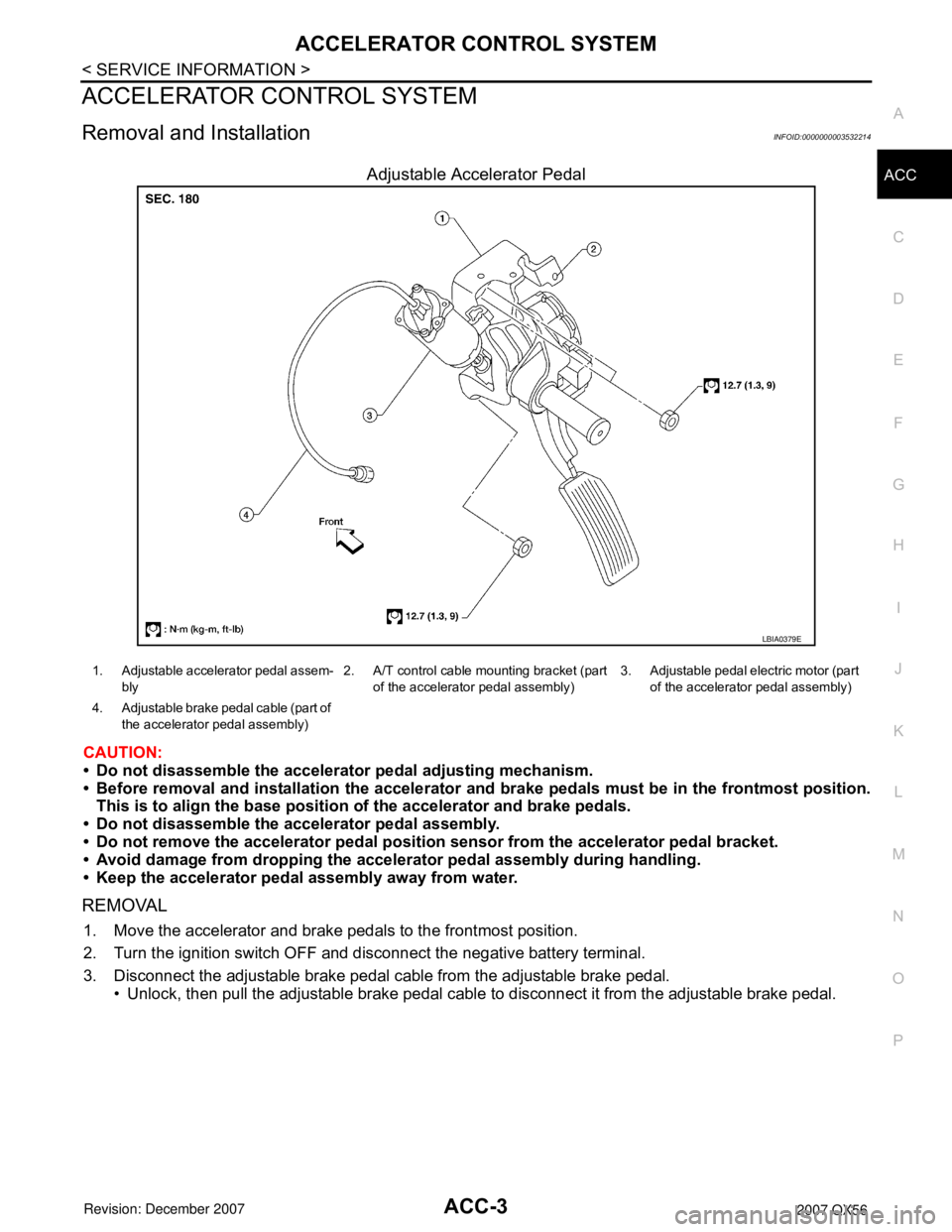

Adjustable Accelerator Pedal

CAUTION:

• Do not disassemble the accelerator pedal adjusting mechanism.

• Before removal and installation the accelerator and brake pedals must be in the frontmost position.

