ignition INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1995 of 3061

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

GI-29

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

P

• Close the relay and probe at the solenoid.

voltage; open is further down the circuit than the solenoid.

no voltage; open is between relay and solenoid (point C).

Any powered circuit can be diagnosed using the approach in the previous example.

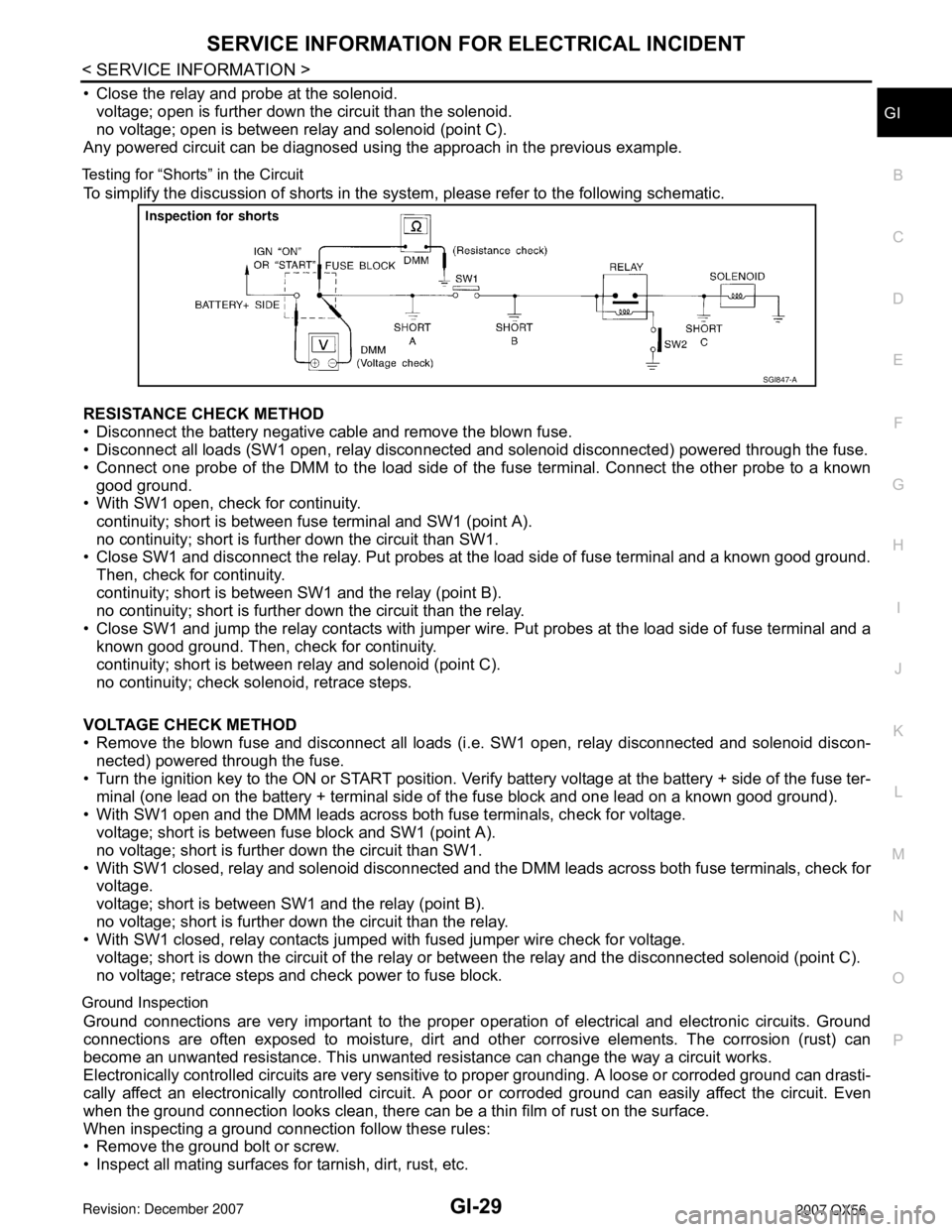

Testing for “Shorts” in the Circuit

To simplify the discussion of shorts in the system, please refer to the following schematic.

