horn INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1 of 3061

-1

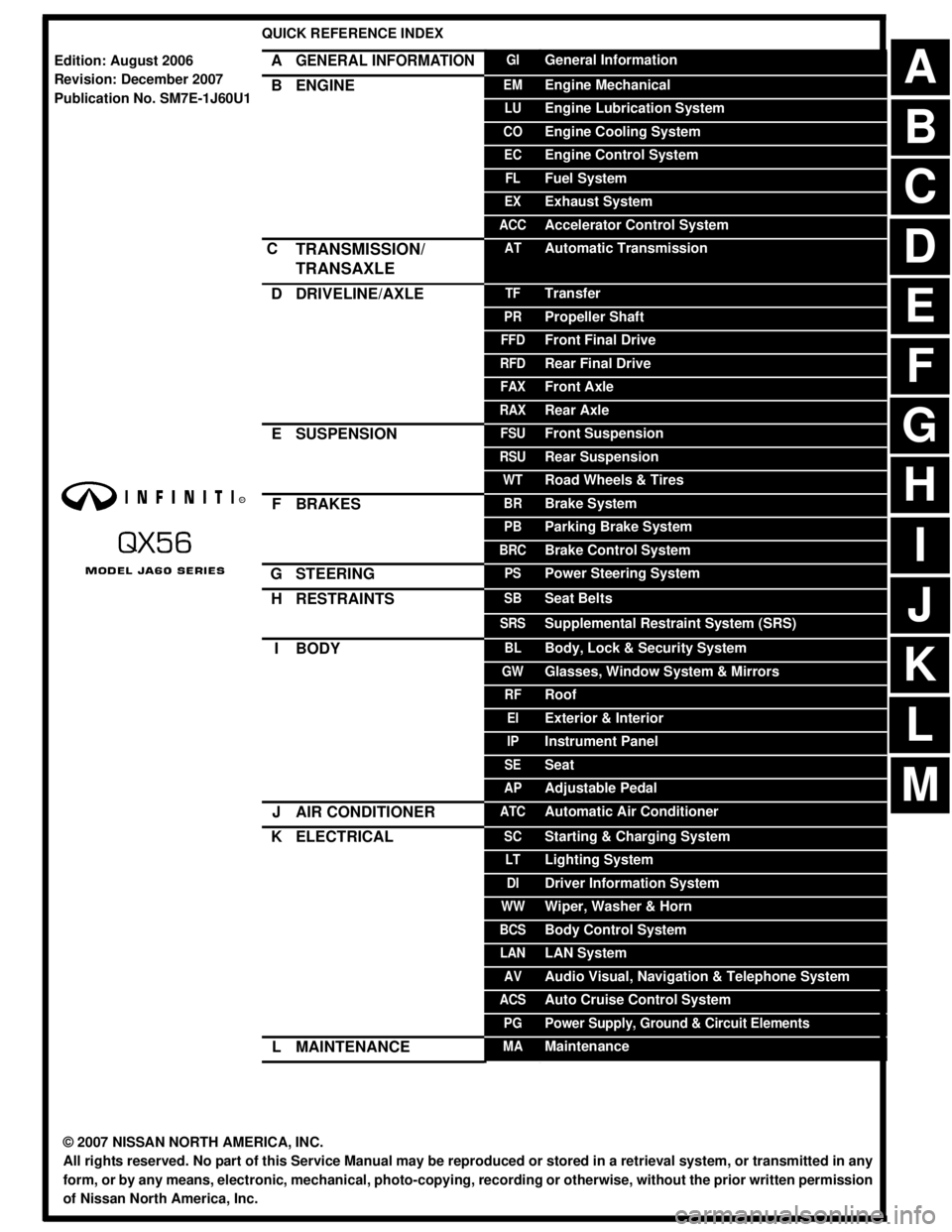

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

ACCAccelerator Control System

CTRANSMISSION/

TRANSAXLEATAutomatic Transmission

DDRIVELINE/AXLETFTransfer

PRPropeller Shaft

FFDFront Final Drive

RFDRear Final Drive

FAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGPSPower Steering System

HRESTRAINTSSBSeat Belts

SRSSupplemental Restraint System (SRS)

IBODYBLBody, Lock & Security System

GWGlasses, Window System & Mirrors

RFRoof

EIExterior & Interior

IPInstrument Panel

SESeat

APAdjustable Pedal

JAIR CONDITIONERATCAutomatic Air Conditioner

KELECTRICALSCStarting & Charging System

LTLighting System

DIDriver Information System

WWWiper, Washer & Horn

BCSBody Control System

LANLAN System

AVAudio Visual, Navigation & Telephone System

ACSAuto Cruise Control System

PGPower Supply, Ground & Circuit Elements

LMAINTENANCEMAMaintenance

Edition: August 2006

Revision: December 2007

Publication No. SM7E-1J60U1

B

D

© 2007 NISSAN NORTH AMERICA, INC.

