belt INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 2707 of 4083

MWI-62

< ECU DIAGNOSIS >

COMBINATION METER

DTC Index

INFOID:0000000001691312

Function Specifications

Speedometer

Zero indication.

Tachometer

Fuel gauge

Engine coolant temperature gauge

Engine oil pressure gauge

Voltage gauge

A/T oil temperature gauge

Illumination control

Meter illumination Change to nighttime mode when communication is lost.

Segment LCD Odometer

Freeze current indication.

A/T position Display turns off.

Buzzer Buzzer turns off.

Warning lamp/indicator lamp ABS warning lamp

Lamp turns on when communication is lost.

Brake warning lamp

VDC OFF indicator lamp

SLIP indicator lamp

A/T CHECK warning lamp

Lamp turns off when communication is lost.

Oil pressure/coolant temperature

warning lamp

Light indicator

Malfunction indicator lamp

Master warning lamp

Air bag warning lamp

High beam indicator

Turn signal indicator lamp

CRUISE indicator lamp

Driver and passenger seat belt warn-

ing lamp

Lamp turns off when disconnected.

Charge warning lamp

Security indicator lamp

4WD indicator lamp

AT P i n d i c a t o r l a m p

CK SUSP warning lamp

Low tire pressure warning lamp

Lamp will flash every second for 1 minute and then stay on con-

tinuously thereafter.

CONSULT-III display

MalfunctionReference

page

CAN COMM CIRC

[U1000] Malfunction is detected in CAN communication.

CAUTION:

Even when there is no malfunction on CAN communication system, malfunction may be

misinterpreted when battery has low voltage (when maintaining 7 - 8 V for about 2 sec-

onds) or 10A fuse [No. 19, located in

the fuse block (J/B)] is disconnected. MWI-28

VEHICLE SPEED

CIRC

[B2205]Malfunction is detected when an erroneous speed signal is input.

CAUTION:

Even when there is no malfunction on speed signal system, malfunction may be misin-

