sensor INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2814 of 3061

SRS-44

< SERVICE INFORMATION >

CRASH ZONE SENSOR

CRASH ZONE SENSOR

Removal and InstallationINFOID:0000000003532877

REMOVAL

CAUTION:

• Before servicing the SRS, turn the ignition switch off, disconnect both battery cables and wait at

least 3 minutes.

1. Disconnect the negative and positive battery cables, then wait at least 3 minutes.

2. Remove front grille. Refer to EI-16

.

3. Disconnect the crash zone sensor harness connector.

4. Remove crash zone sensor nuts.

CAUTION:

• Replace crash zone sensor if it has been dropped or sustained an impact.

• Do not disassemble crash zone sensor.

INSTALLATION

Installation is in the reverse order of removal.

• After the work is complete, perform self-diagnosis to check that no malfunction is detected. Refer to SRS-20,

"SRS Operation Check" .

LHIA0056E

Page 2815 of 3061

SIDE AIR BAG (SATELLITE) SENSOR

SRS-45

< SERVICE INFORMATION >

C

D

E

F

G

I

J

K

L

MA

B

SRS

N

O

P

SIDE AIR BAG (SATELLITE) SENSOR

Removal and InstallationINFOID:0000000003532878

REMOVAL

CAUTION:

• Before servicing the SRS, turn the ignition switch off, disconnect both battery cables and wait at

least 3 minutes.

1. Disconnect the negative and positive battery cables, then wait at least 3 minutes.

2. Remove seat belt pre-tensioner. Refer to SB-3, "

Removal and

Installation of Front Seat Belt" .

3. Remove side air bag (satellite) sensor nuts.

4. Disconnect the side air bag (satellite) sensor harness connector.

CAUTION:

• Do not use old nuts after removal; replace with new nuts.

• Check side air bag (satellite) sensor to make sure it is free of deformities, dents, cracks or rust. If it

shows any visible signs of damage, replace it with new one.

• Do not disassemble side air bag (satellite) sensor.

• Replace side air bag (satellite) sensor if it has been dropped or sustained an impact.

INSTALLATION

Installation is in the reverse order of removal.

• After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to SRS-

20, "SRS Operation Check" .

