service INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 725 of 4083

CHG

B TERMINAL CIRCUITCHG-13

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

B TERMINAL CIRCUIT

DescriptionINFOID:0000000001696186

The terminal “1” circuit supplies power to charge the battery and operate the vehicles electrical system.

Diagnosis ProcedureINFOID:0000000001696187

1.CHECK TERMINAL “1” CONNECTION

1. Turn ignition switch OFF.

2. Verify terminal “1” is clean and tight.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair terminal “1” connection. Confirm repa ir by performing complete Starting/Charging system

test. Refer to Technical Service Bulletin.

2.CHECK TERMINAL “1” CIRCUIT

Check voltage between generator connector E204 terminal 1 and

ground.

Is voltage reading as specified?

YES >> GO TO 3.

NO >> Check harness for open between generator and fusible link.

3.CHECK TERMINAL “1” CONNECTION (VOLTAGE DROP TEST)

1. Start engine, then engine running at idle and warm.

2. Check voltage between battery positive terminal and generator connector E204 terminal 1.

Is the voltage reading as specified?

YES >> Terminal “1” circuit is normal. Refer to CHG-5, "Work

Flow".

NO >> Check harness between battery and generator for high resistance.

(+) (-) Voltage

Connector Terminal

E204 1Ground Battery voltage

ALMIA0197ZZ

(+)

(-)Voltage

Connector Terminal

E204 1 Battery positive terminal Less than 0.2V

ALMIA0198ZZ

Revision: March 2010 2008 QX56

Page 726 of 4083

CHG-14

< COMPONENT DIAGNOSIS >

L TERMINAL CIRCUIT

L TERMINAL CIRCUIT

DescriptionINFOID:0000000001696188

The terminal “2” (L) circuit controls the charge warning lamp. The charge warning lamp illuminates when the

ignition switch is set to ON or START. When the generator is providing sufficient voltage with the engine run-

ning, the charge warning lamp will go off. If the c harge warning lamp illuminates with the engine running, a

malfunction is indicated.

Diagnosis ProcedureINFOID:0000000001696189

1.CHECK CHARGE WARNING LAMP CIRCUIT CONNECTION

Verify generator connector E205 terminal 2 is clean and tight.

Is the connection secure?

YES >> GO TO 2

NO >> Repair the connection. Confirm repair by per forming complete Starting/Charging system test.

Refer to Technical Service Bulletin.

2.CHECK CHARGE WARNING LAMP CIRCUIT

1. Disconnect generator connector E205.

2. Apply ground to generator harness connector E205 terminal 2 with the ignition switch in the ON position.

Does the charge lamp illuminate?

YES >> Check generator function. Refer to CHG-5, "Work Flow".

NO >> GO TO 3

3.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect the generator connector E205 and combination meter connector M24.

3. Check continuity between generator harness connector E205 (A) terminal 2 and combination meter harness connector M24

(B) terminal 6.

4. Check continuity between generator harness connector E205 (A) terminal 2 and ground.

Are the continuity results as specified?

YES >> Replace the combination meter. Refer to MWI-76, "Removal and Installation".

NO >> Repair the harness or connector. Charge lamp should illuminate

ALMIA0200ZZ

AB

Continuity

Connector Terminal Connector Terminal

E205 2M24 6Yes

A —

Continuity

Connector Terminal

E205 2Ground No

AWMIA0596ZZ

Revision: March 2010 2008 QX56

Page 727 of 4083

CHG

S TERMINAL CIRCUITCHG-15

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

S TERMINAL CIRCUIT

DescriptionINFOID:0000000001696190

The output voltage of the generator is controlled by the IC

regulator at terminal “3” (S) detecting the input volt-

age. Terminal “3” circuit detects the battery voltage to adjust the generator output voltage with the IC regulator.

Diagnosis ProcedureINFOID:0000000001696191

1.CHECK VOLTAGE REGULATOR CIRCUIT CONNECTION

Check to see if connector E205 terminal 3 is clean and tight.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair terminal connection. Confirm repair by performing complete Starting/Charging system test.

Refer to Technical Service Bulletin.

