refrigerant type INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 373 of 3061

PRECAUTIONSATC-3

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003533217

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Workin g with HFC-134a (R-134a)INFOID:0000000003533218

WARNING:

• CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refr igerant are not compatible. If the refrigerants

are mixed compressor failure is likely to occur. Refer to AT C - 3 , "

Contaminated Refrigerant". To

determine the purity of HFC-134a (R-134a) in the vehicle and recovery tank, use recovery/recycling

equipment and refrigerant identifier.

• Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If

oil other than that specifi ed is used, compressor fa ilure is likely to occur.

• The specified HFC-134a (R-134a) oil rapidly absorb s moisture from the atmosphere. The following

handling precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of mois ture from the atmosphere.

- When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the co mponents. Connect all refrigerant lo op components as quickly as possible

to minimize the entry of moisture into system.

- Only use the specified oil from a sealed container. Immediately reseal containers of oil. Without

proper sealing, oil will become moisture saturat ed and should not be used.

- Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Remove HFC-134a (R-134a) from the A/C system usi ng certified service equipment meeting require-

ments of SAE J2210 [HFC-134a (R-134a) recycling eq uipment], or J2209 [HFC-134a (R-134a) recovery

equipment]. If accidental system discharge occurs , ventilate work area before resuming service.

Additional health and safety information may be ob tained from refrigerant and oil manufacturers.

- Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

Contaminated RefrigerantINFOID:0000000003533219

If a refrigerant other than pure HFC-134a (R-134a) is identified in a vehicle, your options are:

• Explain to the customer that environmental regulations prohibit the release of contaminated refrigerant into

the atmosphere.

• Explain that recovery of the contaminated refri gerant could damage your service equipment and refrigerant

supply.

• Suggest the customer return the vehicle to the locati on of previous service where the contamination may

have occurred.

• If you choose to perform the repair, recover the refrigerant using only dedicated equipment and contain-

ers. Do not recover contaminated refriger ant into your existing service equipment. If your facility does

Page 374 of 3061

ATC-4

< SERVICE INFORMATION >

PRECAUTIONS

not have dedicated recovery equipment, you may contact a local refrigerant product retailer for available ser-

vice. This refrigerant must be disposed of in acco rdance with all federal and local regulations. In addition,

replacement of all refrigerant system components on the vehicle is recommended.

• If the vehicle is within the warranty period, the air conditioner warranty is void. Please contact NISSAN Cus-

tomer Affairs for further assistance.

General Refrigerant PrecautionINFOID:0000000003533220

WARNING:

• Do not release refrigerant into th e air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

• Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or air

conditioning system.

• Do not store or heat refrigerant containers above 52 °C (125 °F).

• Do not heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

• Do not intentionally drop, puncture, or incinerate refrigerant containers.

• Keep refrigerant away from open flames: poisonou s gas will be produced if refrigerant burns.

• Refrigerant will displace oxygen, therefore be certa in to work in well ventilated areas to prevent suf-

focation.

• Do not pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air condition-

ing systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a) have

been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause injury or

property damage. Additional heal th and safety information may be obtained from refrigerant manu-

facturers.

Precaution for Leak Detection DyeINFOID:0000000003533221

• The A/C system contains a fluorescent leak detection dye used for locating refrigerant leaks. An ultraviolet

(UV) lamp is required to illuminate the dye when inspecting for leaks.

• Always wear fluorescence enhancing UV safety goggles to protect your eyes and enhance the visibility of

the fluorescent dye.

• The fluorescent dye leak detector is not a replacement for an electronic refrigerant leak detector. The fluo-

rescent dye leak detector should be used in conjuncti on with an electronic refrigerant leak detector (J-

41995).

• For your safety and the customer's satisfaction, r ead and follow all manufacturer's operating instructions and

precautions prior to performing work.

• A compressor shaft seal should not be repaired because of dye seepage. The compressor shaft seal should only be repaired after confirming the leak with an electronic refrigerant leak detector (J-41995).

• Always remove any dye from the leak area after repairs are complete to avoid a misdiagnosis during a future

service.

• Do not allow dye to come into contact with painted body panels or interior components. If dye is spilled,

clean immediately with the approved dye cleaner. Fluoresc ent dye left on a surface for an extended period of

time cannot be removed .

• Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

• Do not use more than one refrigerant dye bottle (1/4 ounce / 7.4 cc) per A/C system.

• Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R -12) A/C systems are different. Do not use HFC-

134a (R-134a) leak detection dye in CFC-12 (R-12) A/ C systems or CFC-12 (R-12) leak detection dye in

HFC-134a (R-134a) A/C systems or A/C system damage may result.

• The fluorescent properties of the dye will remain for ov er three (3) years unless a compressor failure occurs.

A/C Identification LabelINFOID:0000000003533222

Vehicles with factory installed fluorescent dye have this identification label on the underside of hood.

Precaution for Refrigerant ConnectionINFOID:0000000003533223

A new type refrigerant connection has been introduced to al l refrigerant lines except the following locations.

• Expansion valve to cooling unit

• Evaporator pipes to evaporator (inside cooling unit)

• Refrigerant pressure sensor

FEATURES OF NEW TYPE REFRIGERANT CONNECTION

Page 378 of 3061

ATC-8

< SERVICE INFORMATION >

PRECAUTIONS

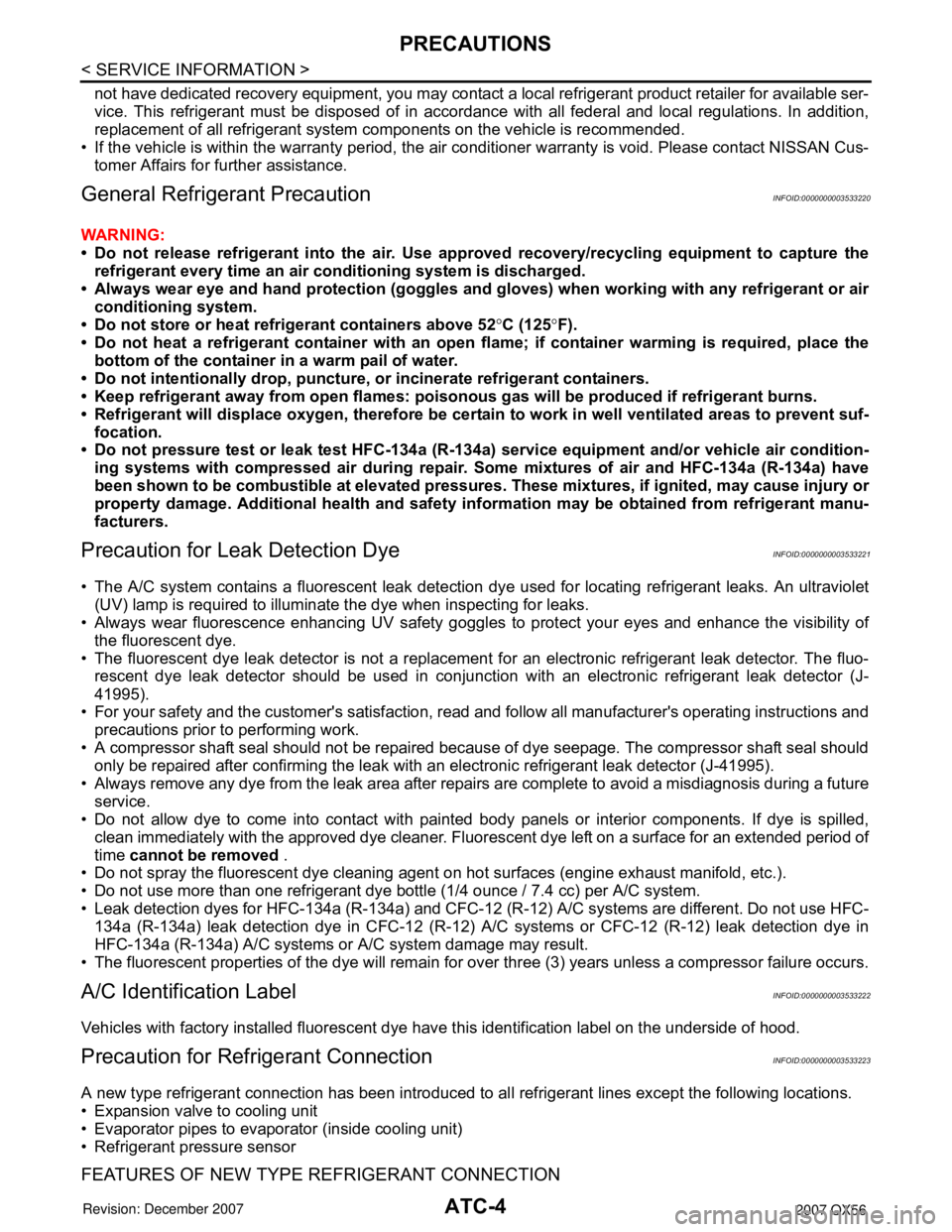

*: Always check with the Parts Department for the latest parts information.