RESISTANCE CHECK METHOD

• Disconnect the battery negative cable and remove the blown fuse.

• Disconnect all loads (SW1 open, relay disconnected and solenoid disconnected) powered through the fuse.

• Connect one probe of the DMM to the load side of the fuse terminal. Connect the other probe to a known

good ground.

• With SW1 open, check for continuity.

continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

• Close SW1 and disconnect the relay. Put probes at the load side of fuse terminal and a known good ground.

Then, check for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

• Close SW1 and jump the relay contacts with jumper wire. Put probes at the load side of fuse terminal and a

known good ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

VOLTAGE CHECK METHOD

• Remove the blown fuse and disconnect all loads (i.e. SW1 open, relay disconnected and solenoid discon-

nected) powered through the fuse.

• Turn the ignition key to the ON or START position. Verify battery voltage at the battery + side of the fuse ter-

minal (one lead on the battery + terminal side of the fuse block and one lead on a known good ground).

• With SW1 open and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between fuse block and SW1 (point A).

no voltage; short is further down the circuit than SW1.

• With SW1 closed, relay and solenoid disconnected and the DMM leads across both fuse terminals, check for

voltage.

voltage; short is between SW1 and the relay (point B).

no voltage; short is further down the circuit than the relay.

• With SW1 closed, relay contacts jumped with fused jumper wire check for voltage.

voltage; short is down the circuit of the relay or between the relay and the disconnected solenoid (point C).

no voltage; retrace steps and check power to fuse block.

Ground Inspection

Ground connections are very important to the proper operation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and other corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted resistance can change the way a circuit works.

Electronically controlled circuits are very sensitive to proper grounding. A loose or corroded ground can drasti-

cally affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit. Even

when the ground connection looks clean, there can be a thin film of rust on the surface.

When inspecting a ground connection follow these rules:

• Remove the ground bolt or screw.

• Inspect all mating surfaces for tarnish, dirt, rust, etc.

