seat memory INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 371 of 3061

ATC-1

AIR CONDITIONER

C

DE

F

G H

I

K L

M

SECTION AT C

A

B

AT C

N

O P

CONTENTS

AUTOMATIC AIR CONDITIONER

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Working with HFC-134a (R-134a) ......3

Contaminated Refrigerant .........................................3

General Refrigerant Precaution ................................4

Precaution for Leak Detection Dye ...........................4

A/C Identification Label .............................................4

Precaution for Refrigerant Connection ......................4

Precaution for Service of Compressor ................ ......9

Precaution for Service Equipment ....................... ......9

PREPARATION ..................................................12

Special Service Tool ........................................... ....12

HFC-134a (R-134a) Service Tool and Equipment ....12

Commercial Service Tool ........................................14

REFRIGERATION SYSTEM ..............................16

Refrigerant Cycle ................................................ ....16

Refrigerant System Protection ................................16

Component Part Location ................................... ....17

OIL ......................................................................20

Maintenance of Oil Quantity in Compressor ....... ....20

AIR CONDITIONER CONTROL .........................22

Description .......................................................... ....22

Operation ................................................................22

Description of Control System .................................23

Control Operation ....................................................24

Discharge Air Flow ..................................................26

System Description (Front) .....................................27

System Description (Rear) .................................. ....28

CAN Communication System Description ...............29

TROUBLE DIAGNOSIS .....................................30

CONSULT-II Function (HVAC) ............................ ....30

CONSULT-II Function (BCM) ..................................31

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ................................................... ....

32

Component Parts and Harness Connector Loca-

tion ...........................................................................

32

Schematic ................................................................36

Wiring Diagram - A/C,A - .........................................37

Front Air Control Terminal and Reference Value ....47

A/C System Self-Diagnosis Function .......................48

Operational Check (Front) ................................... ....50

Operational Check (Rear) ........................................51

Power Supply and Ground Circuit for Front Air

Control ................................................................. ....

52

Mode Door Motor Circuit .........................................54

Air Mix Door Motor Circuit ................................... ....59

Intake Door Motor Circuit .........................................70

Defroster Door Motor Circuit ....................................74

Front Blower Motor Circuit .......................................78

Rear Blower Motor Circuit ................................... ....85

Rear Air Control Circuit ............................................93

Magnet Clutch Circuit ..............................................96

Insufficient Cooling ................................................100

Insufficient Heating ................................................108

Noise .....................................................................109

Self-Diagnosis .......................................................111

Memory Function ...................................................112

Water Valve Circuit ................................................113

Ambient Sensor Circuit ..........................................114

In-vehicle Sensor Circuit ........................................116

Optical Sensor Circuit ............................................119

Intake Sensor Circuit .............................................120

CONTROL UNIT ..............................................123

Removal and Installation .......................................123

AMBIENT SENSOR ........................................124

Removal and Installation .......................................124

IN-VEHICLE SENSOR ....................................125

Removal and Installation .......................................125

OPTICAL SENSOR .........................................126

Page 1760 of 3061

DOOR FINISHER

EI-31

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

EI

N

O

P

DOOR FINISHER

Removal and InstallationINFOID:0000000003533135

Front Door

REMOVAL

1. Disconnect the negative battery cable.

2. Remove power window switch assembly.

• Disconnect harness connectors.

3. Remove pull handle cover.

• Remove screws behind pull handle cover.

4. Remove cap from pull handle escutcheon and remove screw.

5. Remove pull handle escutcheon.

• Remove screws behind pull handle escutcheon.

6. Remove armrest.

• Remove screw behind armrest.

7. Remove memory seat switch.

• Disconnect harness connector.

WIIA0965E

1. Power window switch assembly 2. Armrest 3. Front door finisher LH

4. Pull handle cover 5. Pull handle escutcheon 6. Cap

7. Door lock knob 8. Step lamp 9. Seat memory switch

Page 2673 of 3061

SE-1

BODY

C

D

E

F

G

H

J

K

L

M

SECTION SE

A

B

SE

N

O

P

CONTENTS

SEAT

SERVICE INFORMATION ............................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for Work ..................................................3

PREPARATION ...................................................4

Special Service Tool .................................................4

Commercial Service Tool ..........................................4

SQUEAK AND RATTLE TROUBLE DIAGNO-

SIS .......................................................................