WARNING:

Make sure all refrigerant is discharged into the recycling equipment and the pressure in the system is

less than atmospheric pressure. Then gradually loo sen the discharge side hose fitting and remove it.

CAUTION:

When replacing or cleaning refrigeran t cycle components, observe the following.

• When the compressor is removed, store it in the same position as it is when mounted on the car.

Failure to do so will cause oil to enter the low pressure chamber.

• When connecting tubes, always use a torque wrench and a back-up wrench.

• After disconnecting tubes, immedi ately plug all openings to prevent entry of dirt and moisture.

• When installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and othe r components until just before required for con-

nection.

• Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

• Thoroughly remove moisture from the refrigerat ion system before charging the refrigerant.

• Always replace used O-rings.

• When connecting tube, apply oil to circle of the O-rings shown in illustration. Be careful not to apply

oil to threaded portion.

Oil name: NISSAN A/C System Oil Type S or equivalent

• O-ring must be closely attached to dented portion of tube.

• When replacing the O-ring, be careful not to damage O-ring and tube.

• Connect tube until you hear it cl ick, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

• After connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is foun d, disconnect that line and replace the O-ring. Then tighten con-

nections of seal seat to the specified torque.

Connec-

tion typeO-ring

size Part number* D mm (in) W mm (in)

New 8 92471 N8210 6.8 (0.268) 1.85 (0.0728)

Former 10 J2476 89956 9.25 (0.3642) 1.78 (0.0701) New 1292472 N8210 10.9 (0.429) 2.43 (0.0957)

Former 92475 71L00 11.0 (0.433) 2.4 (0.094) New 1692473 N8210 13.6 (0.535) 2.43 (0.0957)

Former 92475 72L00 14.3 (0.563) 2.3 (0.091) New 1992474 N8210 16.5 (0.650) 2.43 (0.0957)

Former 92477 N8200 17.12 (0.6740) 1.78 (0.0701) New 24 92195 AH300 21.8 (0.858) 2.4 (0.094)