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photo-copying, recording or otherwise, without the prior written permission

of Nissan North America, Inc.

A

C

E

F

G

H

I

J

K

L

M

Page 712 of 3061

BL-1

BODY

C

D

E

F

G

H

J

K

L

M

SECTION BL

A

B

BL

N

O

P

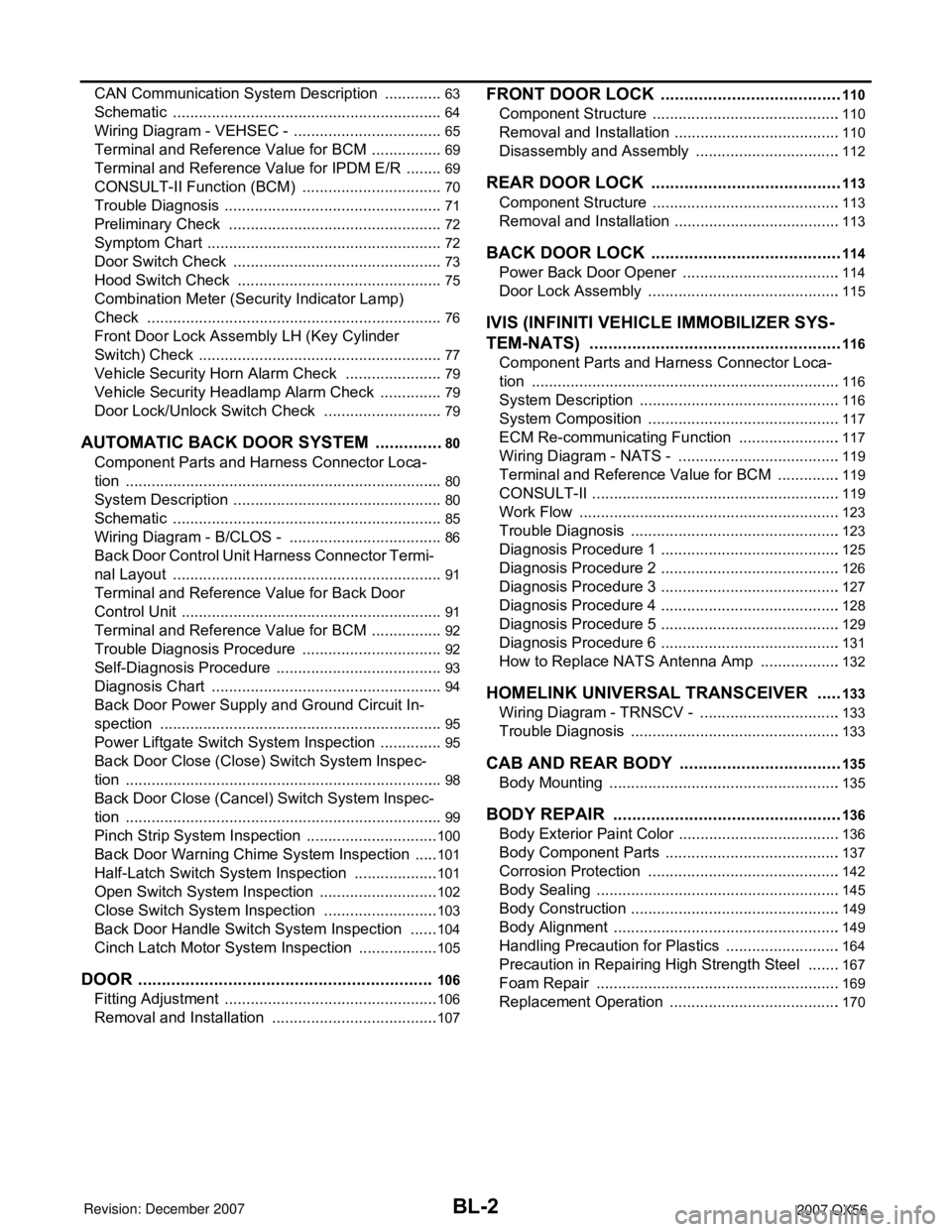

CONTENTS

BODY, LOCK & SECURITY SYSTEM

SERVICE INFORMATION ............................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for work ...................................................3

PREPARATION ...................................................4

Special Service Tool .................................................4

Commercial Service Tool ..........................................4

SQUEAK AND RATTLE TROUBLE DIAGNO-

SIS .......................................................................