5

Work Flow .................................................................5

Generic Squeak and Rattle Troubleshooting ............7

Diagnostic Worksheet ...............................................9

AUTOMATIC DRIVE POSITIONER ...................11

Component Parts and Harness Connector Loca-

tion ..........................................................................

11

System Description .................................................11

CAN Communication System Description ...............13

Schematic ...............................................................13

Wiring Diagram - AUT/DP - .....................................15

Terminal and Reference Value for BCM .................24

Driver Seat Control Unit Harness Connector Ter-

minal Layout ............................................................

25

Terminal and Reference Value for Driver Seat

Control Unit .............................................................

25

Automatic Drive Positioner Control Unit Harness

Connector Terminal Layout .....................................

28

Terminal and Reference Value for Automatic

Drive Positioner Control Unit ...................................

28

Work Flow ...............................................................30

Preliminary Check ...................................................30

BCM Power Supply and Ground Circuit Inspection

....

31

Power Supply and Ground Circuit Inspection .........31

CONSULT-II Function (AUTO DRIVE POS.) ..........32

CAN Communication Inspection Using CON-

SULT-II (Self-Diagnosis) ..........................................

35

Symptom Chart ........................................................35

Sliding Motor Circuit Inspection ...............................37

Reclining Motor LH Circuit Inspection .....................38

Lifting Motor (Front) Circuit Inspection ....................39

Lifting Motor (Rear) Circuit Inspection .....................40

Pedal Adjusting Motor Circuit Inspection .................41

Mirror Motor LH Circuit Inspection ...........................42

Mirror Motor RH Circuit Inspection ..........................44

Steering Wheel Tilt Circuit Inspection ......................45

Sliding Sensor Circuit Inspection .............................46

Reclining Sensor Circuit Inspection .........................47

Lifting Sensor (Front) Circuit Inspection ..................48

Lifting Sensor (Rear) Circuit Inspection ...................49

Pedal Adjusting Sensor Circuit Inspection ...............50

Mirror Sensor LH Circuit Inspection .........................51

Mirror Sensor RH Circuit Inspection ........................53

Steering Wheel Tilt Sensor Circuit Inspection .........54

Sliding Switch Circuit Inspection ..............................55

Reclining Switch Inspection .....................................56

Lifting Switch (Front) Circuit Inspection ...................58

Lifting Switch (Rear) Circuit Inspection ....................59

Power Seat Switch Ground Inspection ....................60

Pedal Adjusting Switch Circuit Inspection ...............61

Door Mirror Remote Control Switch (Changeover

Switch) Circuit Inspection ........................................

62

Door Mirror Remote Control Switch (Mirror

Switch) Circuit Inspection ........................................

64

Door Mirror Remote Control Switch Ground Circuit

Inspection ................................................................

65

Seat Memory Switch Circuit Inspection ...................66

Seat Memory Indicator Lamp Circuit Inspection ......67

Door Mirror Sensor Power Supply and Ground

Circuit inspection .....................................................

69

A/T Device (Park Position Switch) Circuit Inspec-

tion ...........................................................................

69

Steering Wheel Tilt Switch Circuit Inspection ..........70

Front Door Switch LH Circuit Inspection ..................72

UART Communication Line Circuit Inspection ........73

Page 2683 of 3061

AUTOMATIC DRIVE POSITIONER

SE-11

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

SE

N

O

P

AUTOMATIC DRIVE POSITIONER

Component Parts and Harness Connector LocationINFOID:0000000003533156

System DescriptionINFOID:0000000003533157

• Refer to Owner's Manual for Automatic Drive Positioner system operating instructions.

• The settings (ON/OFF) of the automatic sliding seat (entry/exiting operation) at entry/exit can be changed as

desired, using the display unit in the center of the instrument panel. The set content is transmitted by CAN

communication, from display control unit to driver seat control unit.

• Using CONSULT-ll, the seat slide amount at entry/exit setting can be changed.