SHA814E

Page 382 of 3061

ATC-12

< SERVICE INFORMATION >

PREPARATION

PREPARATION

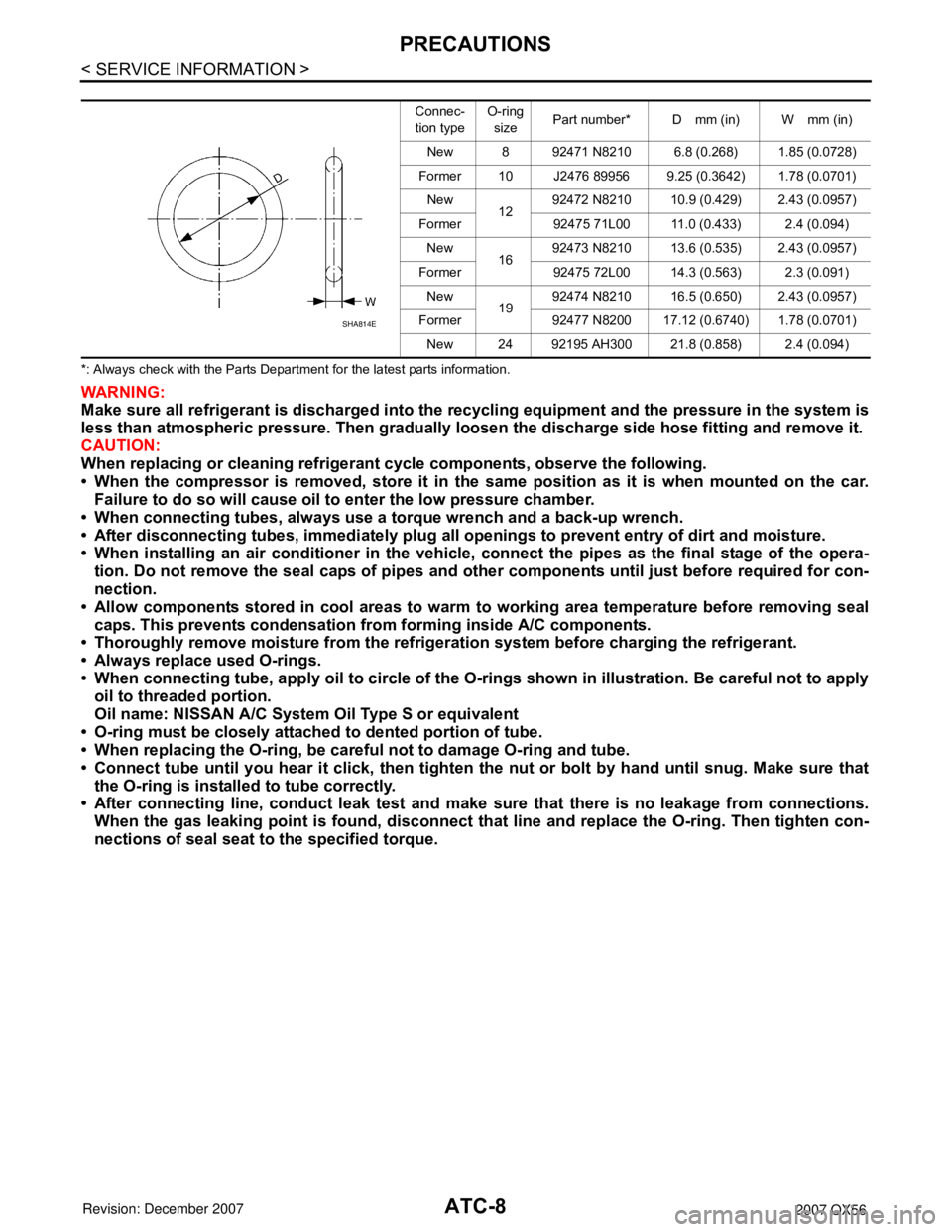

Special Service ToolINFOID:0000000003533226

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

HFC-134a (R-134a) Service Tool and EquipmentINFOID:0000000003533227

Never mix HFC-134a (R-134a) refrigerant and/or the spec ified oil with CFC-12 (R-12) refrigerant and/or the

oil.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/oil.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or oil) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid mixed

use of the refrigerants/oil.

Adapters that convert one size fitting to another must never be used refrigerant/oil contamination will occur

and compressor failure will result.

Tool number

(Kent-Moore No.)

Tool name Description

—

(J-38873-A)

Pulley installer Installing pulley

KV99233130

(J-29884)

Pulley puller Removing pulley

LHA171

LHA172

Tool number

(Kent-Moore No.)

Tool nameDescription

HFC-134a (R-134a)

(—)

Refrigerant Container color: Light blue

Container marking: HFC-134a (R-

134a)

Fitting size: Thread size

• large container 1/2”-16 ACME

—

(—)

NISSAN A/C System Oil Type S Type: Poly alkylene glycol oil (PAG),

type S

Application: HFC-134a (R-134a)

swash plate compressors (NISSAN

only)

Lubricity: 40 m (1.4 US fl oz, 1.4 Imp

fl oz)