This is to align the base position of the accelerator and brake pedals.

• Do not disassemble the accelerator pedal assembly.

• Do not remove the accelerator pedal position sensor from the accelerator pedal bracket.

• Avoid damage from dropping the accelerator pedal assembly during handling.

• Keep the accelerator pedal assembly away from water.

REMOVAL

1. Move the accelerator and brake pedals to the frontmost position.

2. Turn the ignition switch OFF and disconnect the negative battery terminal.

3. Disconnect the adjustable brake pedal cable from the adjustable brake pedal.

• Unlock, then pull the adjustable brake pedal cable to disconnect it from the adjustable brake pedal.

LBIA0379E

1. Adjustable accelerator pedal assem-

bly2. A/T control cable mounting bracket (part

of the accelerator pedal assembly)3. Adjustable pedal electric motor (part

of the accelerator pedal assembly)

4. Adjustable brake pedal cable (part of

the accelerator pedal assembly)

Page 37 of 3061

![INFINITI QX56 2007 Factory Service Manual ACS-24

< SERVICE INFORMATION >[ICC]

TERMINALS AND REFERENCE VALUE

TERMINALS AND REFERENCE VALUE

Terminal and Reference Value for ICC UnitINFOID:0000000003533789

Terminal and Reference Value for ICC Se INFINITI QX56 2007 Factory Service Manual ACS-24

< SERVICE INFORMATION >[ICC]

TERMINALS AND REFERENCE VALUE

TERMINALS AND REFERENCE VALUE

Terminal and Reference Value for ICC UnitINFOID:0000000003533789

Terminal and Reference Value for ICC Se](/img/42/57029/w960_57029-36.png)

ACS-24

< SERVICE INFORMATION >[ICC]

TERMINALS AND REFERENCE VALUE

TERMINALS AND REFERENCE VALUE

Terminal and Reference Value for ICC UnitINFOID:0000000003533789

Terminal and Reference Value for ICC SensorINFOID:0000000003533790

Te r m i n a lWire col-

orItemCondition

Voltage (V)

(Approx.) Ignition

switchOperation

1W/L

Battery power supply OFF — Battery voltage

2W/L

5 P CAN-L — — —

7 B/R N-P RANGE ON A/T selector lever in "P" or "N" Battery voltage

10 V/R Brake booster signal ON —

14 L CAN-H — — —

19 B

Ground

ON——

20 B

29 BR/WICC brake switch

(normally closed)Selector le-

ver: Not in

“N” or “P”

positionDepress the brake

pedal0

Release the brake

pedalBattery voltage

30 L DDL-TX — — —

33 R/B Ignition switch power supply ON —

Battery voltage

38 R/GSt op la mp sw i tc h

(normally open) OFFDepress the brake pedal

Release the brake pedal 0

39 V/W DDL-RX — — —

40 G Parking brake signal

ONParking brake is ON 0

Parking brake is OFF Battery voltage

42 R/B Ignition switch power supply — Battery voltage

46 B Ground — —

47 BR Stop lamp drive output signalBrake operating with ICC system Battery voltage

Brake not operating with ICC sys-

tem0

SKIA1243E

Te r m i n a lWire

colorItemCondition

Voltage (V)

Ignition

switchOperation

1 R/B Ignition switch power supply

ON— Battery voltage

2LCAN-H — —

3PCAN-L — —

4 B Ground — —

Page 50 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-37

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

1. Turn ignition switch OFF.

2. Disconnect ICC unit and ABS actuator and electric unit INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-37

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

1. Turn ignition switch OFF.

2. Disconnect ICC unit and ABS actuator and electric unit](/img/42/57029/w960_57029-49.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-37

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

1. Turn ignition switch OFF.

2. Disconnect ICC unit and ABS actuator and electric unit (control

unit) connectors.

3. Check continuity between ICC unit harness connector B13 ter-

minal 10, and ABS actuator and electric unit (control unit) con-

nector E125 terminal 7.