1. A. Automatic drive positioner control

unit M33, M34

B. Pedal adjusting motor E109, E1102. A. Steering column

B. Key switch and key lock solenoid

M27

C. BCM M18, M19, M20 (view with

instrument panel removed)3. A. Door mirror remote control switch

D10

B. Seat memory switch D5

4. Pedal adjusting switch M96 5. A. Door mirrror LH D4, RH D107

B. Front door switch LH B86. A. A/T selector lever

B. A/T device (park position switch)

M203

7. A. Sliding motor LH P4 (driver seat

view), reclining motor LH P5, lifting

motor (front) P6, lifting motor (rear)

P7

B. Driver seat control unit P2, P3

C. Power seat switch LH P88. A. ADP steering switch M16

B.Tilt motor M68, M69

LIIA2726E

Page 2684 of 3061

SE-12

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

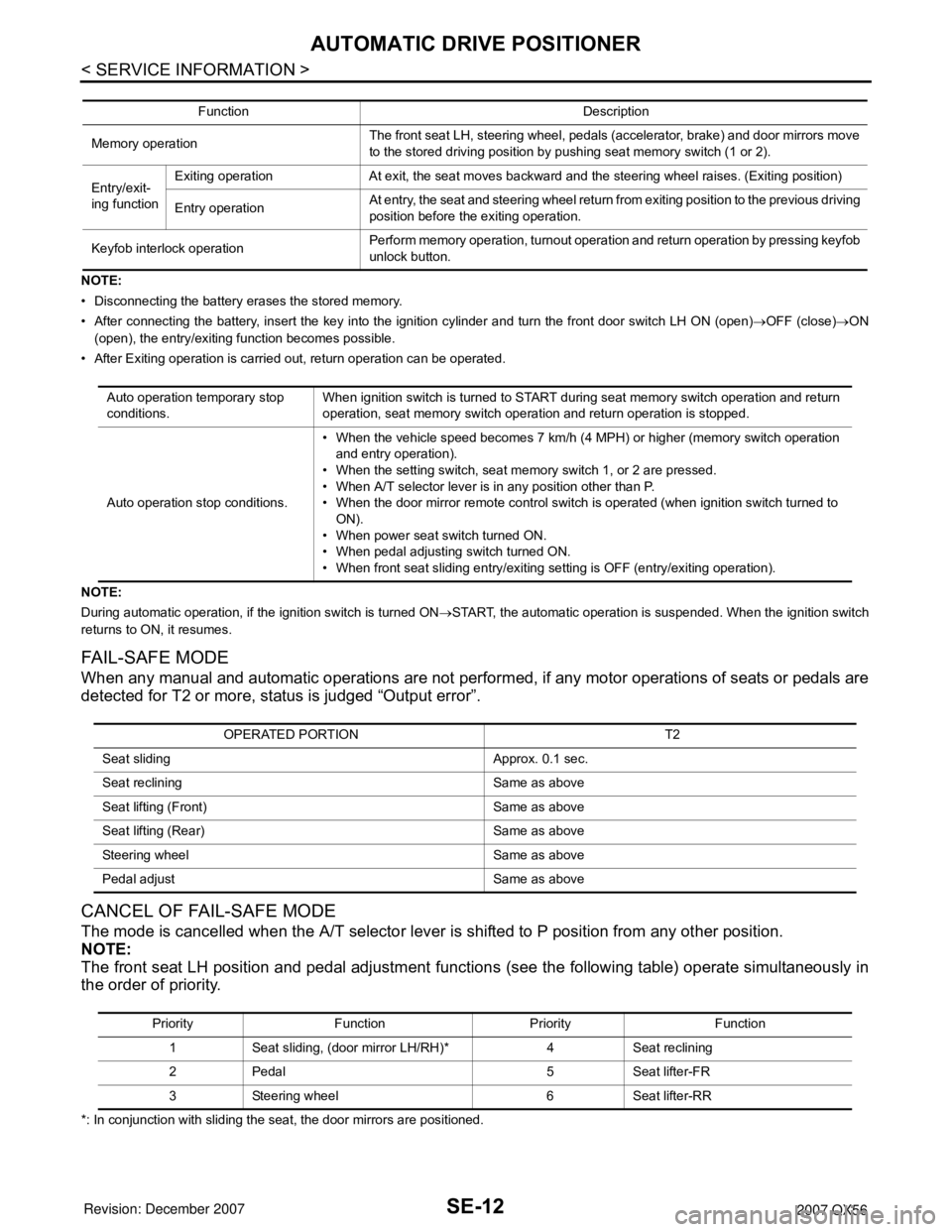

NOTE:

• Disconnecting the battery erases the stored memory.