S-NT196

S-NT197

Page 390 of 3061

ATC-20

< SERVICE INFORMATION >

OIL

OIL

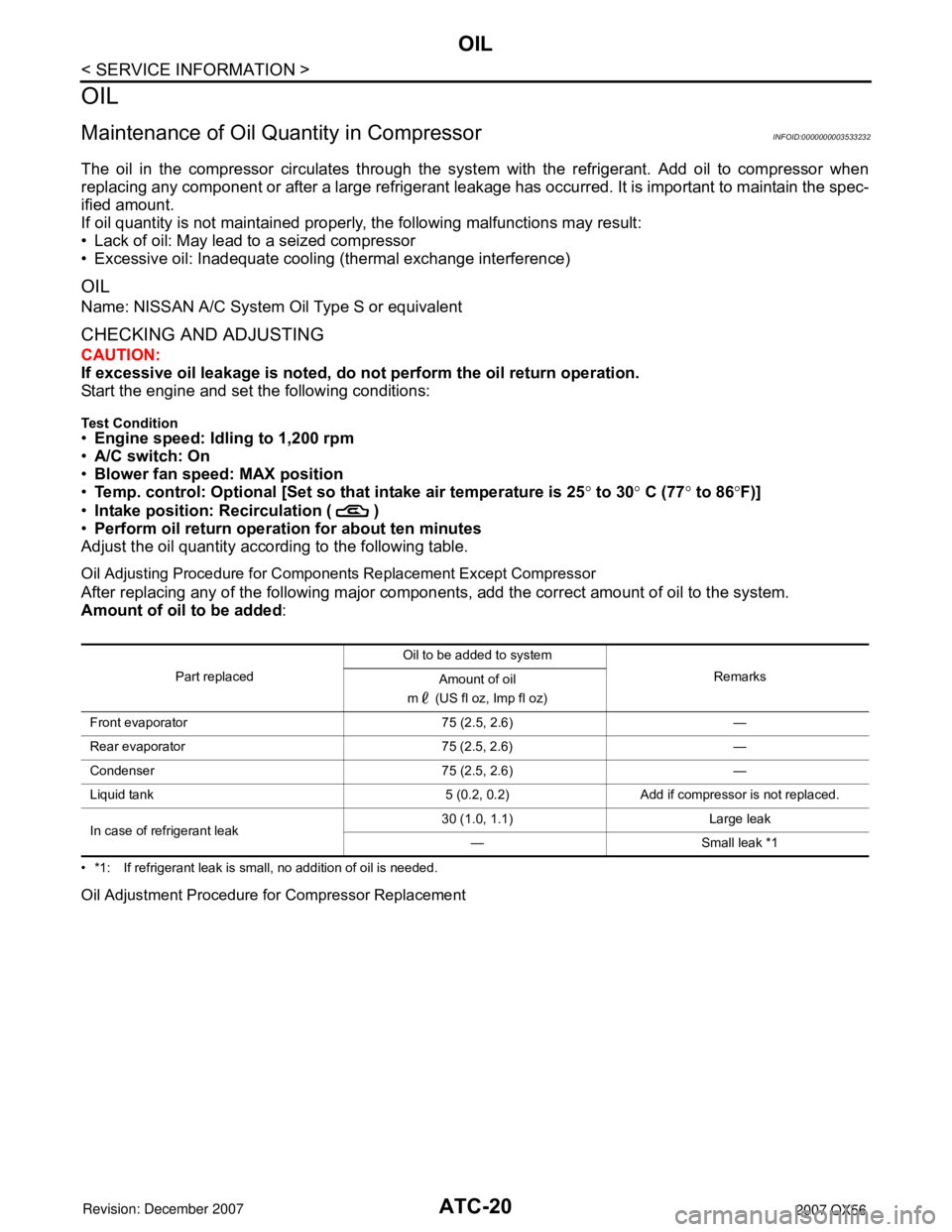

Maintenance of Oil Quantity in CompressorINFOID:0000000003533232

The oil in the compressor circulates through the system with the refrigerant. Add oil to compressor when

replacing any component or after a large refrigerant leakage has occurred. It is important to maintain the spec-

ified amount.

If oil quantity is not maintained properly, the following malfunctions may result:

• Lack of oil: May lead to a seized compressor

• Excessive oil: Inadequate cooling (thermal exchange interference)

OIL

Name: NISSAN A/C System Oil Type S or equivalent

CHECKING AND ADJUSTING

CAUTION:

If excessive oil leakage is noted, do no t perform the oil return operation.

Start the engine and set the following conditions:

Test Condition

• Engine speed: Idling to 1,200 rpm

• A/C switch: On

• Blower fan speed: MAX position

• Temp. control: Optional [Set so that intake air temperature is 25 ° to 30 ° C (77 ° to 86 °F)]

• Intake position: Recirculation ( )

• Perform oil return operation for about ten minutes

Adjust the oil quantity according to the following table.

Oil Adjusting Procedure for Components Replacement Except Compressor

After replacing any of the following major component s, add the correct amount of oil to the system.

Amount of oil to be added :

• *1: If refrigerant leak is small, no addition of oil is needed.