5

Work Flow .................................................................5

Generic Squeak and Rattle Troubleshooting ............7

Diagnostic Worksheet ...............................................9

HOOD .................................................................11

Fitting Adjustment ...................................................11

Removal and Installation of Hood Assembly ...........12

Removal and Installation of Hood Lock Control ......13

Hood Lock Control Inspection .................................14

POWER DOOR LOCK SYSTEM ........................15

Component Parts and Harness Connector Loca-

tion ..........................................................................

15

System Description .................................................15

Schematic ...............................................................18

Wiring Diagram - D/LOCK - .....................................19

Terminal and Reference Value for BCM .................23

Work Flow ...............................................................23

CONSULT-II Function (BCM) ..................................24

Trouble Diagnosis Symptom Chart .........................25

BCM Power Supply and Ground Circuit Inspection

....

25

Door Switch Check ..................................................25

Key Switch (Insert) Check .......................................27

Door Lock/Unlock Switch Check .............................28

Glass Hatch Switch Circuit Inspection ....................30

Front Door Lock Assembly LH (Actuator) Check ....32

Front Door Lock Actuator RH Check .......................32

Rear Door Lock Actuator RH/LH Check ..................33

Glass Hatch Lock Actuator Check ...........................34

Front Door Lock Assembly LH (Key Cylinder

Switch) Check ..........................................................

35

REMOTE KEYLESS ENTRY SYSTEM .............37

Component Parts and Harness Connector Loca-

tion ...........................................................................

37

System Description ..................................................37

CAN Communication System Description ...............40

Schematic ................................................................41

Wiring Diagram - KEYLES - ....................................42

Terminal and Reference Value for BCM ..................44

Terminal and Reference Value for IPDM E/R ..........44

CONSULT-II Function (BCM) ..................................45

CONSULT-II Start Procedure ..................................45

CONSULT-II Application Item ..................................45

Trouble Diagnosis Procedure ..................................47

BCM Power Supply and Ground Circuit Inspection

....

47

Trouble Diagnosis ....................................................47

Key Switch (Insert) Check .......................................49

Door Switch Check ..................................................49

Keyfob Battery and Function Check ........................52

Remote Keyless Entry Receiver System Inspec-

tion ...........................................................................

53

ACC Power Check ...................................................54

IPDM E/R Operation Check .....................................54

Check Hazard Function ...........................................55

Check Horn Function ...............................................55

Check Headlamp Function ......................................55

Check Map Lamp Illumination Function ..................56

ID Code Entry Procedure ........................................56

Keyfob Battery Replacement ...................................59

VEHICLE SECURITY (THEFT WARNING)

SYSTEM ............................................................

60

Component Parts and Harness Connector Loca-

tion ...........................................................................

60

System Description ..................................................61

Page 713 of 3061

BL-2

CAN Communication System Description ..............63

Schematic ...............................................................64

Wiring Diagram - VEHSEC - ...................................65

Terminal and Reference Value for BCM .................69

Terminal and Reference Value for IPDM E/R .........69

CONSULT-II Function (BCM) .................................70

Trouble Diagnosis ...................................................71

Preliminary Check ..................................................72

Symptom Chart .......................................................72

Door Switch Check .................................................73

Hood Switch Check ................................................75

Combination Meter (Security Indicator Lamp)

Check .....................................................................

76

Front Door Lock Assembly LH (Key Cylinder

Switch) Check .........................................................

77

Vehicle Security Horn Alarm Check .......................79

Vehicle Security Headlamp Alarm Check ...............79

Door Lock/Unlock Switch Check ............................79

AUTOMATIC BACK DOOR SYSTEM ...............80

Component Parts and Harness Connector Loca-

tion ..........................................................................

80

System Description .................................................80

Schematic ...............................................................85

Wiring Diagram - B/CLOS - ....................................86

Back Door Control Unit Harness Connector Termi-

nal Layout ...............................................................

91

Terminal and Reference Value for Back Door

Control Unit .............................................................

91

Terminal and Reference Value for BCM .................92

Trouble Diagnosis Procedure .................................92

Self-Diagnosis Procedure .......................................93

Diagnosis Chart ......................................................94

Back Door Power Supply and Ground Circuit In-

spection ..................................................................

95

Power Liftgate Switch System Inspection ...............95

Back Door Close (Close) Switch System Inspec-

tion ..........................................................................

98

Back Door Close (Cancel) Switch System Inspec-

tion ..........................................................................

