checking oil INFINITI QX56 2007 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2385 of 3061

CHASSIS AND BODY MAINTENANCE

MA-23

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

10. Tighten the level gauge bolt to specification.

Changing Automatic Transmission Fluid (ATF)INFOID:0000000003533878

1. Drive the vehicle to warm up the ATF to 80° C (176° F).

2. Stop the engine.

3. Remove the ATF level gauge bolt.

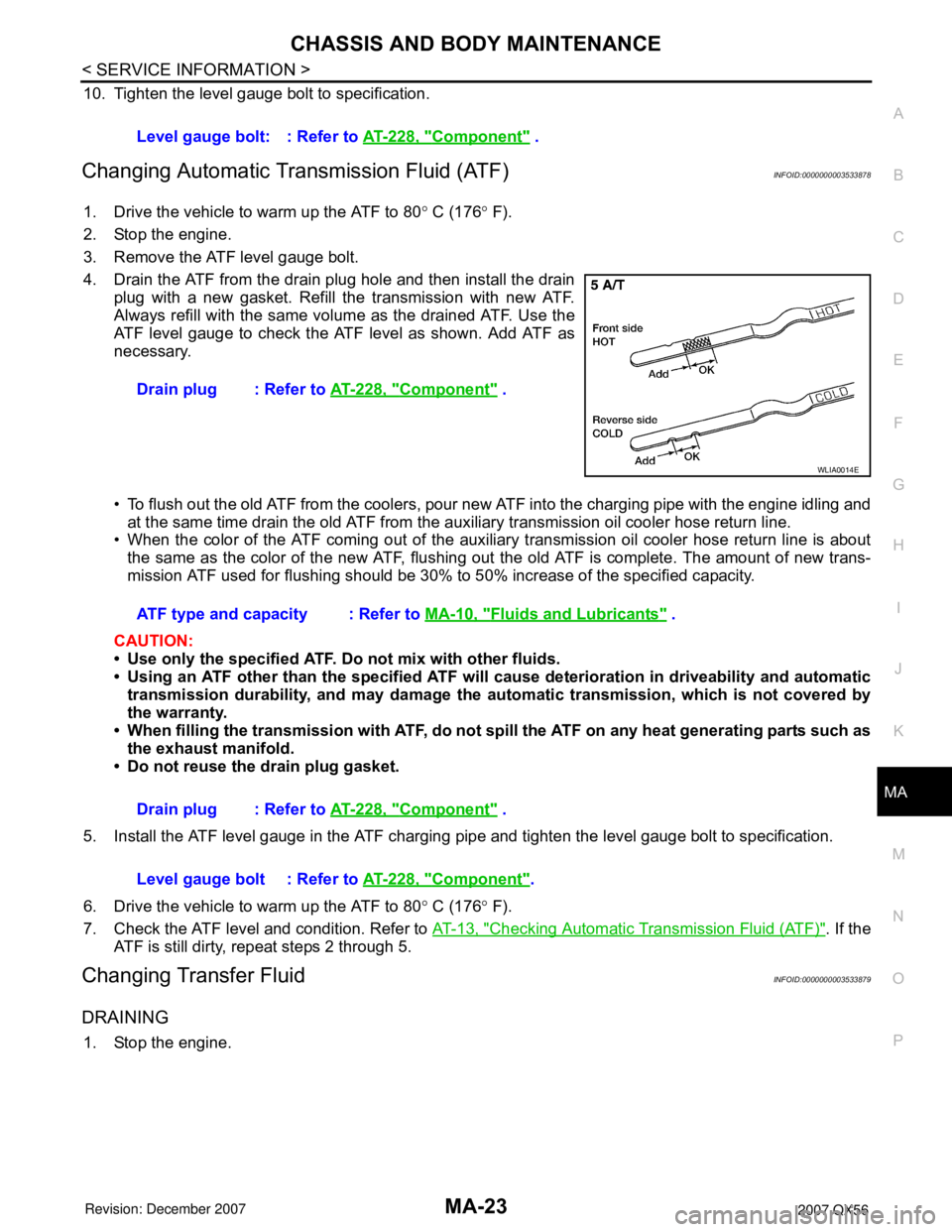

4. Drain the ATF from the drain plug hole and then install the drain

plug with a new gasket. Refill the transmission with new ATF.

Always refill with the same volume as the drained ATF. Use the

ATF level gauge to check the ATF level as shown. Add ATF as

necessary.

• To flush out the old ATF from the coolers, pour new ATF into the charging pipe with the engine idling and

at the same time drain the old ATF from the auxiliary transmission oil cooler hose return line.

• When the color of the ATF coming out of the auxiliary transmission oil cooler hose return line is about

the same as the color of the new ATF, flushing out the old ATF is complete. The amount of new trans-

mission ATF used for flushing should be 30% to 50% increase of the specified capacity.

CAUTION:

• Use only the specified ATF. Do not mix with other fluids.

• Using an ATF other than the specified ATF will cause deterioration in driveability and automatic

transmission durability, and may damage the automatic transmission, which is not covered by

the warranty.