SGI847-A

Page 2001 of 3061

CONSULT-II CHECKING SYSTEM

GI-35

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

PCONSULT-II CHECKING SYSTEM

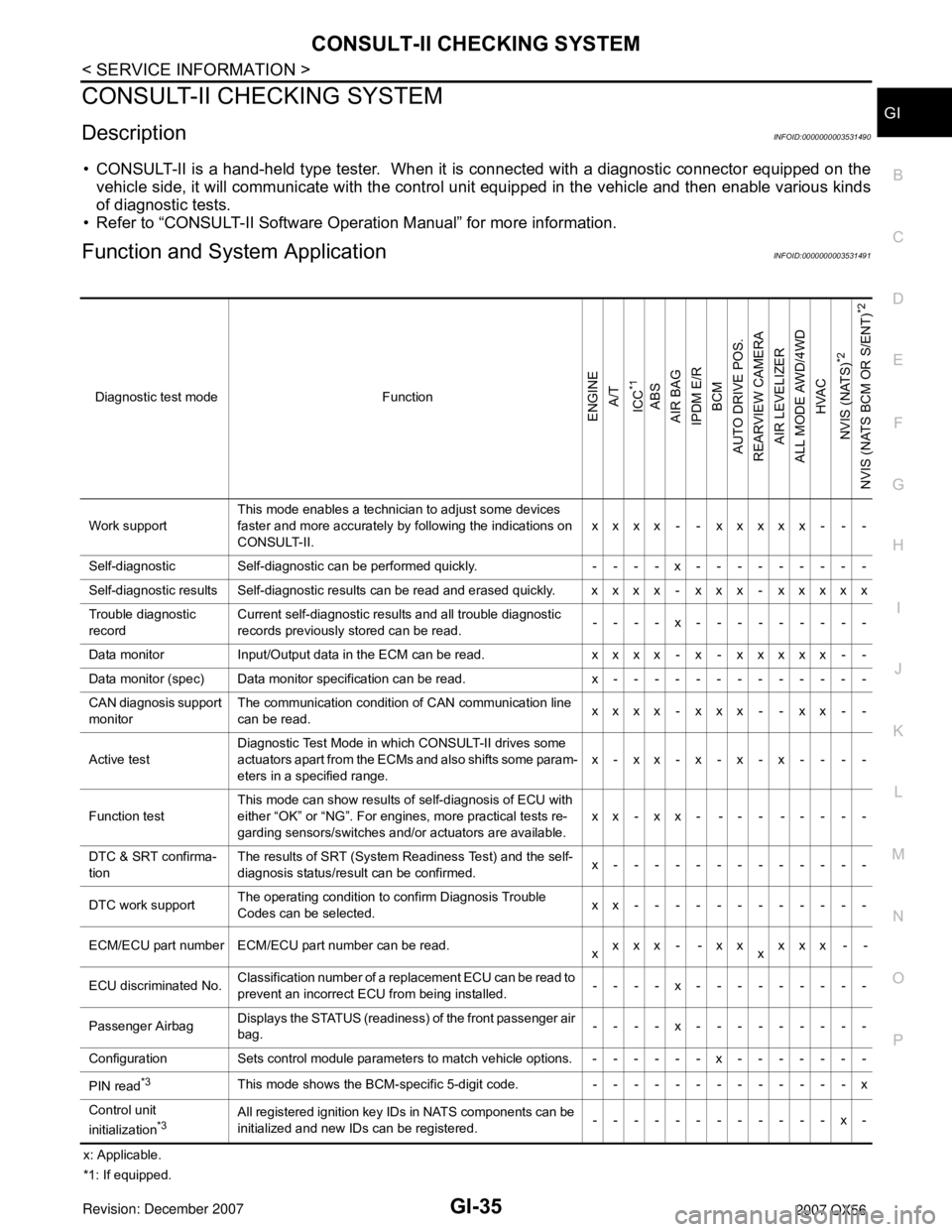

DescriptionINFOID:0000000003531490

• CONSULT-II is a hand-held type tester. When it is connected with a diagnostic connector equipped on the

vehicle side, it will communicate with the control unit equipped in the vehicle and then enable various kinds

of diagnostic tests.

• Refer to “CONSULT-II Software Operation Manual” for more information.

Function and System ApplicationINFOID:0000000003531491

x: Applicable.

*1: If equipped.Diagnostic test mode Function

ENGINE

A/T

ICC

*1

ABS

AIR BAG

IPDM E/R

BCM

AUTO DRIVE POS.

REARVIEW CAMERA

AIR LEVELIZER

ALL MODE AWD/4WD

HVAC

NVIS (NATS)

*2

NVIS (NATS BCM OR S/ENT)

*2

Work supportThis mode enables a technician to adjust some devices

faster and more accurately by following the indications on

CONSULT-II.xxxx - - xxxxx - - -

Self-diagnostic Self-diagnostic can be performed quickly. ----x---------

Self-diagnostic results Self-diagnostic results can be read and erased quickly. xxxx - xxx - xxxxx

Trouble diagnostic

recordCurrent self-diagnostic results and all trouble diagnostic

records previously stored can be read.--- - x---------

Data monitor Input/Output data in the ECM can be read. xxxx - x - xxxxx - -

Data monitor (spec) Data monitor specification can be read. x-------------

CAN diagnosis support

monitorThe communication condition of CAN communication line

can be read.xxxx - xxx - - xx - -

Active testDiagnostic Test Mode in which CONSULT-II drives some

actuators apart from the ECMs and also shifts some param-

eters in a specified range.x-xx-x-x-x----

Function testThis mode can show results of self-diagnosis of ECU with

either “OK” or “NG”. For engines, more practical tests re-

garding sensors/switches and/or actuators are available.xx-xx- --- -----

DTC & SRT confirma-

tionThe results of SRT (System Readiness Test) and the self-

diagnosis status/result can be confirmed.x-------------

DTC work supportThe operating condition to confirm Diagnosis Trouble

Codes can be selected.xx------------

ECM/ECU part number ECM/ECU part number can be read.