• After connecting the battery, insert the key into the ignition cylinder and turn the front door switch LH ON (open)→OFF (close)→ON

(open), the entry/exiting function becomes possible.

• After Exiting operation is carried out, return operation can be operated.

NOTE:

During automatic operation, if the ignition switch is turned ON→START, the automatic operation is suspended. When the ignition switch

returns to ON, it resumes.

FA I L - S A F E M O D E

When any manual and automatic operations are not performed, if any motor operations of seats or pedals are

detected for T2 or more, status is judged “Output error”.

CANCEL OF FAIL-SAFE MODE

The mode is cancelled when the A/T selector lever is shifted to P position from any other position.

NOTE:

The front seat LH position and pedal adjustment functions (see the following table) operate simultaneously in

the order of priority.

*: In conjunction with sliding the seat, the door mirrors are positioned.Function Description

Memory operation The front seat LH, steering wheel, pedals (accelerator, brake) and door mirrors move

to the stored driving position by pushing seat memory switch (1 or 2).

Entry/exit-

ing functionExiting operation At exit, the seat moves backward and the steering wheel raises. (Exiting position)

Entry operationAt entry, the seat and steering wheel return from exiting position to the previous driving

position before the exiting operation.

Keyfob interlock operationPerform memory operation, turnout operation and return operation by pressing keyfob

unlock button.

Auto operation temporary stop

conditions.When ignition switch is turned to START during seat memory switch operation and return

operation, seat memory switch operation and return operation is stopped.

Auto operation stop conditions.• When the vehicle speed becomes 7 km/h (4 MPH) or higher (memory switch operation

and entry operation).

• When the setting switch, seat memory switch 1, or 2 are pressed.

• When A/T selector lever is in any position other than P.

• When the door mirror remote control switch is operated (when ignition switch turned to

ON).

• When power seat switch turned ON.

• When pedal adjusting switch turned ON.

• When front seat sliding entry/exiting setting is OFF (entry/exiting operation).

OPERATED PORTION T2

Seat sliding Approx. 0.1 sec.

Seat reclining Same as above

Seat lifting (Front) Same as above

Seat lifting (Rear) Same as above

Steering wheel Same as above

Pedal adjust Same as above

Priority Function Priority Function

1 Seat sliding, (door mirror LH/RH)* 4 Seat reclining

2 Pedal 5 Seat lifter-FR

3 Steering wheel 6 Seat lifter-RR

Page 2700 of 3061

SE-28

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

Automatic Drive Positioner Control Unit Harness Connector Terminal Layout

INFOID:0000000003533164

Terminal and Reference Value for Automatic Drive Positioner Control UnitINFOID:0000000003533165

LIIA2449E

Te r m i n a l Wire Col-

orItem ConditionVoltage (V)

(Approx.)

1 W/G ADP steering switch TILT UPADP steering switch in UP position 0

Other than above 5

2 LG Changeover switch RH signalChangeover switch in RH position 0

Other than above 5

3 Y/B Mirror switch UP signalMirror switch in UP position 0

Other than above 5

4 V/W Mirror switch LEFT signalMirror switch in LEFT position 0

Other than above 5

5R/BMirror sensor (RH vertical) sig-

nalMirror motor RH is operated UP or

DOWNChanges between 3.4 (close to

peak) 0.6 (close to valley)

6L/YMirror sensor (LH vertical) sig-

nalMirror motor LH is operated UP or

DOWNChanges between 3.4 (close to

peak) 0.6 (close to valley)

7 Y/BR Tilt sensor inputTilt position TOP 2

Tilt position BOTTOM 4

8 BR/Y Pedal sensor input signalPedal position front end 0.5

Pedal position rear end 4.5

9 LG/B Seat memory switch 1 signalMemory switch 1 ON 0

Memory switch 1 OFF 5

10 L UART LINE (TX)Pedal adjusting switch ON (FOR-

WARD or BACKWARD operation)