99

Pinch Strip System Inspection ...............................100

Back Door Warning Chime System Inspection ......101

Half-Latch Switch System Inspection ....................101

Open Switch System Inspection ............................102

Close Switch System Inspection ...........................103

Back Door Handle Switch System Inspection .......104

Cinch Latch Motor System Inspection ...................105

DOOR ...............................................................106

Fitting Adjustment ..................................................106

Removal and Installation .......................................107

FRONT DOOR LOCK .......................................110

Component Structure ............................................110

Removal and Installation .......................................110

Disassembly and Assembly ..................................112

REAR DOOR LOCK .........................................113

Component Structure ............................................113

Removal and Installation .......................................113

BACK DOOR LOCK .........................................114

Power Back Door Opener .....................................114

Door Lock Assembly .............................................115

IVIS (INFINITI VEHICLE IMMOBILIZER SYS-

TEM-NATS) ......................................................

116

Component Parts and Harness Connector Loca-

tion ........................................................................

116

System Description ...............................................116

System Composition .............................................117

ECM Re-communicating Function ........................117

Wiring Diagram - NATS - ......................................119

Terminal and Reference Value for BCM ...............119

CONSULT-II ..........................................................119

Work Flow .............................................................123

Trouble Diagnosis .................................................123

Diagnosis Procedure 1 ..........................................125

Diagnosis Procedure 2 ..........................................126

Diagnosis Procedure 3 ..........................................127

Diagnosis Procedure 4 ..........................................128

Diagnosis Procedure 5 ..........................................129

Diagnosis Procedure 6 ..........................................131

How to Replace NATS Antenna Amp ...................132

HOMELINK UNIVERSAL TRANSCEIVER ......133

Wiring Diagram - TRNSCV - .................................133

Trouble Diagnosis .................................................133

CAB AND REAR BODY ...................................135

Body Mounting ......................................................135

BODY REPAIR .................................................136

Body Exterior Paint Color ......................................136

Body Component Parts .........................................137

Corrosion Protection .............................................142

Body Sealing .........................................................145

Body Construction .................................................149

Body Alignment .....................................................149

Handling Precaution for Plastics ...........................164

Precaution in Repairing High Strength Steel ........167

Foam Repair .........................................................169

Replacement Operation ........................................170

Page 749 of 3061

BL-38

< SERVICE INFORMATION >

REMOTE KEYLESS ENTRY SYSTEM

• to BCM terminal 70

• through 50A fusible link (letter f , located in the fuse and fusible link box).

• to BCM terminal 57

• through 15A fuse [No. 22, located in the fuse block (J/B)].

When the key is inserted in the key switch and key lock solenoid, power is supplied

• to BCM terminal 37

• through key switch and key lock solenoid terminals 3 and 4

• through 10A fuse [No. 19, located in the fuse block (J/B)].

When the ignition switch is ACC or ON, power is supplied

• to BCM terminal 11

• through 10A fuse [No. 4, located in the fuse block (J/B)].

When the ignition switch is ON or START, power is supplied

• to BCM terminal 38

• through 10A fuse (No. 59, located in the fuse and relay box).

When the front door switch LH is ON (door is OPEN), ground is supplied

• to BCM terminal 47

• through front door switch LH terminal 2

• through front door switch LH case ground.

When the front door switch RH is ON (door is OPEN), ground is supplied

• to BCM terminal 12

• through front door switch RH terminal 2

• through front door switch RH case ground.

When the rear door switch LH is ON (door is OPEN), ground is supplied

• to BCM terminal 48

• through rear door switch LH terminal 2

• through rear door switch LH case ground.

When the rear door switch RH is ON (door is OPEN), ground is supplied

• to BCM terminal 13

• through rear door switch RH terminal 2

• through rear door switch RH case ground.

When the back door latch (door ajar switch) is ON (door is OPEN), ground is supplied

• to BCM terminal 43

• through back door latch (door ajar switch) terminal 7,

• through back door latch (door ajar switch) terminal 8,

• through body grounds B7 and B19.

Keyfob signal is input into the BCM from the remote keyless entry receiver.

The remote keyless entry system controls operation of the

• power door lock

• back door opener

• interior lamp and step lamps

• panic alarm

• hazard and horn reminder

• keyless power window down (open)

• auto door lock operation

OPERATING PROCEDURE

• When the keyfob is operated, the signal from the keyfob is sent and the remote keyless entry receiver

receives the signal and sends it to the BCM. The BCM only locks/unlocks the doors if the ID number

matches. (Remote control entry functions)

• Using the keyfob, the transmitter sends radio waves to the remote keyless entry receiver, which then sends

the received waves to the BCM. Only if the ID number matches does the BCM lock/unlock the doors.

(Remote control door function)

• Unless the key is inserted into the ignition key cylinder or one of the doors is opened within 1 minute after the

UNLOCK switch on the keyfob is pressed, all the doors are automatically locked. (Auto lock function)

• When a door is locked or unlocked, the vehicle turn signal lamps flash and the horn sounds to verify opera-

tion. (Active check function)

• When the key is in the ignition key cylinder (when the key switch is ON) and one of the doors is open, the

door lock function does not work even when the door lock is operated with the keyfob.