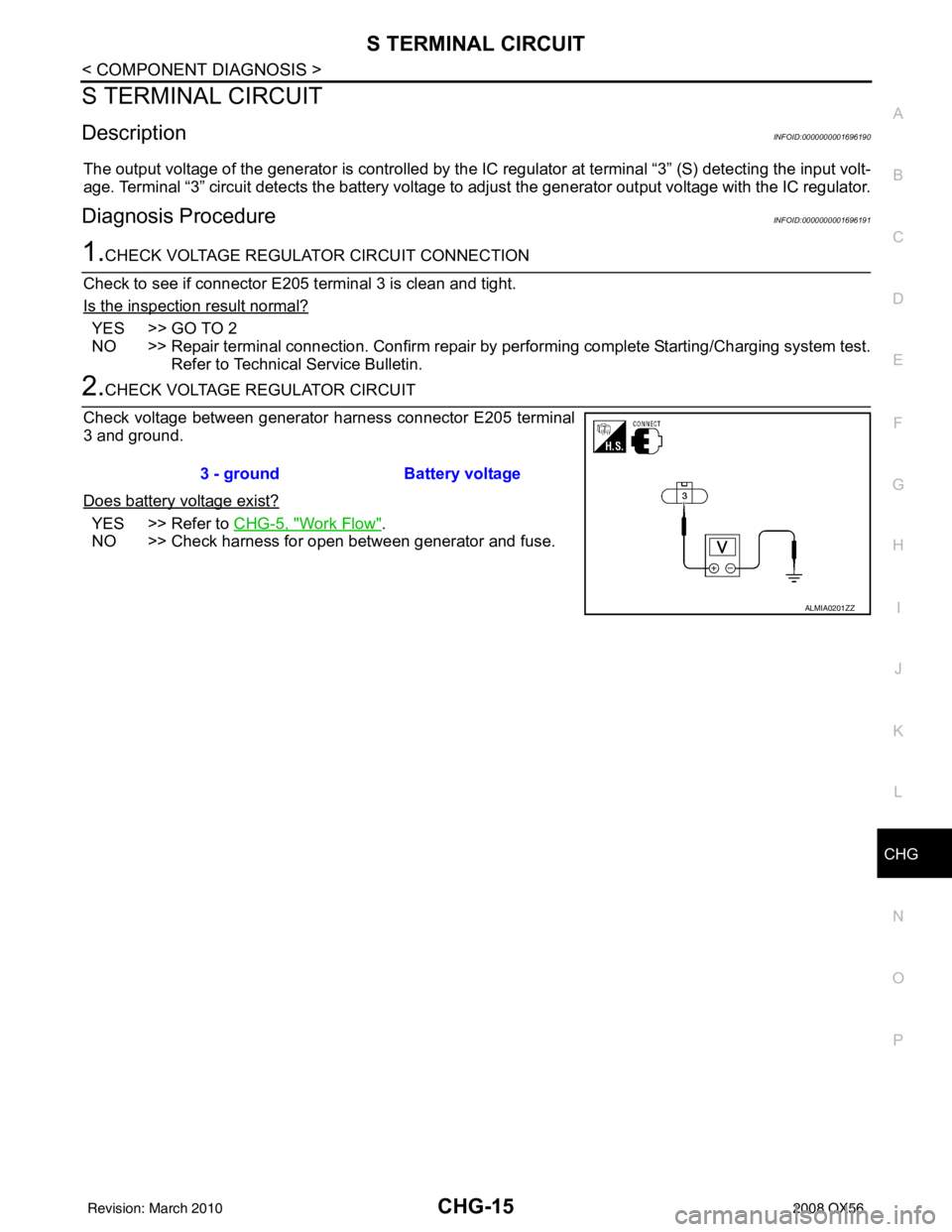

2.CHECK VOLTAGE REGULATOR CIRCUIT

Check voltage between generator harness connector E205 terminal

3 and ground.

Does battery voltage exist?

YES >> Refer to CHG-5, "Work Flow".