xxxx - -xx

xxxx - -

ECU discriminated No.Classification number of a replacement ECU can be read to

prevent an incorrect ECU from being installed.----x---------

Passenger Airbag Displays the STATUS (readiness) of the front passenger air

bag.----x---------

Configuration Sets control module parameters to match vehicle options. ------x-------

PIN read

*3This mode shows the BCM-specific 5-digit code. -------------x

Control unit

initialization

*3All registered ignition key IDs in NATS components can be

initialized and new IDs can be registered.------------x-

Page 2002 of 3061

![INFINITI QX56 2007 Factory Service Manual GI-36

< SERVICE INFORMATION >

CONSULT-II CHECKING SYSTEM

*2: IVIS (NATS) [Infiniti Vehicle Immobilizer System (Nissan Anti-Theft System)].

*3: This system is shown with IVIS (NATS) using program card INFINITI QX56 2007 Factory Service Manual GI-36

< SERVICE INFORMATION >

CONSULT-II CHECKING SYSTEM

*2: IVIS (NATS) [Infiniti Vehicle Immobilizer System (Nissan Anti-Theft System)].

*3: This system is shown with IVIS (NATS) using program card](/img/42/57029/w960_57029-2001.png)

GI-36

< SERVICE INFORMATION >

CONSULT-II CHECKING SYSTEM

*2: IVIS (NATS) [Infiniti Vehicle Immobilizer System (Nissan Anti-Theft System)].

*3: This system is shown with IVIS (NATS) using program card AEN06B or later.

Nickel Metal Hydride Battery ReplacementINFOID:0000000003531492

CONSULT-II contains a nickel metal hydride battery. When replacing the battery obey the following:

WARNING:

Replace the nickel metal hydride battery with Genuine CONSULT-II battery only. Use of another bat-

tery may present a risk of fire or explosion. The battery may present a fire or chemical burn hazard

ifmistreated. Do not recharge, disassemble or dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regulations.

Checking EquipmentINFOID:0000000003531493

When ordering the below equipment, contact your NISSAN distributor.

CAUTION:

• Previous CONSULT-II “I” and “Y” DLC-I and DLC-II cables should NOT be used anymore because

their DDL connector pins can be damaged during cable swapping.

• If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self- diagnosis depending on control unit which carries out CAN communication.

• If CONSULT-II CONVERTER is not connected with CONSULT-II, the vehicle enters “FAIL SAFE

MODE” which will “LIGHT UP the HEAD LIGHT” and /or “COOLING FAN ROTATING” when CONSULT-

II is started.

NOTE:

• The CONSULT-II must be used in conjunction with a program card.

CONSULT-II does not require loading (Initialization) procedure.

• Be sure the CONSULT-II is turned OFF before installing or removing a program card.

CONSULT-II Start ProcedureINFOID:0000000003531494

NOTE:

Turning ignition switch off when performing CAN diagnosis could cause CAN memory to be erased.

1. Connect CONSULT-II and CONSULT-II CONVERTER to the

data link connector.

Tool name Description

NISSAN CONSULT-II (J-44200)

1. CONSULT-II unit (Tester internal soft: Resi-

dent Version 3.4.0) and accessories.

2. Program card UED06E-1 and AEN06B (for

NATS) or later, to confirm the best combina-

tion of these software, refer to CONSULT-II

Operation Manual.

3. CONSULT-II CONVERTER.

4. CONSULT-II pigtail cable.

SAIA0363E

PAIA0070E

Page 2003 of 3061

CONSULT-II CHECKING SYSTEM

GI-37

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

P

2. If necessary, turn on the ignition switch.

3. Touch “START (NISSAN BASED VHCL)” or system shortcut (eg:

ENGINE) on the screen.