LHIA0062E

Page 2817 of 3061

DIAGNOSIS SENSOR UNIT

SRS-47

< SERVICE INFORMATION >

C

D

E

F

G

I

J

K

L

MA

B

SRS

N

O

P

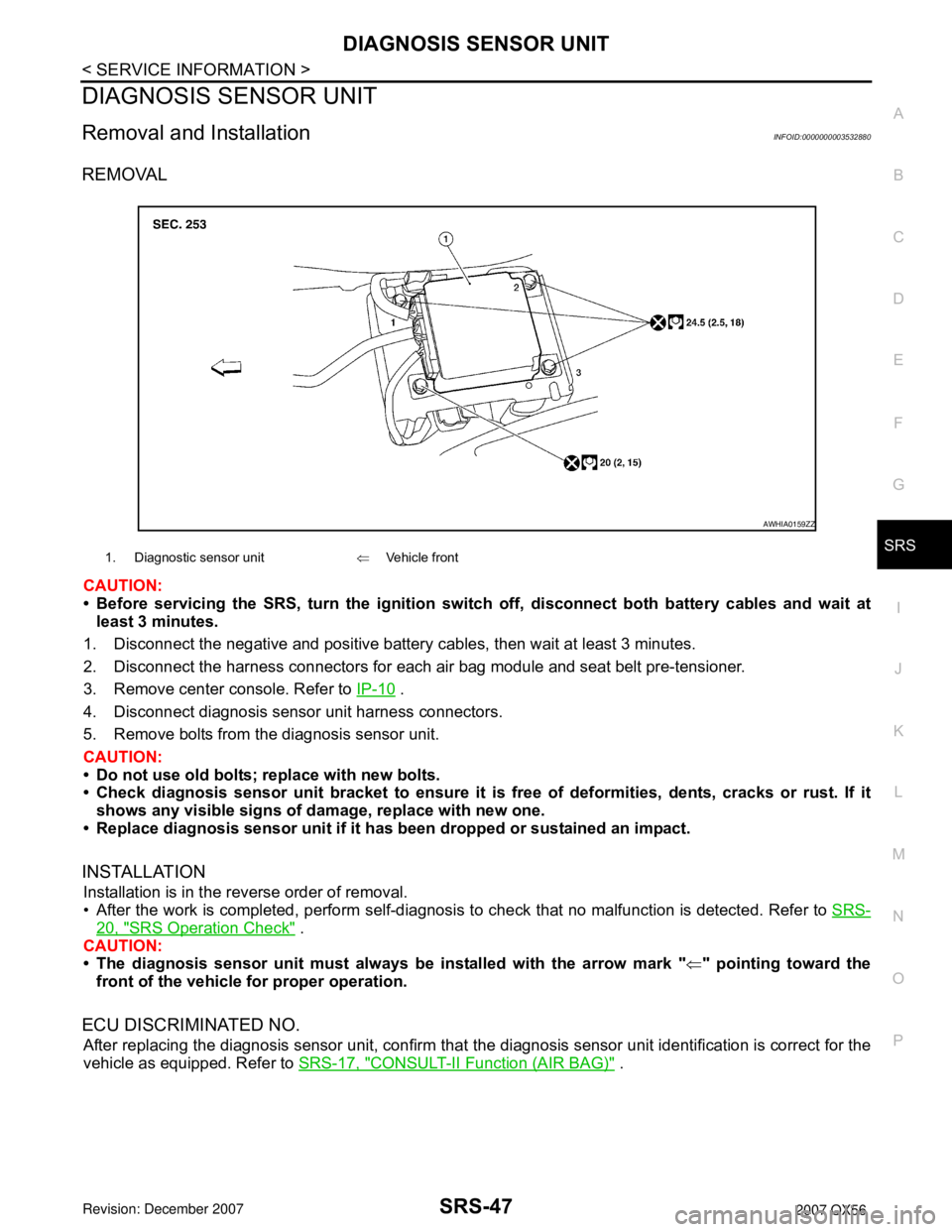

DIAGNOSIS SENSOR UNIT

Removal and InstallationINFOID:0000000003532880

REMOVAL

CAUTION:

• Before servicing the SRS, turn the ignition switch off, disconnect both battery cables and wait at

least 3 minutes.

1. Disconnect the negative and positive battery cables, then wait at least 3 minutes.

2. Disconnect the harness connectors for each air bag module and seat belt pre-tensioner.

3. Remove center console. Refer to IP-10

.

4. Disconnect diagnosis sensor unit harness connectors.

5. Remove bolts from the diagnosis sensor unit.

CAUTION:

• Do not use old bolts; replace with new bolts.

• Check diagnosis sensor unit bracket to ensure it is free of deformities, dents, cracks or rust. If it

shows any visible signs of damage, replace with new one.

• Replace diagnosis sensor unit if it has been dropped or sustained an impact.

INSTALLATION

Installation is in the reverse order of removal.

• After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to SRS-

20, "SRS Operation Check" .

CAUTION:

• The diagnosis sensor unit must always be installed with the arrow mark "⇐" pointing toward the

front of the vehicle for proper operation.

ECU DISCRIMINATED NO.

After replacing the diagnosis sensor unit, confirm that the diagnosis sensor unit identification is correct for the

vehicle as equipped. Refer to SRS-17, "

CONSULT-II Function (AIR BAG)" .

1. Diagnostic sensor unit⇐Vehicle front

AWHIA0159ZZ

Page 2818 of 3061

SRS-48

< SERVICE INFORMATION >

OCCUPANT CLASSIFICATION SYSTEM CONTROL UNIT

OCCUPANT CLASSIFICATION SYSTEM CONTROL UNIT

Removal and InstallationINFOID:0000000003532881

The occupant classification control unit, occupant classification (pressure) sensor, and bladder are an integral

part of the front passenger seat cushion and are replaced as an assembly. Refer to SE-83, "

Removal and

Installation" to remove the seat, and SE-85, "Disassembly and Assembly" to replace the seat cushion.

Page 2819 of 3061

COLLISION DIAGNOSIS

SRS-49

< SERVICE INFORMATION >

C

D

E

F

G

I

J

K

L

MA

B

SRS

N

O

P

COLLISION DIAGNOSIS

For Frontal CollisionINFOID:0000000003532882

Check the SRS components using the following table.