Oil Adjustment Procedure for Compressor Replacement

Part replaced Oil to be added to system

Remarks

Amount of oil

m (US fl oz, Imp fl oz)

Front evaporator 75 (2.5, 2.6) —

Rear evaporator 75 (2.5, 2.6) —

Condenser 75 (2.5, 2.6) —

Liquid tank 5 (0.2, 0.2) Add if compressor is not replaced.

In case of refrigerant leak 30 (1.0, 1.1) Large leak

— Small leak *1

Page 540 of 3061

ATC-170

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

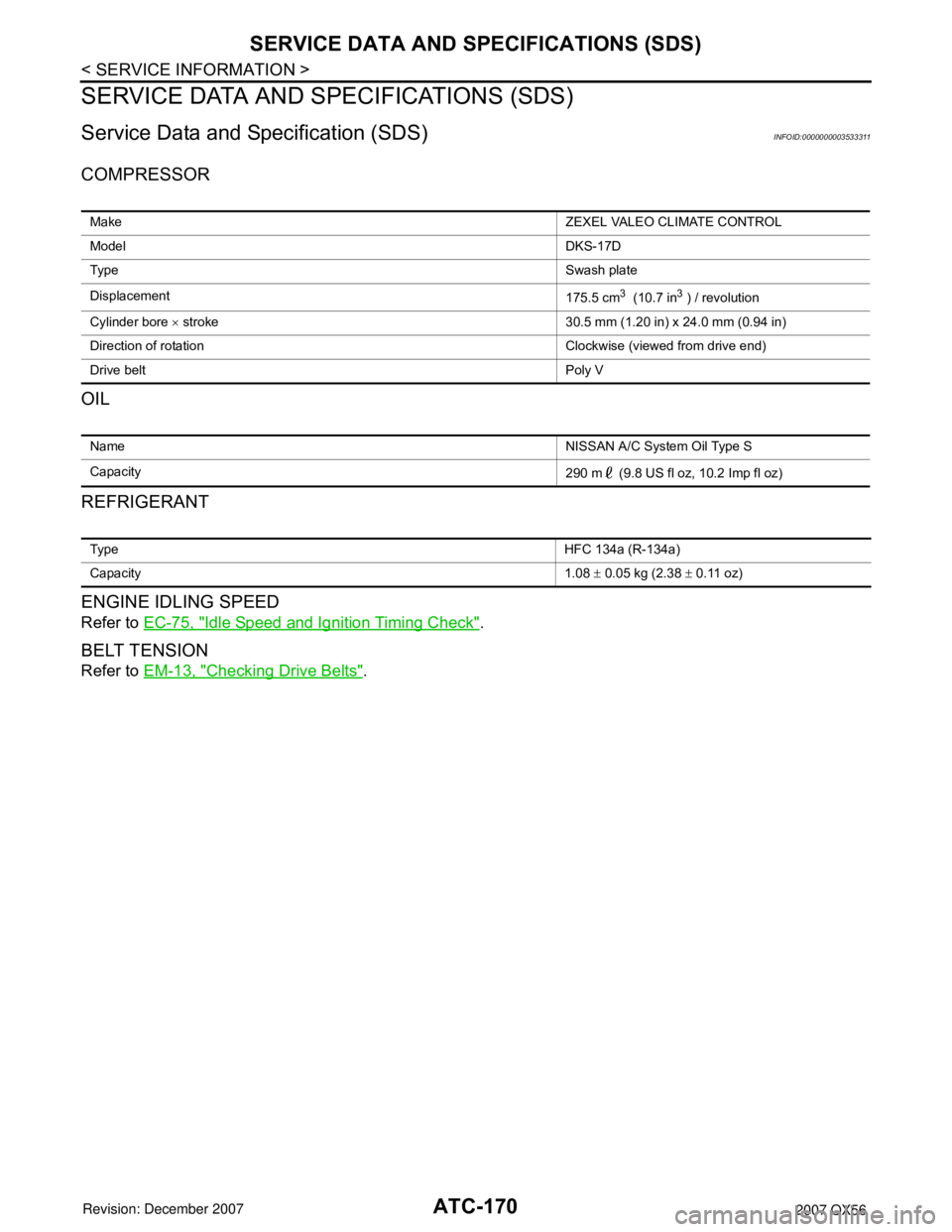

Service Data and Specification (SDS)INFOID:0000000003533311

COMPRESSOR

OIL

REFRIGERANT

ENGINE IDLING SPEED

Refer to EC-75, "Idle Speed and Ignition Timing Check".