OK or NG

OK >> Replace ICC unit. Refer to ACS-55. Erase DTC and per-

form ICC system running test. Refer to ACS-9, "

ICC

System Running Test". Then perform self-diagnosis of ICC system again.

NG >> • Repair harness between ICC unit, and ABS actuator and electric unit (control unit).

• Erase DTC and perform ICC system running test. Refer to ACS-9, "

ICC System Running Test".

Then perform self-diagnosis of ICC system again.

DTC 20 CAN COMM CIRCUITINFOID:0000000003533797

1.CHECK CAN COMMUNICATION

With CONSULT-II

1. Perform self-diagnosis.

2. Print self-diagnostic result.

>> After printing self-diagnostic result, GO TO “CAN system”. Refer to LAN-4, "

CAN Communication

System" .

DTC 31 POWER SUPPLY CIR1, DTC 34 POWER SUPPLY CIR2INFOID:0000000003533798

1.CHECK ICC UNIT CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect ICC unit connectors and connect them securely again. Erase DTC, then perform self-diagno-

sis of ICC system again.

OK or NG

OK >> GO TO 2.

NG >> • Poor connector connection.

• Check connector. Check connector housing for disconnected, loose, bent, and collapsed termi-

nals. If any malfunction is detected, repair as as necessary. Erase DTC and perform ICC system

running test. Refer to ACS-9, "

ICC System Running Test". Then perform self-diagnosis of ICC

system again.

2.CHECK POWER SUPPLY CIRCUIT FOR ICC UNIT

1. Turn ignition switch ON.

2. Check voltage between ICC unit harness connector B17 termi-

nal 33, 42 and ground.

OK or NG

OK >> GO TO 3.

NG >> • Repair ICC unit power supply harness.

• Erase DTC and perform ICC system running test.

Refer to ACS-9, "

ICC System Running Test". Then

perform self-diagnosis of ICC system again.

3.CHECK GROUND CIRCUIT FOR ICC UNITContinuity should exist.

WKIA3616E

Battery voltage should exist.

SKIA1173E

Page 55 of 3061

![INFINITI QX56 2007 Factory Service Manual ACS-42

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

4.CHECK ICC BRAKE SWITCH

Check ICC brake switch. Refer to ACS-54, "

ICC Brake Switch and Stop Lamp Switch" .

OK or NG

OK INFINITI QX56 2007 Factory Service Manual ACS-42

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

4.CHECK ICC BRAKE SWITCH

Check ICC brake switch. Refer to ACS-54, "

ICC Brake Switch and Stop Lamp Switch" .

OK or NG

OK](/img/42/57029/w960_57029-54.png)

ACS-42

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

4.CHECK ICC BRAKE SWITCH

Check ICC brake switch. Refer to ACS-54, "

ICC Brake Switch and Stop Lamp Switch" .

OK or NG

OK >> GO TO 5.

NG >> Replace ICC brake switch. Erase DTC and perform ICC system running test. Refer to ACS-9,

"ICC System Running Test". Then perform self-diagnosis of ICC system again.

5.CHECK ICC BRAKE HOLD RELAY

Disconnect ICC brake hold relay and check continuity between ICC

brake hold relay terminal 4 and terminal 3.

OK or NG

OK >> GO TO 6.

NG >> Replace ICC brake hold relay. Erase DTC and perform

ICC system running test. Refer to ACS-9, "

ICC System

Running Test". Then perform self-diagnosis of ICC sys-

tem again.

6.CHECK HARNESS THROUGH ICC BRAKE HOLD RELAY, ICC BRAKE SWITCH, ICC UNIT

1. Disconnect ECM and ICC unit harness connectors.

2. Check continuity between ICC brake hold relay harness connec-

tor E134 terminal 4 and ICC unit harness connector B17 termi-

nal 29.

3. Check continuity between ICC unit harness connector B17 ter-

minal 29 and ground.

OK or NG

OK >> GO TO 7.

NG >> • Repair harness between ICC brake hold relay and ICC brake switch.