• After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to SRS-

20, "SRS Operation Check" .

SRS INSPECTION (FOR FRONTAL COLLISION)

Part SRS is activated SRS is NOT activated

Driver air bag module If the driver air bag

has deployed:

REPLACE

Install with new fas-

teners.If the driver air bag has NOT been activated:

1. Remove driver air bag module. Check harness cover and connectors for dam-

age, terminals for deformities, and harness for binding.

2. Install driver air bag module into the steering wheel to check fit and alignment

with the wheel.

3. If no damage is found, reinstall with new fasteners.

4. If damaged—REPLACE. Install driver air bag modules with new fasteners.

Front passenger air

bag moduleIf the front passenger

air bag has deployed:

REPLACE

Install with new fas-

teners.If the front passenger air bag has NOT been activated:

1. Remove front passenger air bag module. Check harness cover and connectors

for damage, terminals for deformities, and harness for binding.

2. Install front passenger air bag module into the instrument panel to check fit with

the instrument panel.

3. If no damage is found, reinstall with new fasteners.

4. If damaged—REPLACE. Install front passenger air bag modules with new fas-

teners.

Crash zone sensor If any of the front air

bags or seat belt pre-

tensioners* have

been activated:

REPLACE the crash

zone sensor and

bracket with new fas-

teners.

*: Confirm seat belt

pre-tensioner activa-

tion using CONSULT-

II only.If the front air bags or seat belt pre-tensioners have NOT been activated:

1. Remove the crash zone sensor. Check harness connectors for damage, termi-

nals for deformities, and harness for binding.

2. Check for visible signs of damage (dents, cracks, deformation) of the crash zone

sensor and bracket.

3. Install the crash zone sensor to check fit.

4. If no damage is found, reinstall with new fasteners.

5. If damaged—REPLACE the crash zone sensor and bracket with new fasteners.

Seat belt pre-tension-

er assemblies

(All applicable loca-

tions: buckle, reel, lap

outer)If either the driver or

passenger seat belt

pre-tensioner* has

been activated:

REPLACE all seat

belt pre-tensioner as-

semblies with new

fasteners.

*: Confirm seat belt

pre-tensioner activa-

tion using CONSULT-

II only.If the pre-tensioners have NOT been activated:

1. Remove seat belt pre-tensioners.

Check harness cover and connectors for damage, terminals for deformities, and

harness for binding.

2. Check belts for damage and anchors for loose mounting.

3. Check retractor for smooth operation.

4. Check seat belt adjuster for damage.

5. Check for deformities of the center pillar inner.

6. If the center pillar inner has no damage, REPLACE the seat belt pre-tensioner

assembly.

7. If no damage is found, reinstall seat belt pre-tensioner assembly.

8. If damaged—REPLACE. Install the seat belt pre-tensioners with new fasteners.

Diagnosis sensor unit If any of the SRS com-

ponents have been

activated:

REPLACE the diag-

nosis sensor unit.

Install with new fas-

teners.If none of the SRS components have been activated:

1. Check case for dents, cracks or deformities.

2. Check connectors for damage, and terminals for deformities.

3. If no damage is found, reinstall with new fasteners.

4. If damaged—REPLACE. Install diagnosis sensor unit with new fasteners.

Page 2820 of 3061

SRS-50

< SERVICE INFORMATION >

COLLISION DIAGNOSIS

For Side and Rollover Collision

INFOID:0000000003532883

Check the SRS components using the following table.

• After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to SRS-

20, "SRS Operation Check" .

WHEN SRS IS ACTIVATED IN THE SIDE OR ROLLOVER COLLISION

1. Replace the following components:

- Front seat back assembly (on the side on which side air bag is activated)

- Diagnosis sensor unit

- (LH or RH) side air bag (satellite) sensor (on the side on which side air bag is activated)

2. Check the SRS components and the related parts using the following table.

- Replace any SRS components and the related parts showing visible signs of damage (dents, cracks,

deformation).

3. Conduct self-diagnosis using CONSULT-II and “AIR BAG” warning lamp. Refer to SRS-20, "

SRS Opera-

tion Check" for details. Ensure entire SRS operates properly.