BELT TENSION

Refer to EM-13, "Checking Drive Belts".

Make ZEXEL VALEO CLIMATE CONTROL

Model DKS-17D

Ty p e Swash plate

Displacement 175.5 cm

3 (10.7 in3 ) / revolution

Cylinder bore × stroke 30.5 mm (1.20 in) x 24.0 mm (0.94 in)

Direction of rotation Clockwise (viewed from drive end)

Drive belt Poly V

Name NISSAN A/C System Oil Type S

Capacity 290 m (9.8 US fl oz, 10.2 Imp fl oz)

Ty p eHFC 134a (R-134a)

Capacity 1.08 ± 0.05 kg (2.38 ± 0.11 oz)

Page 2372 of 3061

MA-10

< SERVICE INFORMATION >

RECOMMENDED FLUIDS AND LUBRICANTS

RECOMMENDED FLUIDS AND LUBRICANTS

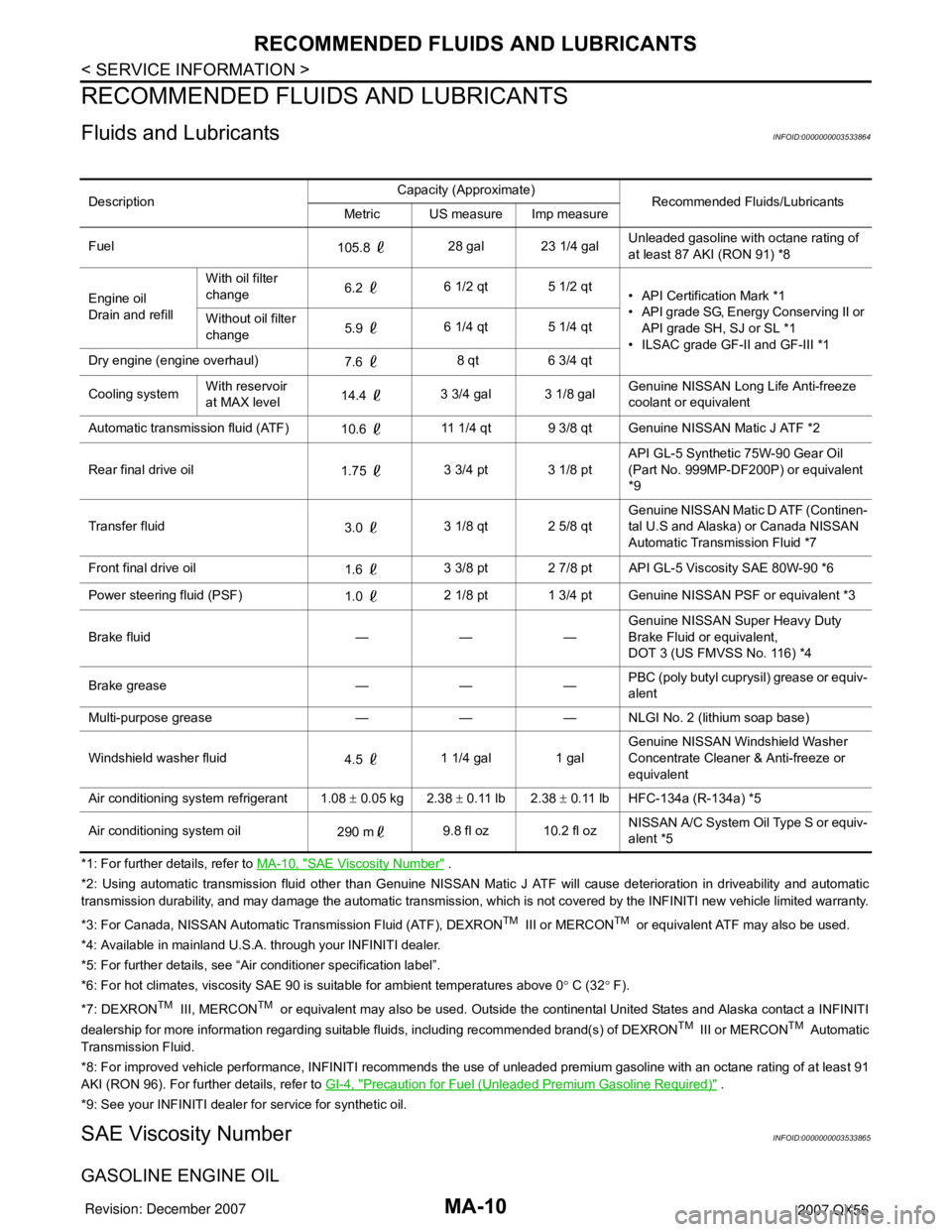

Fluids and LubricantsINFOID:0000000003533864

*1: For further details, refer to MA-10, "SAE Viscosity Number" .