• When filling the transmission with ATF, do not spill the ATF on any heat generating parts such as

the exhaust manifold.

• Do not reuse the drain plug gasket.

5. Install the ATF level gauge in the ATF charging pipe and tighten the level gauge bolt to specification.

6. Drive the vehicle to warm up the ATF to 80° C (176° F).

7. Check the ATF level and condition. Refer to AT-13, "

Checking Automatic Transmission Fluid (ATF)". If the

ATF is still dirty, repeat steps 2 through 5.

Changing Transfer FluidINFOID:0000000003533879

DRAINING

1. Stop the engine.Level gauge bolt: : Refer to AT-228, "

Component" .

Drain plug : Refer to AT-228, "

Component" .

WLIA0014E

ATF type and capacity : Refer to MA-10, "Fluids and Lubricants" .

Drain plug : Refer to AT-228, "

Component" .

Level gauge bolt : Refer to AT-228, "

Component".

Page 2386 of 3061

MA-24

< SERVICE INFORMATION >

CHASSIS AND BODY MAINTENANCE

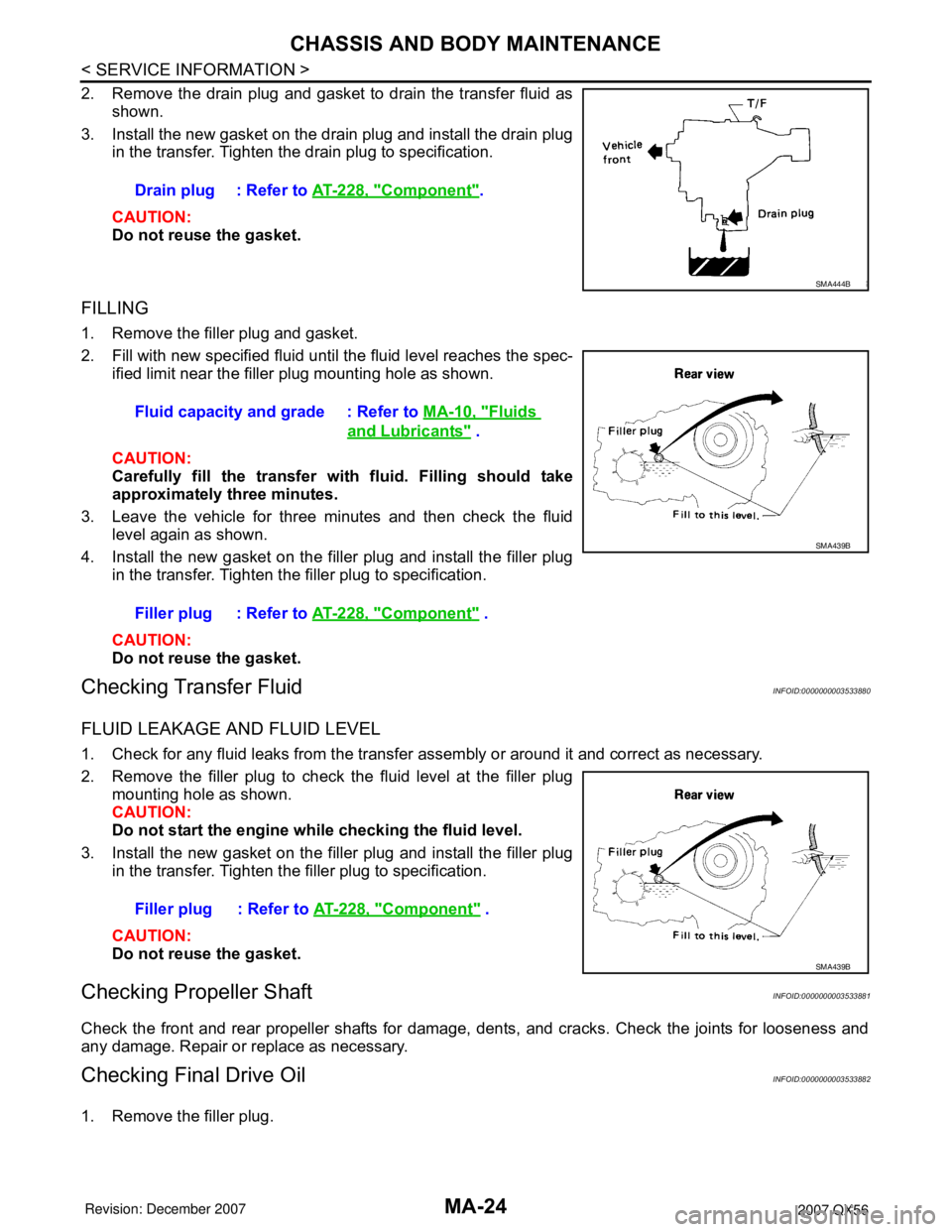

2. Remove the drain plug and gasket to drain the transfer fluid as

shown.

3. Install the new gasket on the drain plug and install the drain plug

in the transfer. Tighten the drain plug to specification.

CAUTION:

Do not reuse the gasket.