• Keyfob ID set up is available.

• If a keyfob is lost, a new keyfob can be set up. A maximum of 5 IDs can be set up simultaneously.

Remote Control Entry Functions

Page 750 of 3061

REMOTE KEYLESS ENTRY SYSTEM

BL-39

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

Operation Description

• When a button on the keyfob is operated, the signal is sent from the keyfob and received by the remote key-

less entry receiver.

• The received signal is sent to the BCM and compared with the registered ID number.

• If the ID number matches, the BCM sends the lock/unlock signal to each door lock actuator.

• When the door lock actuators receive this signal, each operates to lock/unlock its door.

• BCM locks all doors with input of LOCK signal from keyfob.

• When an UNLOCK signal is sent from keyfob once, driver's door will be unlocked.

• Then, if an UNLOCK signal is sent from keyfob again within 5 seconds, all other doors will be unlocked.

Remote control entry operation conditions

Auto Lock Function

Operation Description

• Unless the key is inserted into the ignition key cylinder, one of the doors is opened, or the keyfob is operated

within 1 minute after a door lock is unlocked by keyfob operation, all the doors are automatically locked.

The 1 minute timer count is executed by the BCM and after 1 minute, the BCM sends the lock signal to all

doors.

Lock operations are the same as for the remote control entry function.

Remote Control Automatic Back Door Function

Switching from all closed to all open

• When a button on the keyfob is operated, the signal is sent from the keyfob and received by the remote key-

less entry receiver.

• The received signal is sent to the BCM and compared with the registered ID number.

• If the ID number matches, the BCM uses power window serial link communication to send the back door

open signal to the back door control unit

• When the back door control unit receives the back door open signal for 0.5 seconds, if the remote control

automatic back door operation enable conditions are met, the warning chime is sounded and the back door

unlock signal is sent to the back door latch using communication.

• When the back door latch receives the back door unlock signal, it operates the release actuator and

releases to back door latch.

• The back door control unit operates the back door motor to open the back door. (At this time, speed control,

input reverse, and overload reverse control are executed.)

• When the back door is opened to the fully open position, the full-open position is detected with the rotation

sensor, the back door motor is stopped.

• The door held by the back door stays at the full open position.

Full open → full closed operation

• When a button of the keyfob is operated, the signal is sent from the keyfob and received by the remote key-

less entry receiver.

• The received signal is sent to the BCM and compared with the registered ID number.

• If the ID number matches, the BCM uses power window serial link communication to send the back door

close request signal to the back door control unit.

• When the back door control unit receives the back door close request signal for 0.5 seconds, if the remote

control automatic back door operation enable conditions are met, the warning chime is sounded and the

back door motor begins closing the back door.

• The back door control unit operates the magnetic clutch and the back door motor to close the back door. (At

this time, the back door control unit executes speed control, input reverse, and overload reverse control.)

• When the back door comes to the half-latch state, the back door latch detects the half-latch state through

half-latch switch operation. The back door latch latches the back door.

For the automatic back door system operation enable conditions, refer to BL-80

.

Active Check Function

Operation Description

When a door is locked or unlocked by keyfob operation, the vehicle turn signals flash and the horn sounds to

verify operation.

• When a button on the keyfob is operated, the signal is sent from the remote controller and received by the

keyless remote entry receiver.

Keyfob operation Operation condition

Door lock operation (locking)• With key removed (key switch: OFF)

• Closing all doors (door switch: OFF)

Door lock operation (unlocking) With key removed (key switch: OFF)

Page 751 of 3061

BL-40

< SERVICE INFORMATION >

REMOTE KEYLESS ENTRY SYSTEM

• The received signal is sent to the BCM and compared with the registered ID number.

• If the ID number matches, the BCM sends the turn signal flashing and horn signal to the IPDM E/R.

• The IPDM E/R flashes the turn signal lamps and sounds the horn for each keyfob operation.

Operating function of hazard and horn reminder

Hazard and Horn Reminder

BCM output to IPDM E/R for horn reminder signal as DATA LINE (CAN-H and CAN-L).

The hazard and horn reminder has C mode (horn chirp mode) and S mode (non-horn chirp mode).

How to change hazard and horn reminder mode

With CONSULT-II

Hazard and horn reminder can be changed using “WORK SUPPORT” mode in “MULTI ANSWER BACK SET".

Without CONSULT-II

Refer to Owner's Manual for instructions.

Interior Lamp Operation

When the following input signals are both supplied:

• all door switches are in the OFF position. (when all the doors are closed);

• interior lamp switch is in DOOR position.