WHEN SRS IS NOT ACTIVATED IN THE SIDE OR ROLLOVER COLLISION

1. Check the SRS components and the related parts using the following table.

- If the front seat back assembly is damaged, the front seat back assembly must be replaced.

2. Conduct self-diagnosis using CONSULT-II and “AIR BAG” warning lamp. Refer to SRS-20, "

SRS Opera-

tion Check" for details. Ensure entire SRS operates properly.

SRS INSPECTION (FOR SIDE AND ROLLOVER COLLISION)

Steering wheel 1. Visually check steering wheel for deformities.

2. Check harness (built into steering wheel) and connectors for damage, and terminals for deformities.

3. Install driver air bag module into the steering wheel to check fit and alignment with the wheel.

4. Check steering wheel for excessive free play.

5. If no damage is found, reinstall.

6. If damaged—REPLACE.

Spiral cable If the driver front air

bag has deployed:

REPLACE the spiral

cable.If the driver front air bag has not deployed:

1. Visually check spiral cable and combination switch for damage.

2. Check connectors and protective tape for damage.

3. Check steering wheel for noise, binding or heavy operation.

4. If no damage is found, reinstall.

5. If damaged—REPLACE.

Occupant classifica-

tion system (Passen-

ger seat)1. Remove passenger seat.

2. Check control unit case for dents, cracks of deformities.

3. Check connectors and pressure sensor tube for damage, and terminals for deformities.

4. Check seat frame and cushion pan for dents or deformities.

5. If no damage is found, reinstall seat with new fasteners.

6. If damaged — REPLACE seat cushion assembly with new fasteners.

Harness and connec-

tors1. Check connectors for poor connection, damage, and terminals for deformities.

2. Check harness for binding, chafing, cuts, or deformities.

3. If no damage is found, reinstall the harness and connectors.

4. If damaged—REPLACE the damaged harness. Do not attempt to repair, splice or modify any SRS har-

ness.

Instrument panel If the passenger front

air bag has deployed:

REPLACE the instru-

ment panel assembly.If the passenger front air bag has NOT deployed:

1. Visually check instrument panel for damage.

2. If no damage is found, reinstall the instrument panel.

3. If damaged—REPLACE the instrument panel. Part SRS is activated SRS is NOT activated

Page 2821 of 3061

COLLISION DIAGNOSIS

SRS-51

< SERVICE INFORMATION >

C

D

E

F

G

I

J

K

L

MA

B

SRS

N

O

P

Part SRS is activated SRS is NOT activated

LH side curtain air

bag moduleIf the LH side curtain

air bag has deployed:

REPLACE the LH

side curtain air bag

module. (Repair the

center pillar inner, etc.

before installing new

one if damaged.)If the LH side curtain air bag has NOT deployed:

1. Check for visible signs of damage (dents, tears, deformation) of the center pillar

on the collision side.

2. If damaged—Remove the LH side curtain air bag module.

3. Check for visible signs of damaged (tears etc.) of the LH side curtain air bag mod-

ule.

4. Check harness and connectors for damage, and terminals for deformities.

5. If no damage is found, reinstall the LH side curtain air bag module with new fas-

teners.

6. If damaged—REPLACE the LH side curtain air bag module with new fasteners.

RH side curtain air

bag moduleIf the RH side curtain

air bag has deployed:

REPLACE the RH

side curtain air bag

module. (Repair the

center pillar inner, etc.

before installing new

one if damaged.)If the RH side curtain air bag has NOT deployed:

1. Check for visible signs of damage (dents, tears, deformation) of the center pillar

on the collision side.

2. If damaged—Remove the RH side curtain air bag module.

3. Check for visible signs of damaged (tears etc.) of the RH side curtain air bag

module.

4. Check harness and connectors for damage, and terminals for deformities.

5. If no damage is found, reinstall the RH side curtain air bag module with new fas-

teners.

6. If damaged—REPLACE the RH side curtain air bag module with new fasteners.

Front LH side air bag

moduleIf the front LH side air

bag has deployed:

REPLACE front LH

seatback assembly.If the front LH side air bag has NOT deployed:

1. Check for visible signs of damage (dents, tears, deformation) of the seat back on

the collision side.