FILLING

1. Remove the filler plug and gasket.

2. Fill with new specified fluid until the fluid level reaches the spec-

ified limit near the filler plug mounting hole as shown.

CAUTION:

Carefully fill the transfer with fluid. Filling should take

approximately three minutes.

3. Leave the vehicle for three minutes and then check the fluid

level again as shown.

4. Install the new gasket on the filler plug and install the filler plug

in the transfer. Tighten the filler plug to specification.

CAUTION:

Do not reuse the gasket.

Checking Transfer FluidINFOID:0000000003533880

FLUID LEAKAGE AND FLUID LEVEL

1. Check for any fluid leaks from the transfer assembly or around it and correct as necessary.

2. Remove the filler plug to check the fluid level at the filler plug

mounting hole as shown.

CAUTION:

Do not start the engine while checking the fluid level.

3. Install the new gasket on the filler plug and install the filler plug

in the transfer. Tighten the filler plug to specification.

CAUTION:

Do not reuse the gasket.

Checking Propeller ShaftINFOID:0000000003533881

Check the front and rear propeller shafts for damage, dents, and cracks. Check the joints for looseness and

any damage. Repair or replace as necessary.

Checking Final Drive OilINFOID:0000000003533882

1. Remove the filler plug.Drain plug : Refer to AT-228, "

Component".

SMA444B

Fluid capacity and grade : Refer to MA-10, "Fluids

and Lubricants" .

Filler plug : Refer to AT-228, "

Component" .

SMA439B

Filler plug : Refer to AT-228, "Component" .

SMA439B

Page 2390 of 3061

MA-28

< SERVICE INFORMATION >

CHASSIS AND BODY MAINTENANCE

Check the rotor condition for wear or damage. Refer to BR-18 , BR-

24 .

CALIPER

Check the caliper for any leaks, repair as necessary.

PA D

Check the pads for wear or damage. Refer to BR-18 , BR-24 .

Checking Steering Gear and LinkageINFOID:0000000003533889

STEERING GEAR

• Check the steering gear housing for looseness, damage and oil

leakage as shown.

• Check the steering column connections for looseness.

STEERING LINKAGE

• Check the ball joint, dust cover and other component parts for looseness, wear, damage, and grease leak-

age.