4. Touch necessary system on "SELECT SYSTEM" screen.

If necessary system is not indicated, check power supply and

ground of system control unit. If it is normal, refer to GI-38,

"CONSULT-II Data Link Connector (DLC) Circuit".

5. Select the desired part to be diagnosed on the "SELECT DIAG

MODE" screen.

BCIA0029E

BCIA0030E

BCIA0031E

Page 2008 of 3061

GI-42

< SERVICE INFORMATION >

TOW TRUCK TOWING

TOW TRUCK TOWING

Tow Truck TowingINFOID:0000000003531499

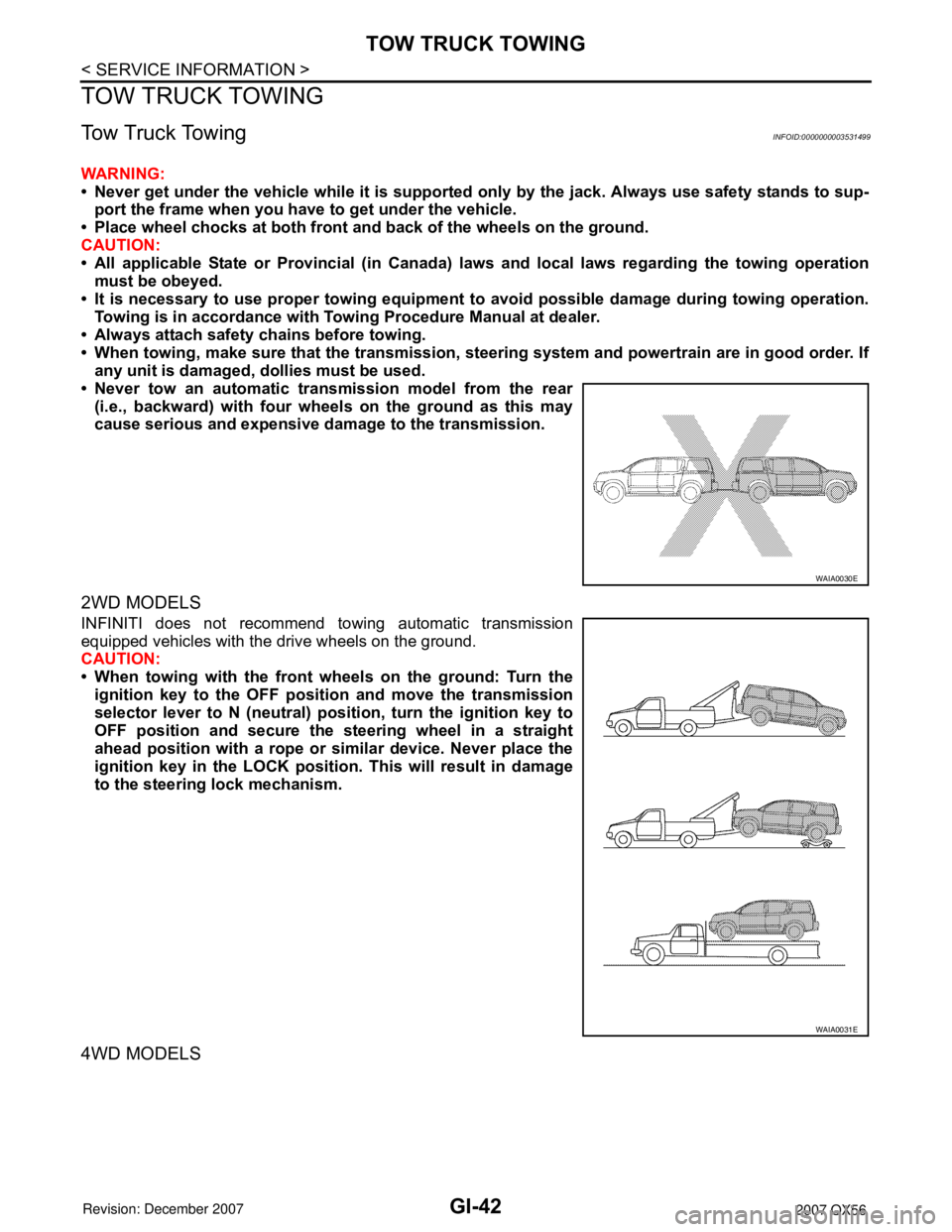

WARNING:

• Never get under the vehicle while it is supported only by the jack. Always use safety stands to sup-

port the frame when you have to get under the vehicle.