2. Check harness and connectors for damage, and terminals for deformities.

3. If damaged—REPLACE the front LH seatback assembly.

Front RH side air bag

moduleIf the front RH side air

bag has deployed:

REPLACE front RH

seatback assembly.If the front RH side air bag has NOT deployed:

1. Check for visible signs of damage (dents, tears, deformation) of the seat back on

the collision side.

2. Check harness and connectors for damage, and terminals for deformities.

3. If damaged—REPLACE the front RH seatback assembly.

(LH or RH) side air

bag (satellite) sensor If any of the SRS

components have de-

ployed:

REPLACE the side air

bag (satellite) sensor

on the collision side

with new fasteners.

(Repair the center pil-

lar inner, etc. before

installing new one if

damaged.)If none of the SRS components have been activated:

1. Remove the side air bag (satellite) sensor on the collision side. Check harness

connectors for damage, terminals for deformities, and harness for binding.

2. Check for visible signs of damage (dents, cracks, deformation) of the side air bag

(satellite) sensor.

3. Install the side air bag (satellite) sensor to check fit.

4. If no damage is found, reinstall the side sir bag (satellite) sensor with new fasten-

ers.

5. If damaged—REPLACE the side air bag (satellite) sensor with new fasteners.

Diagnosis sensor unit If any of the SRS

components have de-

ployed:

REPLACE the diag-

nosis sensor unit with

new fasteners.If none of the SRS components have been activated:

1. Check case and bracket for dents, cracks or deformities.

2. Check connectors for damage, and terminals for deformities.

3. If no damage is found, reinstall the diagnosis sensor unit with new fasteners.

4. If damaged—REPLACE the diagnosis sensor unit with new fasteners.

Seat belt pre-tension-

er assemblies

(All applicable loca-

tions: buckle, reel, lap

outer)If either the driver or

passenger seat belt

pre-tensioner* has

been activated:

REPLACE all seat

belt pre-tensioner as-

semblies with new

fasteners.

*: Confirm seat belt

pre-tensioner activa-

tion using CONSULT-

II only.If the pre-tensioners have NOT been activated:

1. Remove seat belt pre-tensioners.

Check harness cover and connectors for damage, terminals for deformities, and

harness for binding.

2. Check belts for damage and anchors for loose mounting.

3. Check retractor for smooth operation.

4. Check seat belt adjuster for damage.

5. Check for deformities of the center pillar inner.

6. If the center pillar inner has no damage, REPLACE the seat belt pre-tensioner

assembly.

7. If no damage is found, reinstall seat belt pre-tensioner assembly.

8. If damaged—REPLACE. Install the seat belt pre-tensioners with new fasteners.

Page 2823 of 3061

TF-1

DRIVELINE/AXLE

C

E

F

G

H

I

J

K

L

M

SECTION TF

A

B

TF

N

O

P

CONTENTS

TRANSFER

SERVICE INFORMATION ............................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for Transfer Assembly and Transfer

Control Unit Replacement .........................................

3

Precaution .................................................................4

Service Notice ...........................................................4

PREPARATION ...................................................6

Special Service Tool .................................................6

Commercial Service Tool ..........................................9

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ............................

10

NVH Troubleshooting Chart ....................................10

TRANSFER FLUID .............................................11

Replacement ...........................................................11

Inspection ................................................................11

ALL-MODE 4WD SYSTEM ................................12

Cross-Sectional View ..............................................12

Power Transfer ........................................................12

System Description .................................................14

Schematic ...............................................................19

CAN Communication ...............................................20

TROUBLE DIAGNOSIS .....................................21

How to Perform Trouble Diagnosis .........................21

Location of Electrical Parts ......................................22

Circuit Diagram .......................................................23

Wiring Diagram - T/F - .............................................24

Inspections Before Trouble Diagnosis ....................31

Trouble Diagnosis Chart by Symptom ....................34

Transfer Control Unit Input/Output Signal Refer-

ence Value ..............................................................