Checking Power Steering Fluid and LineINFOID:0000000003533890

CHECKING FLUID LEVEL

SMA260A

SMA922A

LMA051

SGIA0506E

Page 2391 of 3061

CHASSIS AND BODY MAINTENANCE

MA-29

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

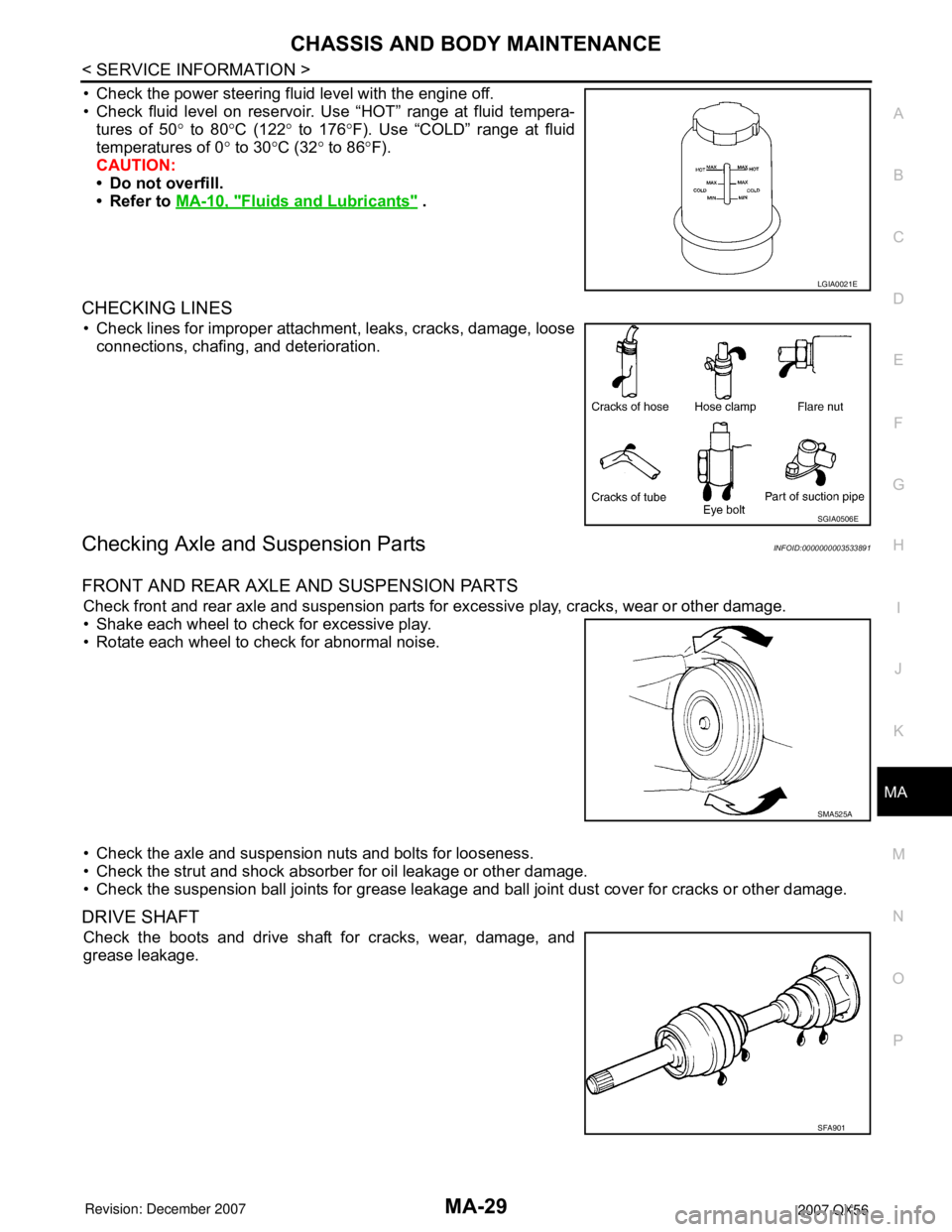

• Check the power steering fluid level with the engine off.

• Check fluid level on reservoir. Use “HOT” range at fluid tempera-

tures of 50° to 80°C (122° to 176°F). Use “COLD” range at fluid

temperatures of 0° to 30°C (32° to 86°F).

CAUTION:

• Do not overfill.

• Refer to MA-10, "

Fluids and Lubricants" .

CHECKING LINES

• Check lines for improper attachment, leaks, cracks, damage, loose

connections, chafing, and deterioration.

Checking Axle and Suspension PartsINFOID:0000000003533891

FRONT AND REAR AXLE AND SUSPENSION PARTS

Check front and rear axle and suspension parts for excessive play, cracks, wear or other damage.

• Shake each wheel to check for excessive play.

• Rotate each wheel to check for abnormal noise.

• Check the axle and suspension nuts and bolts for looseness.

• Check the strut and shock absorber for oil leakage or other damage.

• Check the suspension ball joints for grease leakage and ball joint dust cover for cracks or other damage.

DRIVE SHAFT

Check the boots and drive shaft for cracks, wear, damage, and

grease leakage.

LGIA0021E

SGIA0506E

SMA525A

SFA901

Page 2492 of 3061

PS-1

STEERING

C

D

E

F

H

I

J

K

L

M

SECTION PS

A

B

PS

N

O

P

CONTENTS

POWER STEERING SYSTEM

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

Precaution for Steering System ................................2

PREPARATION ...................................................3

Special Service Tool .................................................3

Commercial Service Tool ..........................................4

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

5

NVH Troubleshooting Chart ......................................5

POWER STEERING FLUID ................................6

Checking Fluid Level .................................................6

Checking Fluid Leakage ............................................6

Air Bleeding Hydraulic System ..................................6

STEERING WHEEL .............................................7

On-Vehicle Inspection and Service ...........................7

Removal and Installation ...........................................8

TILT SYSTEM ......................................................9

Removal and Installation ..........................................9

STEERING COLUMN ........................................10

Removal and Installation .........................................10

Disassembly and Assembly .....................................13

POWER STEERING GEAR AND LINKAGE ....15

Removal and Installation .........................................15

Disassembly and Assembly .....................................17

POWER STEERING OIL PUMP .......................21

On-Vehicle Inspection and Service .........................21

Removal and Installation .........................................21

Disassembly and Assembly .....................................22

HYDRAULIC LINE ............................................23

Removal and Installation .........................................23

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

25

Steering Wheel ........................................................25

Steering Column ......................................................25

Steering Outer Socket and Inner Socket .................26

Steering Gear ..........................................................26

Oil Pump ..................................................................27

Steering Fluid ..........................................................27

Page 2497 of 3061

PS-6

< SERVICE INFORMATION >

POWER STEERING FLUID

POWER STEERING FLUID

Checking Fluid LevelINFOID:0000000003532821

Check power steering fluid level with engine off, referring to the scale

on reservoir tank.

Use HOT range for fluid temperatures of 50° – 80°C (122° – 176°F).

Use COLD range for fluid temperatures of 0° – 30°C (32° – 86°F).

CAUTION:

• Do not overfill.

• Do not reuse any used power steering fluid.

• Recommended fluid is Genuine NISSAN PSF or equivalent.

Refer to MA-10

.

Checking Fluid LeakageINFOID:0000000003532822

Check the hydraulic piping lines for improper attachment and for

leaks, cracks, damage, loose connections, chafing or deterioration.

1. Run engine until fluid temperature reaches 50° – 80°C (122° –

176°F) in reservoir tank. Keep engine speed idle.

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each “lock” position for five seconds to

check fluid leakage.

CAUTION:

Do not hold steering wheel in a locked position for more

than 10 seconds. (There is the possibility that oil pump may

be damaged.)

4. If fluid leakage at connections is noticed, then loosen flare nut and then retighten. Do not over tighten con-

nector as this can damage O-ring, washer and connector.

5. If fluid leakage from oil pump is noticed, check oil pump. Refer to PS-21

.