12 PSeat memory switch indictor 1

signalMemory switch 1 ON 0

Memory switch 1 OFF Battery voltage

PIIA4813E

Page 2701 of 3061

AUTOMATIC DRIVE POSITIONER

SE-29

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

SE

N

O

P

13 Y/GSeat memory switch indictor 2

signalMemory switch 2 ON 0

Memory switch 2 OFF Battery voltage

14 GR/R Mirror motor RH UP signalMirror motor RH is operated UP 1.5 - Battery voltage

Other than above 0

15 V/R Mirror motor RH LEFT signalMirror motor RH is operated LEFT 1.5 - Battery voltage

Other than above 0

16 OMirror motor LH DOWN signalMirror motor LH is operated DOWN 1.5 - Battery voltage

Other than above 0

Mirror motor LH RIGHT signalMirror motor LH is operated RIGHT 1.5 - Battery voltage

Other than above 0

17 G/BADP steering switch TILT

DOWNADP steering switch in DOWN posi-

tion0

Other than above 5

18 BR/W Changeover switch LH signalChangeover switch in LH position 0

Other than above 5

19 SB Mirror switch DOWN signalMirror switch in DOWN position 0

Other than above 5

20 GR Mirror switch RIGHT signalMirror switch in RIGHT position 0

Other than above 5

21 L/WMirror sensor (RH horizontal)

signalMirror motor RH is operated LEFT or

RIGHTChanges between 3.4 (close to left

edge) 0.6 (close to right edge)

22 GMirror sensor (LH horizontal)

signalMirror motor LH is operated LEFT or

RIGHTChanges between 3.4 (close to left

edge) 0.6 (close to right edge)

24 G/O Seat memory set switch signalSet switch 1 ON 0

Set switch 1 OFF 5

25 P/L Seat memory switch 2 signalMemory switch 2 ON 0

Memory switch 2 OFF 5

26 W UART LINE (RX)Pedal adjusting switch ON (FOR-

WARD or BACKWARD operation)

30 YMirror motor RH DOWN signalMirror motor RH is operated DOWN 1.5 - Battery voltage

Other than above 0

Mirror motor RH RIGHT signalMirror motor RH is operated RIGHT 1.5 - Battery voltage

Other than above 0

31 R Mirror motor LH UP signalMirror motor LH is operated UP 1.5 - Battery voltage

Other than above 0

32 BR Mirror motor LH LEFT signalMirror motor LH is operated LEFT 1.5 - Battery voltage

Other than above 0

33 W/L Sensor power supply — 5

34 Y/R Battery power supply — Battery voltage Te r m i n a l Wire Col-

orItem ConditionVoltage (V)

(Approx.)

PIIA4814E

Page 2705 of 3061

AUTOMATIC DRIVE POSITIONER

SE-33

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

SE

N

O

P

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

SELF-DIAGNOSIS RESULTS

DISPLAY ITEM LIST

NOTE:

• If park switch error is detected, manual adjustable pedal operation cannot be performed when ignition switch

turns ON.

• The displays of CAN communication and detection switch display error detecting condition from memory

erase to the present on “TIME”.

- If error is detected in the past and present error is detected, “CRNT” is displayed.

- If error is detected in the past and present error is not detected, “PAST” is displayed.

- If error has never been detected, nothing is displayed on “TIME”.

• Any items other than CAN communication and park switch count error detection frequency occurred after

erase history to “1-127”.

- If error was detected in the past, error detection frequency from memory erase to the present is displayed on

“TIME”.

- If error has never been detected, nothing is displayed on “TIME”.

- Can clear the detected memory.

Normal: Clear memory in normal condition, history is erased and nothing is displayed on “TIME”.

Error: Clear memory in error condition, error is detected again and “1” is displayed on “TIME”.