• Repair harness between ICC brake switch and ICC unit.

• Erase DTC and perform ICC system running test. Refer to ACS-9, "

ICC System Running Test".

Then perform self-diagnosis of ICC system again.

7.CHECK ICC BRAKE HOLD RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between ICC brake hold relay harness connector

E134 terminal 3 and ground.

OK or NG

OK >> Replace ICC unit. Refer to ACS-55, "ICC Unit". Erase

DTC and perform ICC system running test. Refer to

ACS-9, "

ICC System Running Test". Then perform self-

diagnosis of ICC system again.

NG >> • Check fuse or ICC brake hold relay power supply sys-

tem harness.

• Erase DTC and perform ICC system running test. Refer to ACS-9, "

ICC System Running Test".

Then perform self-diagnosis of ICC system again.

8.CHECK STOP LAMP SWITCHContinuity should exist.

SKIA6658E

Continuity should exist.

Continuity should not exist.

WKIA1929E

Battery voltage should exist

WKIA3618E

Page 57 of 3061

![INFINITI QX56 2007 Factory Service Manual ACS-44

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Check continuity between ICC brake hold relay terminal 1 and termi-

nal 2.

OK or NG

OK >> GO TO 13.

NG >> Replace ICC br INFINITI QX56 2007 Factory Service Manual ACS-44

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Check continuity between ICC brake hold relay terminal 1 and termi-

nal 2.

OK or NG

OK >> GO TO 13.

NG >> Replace ICC br](/img/42/57029/w960_57029-56.png)

ACS-44

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Check continuity between ICC brake hold relay terminal 1 and termi-

nal 2.

OK or NG

OK >> GO TO 13.

NG >> Replace ICC brake hold relay. Erase DTC and perform

ICC system running test. Refer to ACS-9, "

ICC System

Running Test". Then perform self-diagnosis of ICC sys-

tem again.

13.CHECK ICC UNIT STANDARD VOLTAGE

With CONSULT-II

1. Connect connectors of ICC unit and stop lamp switch.

2. While performing active test (STOP LAMP: STP LMP DRIVE

ON) with CONSULT-II, check voltage between ICC unit harness

connector B17 terminal 47 and ground.

OK or NG

OK >> GO TO 14.

NG >> Replace ICC unit. Refer to ACS-55, "

ICC Unit". Erase

DTC and perform ICC system running test. Refer to

ACS-9, "

ICC System Running Test". Then perform self-diagnosis of ICC system again.

14.CHECK ICC BRAKE HOLD RELAY POWER SUPPLY CIRCUIT

Check voltage between ICC brake hold relay harness connector

E134 terminal 6 and ground.

OK or NG

OK >> GO TO 15.

NG >> • Check fuse or ICC brake hold relay power supply har-

ness.

• Erase DTC and perform ICC system running test.

Refer to ACS-9, "

ICC System Running Test". Then

perform self-diagnosis of ICC system again.

15.CHECK HARNESS BETWEEN ICC BRAKE HOLD RELAY AND ICC UNIT

1. Turn ignition switch OFF.

2. Disconnect ICC unit harness connectors.

3. Check continuity between ICC brake hold relay harness connec-

tor E134 terminal 7 and ICC unit harness connector B17 termi-

nal 38.

4. Check continuity between ICC unit harness connector B17 ter-

minal 38 (R/G) and ground.

OK or NG

OK >> GO TO 16.

NG >> • Repair harness between ICC brake hold relay and ICC unit or between ICC brake hold relay

and stop lamp switch. Continuity should exist

(minimal resistance through coil will exist)

SKIA6662E

47 - Ground Battery voltage should exist

(during active test)

SKIA3075E

6 - Ground Battery voltage should exist

WKIA1931E

7 - 38 Continuity should exist.

38 - Ground Continuity should not exist.

WKIA1932E

Page 78 of 3061

AT-8

< SERVICE INFORMATION >

PRECAUTIONS

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003532218

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for On Board Diagnosis (OBD) System of A/T and EngineINFOID:0000000003532219

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch “OFF” and disconnect the negative battery cable before any repair

or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc. Will

cause the MIL to light up.

• Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. May cause the MIL to light up due to a short circuit.

• Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to a malfunction of the EGR system or fuel injection system, etc.

• Be sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

PrecautionINFOID:0000000003532220

•Before connecting or disconnecting the A/T assembly har-

ness connector, turn ignition switch “OFF” and disconnect

negative battery cable. Because battery voltage is applied to

TCM even if ignition switch is turned “OFF”.

SEF289H

Page 110 of 3061

AT-40

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

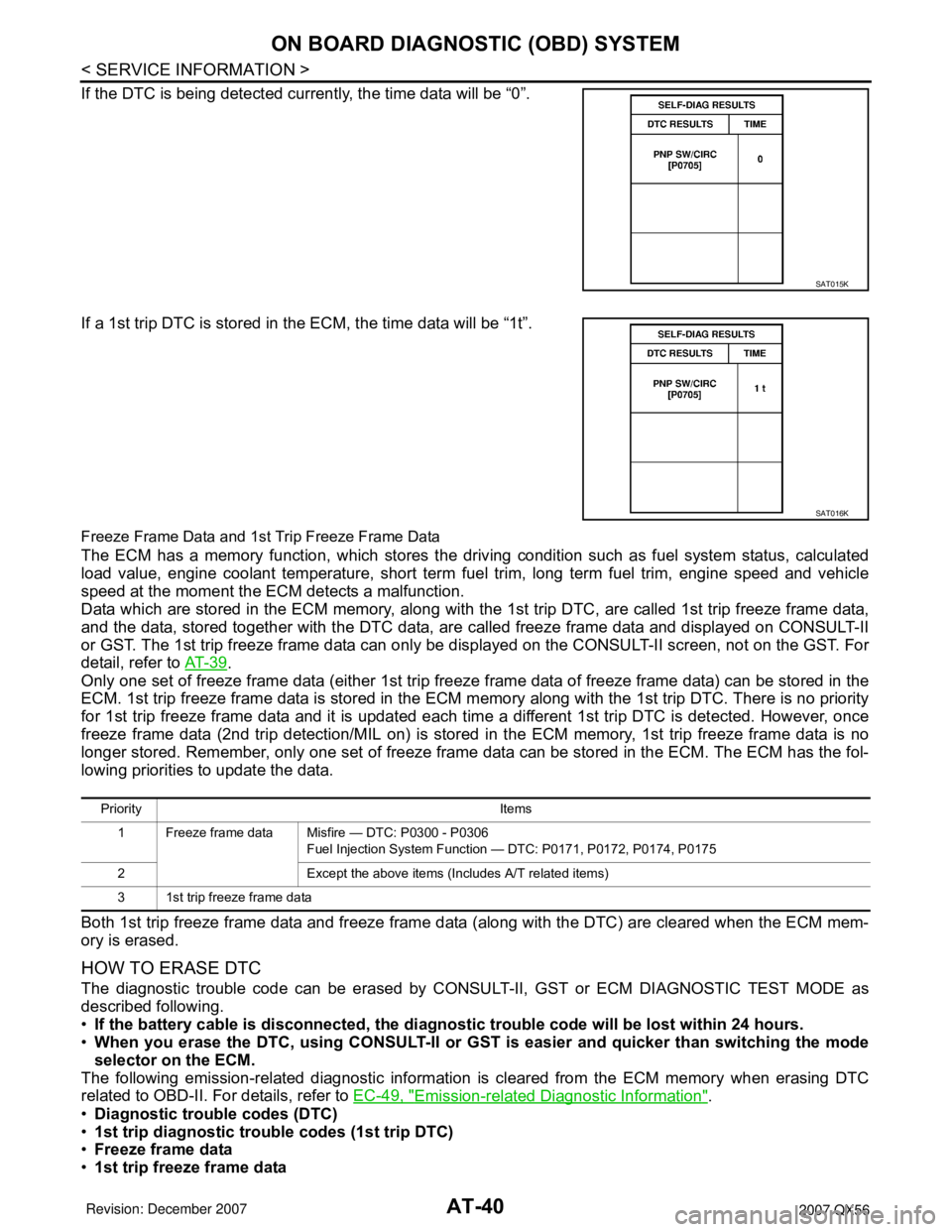

If the DTC is being detected currently, the time data will be “0”.