6. Check steering gear boots for accumulation of fluid indicating a leak from the steering gear.

Air Bleeding Hydraulic SystemINFOID:0000000003532823

Incomplete air bleeding causes the following. When this happens, bleed air again.

• Air bubbles in reservoir tank.

• Clicking noise in oil pump.

• Excessive buzzing in oil pump.

NOTE:

When vehicle is stationary or while steering wheel is being turned slowly, some noise may be heard from oil

pump or gear. This noise is normal and does not affect any system.

1. Stop engine, and then turn steering wheel fully to right and left several times.

CAUTION:

Do not allow steering fluid reservoir tank to go below the MIN level line. Check tank frequently and

add fluid as needed.

2. Run engine at idle speed. Turn steering wheel fully right and then fully left, hold for about three seconds.

Then check for fluid leakage.

3. Repeat step 2 several times at about three second intervals.

CAUTION:

Do not hold steering wheel in the locked position for more than 10 seconds. (There is the possibil-

ity that oil pump may be damaged.)

4. Check for air bubbles or cloudy fluid.

5. If air bubbles or cloudiness still exists, stop engine, perform steps 2 and 3 again until air bubbles or cloud-

iness does not exist.

6. Stop engine, check fluid level.

LGIA0021E

SGIA0506E

Page 2512 of 3061

POWER STEERING OIL PUMP

PS-21

< SERVICE INFORMATION >

C

D

E

F

H

I

J

K

L

MA

B

PS

N

O

P

POWER STEERING OIL PUMP

On-Vehicle Inspection and ServiceINFOID:0000000003532831

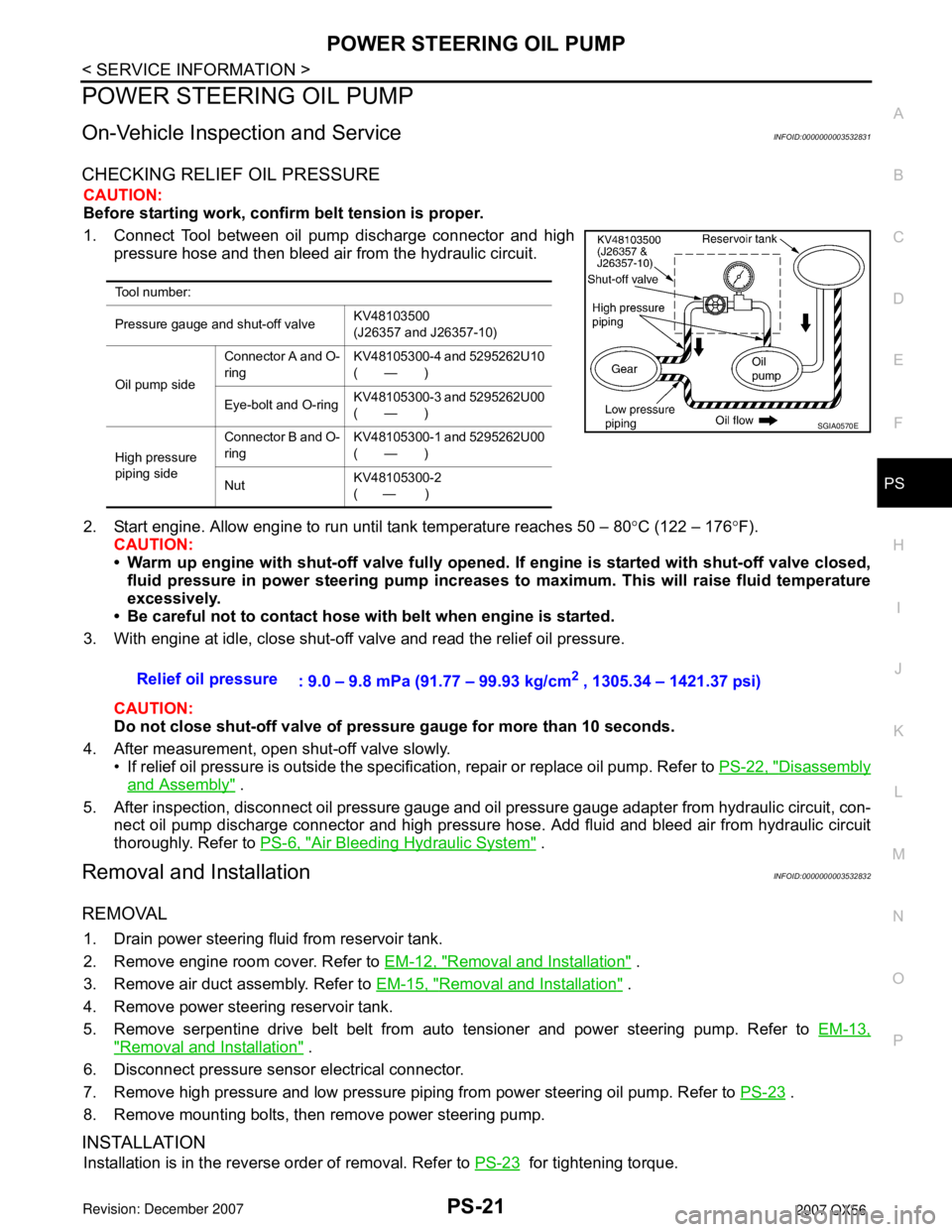

CHECKING RELIEF OIL PRESSURE

CAUTION:

Before starting work, confirm belt tension is proper.