Remote keyless entry system turns on interior lamp and ignition keyhole illumination (for 30 seconds) with

input of UNLOCK signal from keyfob.

For detailed description, refer to LT-101, "

System Description".

Panic Alarm Operation

When key switch is OFF (when ignition key is not inserted in key cylinder), remote keyless entry system turns

on and off horn and headlamp intermittently with input of PANIC ALARM signal from keyfob.

The alarm automatically turns off after 25 seconds or when BCM receives any signal from keyfob.

Keyless Power Window Down (Open) Operation

When keyfob unlock switch is turned ON with ignition switch OFF, and the switch is detected to be ON contin-

uously for more than 1 second, the driver's door and passenger's door power windows are simultaneously

opened.

Power window is operated to open and the operation continues as long as the keyfob unlock switch is

pressed.

CAN Communication System DescriptionINFOID:0000000003532915

Refer to LAN-4.

C mode S mode

Keyfob operation Lock Unlock Lock Unlock

Hazard warning lamp

flashTwiceOnceTwice —

Horn sound Once — — —

Page 757 of 3061

BL-46

< SERVICE INFORMATION >

REMOTE KEYLESS ENTRY SYSTEM

Work Support

Hazard and horn reminder mode

Auto locking function mode

Panic alarm operation mode

Back door open operation mode

Te s t I t e m D e s c r i p t i o n

FLASHER This test is able to check right and left hazard reminder operation. The right hazard lamp turns on

when “RH” on CONSULT-II screen is touched and the left hazard lamp turns on when "LH" on CON-

SULT-II screen is touched.

POWER WINDOW DOWN This test is able to check power window down operation. The windows are lowered when “ON” on

CONSULT-II screen is touched.

HORN This test is able to check panic alarm and horn reminder operations. The alarm activate for 0.5 sec-

onds after “ON” on CONSULT-II screen is touched.

DOOR LOCK This test is able to check door lock operation. The doors lock and unlock based on the item on CON-

SULT-II screen touched.

TRUNK/BACK DOOR This test is able to check back door actuator operation. The back door is opened when “OPEN” on

CONSULT-II screen is touched.

PSB/PBD OPEN TESTThis test is able to check power back door operation. The power back door is fully opened when

“OPEN” on the CONSULT-II screen is touched if the door operation enable conditions are met.

Te s t I t e m D e s c r i p t i o n

REMO CONT ID REGIST Keyfob ID code can be registered.

REMO CONT ID ERASUR Keyfob ID code can be erased.

REMO CONT ID CONFIR It can be checked whether keyfob ID code is registered or not in this mode.

HORN CHIRP SET Horn chirp function mode can be changed in this mode. The function mode will be changed when

"CHANG SETT" on CONSULT-II screen is touched.

HAZARD LAMP SET Hazard lamp function mode can be changed in this mode. The function mode will be changed when

"CHANG SETT" on CONSULT-II screen is touched.

MULTI ANSWER BACK SETHazard and horn reminder mode can be changed in this mode. The reminder mode will be changed

when “CHANG SETT” on CONSULT-II screen is touched.

AUTO LOCK SETAuto locking function mode can be changed in this mode. The function mode will be changed when

"CHANG SETT" on CONSULT-II screen is touched.

PANIC ALRM SETPanic alarm operation mode can be changed in this mode. The operation mode will be changed when

"CHANG SETT" on CONSULT-II screen is touched.

TRUNK OPEN SETBack door opener operation mode can be changed in this mode. The operation mode will be changed

when "CHANG SETT" on CONSULT-II screen is touched.

PW DOWN SETKeyless power window down (open) operation mode can be changed in this mode. The operation

mode will be changed when "CHANG SETT" on CONSULT-II screen is touched.

MODE 1

(C mode)MODE 2

(S mode)MODE 3MODE 4MODE 5MODE 6

Keyfob

operation Lock Unlock Lock Unlock Lock Unlock Lock Unlock Lock Unlock Lock Unlock