• Place wheel chocks at both front and back of the wheels on the ground.

CAUTION:

• All applicable State or Provincial (in Canada) laws and local laws regarding the towing operation

must be obeyed.

• It is necessary to use proper towing equipment to avoid possible damage during towing operation.

Towing is in accordance with Towing Procedure Manual at dealer.

• Always attach safety chains before towing.

• When towing, make sure that the transmission, steering system and powertrain are in good order. If

any unit is damaged, dollies must be used.

• Never tow an automatic transmission model from the rear

(i.e., backward) with four wheels on the ground as this may

cause serious and expensive damage to the transmission.

2WD MODELS

INFINITI does not recommend towing automatic transmission

equipped vehicles with the drive wheels on the ground.

CAUTION:

• When towing with the front wheels on the ground: Turn the

ignition key to the OFF position and move the transmission

selector lever to N (neutral) position, turn the ignition key to

OFF position and secure the steering wheel in a straight

ahead position with a rope or similar device. Never place the

ignition key in the LOCK position. This will result in damage

to the steering lock mechanism.

4WD MODELS

WAIA0030E

WAIA0031E

Page 2016 of 3061

GI-50

< SERVICE INFORMATION >

TERMINOLOGY

TERMINOLOGY

SAE J1930 Terminology ListINFOID:0000000003531507

All emission related terms used in this publication in accordance with SAE J1930 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Canister *** Canister

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC ***

Data link connector for CONSULT-II DLC for CONSULT-II Diagnostic connector for CONSULT-II

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read

only memoryEEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

Erasable programmable read only memory EPROM ***

Evaporative emission canister EVAP canister Canister

Evaporative emission system EVAP system Canister control solenoid valve

Exhaust gas recirculation valve EGR valve EGR valve

Page 2017 of 3061

TERMINOLOGY

GI-51

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

P

Exhaust gas recirculation control-BPT

valveEGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid

valveEGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sen-

sor

EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memoryFEEPROM ***

Flash erasable programmable read only

memoryFEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulator *** Pressure regulator

Fuel pressure regulator control solenoid

valve*** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control

valveIACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control sole-

noid valveIACV-idle up control solenoid valve Idle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection System MFI system Fuel injection controlNEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Page 2034 of 3061