1. Connect Tool between oil pump discharge connector and high

pressure hose and then bleed air from the hydraulic circuit.

2. Start engine. Allow engine to run until tank temperature reaches 50 – 80°C (122 – 176°F).

CAUTION:

• Warm up engine with shut-off valve fully opened. If engine is started with shut-off valve closed,

fluid pressure in power steering pump increases to maximum. This will raise fluid temperature

excessively.

• Be careful not to contact hose with belt when engine is started.

3. With engine at idle, close shut-off valve and read the relief oil pressure.

CAUTION:

Do not close shut-off valve of pressure gauge for more than 10 seconds.

4. After measurement, open shut-off valve slowly.

• If relief oil pressure is outside the specification, repair or replace oil pump. Refer to PS-22, "

Disassembly

and Assembly" .

5. After inspection, disconnect oil pressure gauge and oil pressure gauge adapter from hydraulic circuit, con-

nect oil pump discharge connector and high pressure hose. Add fluid and bleed air from hydraulic circuit

thoroughly. Refer to PS-6, "

Air Bleeding Hydraulic System" .

Removal and InstallationINFOID:0000000003532832

REMOVAL

1. Drain power steering fluid from reservoir tank.

2. Remove engine room cover. Refer to EM-12, "

Removal and Installation" .

3. Remove air duct assembly. Refer to EM-15, "

Removal and Installation" .

4. Remove power steering reservoir tank.

5. Remove serpentine drive belt belt from auto tensioner and power steering pump. Refer to EM-13,

"Removal and Installation" .

6. Disconnect pressure sensor electrical connector.

7. Remove high pressure and low pressure piping from power steering oil pump. Refer to PS-23

.

8. Remove mounting bolts, then remove power steering pump.

INSTALLATION

Installation is in the reverse order of removal. Refer to PS-23 for tightening torque.

Tool number:

Pressure gauge and shut-off valveKV48103500

(J26357 and J26357-10)

Oil pump sideConnector A and O-

ringKV48105300-4 and 5295262U10

(—)

Eye-bolt and O-ringKV48105300-3 and 5295262U00

(—)

High pressure

piping sideConnector B and O-

ringKV48105300-1 and 5295262U00

(—)

NutKV48105300-2

( — )

SGIA0570E

Relief oil pressure

: 9.0 – 9.8 mPa (91.77 – 99.93 kg/cm2 , 1305.34 – 1421.37 psi)

Page 2558 of 3061

RFD-1

DRIVELINE/AXLE

C

E

F

G

H

I

J

K

L

M

SECTION RFD

A

B

RFD

N

O

P

CONTENTS

REAR FINAL DRIVE

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Servicing Rear Final Drive .................2