NO >> Check harness for open between generator and fuse. 3 - ground

Battery voltage

ALMIA0201ZZ

Revision: March 2010 2008 QX56

Page 735 of 4083

CHG

GENERATORCHG-23

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DE

F

G H

I

J

K L

B A

O P

N

SERVICE DATA AND SPECIFICATIONS (SDS)

GENERATOR

GeneratorINFOID:0000000004834896

Model

TG15C13

Manufacturer Va l e o

Nominal rating 14V-130A

Ground polarity Negative

Minimum revolution under no-load 1,200 rpm

Hot output current (When 13.5 volts is applied) More than 52A/1,500 rpm

More than 82A/1,800 rpm

More than 115A/2,500 rpm

More than 130A/5,000 rpm

Regulated output voltage 13.5V @ 5,000 rpm @ 20°C

Adjustment range of power generation variable voltage control 11.4-15.6V

Revision: March 2010 2008 QX56

Page 736 of 4083

CO-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION CO

A

CO

N

O P

CONTENTS

ENGINE COOLING SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Liquid Gasket .....................................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................5

FUNCTION DIAGNOSIS ...............................6

COOLING SYSTEM ....................................... .....6

Cooling Circuit ..................................................... ......6

Schematic .................................................................7

OVERHEATING CAUSE ANALYSIS ..................8

Troubleshooting Chart ...............................................8

ON-VEHICLE MAINTENA NCE ....................10

ENGINE COOLANT ....................................... ....10

Inspection ............................................................ ....10

Changing Engine Coolant ........................................11

RADIATOR ........................................................14

Checking Radiator ............................................... ....14

ON-VEHICLE REPAIR .................................15

RADIATOR ....... .................................................15

Removal and Installation ..................................... ....15

ENGINE COOLING FAN ...................................18

Removal and Installation (Crankshaft Driven

Type) .......................................................................