35

CONSULT-II Function (ALL MODE AWD/4WD) .....42

Self-Diagnosis Procedure .......................................48

TROUBLE DIAGNOSIS FOR SYSTEM ............51

Power Supply Circuit for Transfer Control Unit ........51

Transfer Control Unit ...............................................53

Output Shaft Revolution Signal (TCM) ....................53

Vehicle Speed Sensor (ABS) ..................................54

Neutral-4LO Switch .................................................54

4WD Shift Switch .....................................................57

Wait Detection Switch ..............................................60

PNP Switch Signal (TCM) .......................................63

Actuator Motor .........................................................64

Actuator Position Switch ..........................................69

Transfer Control Device ...........................................72

Engine Speed Signal (ECM) ....................................76

Clutch Pressure Solenoid ........................................76

2-4WD Solenoid ......................................................80

Transfer Motor .........................................................84

Transfer Fluid Temperature .....................................90

Clutch Pressure Switch ...........................................92

Line Pressure Switch ...............................................94

Throttle Position Signal (ECM) ................................97

ABS Operation Signal (ABS) ...................................97

VDC Operation Signal (ABS) ...................................98

TCS Operation Signal (ABS) ...................................98

CAN Communication Line .......................................99

ATP Switch ..............................................................99

TROUBLE DIAGNOSIS FOR SYMPTOMS ....102

4WD Shift Indicator Lamp and 4LO Indicator

Lamp Do Not Turn ON ...........................................

102

4WD Warning Lamp Does Not Turn ON ...............104

4WD Shift Indicator Lamp or 4LO Indicator Lamp

Does Not Change ..................................................

107

ATP Warning Lamp Turns ON ...............................109

4LO Indicator Lamp Repeats Flashing ..................110

4WD Warning Lamp Flashes Rapidly ....................111

4WD Warning Lamp Flashes Slowly .....................112

Heavy Tight-corner Braking Symptom Occurs ......113

4WD System Does Not Operate ............................114

TRANSFER CONTROL UNIT .........................115

Removal and Installation .......................................115

Page 2839 of 3061

ALL-MODE 4WD SYSTEM

TF-17

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

*: After 2.5 seconds have elapsed.

• 4WD shift switch, PNP switch, Neutral-4LO switch, vehicle speed sensor and throttle position sensor are

used in conjunction with the transfer motor.

WAIT DETECTION SWITCH

• The wait detection switch operates when there is “circulating” torque produced in the propeller shaft (L→H)

or when there is a phase difference between 2-4 sleeve and clutch drum (H→L). After the release of the “cir-

culating” torque, the wait detection switch helps provide the 4WD lock gear (clutch drum) shifts. A difference

may occur between the operation of the 4WD shift switch and actual drive mode. At this point, the wait

detection switch senses an actual drive mode.

• The wait detection switch operates as follows.

- 4WD lock gear (clutch drum) locked: ON

- 4WD lock gear (clutch drum) released: OFF

• The wait detection switch senses an actual drive mode and the 4WD shift indicator lamp indicates the vehi-

cle drive mode.

NEUTRAL-4LO SWITCH

The neutral-4LO switch detects that transfer gear is in neutral or 4LO (or shifting from neutral to 4LO) condi-

tion by L-H shift fork position.

AT P S W I T C H

ATP switch detects if transfer gear is in a neutral condition by L-H shift fork position.

NOTE:

Transfer gear may be in a neutral condition in 4H-4LO.

2-4WD SHIFT SOLENOID VALVE

The 2-4WD shift solenoid valve operates to apply oil pressure to the wet-multiplate clutch, depending on the

drive mode. The driving force is transmitted to the front wheels through the clutch so the vehicle is set in the

4WD mode. Setting the vehicle in the 2WD mode requires no pressure buildup. In other words, pressure force

applied to the wet-multiplate clutch becomes zero.

CLUTCH PRESSURE SOLENOID VALVE

The clutch pressure solenoid valve distributes torque (front and rear) in AUTO mode.