DATA MONITOR

SELECTIOM FROM MENU

CONSULT-II display Item Malfunction is detected when...Reference

page

CAN COMM CIRC

[U1000]CAN communication Malfunction is detected in CAN communication. SE-35

SEAT SLIDE

[B2112]Seat slide motorWhen any manual and automatic operations are not performed, if any

motor operations of seat slide is detected for 0.1 second or more, sta-

tus is judged “Output error”.SE-37

SEAT RECLINING

[B2113]Seat reclining motorWhen any manual and automatic operations are not performed, if any

motor operations of seat reclining is detected for 0.1 second or more,

status is judged “Output error”.SE-38

SEAT LIFTER FR

[B2114]Seat lifting FR motorWhen any manual and automatic operations are not performed, if any

motor operations of seat lifting FR is detected for 0.1 second or more,

status is judged “Output error”.SE-39

SEAT LIFTER RR

[B2115]Seat lifting RR motorWhen any manual and automatic operations are not performed, if any

motor operations of seat lifting RR is detected for 0.1 second or more,

status is judged “Output error”.SE-40

STEERING TILT

[B2116]Steering tilt motorWhen any manual and automatic operations are not performed, if any

motor operations of tilt is detected for 0.1 second or more, status is

judged “Output error”.SE-45

TILT SENSOR

[B2118]Steering tilt sensorWhen steering tilt sensor detects 0.5V or lower, or 4.5V or higher, for

0.5 seconds or more.SE-54

ADJ PEDAL MO-

TOR

[B2117]Pedal adjust motorWhen any manual and automatic operations are not performed, if mo-

tor operations of seat pedal is detected for 0.1 second or more, status

is judged “Output error”.SE-41

ADJ PEDAL SEN-

SOR

[B2120]Pedal adjust sensorWhen pedal adjust sensor detects 0.5V or lower, or 4.5V or higher, for

0.5 seconds or more.SE-50

DETENT SW

[B2126]Park SWWith the A/T selector lever in P position (park position switch OFF), if

the vehicle speed of 7 km/h (4 MPH) or higher was input the park po-

sition switch input system is judged malfunctioning.SE-69

UART COMM

[B2128]UART communica-

tionMalfunction is detected in UART communication.SE-73

Page 2706 of 3061

![INFINITI QX56 2007 Factory Service Manual SE-34

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

ACTIVE TEST

CAUTION:

During vehicle driving, do not perform active test.

NOTE:

Monitor item [OPERATION or UNIT] Contents

SLIDE SW-FR “ON/OFF� INFINITI QX56 2007 Factory Service Manual SE-34

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

ACTIVE TEST

CAUTION:

During vehicle driving, do not perform active test.

NOTE:

Monitor item [OPERATION or UNIT] Contents

SLIDE SW-FR “ON/OFF�](/img/42/57029/w960_57029-2705.png)

SE-34

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

ACTIVE TEST

CAUTION:

During vehicle driving, do not perform active test.

NOTE:

Monitor item [OPERATION or UNIT] Contents

SLIDE SW-FR “ON/OFF” ON/OFF status judged from the sliding switch (FR) signal is displayed.

SLIDE SW-RR “ON/OFF” ON/OFF status judged from the sliding switch (RR) signal is displayed.

RECLN SW-FR “ON/OFF” ON/OFF status judged from the reclining switch (FR) signal is displayed.

RECLN SW-RR “ON/OFF” ON/OFF status judged from the reclining switch (RR) signal is displayed.

LIFT FR SW-UP “ON/OFF” ON/OFF status judged from the FR lifter switch (UP) signal is displayed.

LIFT FR SW-DN “ON/OFF” ON/OFF status judged from the FR lifter switch (DOWN) signal is displayed.

LIFT RR SW-UP “ON/OFF” ON/OFF status judged from the RR lifter switch (UP) signal is displayed.

LIFT RR SW-DN “ON/OFF” ON/OFF status judged from the RR lifter switch (DOWN) signal is displayed.

MIR CON SW-UP “ON/OFF”ON/OFF status judged from the door mirror remote control switch (UP) signal is dis-

played.

MIR CON SW-DN “ON/OFF”ON/OFF status judged from the door mirror remote control switch (DOWN) signal

is displayed.

MIR CON SW-RH “ON/OFF”ON/OFF status judged from the door mirror remote control switch (RIGHT) signal

is displayed.

MIR CON SW-LH “ON/OFF”ON/OFF status judged from the door mirror remote control switch (LEFT) signal is

displayed.

MIR CHNG SW-R “ON/OFF”ON/OFF status judged from the door mirror remote control switch (switching to

RIGHT) signal is displayed.

MIR CHNG SW-L “ON/OFF”ON/OFF status judged from the door mirror remote control switch (switching to

LEFT) signal is displayed.

SET SW “ON/OFF” ON/OFF status judged from the setting switch signal is displayed.