18

Removal and Installation (Motor Driven Type) ........19

WATER PUMP ..................................................20

Removal and Installation .........................................20

THERMOSTAT AND WATER PIPING ..............22

Removal and Installation .........................................22

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

24

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

24

Standard and Limit .............................................. ....24

Revision: March 2010 2008 QX56

Page 737 of 4083

CO-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000004857577

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000004857586

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: March 2010 2008 QX56

Page 739 of 4083

CO-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

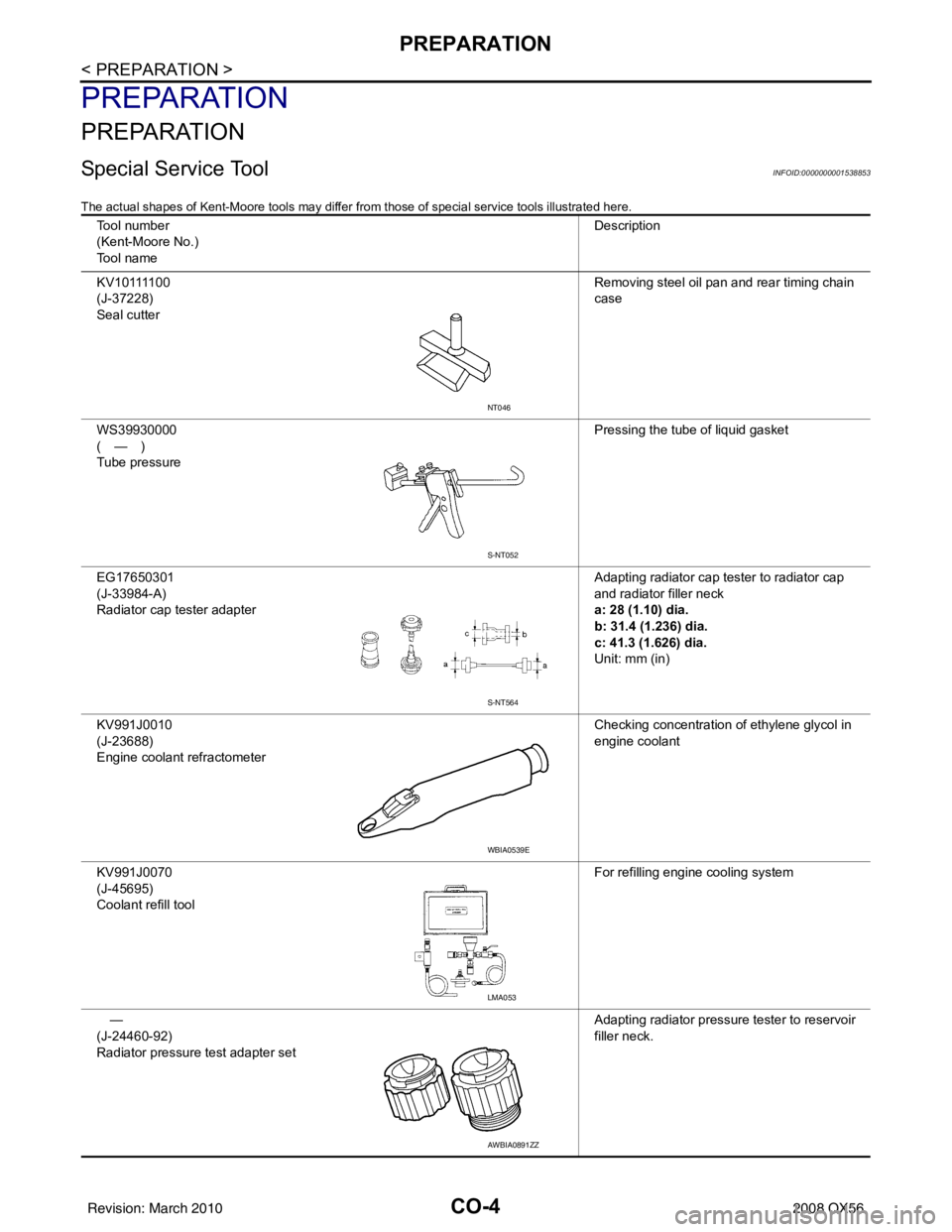

Special Service ToolINFOID:0000000001538853

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name Description

K V 1 0 1111 0 0

(J-37228)

Seal cutter Removing steel oil pan and rear timing chain

case

WS39930000

(—)

Tube pressure Pressing the tube of liquid gasket

EG17650301

(J-33984-A)

Radiator cap tester adapter Adapting radiator cap tester to radiator cap

and radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

KV991J0010

(J-23688)

Engine coolant refractometer Checking concentration of ethylene glycol in

engine coolant

KV991J0070

(J-45695)

Coolant refill tool For refilling engine cooling system

—

(J-24460-92)

Radiator pressure test adapter set Adapting radiator pressure tester to reservoir

filler neck.

NT046

S-NT052

S-NT564

WBIA0539E

LMA053

AWBIA0891ZZ

Revision: March 2010

2008 QX56

Page 740 of 4083

PREPARATIONCO-5

< PREPARATION >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

Commercial Service ToolINFOID:0000000001538854

Tool name

Description

Power tool Loosening bolts and nuts

Radiator cap tester Checking radiator and radiator cap

Coolant system tester adapter Adapting radiator cap tester to reservoir filler neck

Coolant system tester adapter Adapting radiator cap tester to reservoir cap

PBIC0190E

PBIC1982E

WBIA0408E

WBIA0409E

Revision: March 2010 2008 QX56

Page 759 of 4083

CO-24

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000001538866

ENGINE COOLANT CAPACITY (APPROXIMATE)

Unit: (US qt, Imp qt)

THERMOSTAT

RADIATOR

Unit: kPa (kg/cm2 , psi)

Engine coolant capacity with reservoir ("MAX" level)14.4 (15 1/4, 12 5/8)

Valve opening temperature80 - 84°C (176 - 183 °F)

Maximum valve lift More than 10 mm/95°C (0.39 in/203 °F)

Valve closing temperature 77°C (171 °F) or higher

Reservoir cap relief pressure Standard 95 - 125 (0.97- 1.28, 14 - 18)

Leakage test pressure 137 (1.4, 20)

Revision: March 2010 2008 QX56

Page 790 of 4083

PRECAUTIONSDEF-31

< PRECAUTION >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000004894308

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000004894309

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: March 2010 2008 QX56