4H (LOCK) and 4LO“N” position 0 — ON

“P” position 00 - 0.07/8 OFF*

0.07/8 - 1/8 HOLD

1/8 - MAX ON

Other than “R” position0 < VSS ≤ 50 km/h (31 MPH)

— ON

50 km/h (31 MPH) < VSS < 55

km/h (34 MPH) HOLD

55 km/h (34 MPH) ≤ VSS OFF

“R” position — — ON

“R” position — — ON

AUTO“P” or “N” position00 - 0.07/8 OFF*

0.07/8 - 1/8 HOLD

1/8 - MAX ON

0 < VSS ≤ 50 km/h (31 MPH)

— ON

50 km/h (31 MPH) < VSS < 55

km/h (34 MPH) HOLD

55 km/h (34 MPH) ≤ VSS OFF

Other than “R”, "P" and "N"

position0 < VSS ≤ 50 km/h (31 MPH)

— ON

50 km/h (31 MPH) < VSS < 55

km/h (34 MPH) HOLD

55 km/h (34 MPH) ≤ VSS OFF 4WD shift switch A/T selector lever positionVehicle speed

(VSS)Accelerator pedal positionMotor relay drive

command

Page 2840 of 3061

TF-18

< SERVICE INFORMATION >

ALL-MODE 4WD SYSTEM

LINE PRESSURE SWITCH

• With the transfer system design, control of the oil pressure provides the transmission of drive torque to the

front wheels. The main pressure to control the oil pressure is referred to as the line pressure.

• The line pressure switch determines whether or not adequate line pressure has built up under different oper-

ating conditions.

• The line pressure switch turns ON when line pressure is produced.

• The line pressure switch senses line pressure abnormalities and turns the 4WD warning lamp ON.

CLUTCH PRESSURE SWITCH

• The clutch pressure switch determines whether or not adequate clutch pressure has built up under different

operating conditions.

• The clutch pressure switch turns ON when clutch pressure is produced.

• The clutch pressure switch senses clutch pressure abnormalities and turns the 4WD warning lamp ON.

TRANSFER FLUID TEMPERATURE SENSOR

The transfer temperature sensor detects the transfer fluid temperature and sends a signal to the transfer con-

trol unit.

TRANSFER CONTROL UNIT

• Transfer control unit controls transfer control device by input signals of each sensor and each switch.

• Self-diagnosis can be done.

TRANSFER CONTROL DEVICE

The transfer control device changes the state of transfer assembly between 2WD, AUTO, 4H⇔4LO with the

2WD, AUTO, 4H and 4LO signals of 4WD shift switch.

NOTE:

• To shift between 4H⇔4LO, stop the vehicle, depress the brake pedal and shift the transmission selector to

the "N" position. Depress and turn the 4WD shift switch. The shift switch will not shift to the desired mode if

the transmission is not in "N" or the vehicle is moving. The 4LO indicator lamp will be lit when the 4LO is

engaged.

• Actuator motor and actuator position switch are integrated.

4WD SHIFT SWITCH AND INDICATOR LAMP

4WD Shift Switch

The 4WD shift switch allows selection from 2WD, AUTO, 4H or 4LO.

4WD Shift Indicator Lamp

• Displays driving conditions selected by 4WD shift switch with 2WD, AUTO and 4H indicators while engine is

running. (When 4WD warning lamp is turned on, all 4WD shift indicator lamps are turned off.)

• Turns ON for approximately 1 second when ignition switch is turned ON, for purpose of lamp check.

4LO Indicator Lamp

• Displays 4LO condition while engine is running. 4LO indicator lamp flashes if transfer gear does not shift

completely under 2WD, AUTO, 4H⇔4LO. (When 4WD warning lamp is turned on, 4LO indicator lamp is

turned off.)

• Turns ON for approximately 1 second when ignition switch is turned ON, for purpose of lamp check.

4WD WARNING LAMP

Turns ON or FLASH when there is a malfunction in 4WD system.

Also turns ON when ignition switch is turned ON, for purpose of lamp check. Turns OFF for approximately 1

second after the engine starts if system is normal.

4WD Warning Lamp Indication

Condition Content 4WD warning lamp

During self-diagnosis Indicates the malfunction position by number of flickers. Flickers at malfunction mode.

Lamp check*Checks the lamp by turning ON during engine starting. After

engine starts, it turns OFF if there are no malfunctions.ON

Malfunction in 4WD system*Turns ON to indicate malfunction. When ignition switch is

turned to “OFF” or the malfunction is corrected, it turns OFF.ON

When vehicle is driven with different

diameters of front and rear tiresFlickers once every 2 seconds.

Turns OFF when ignition switch is “OFF”.Flickers once every 2 sec-

onds.