If a 1st trip DTC is stored in the ECM, the time data will be “1t”.

Freeze Frame Data and 1st Trip Freeze Frame Data

The ECM has a memory function, which stores the driving condition such as fuel system status, calculated

load value, engine coolant temperature, short term fuel trim, long term fuel trim, engine speed and vehicle

speed at the moment the ECM detects a malfunction.

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data,

and the data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-II

or GST. The 1st trip freeze frame data can only be displayed on the CONSULT-II screen, not on the GST. For

detail, refer to AT- 3 9

.

Only one set of freeze frame data (either 1st trip freeze frame data of freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM memory along with the 1st trip DTC. There is no priority

for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MIL on) is stored in the ECM memory, 1st trip freeze frame data is no

longer stored. Remember, only one set of freeze frame data can be stored in the ECM. The ECM has the fol-

lowing priorities to update the data.

Both 1st trip freeze frame data and freeze frame data (along with the DTC) are cleared when the ECM mem-

ory is erased.

HOW TO ERASE DTC

The diagnostic trouble code can be erased by CONSULT-II, GST or ECM DIAGNOSTIC TEST MODE as

described following.

•If the battery cable is disconnected, the diagnostic trouble code will be lost within 24 hours.

•When you erase the DTC, using CONSULT-II or GST is easier and quicker than switching the mode

selector on the ECM.

The following emission-related diagnostic information is cleared from the ECM memory when erasing DTC

related to OBD-II. For details, refer to EC-49, "

Emission-related Diagnostic Information".

•Diagnostic trouble codes (DTC)

•1st trip diagnostic trouble codes (1st trip DTC)

•Freeze frame data

•1st trip freeze frame data

SAT015K

SAT016K

Priority Items

1 Freeze frame data Misfire — DTC: P0300 - P0306

Fuel Injection System Function — DTC: P0171, P0172, P0174, P0175

2 Except the above items (Includes A/T related items)

3 1st trip freeze frame data

Page 111 of 3061

ON BOARD DIAGNOSTIC (OBD) SYSTEM

AT-41

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

•System readiness test (SRT) codes

•Test values

HOW TO ERASE DTC (WITH CONSULT-II)

•If a DTC is displayed for both ECM and TCM, it is necessary to be erased for both ECM and TCM.

1. If the ignition switch stays “ON” after repair work, be sure to turn ignition switch “OFF” once. Wait at least

10 seconds and then turn it “ON” (engine stopped) again.

2. Turn CONSULT-II “ON” and touch “A/T”.

3. Touch “SELF-DIAG RESULTS”.

4. Touch “ERASE”. (The DTC in the TCM will be erased.) Then touch “BACK” twice.

5. Touch “ENGINE”.

6. Touch “SELF-DIAG RESULTS”.

7. Touch “ERASE”. (The DTC in the ECM will be erased.)

HOW TO ERASE DTC (WITH GST)

1. If the ignition switch stays “ON” after repair work, be sure to turn ignition switch “OFF” once. Wait at least

10 seconds and then turn it “ON” (engine stopped) again.

2. Select Mode 4 with the Generic Scan Tool (GST). For details refer to EC-122, "

Generic Scan Tool (GST)

Function".

HOW TO ERASE DTC (NO TOOLS)

1. Disconnect battery for 24 hours.

2. Reconnect battery.

Malfunction Indicator Lamp (MIL)INFOID:0000000003532242

DESCRIPTION

SCIA5671E

Page 152 of 3061

AT-82

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

TCM Input/Output Signal Reference Value

INFOID:0000000003532258

A/T ASSEMBLY HARNESS CONNECTOR TERMINAL LAYOUT

TERMINAL AND REFERENCE VALUES FOR TCM

Data are reference value and are measured between each terminal and ground.