*2: Using automatic transmission fluid other than Genuine NISSAN Matic J ATF will cause deterioration in driveability and automatic

transmission durability, and may damage the automatic transmission, which is not covered by the INFINITI new vehicle limited warranty.

*3: For Canada, NISSAN Automatic Transmission Fluid (ATF), DEXRON

TM III or MERCONTM or equivalent ATF may also be used.

*4: Available in mainland U.S.A. through your INFINITI dealer.

*5: For further details, see “Air conditioner specification label”.

*6: For hot climates, viscosity SAE 90 is suitable for ambient temperatures above 0° C (32° F).

*7: DEXRON

TM III, MERCONTM or equivalent may also be used. Outside the continental United States and Alaska contact a INFINITI

dealership for more information regarding suitable fluids, including recommended brand(s) of DEXRONTM III or MERCONTM Automatic

Transmission Fluid.

*8: For improved vehicle performance, INFINITI recommends the use of unleaded premium gasoline with an octane rating of at least 91

AKI (RON 96). For further details, refer to GI-4, "

Precaution for Fuel (Unleaded Premium Gasoline Required)" .

*9: See your INFINITI dealer for service for synthetic oil.

SAE Viscosity NumberINFOID:0000000003533865

GASOLINE ENGINE OIL

DescriptionCapacity (Approximate)

Recommended Fluids/Lubricants

Metric US measure Imp measure

Fuel

105.8 28 gal 23 1/4 galUnleaded gasoline with octane rating of

at least 87 AKI (RON 91) *8

Engine oil

Drain and refillWith oil filter

change6.2 6 1/2 qt 5 1/2 qt

• API Certification Mark *1

• API grade SG, Energy Conserving II or

API grade SH, SJ or SL *1

• ILSAC grade GF-II and GF-III *1 Without oil filter

change5.9 6 1/4 qt 5 1/4 qt

Dry engine (engine overhaul)

7.6 8 qt 6 3/4 qt

Cooling systemWith reservoir

at MAX level14.4 3 3/4 gal 3 1/8 galGenuine NISSAN Long Life Anti-freeze

coolant or equivalent

Automatic transmission fluid (ATF)

10.6 11 1/4 qt 9 3/8 qt Genuine NISSAN Matic J ATF *2

Rear final drive oil

1.75 3 3/4 pt 3 1/8 ptAPI GL-5 Synthetic 75W-90 Gear Oil

(Part No. 999MP-DF200P) or equivalent

*9

Transfer fluid

3.0 3 1/8 qt 2 5/8 qtGenuine NISSAN Matic D ATF (Continen-

tal U.S and Alaska) or Canada NISSAN

Automatic Transmission Fluid *7

Front final drive oil

1.6 3 3/8 pt 2 7/8 pt API GL-5 Viscosity SAE 80W-90 *6

Power steering fluid (PSF)

1.0 2 1/8 pt 1 3/4 pt Genuine NISSAN PSF or equivalent *3

Brake fluid — — —Genuine NISSAN Super Heavy Duty

Brake Fluid or equivalent,

DOT 3 (US FMVSS No. 116) *4

Brake grease — — —PBC (poly butyl cuprysil) grease or equiv-

alent

Multi-purpose grease — — — NLGI No. 2 (lithium soap base)

Windshield washer fluid

4.5 1 1/4 gal 1 galGenuine NISSAN Windshield Washer

Concentrate Cleaner & Anti-freeze or

equivalent

Air conditioning system refrigerant 1.08 ± 0.05 kg 2.38 ± 0.11 lb 2.38 ± 0.11 lb HFC-134a (R-134a) *5

Air conditioning system oil

290 m9.8 fl oz 10.2 fl ozNISSAN A/C System Oil Type S or equiv-

alent *5