PREPARATION ...................................................3

Special Service Tool .................................................3

Commercial Service Tool ..........................................6

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

7

NVH Troubleshooting Chart ......................................7

DIFFERENTIAL GEAR OIL .................................8

Changing Differential Gear Oil ..................................8

Checking Differential Gear Oil ...................................8

FRONT OIL SEAL ..............................................9

Removal and Installation ..........................................9

SIDE OIL SEAL .................................................11

Removal and Installation .........................................11

CARRIER COVER .............................................13

Removal and Installation .........................................13

REAR FINAL DRIVE ASSEMBLY ....................14

Removal and Installation .........................................14

Disassembly and Assembly .....................................15

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

32

General Specification ..............................................32

Inspection and Adjustment ......................................32

Page 2565 of 3061

RFD-8

< SERVICE INFORMATION >

DIFFERENTIAL GEAR OIL

DIFFERENTIAL GEAR OIL

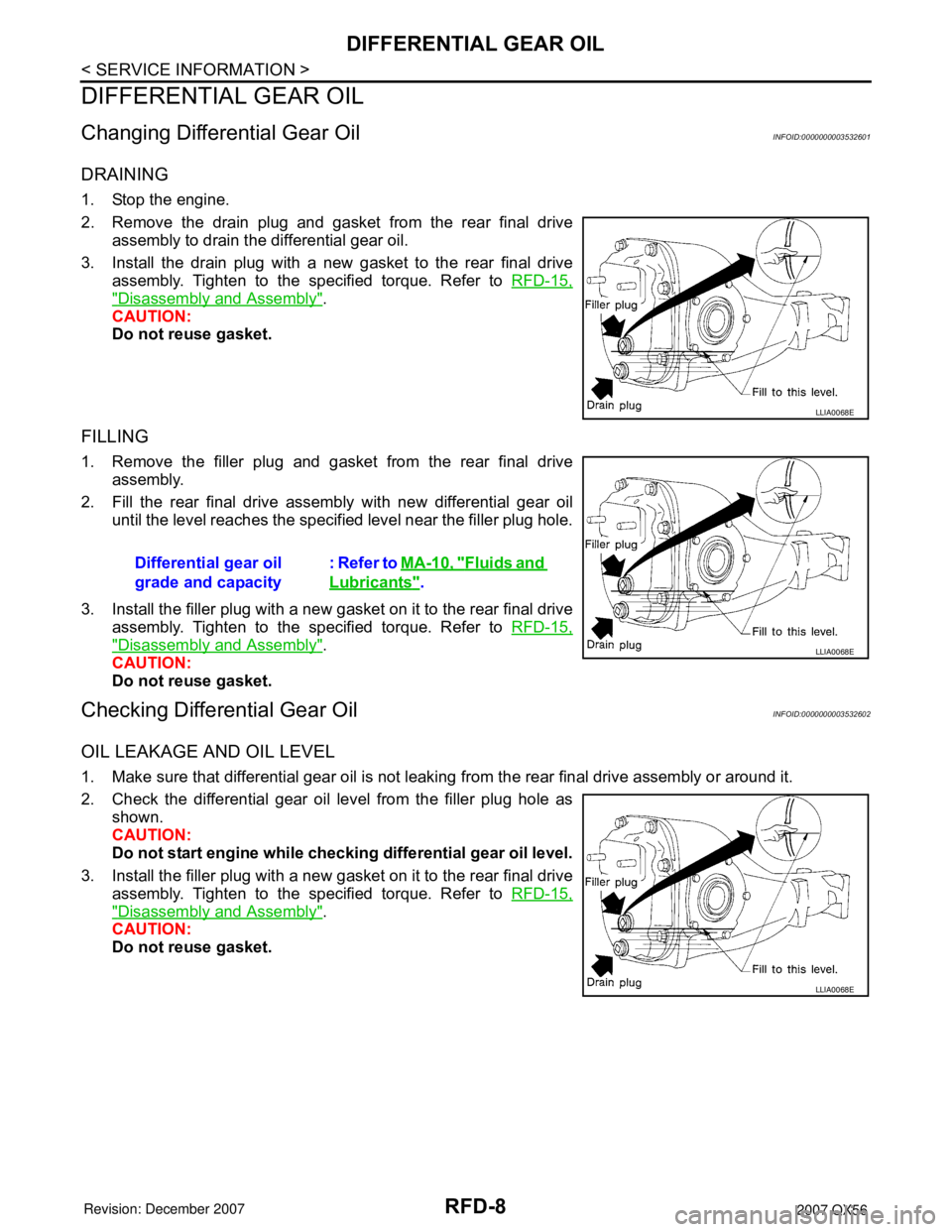

Changing Differential Gear OilINFOID:0000000003532601

DRAINING

1. Stop the engine.

2. Remove the drain plug and gasket from the rear final drive

assembly to drain the differential gear oil.

3. Install the drain plug with a new gasket to the rear final drive

assembly. Tighten to the specified torque. Refer to RFD-15,

"Disassembly and Assembly".

CAUTION:

Do not reuse gasket.

FILLING

1. Remove the filler plug and gasket from the rear final drive

assembly.

2. Fill the rear final drive assembly with new differential gear oil

until the level reaches the specified level near the filler plug hole.

3. Install the filler plug with a new gasket on it to the rear final drive

assembly. Tighten to the specified torque. Refer to RFD-15,

"Disassembly and Assembly".

CAUTION:

Do not reuse gasket.

Checking Differential Gear OilINFOID:0000000003532602

OIL LEAKAGE AND OIL LEVEL

1. Make sure that differential gear oil is not leaking from the rear final drive assembly or around it.

2. Check the differential gear oil level from the filler plug hole as

shown.

CAUTION:

Do not start engine while checking differential gear oil level.

3. Install the filler plug with a new gasket on it to the rear final drive

assembly. Tighten to the specified torque. Refer to RFD-15,

"Disassembly and Assembly".

CAUTION:

Do not reuse gasket.

LLIA0068E

Differential gear oil

grade and capacity: Refer to MA-10, "Fluids and

Lubricants".