POWER WINDOW SYSTEM

GW-15

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

GW

N

O

P

POWER WINDOW SYSTEM

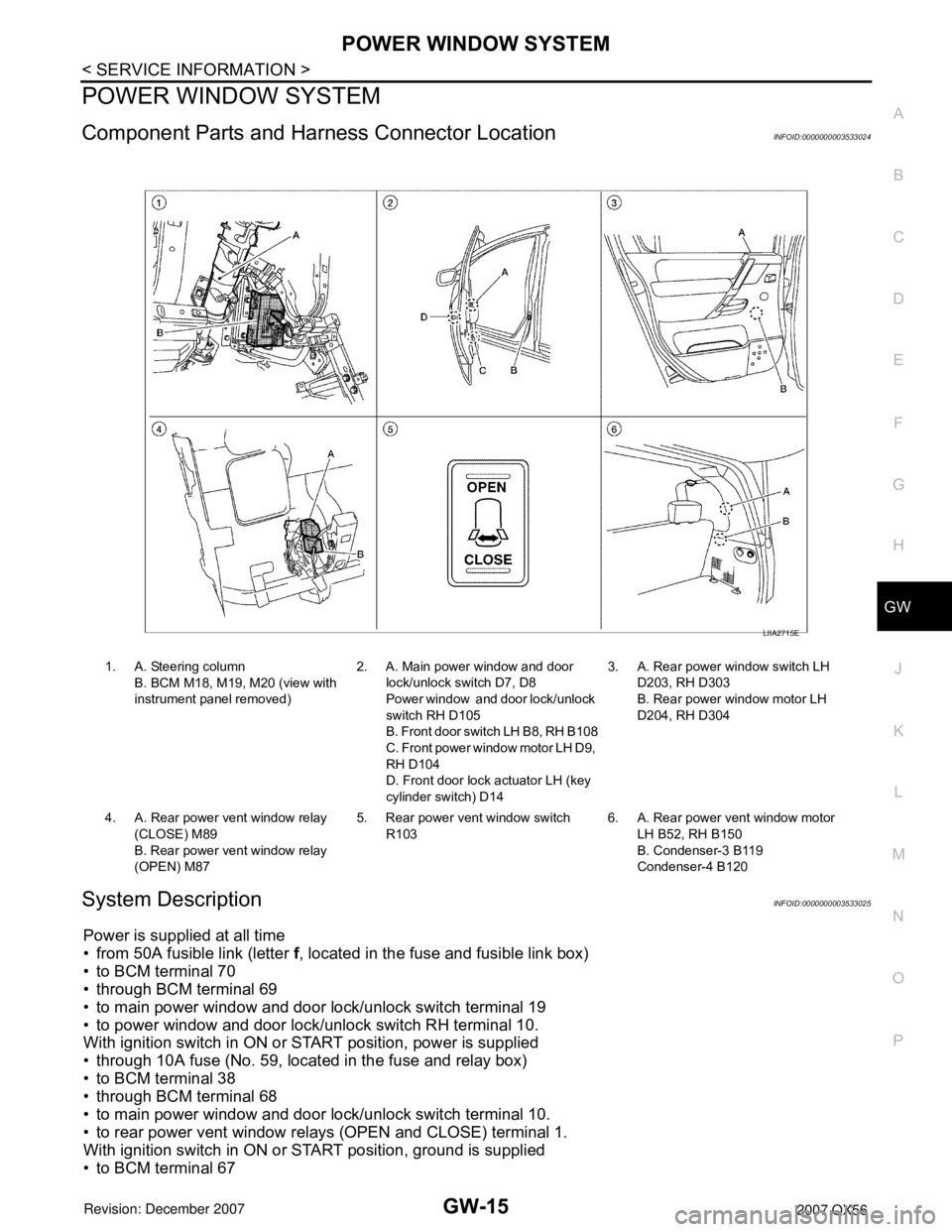

Component Parts and Harness Connector LocationINFOID:0000000003533024

System DescriptionINFOID:0000000003533025

Power is supplied at all time

• from 50A fusible link (letter f, located in the fuse and fusible link box)

• to BCM terminal 70

• through BCM terminal 69

• to main power window and door lock/unlock switch terminal 19

• to power window and door lock/unlock switch RH terminal 10.

With ignition switch in ON or START position, power is supplied

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38

• through BCM terminal 68

• to main power window and door lock/unlock switch terminal 10.

• to rear power vent window relays (OPEN and CLOSE) terminal 1.

With ignition switch in ON or START position, ground is supplied

• to BCM terminal 67

1. A. Steering column

B. BCM M18, M19, M20 (view with

instrument panel removed)2. A. Main power window and door

lock/unlock switch D7, D8

Power window and door lock/unlock

switch RH D105

B. Front door switch LH B8, RH B108

C. Front power window motor LH D9,

RH D104

D. Front door lock actuator LH (key

cylinder switch) D143. A. Rear power window switch LH

D203, RH D303

B. Rear power window motor LH

D204, RH D304

4. A. Rear power vent window relay

(CLOSE) M89

B. Rear power vent window relay

(OPEN) M875. Rear power vent window switch

R1036. A. Rear power vent window motor

LH B52, RH B150

B. Condenser-3 B119

Condenser-4 B120

LIIA2715E

Page 2037 of 3061

GW-18

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

The signal is transmitted from main power window and door lock/unlock switch to power window and door

lock/unlock switch RH

• Front door window RH operation signal.