65 OthersEngine speed does

not return to idle.

Refer to AT-191, "En-

gine Speed Does Not

Return to Idle".ON vehicle1. Fluid level and stateAT- 5 1

2. ATF pressure switch 5 and direct clutch solenoid valveAT- 1 5 4,

AT- 1 3 8

3. ATF pressure switch 1 and front brake solenoid valveAT- 1 5 0,

AT- 1 3 4

4. Accelerator pedal position sensorAT- 11 7

5. Vehicle speed sensor A/T and vehicle speed sensor MTRAT- 1 0 5,

AT- 1 2 4

6. CAN communication lineAT- 9 1

7. Control valve with TCMAT- 2 1 0

OFF vehicle8. Front brake (brake band)AT- 2 4 09. Direct clutchAT- 2 7 4

No. Items Symptom Condition Diagnostic ItemReference

page

SCIA1658E

Te r m i n a l

No.Wire

colorItem Condition Data (Pyrex.)

1PPower supply

(Memory back-up)Always Battery voltage

2PPower supply

(Memory back-up)Always Battery voltage

3 L CAN-H – –

4VK-line (CONSULT-

II signal)The terminal is connected to the data link connector for CONSULT-II. –

5 B Ground Always 0V

6Y/RPower supply– Battery voltage

–0V

7RBack-up lamp re-

laySelector lever in “R” position. 0V

Selector lever in other positions. Battery voltage

8 P CAN-L – –

Page 153 of 3061

TROUBLE DIAGNOSIS

AT-83

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

PCONSULT-II Function (A/T)INFOID:0000000003532259

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II REFERENCE VALUE

NOTICE:

1. The CONSULT-II electrically displays shift timing and lock-up timing (that is, operation timing of each sole-

noid).

Check for time difference between actual shift timing and the CONSULT-II display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-II and that indicated in Service Man-

ual may differ slightly. This occurs because of the following reasons:

- Actual shift schedule has more or less tolerance or allowance,

- Shift schedule indicated in Service Manual refers to the point where shifts start, and

- Gear position displayed on CONSULT-II indicates the point where shifts are completed.

3. Display of solenoid valves on CONSULT-II changes at the start of shifting, while gear position is displayed

upon completion of shifting (which is computed by TCM).

9 B/R Starter relaySelector lever in “N”,“ P” positions. Battery voltage

Selector lever in other positions. 0V

10 B Ground Always 0V Te r m i n a l

No.Wire

colorItem Condition Data (Pyrex.)

TCM diagnostic mode Description

WORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the TCM for setting the status

suitable for required operation, input/output signals are received from the TCM and received data is

displayed.

SELF-DIAG RESULTS Displays TCM self-diagnosis results.

DATA MONITOR Displays TCM input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

FUNCTION TEST Conducted by CONSULT-II instead of a technician to determine whether each system is “OK” or “NG”.

ECU PART NUMBER TCM part number can be read.

Item name Condition Display value (Approx.)

ATF TEMP SE 1

0°C (32° F) - 20°C (68°F) - 80°C (176°F)3.3 - 2.7 - 0.9 V

ATF TEMP SE 23.3 - 2.5 - 0.7 V

TCC SOLENOIDWhen perform slip lock-up 0.2 - 0.4 A

When perform lock-up 0.4 - 0.6 A

SLCT LVR POSISelector lever in “N”,“P” position. N/P

Selector lever in “R” position. R

Selector lever in “D” position. D

Selector lever in “4” position. 4

Selector lever in “3” position. 3

Selector lever in “2” position. 2

Selector lever in “1” position. 1

VHCL/S SE·A/T During drivingApproximately matches the

speedometer reading.

ENGINE SPEED Engine runningClosely matches the tachometer

reading.