Hazard warning

lamp flashTwiceOnceTwice — — — TwiceOnceTwice — — Once

Horn sound Once———————Once—Once—

MODE 1 MODE 2 MODE 3

Auto locking function 5 minutes Nothing 1 minute

MODE 1 MODE 2 MODE 3

Keyfob operation 0.5 seconds Nothing 1.5 seconds

MODE 1 MODE 2 MODE 3

Keyfob operation 0.5 seconds Nothing 0.5 seconds

Page 759 of 3061

BL-48

< SERVICE INFORMATION >

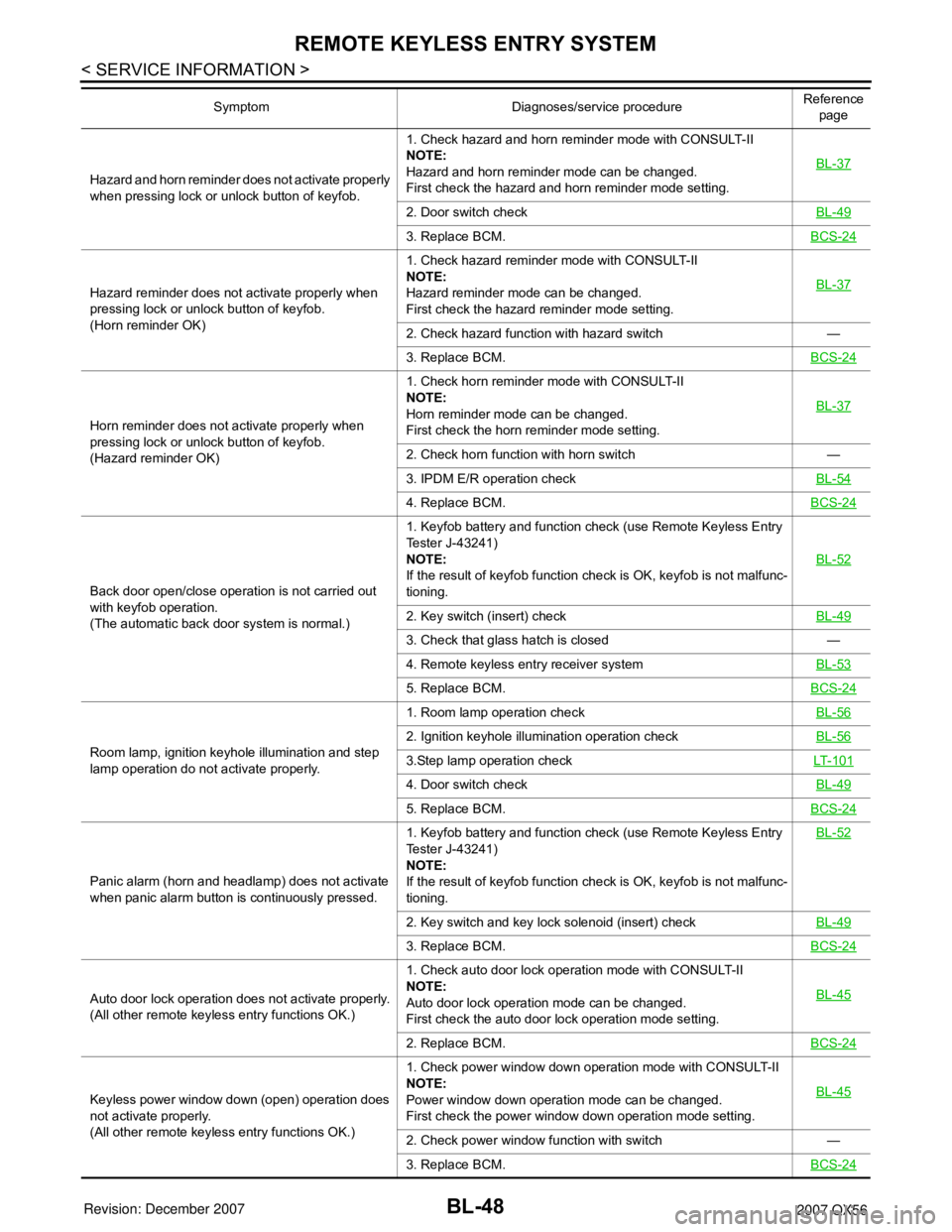

REMOTE KEYLESS ENTRY SYSTEM

Hazard and horn reminder does not activate properly

when pressing lock or unlock button of keyfob.1. Check hazard and horn reminder mode with CONSULT-II

NOTE:

Hazard and horn reminder mode can be changed.

First check the hazard and horn reminder mode setting.BL-37

2. Door switch checkBL-49

3. Replace BCM.BCS-24

Hazard reminder does not activate properly when

pressing lock or unlock button of keyfob.

(Horn reminder OK)1. Check hazard reminder mode with CONSULT-II

NOTE:

Hazard reminder mode can be changed.

First check the hazard reminder mode setting.BL-37

2. Check hazard function with hazard switch —

3. Replace BCM.BCS-24

Horn reminder does not activate properly when

pressing lock or unlock button of keyfob.

(Hazard reminder OK)1. Check horn reminder mode with CONSULT-II

NOTE:

Horn reminder mode can be changed.

First check the horn reminder mode setting.BL-37

2. Check horn function with horn switch —

3. IPDM E/R operation checkBL-54

4. Replace BCM.BCS-24

Back door open/close operation is not carried out

with keyfob operation.