TILT SW-UP “ON/OFF” ON/OFF status judged from the tilt adjusting switch (UP) signal is displayed.

PEDAL SW-FR “ON/OFF” ON/OFF status judged from the pedal adjusting switch (FR) signal is displayed.

PEDAL SW-RR “ON/OFF” ON/OFF status judged from the pedal adjusting switch (RR) signal is displayed.

MEMORY SW1 “ON/OFF” ON/OFF status judged from the seat memory switch 1 signal is displayed.

MEMORY SW2 “ON/OFF” ON/OFF status judged from the seat memory switch 2 signal is displayed.

DETENT SW “ON/OFF”The A/T selector lever position “OFF (P position) / ON (other than P position)”

judged from the park position switch signal is displayed.

STARTER SW “ON/OFF”Ignition key switch ON (START, ON) /OFF (ignition switch IGN, ACC, or OFF) sta-

tus judged from the ignition switch signal is displayed.

SLIDE PULSE —Value (32768) when battery connects is as standard. If it moves BACKWARD, the

value increases. If it moves FORWARD, the value decreases.

RECLN PULSE —Value (32768) when battery connects is as standard. If it moves BACKWARD, the

value increases. If it moves FORWARD, the value decreases.

LIFT FR PULSE —Value (32768) when battery connects is as standard. If it moves DOWN, the value

increases. If it moves UP, the value decreases.

LIFT RR PULSE —Value (32768) when battery connects is as standard. If it moves DOWN, the value

increases. If it moves UP, the value decreases.

MIR/SEN RH R-L “V” Voltage output from RH door mirror sensor (LH/RH) is displayed.

MIR/SEN RH U-D “V” Voltage output from RH door mirror sensor (UP/DOWN) is displayed.

MIR/SEN LH R-L “V” Voltage output from LH door mirror sensor (LH/RH) is displayed.

MIR/SEN LH U-D “V” Voltage output from LH door mirror sensor (UP/DOWN) is displayed.

PEDAL SEN “V”The pedal position (voltage) judged from the pedal adjust sensor signal is dis-

played.

Page 2707 of 3061

AUTOMATIC DRIVE POSITIONER

SE-35

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

SE

N

O

P

If active test is performed, reset seat memory and automatic drive positioner seat memory after performing

work.

DISPLAY ITEM LIST

CAN Communication Inspection Using CONSULT-II (Self-Diagnosis)INFOID:0000000003533171

1.SELF-DIAGNOSTIC RESULT CHECK

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carries out CAN communication.

1. Connect to CONSULT-II, and select “AUTO DRIVE POS.” on the “SELECT DIAG SYSTEM” screen.

2. Select “SELF-DIAG RESULTS” on "SELECT DIAG MODE" screen.

3. Check display content in self-diagnostic results.

Contents displayed

No malfunction>>Inspection End.

Malfunction in CAN communication system>>After printing the monitor items, go to “CAN System”. Refer to

LAN-3, "

Precaution When Using CONSULT-II".

Symptom ChartINFOID:0000000003533172

Test item Description

SEAT SLIDE The sliding motor is activated by receiving the drive signal.

SEAT RECLINING The reclining motor is activated by receiving the drive signal.

SEAT LIFTER FR The lifting motor (front) is activated by receiving the drive signal.

SEAT LIFTER RR The lifting motor (rear) is activated by receiving the drive signal.

PEDAL MOTOR The pedal adjust motor is activated by receiving the drive signal.

MEMORY SW INDCTR The memory switch indicator is lit by receiving the drive signal.

MIRROR MOTOR RHThe RH mirror motor moves the mirror UP/DOWN and LEFT/RIGHT by receiving the drive

signal.

MIRROR MOTOR LHThe LH mirror motor moves the mirror UP/DOWN and LEFT/RIGHT by receiving the drive

signal.

CONSULT-II display code Diagnosis item

U1000INITIAL DIAG

TRANSMIT DIAG

BCM

METER/M&A

ECM

I-KEY

Symptom Diagnoses / service procedure Refer to page

Only setting change function cannot be set with display.1. Preliminary checkSE-30

2. CAN communication inspection using CONSULT-II (self-

diagnosis)SE-35

3. If the above systems are normal, check display system.AV- 7 3