LLIA0068E

LLIA0068E

Page 2567 of 3061

RFD-10

< SERVICE INFORMATION >

FRONT OIL SEAL

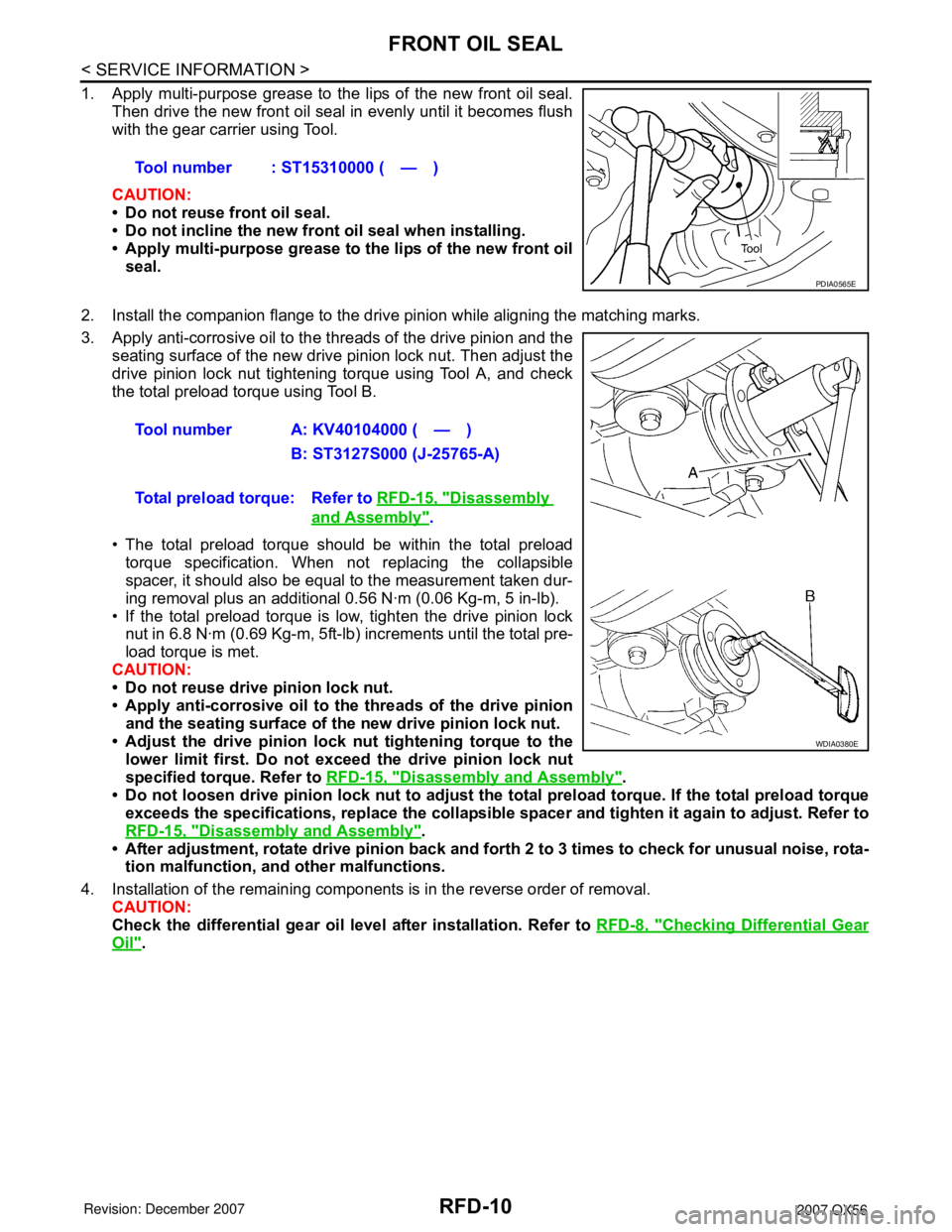

1. Apply multi-purpose grease to the lips of the new front oil seal.

Then drive the new front oil seal in evenly until it becomes flush

with the gear carrier using Tool.

CAUTION:

• Do not reuse front oil seal.

• Do not incline the new front oil seal when installing.

• Apply multi-purpose grease to the lips of the new front oil

seal.

2. Install the companion flange to the drive pinion while aligning the matching marks.

3. Apply anti-corrosive oil to the threads of the drive pinion and the

seating surface of the new drive pinion lock nut. Then adjust the

drive pinion lock nut tightening torque using Tool A, and check

the total preload torque using Tool B.

• The total preload torque should be within the total preload

torque specification. When not replacing the collapsible

spacer, it should also be equal to the measurement taken dur-

ing removal plus an additional 0.56 N·m (0.06 Kg-m, 5 in-lb).

• If the total preload torque is low, tighten the drive pinion lock

nut in 6.8 N·m (0.69 Kg-m, 5ft-lb) increments until the total pre-

load torque is met.

CAUTION:

• Do not reuse drive pinion lock nut.

• Apply anti-corrosive oil to the threads of the drive pinion

and the seating surface of the new drive pinion lock nut.

• Adjust the drive pinion lock nut tightening torque to the

lower limit first. Do not exceed the drive pinion lock nut

specified torque. Refer to RFD-15, "

Disassembly and Assembly".

• Do not loosen drive pinion lock nut to adjust the total preload torque. If the total preload torque

exceeds the specifications, replace the collapsible spacer and tighten it again to adjust. Refer to

RFD-15, "

Disassembly and Assembly".

• After adjustment, rotate drive pinion back and forth 2 to 3 times to check for unusual noise, rota-

tion malfunction, and other malfunctions.

4. Installation of the remaining components is in the reverse order of removal.

CAUTION:

Check the differential gear oil level after installation. Refer to RFD-8, "

Checking Differential Gear

Oil". Tool number : ST15310000 ( — )

PDIA0565E

Tool number A: KV40104000 ( — )

B: ST3127S000 (J-25765-A)

Total preload torque: Refer to RFD-15, "

Disassembly

and Assembly".

WDIA0380E