• Power window control by front door lock assembly LH (key cylinder switch) signal.

• Power window lock signal.

• Retained power operation signal.

• Rear power window operation.

POWER WINDOW LOCK

The power window lock is designed to lock operation of all windows except for front door window LH.

When in the lock position, the power window lock signal is transmitted to power window and door lock/unlock

switch RH by power window serial link. This prevents the power window motor from operating.

RETAINED POWER OPERATION

When the ignition switch is turned to the OFF position from ON or START position, power is supplied for 45

seconds

• to main power window and door lock/unlock switch terminal 10

• from BCM terminal 68.

When power and ground are supplied, the BCM continues to be energized, and the power window can be

operated.

The retained power operation is canceled when the front LH or front RH door is opened.

Retained power operation period can be changed by CONSULT-II. Refer to GW-31, "

CONSULT-II Function

(BCM)" .

ANTI-PINCH SYSTEM

Main power window and door lock/unlock switch, power window and door lock/unlock switch RH and rear

power window control unit LH and RH monitors the power window motor operation and the power window

position (full closed or other) for each power window by the signals from encoder and limit switch in power win-

dow motor.

When a window switch detects interruption during the following close operation,

• automatic close operation when ignition switch is in the ON position

• automatic close operation during retained power operation

Main power window and door lock/unlock switch, power window and door lock/unlock switch RH and rear

power window control unit LH and RH controls each power window motor for open and the power window will

be lowered about 150 mm (5.91 in).

POWER WINDOW CONTROL BY THE FRONT DOOR LOCK ASSEMBLY LH (KEY CYLINDER

SWITCH)

When ignition key switch is OFF, front power window LH and RH can be opened or closed by turning the front

door lock assembly LH (key cylinder switch) to the UNLOCK/LOCK position for more than 1 second.

• Front power windows can be opened as the front door lock assembly LH (key cylinder switch) is kept fully

turned to the UNLOCK position.

• Front power windows can be closed as the front door lock assembly LH (key cylinder switch) is kept fully

turned to the LOCK position.

• While performing open/close operation for the windows, power window is stopped when the front door lock

assembly LH (key cylinder switch) is placed in the NEUTRAL position.

• When the ignition switch is turned ON while the power window opening operation is performed, the power

window opening stops.

CAN Communication System DescriptionINFOID:0000000003533026

Refer to LAN-4.

Page 2048 of 3061

POWER WINDOW SYSTEM

GW-29

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

GW

N

O

P

outINFOID:0000000003533029

Terminal and Reference Value for Main Power Window and Door Lock/Unlock Switch

INFOID:0000000003533030

LIIA2455E

Terminal Wire Color Item ConditionVoltage (V)

(Approx.)

2 W/B Limit switch and encoder ground — 0

4LFront door key cylinder switch LH

lock signalKey position

(Neutral → Unlocked)5 → 0

6RFront door key cylinder LH switch

unlock signalKey position

(Neutral → Locked)5 → 0

8G/RFront power window motor LH UP

signalWhen power window motor is op-

erated UP Battery voltage

9 O Limit switch signalFront power window LH is be-

tween fully-open and just before

fully-closed position (ON)0

Front power window LH is be-

tween just before fully-closed po-

sition and fully-closed position

(OFF)5

10 W/L RAP signalWhen ignition switch ON Battery voltage

Within 45 seconds after ignition

switch is turned to OFFBattery voltage

More than 45 seconds after igni-

tion switch is turned to OFF0

When front door LH or RH open

or power window timer operates0

11 G / WFront power window motor LH

DOWN signalWhen power window motor is op-

erated DOWN Battery voltage

13 G/Y Encoder pulse signalWhen power window motor oper-

ates

14 LG/W Power window serial linkWhen ignition switch ON or power

window timer operates

OCC3383D

PIIA2344J