(The automatic back door system is normal.)1. Keyfob battery and function check (use Remote Keyless Entry

Tester J-43241)

NOTE:

If the result of keyfob function check is OK, keyfob is not malfunc-

tioning.BL-52

2. Key switch (insert) checkBL-49

3. Check that glass hatch is closed —

4. Remote keyless entry receiver systemBL-53

5. Replace BCM.BCS-24

Room lamp, ignition keyhole illumination and step

lamp operation do not activate properly.1. Room lamp operation checkBL-56

2. Ignition keyhole illumination operation checkBL-56

3.Step lamp operation checkLT- 1 0 1

4. Door switch checkBL-49

5. Replace BCM.BCS-24

Panic alarm (horn and headlamp) does not activate

when panic alarm button is continuously pressed.1. Keyfob battery and function check (use Remote Keyless Entry

Tester J-43241)

NOTE:

If the result of keyfob function check is OK, keyfob is not malfunc-

tioning.BL-52

2. Key switch and key lock solenoid (insert) checkBL-49

3. Replace BCM.BCS-24

Auto door lock operation does not activate properly.

(All other remote keyless entry functions OK.)1. Check auto door lock operation mode with CONSULT-II

NOTE:

Auto door lock operation mode can be changed.

First check the auto door lock operation mode setting.BL-45

2. Replace BCM.BCS-24

Keyless power window down (open) operation does

not activate properly.

(All other remote keyless entry functions OK.)1. Check power window down operation mode with CONSULT-II

NOTE:

Power window down operation mode can be changed.

First check the power window down operation mode setting.BL-45

2. Check power window function with switch —

3. Replace BCM.BCS-24

Symptom Diagnoses/service procedureReference

page

Page 766 of 3061

REMOTE KEYLESS ENTRY SYSTEM

BL-55

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

Check voltage between IPDM E/R connector E122 terminal 45 and

ground.

OK or NG

OK >> Replace IPDM E/R.

NG >> GO TO 2.

2.CHECK IPDM E/R INPUT VOLTAGE

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R and horn relay.

3. Check continuity between IPDM E/R connector E122 terminal

45 and horn relay connector H-1 terminal 1.

4. Check continuity between IPDM E/R connector E122 terminal

45 and ground.

OK or NG

OK >> Further inspection is necessary. Refer to BL-47, "Trou-

ble Diagnosis".

NG >> Repair or replace harness

Check Hazard FunctionINFOID:0000000003532932

1.CHECK HAZARD WARNING LAMP

Does hazard indicator flash with hazard switch?

Ye s o r N o

Yes >> Hazard warning lamp circuit is OK.

No >> Check hazard indicator. Refer to LT- 5 7

.

Check Horn FunctionINFOID:0000000003532933

First, perform the "SELF-DIAG RESULTS" in "BCM" with CONSULT-II, then perform the trouble diagnosis of

malfunction system indicated in "SELF-DIAG RESULTS" of "BCM".

1.CHECK HORN FUNCTION

Does horn sound with horn switch?

Ye s o r N o

Yes >> Horn circuit is OK.

No >> Check horn circuit. Refer to WW-43

.

Check Headlamp FunctionINFOID:0000000003532934

First, perform the "SELF-DIAG RESULTS" in "BCM" with CONSULT-II, then perform the trouble diagnosis of

malfunction system indicated in "SELF-DIAG RESULTS" of "BCM".

1.CHECK HEADLAMP OPERATION

Does headlamp come on when turning lighting switch ON?

Ye s o r N o

Yes >> Headlamp operation circuit is OK.

No >> Check headlamp circuit. Refer to LT- 5

.

ConnectorTe r m i n a l s

Voltage (V)

(Approx.)

(+) (–)

E122 45 Ground Battery voltage

LIIA1053E

45 - 1 : Continuity should exist.

45 - Ground : Continuity should not exist.

WIIA0679E

Page 771 of 3061

BL-60

< SERVICE INFORMATION >

VEHICLE SECURITY (THEFT WARNING) SYSTEM

VEHICLE SECURITY (THEFT WARNING) SYSTEM

Component Parts and Harness Connector LocationINFOID:0000000003532938

LIIA2374E

1. Fuse block (J/B) 2. Fuse and fusible link box 3. IPDM E/R fuse layout

4. IPDM E/R E122, E123, E124 5. Steering column

(view with instrument panel LH re-

moved)6. Data link connector M22

(view with instrument panel LH re-

moved)

7. BCM M18, M19, M20

(view with instrument panel LH re-

moved)8. Horn E3

(view with grille removed)9. Front door lock assembly LH (key

cylinder switch) D14