terpreted when battery has lo

w voltage (when maintaining 7 - 8 V for about 2 seconds). MWI-29

Revision: March 2010

2008 QX56

Page 2719 of 4083

MWI-74

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000004894341

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000004894342

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: March 2010 2008 QX56

Page 2723 of 4083

PB-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION PB

A

B

PB

N

O P

CONTENTS

PARKING BRAKE SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

PREPARATION ............................................4

PREPARATION .............................................. .....4

Commercial Service Tool .................................... ......4

ON-VEHICLE MAINTENANCE .....................5

PARKING BRAKE SYSTEM .......................... .....5

On-Vehicle Service ............................................. ......5

ON-VEHICLE REPAIR ..................................7

PARKING BRAKE CONTROL ...........................7

Component .......................................................... .....7

Removal and Installation ..........................................7

PARKING BRAKE SHOE ..................................9

Removal and Installation ..........................................9

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

11

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

11

Parking Brake ...................................................... ....11

Parking Brake Control .............................................11

Revision: March 2010 2008 QX56

Page 2724 of 4083

PB-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000004873079

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000004873080

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: March 2010 2008 QX56

Page 2734 of 4083

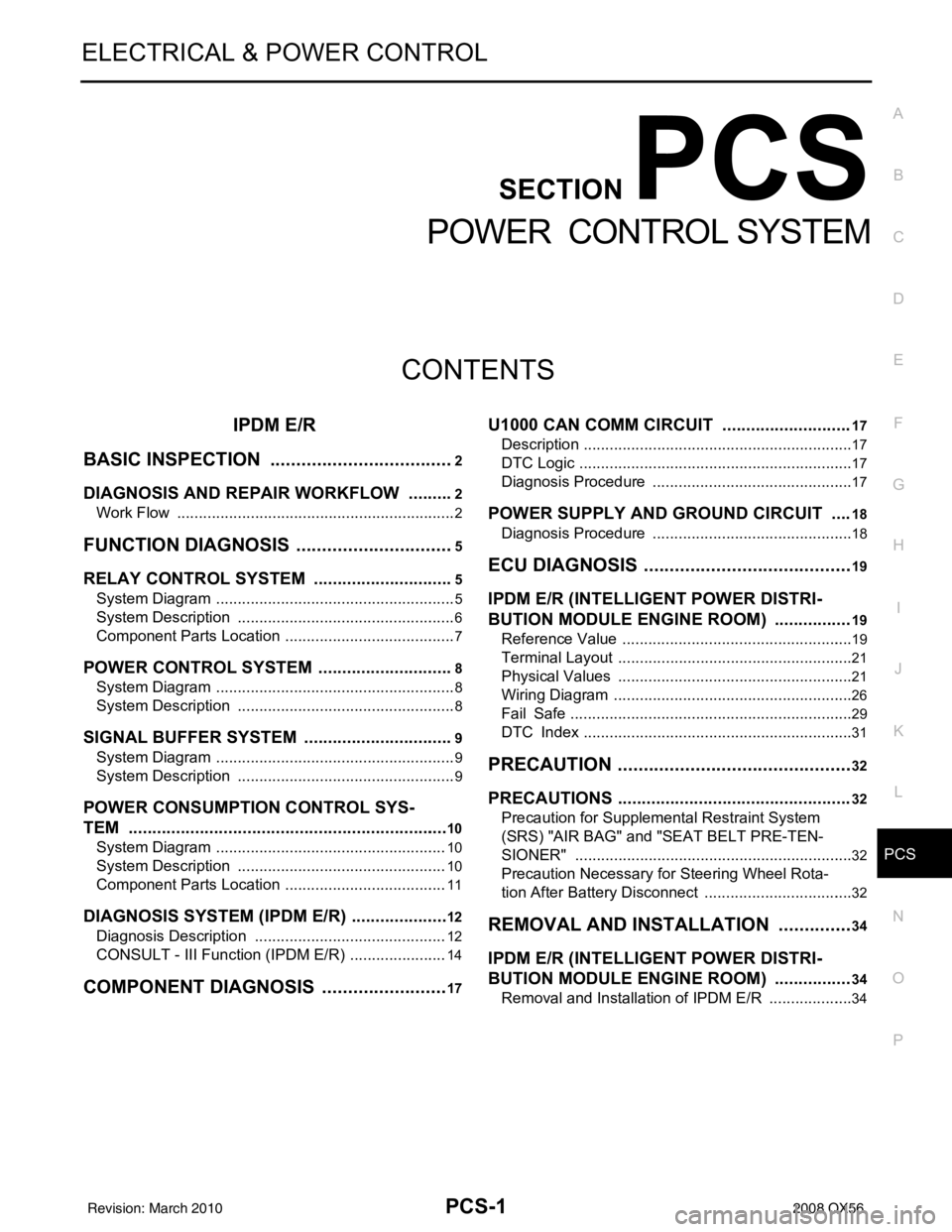

PCS

PCS-1

ELECTRICAL & POWER CONTROL

C

DE

F

G H

I

J

K L

B

SECTION PCS

A

O P

N

CONTENTS

POWER CONTROL SYSTEM

IPDM E/R

BASIC INSPECTION ....... .............................

2

DIAGNOSIS AND REPAIR WORKFLOW ..... .....2

Work Flow ........................................................... ......2

FUNCTION DIAGNOSIS ...............................5

RELAY CONTROL SYSTEM ......................... .....5

System Diagram .................................................. ......5

System Description ...................................................6

Component Parts Location ........................................7

POWER CONTROL SYSTEM .............................8

System Diagram .................................................. ......8

System Description ...................................................8

SIGNAL BUFFER SYSTEM ................................9

System Diagram .................................................. ......9

System Description ...................................................9

POWER CONSUMPTION CONTROL SYS-

TEM ....................................................................

10

System Diagram .................................................. ....10

System Description .................................................10

Component Parts Location ......................................11

DIAGNOSIS SYSTEM (IPDM E/R) .....................12

Diagnosis Description ......................................... ....12

CONSULT - III Function (IPDM E/R) .......................14

COMPONENT DIAGNOSIS .........................17

U1000 CAN COMM CIRCUIT ...........................17

Description ........................................................... ....17

DTC Logic ................................................................17

Diagnosis Procedure ...............................................17

POWER SUPPLY AND GROUND CIRCUIT ....18

Diagnosis Procedure ...............................................18

ECU DIAGNOSIS .........................................19

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

19

Reference Value .................................................. ....19

Terminal Layout .......................................................21

Physical Values ................................................... ....21

Wiring Diagram ........................................................26

Fail Safe ..................................................................29

DTC Index ...............................................................31

PRECAUTION ..............................................32

PRECAUTIONS .................................................32

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

32

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

32

REMOVAL AND INSTALLATION ...............34

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

34

Removal and Installation of IPDM E/R ................ ....34

Revision: March 2010 2008 QX56

Page 2765 of 4083

![INFINITI QX56 2008 Factory Service Manual PCS-32

< PRECAUTION >[IPDM E/R]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000004857510

The Supplemental INFINITI QX56 2008 Factory Service Manual PCS-32

< PRECAUTION >[IPDM E/R]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000004857510

The Supplemental](/img/42/57030/w960_57030-2764.png)

PCS-32

< PRECAUTION >[IPDM E/R]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000004857510

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000004857511

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: March 2010 2008 QX56

Page 2768 of 4083

PG

PG-1

ELECTRICAL & POWER CONTROL

C

DE

F

G H

I

J

K L

B

SECTION PG

A

O P

N

CONTENTS

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

PRECAUTION .......

........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Power Generation Variable Voltage

Control System ..........................................................

3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

BASIC INSPECTION ....................................5

BATTERY ....................................................... .....5

How to Handle Battery ........................................ ......5

Work Flow ........................................................... ......7

INSPECTION AND ADJUSTMENT .....................8

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL ............................... ......

8

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Special Re-

pair Requirement ................................................. ......

8

COMPONENT DIAGNOSIS ..........................9

POWER SUPPLY ROUTING CIRCUIT .......... .....9

Wiring Diagram — Battery Power Supply — ....... ......9

Wiring Diagram — Accessory Power Supply — .....17

Wiring Diagram — Ignition Power Supply — ....... ....21

Fuse .........................................................................29

Fusible Link .............................................................29

GROUND ...........................................................30

Ground Distribution ..................................................30

HARNESS .........................................................40

Harness Layout ................................................... ....40

ELECTRICAL UNITS LOCATION ....................62

Electrical Units Location ..........................................62

HARNESS CONNECTOR .................................65

Description ...............................................................65

STANDARDIZED RELAY .................................68

Description ...............................................................68

FUSE BLOCK - JUNCTION BOX (J/B) ............70

Terminal Arrangement .............................................70

FUSE, FUSIBLE LINK AND RELAY BOX ........71

Terminal Arrangement .............................................71

ON-VEHICLE REPAIR .................................73

BATTERY ..........................................................73

Removal and Installation ..................................... ....73

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

74

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

74

Battery ................................................................. ....74

Revision: March 2010 2008 QX56

Page 2769 of 4083

PG-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000004913900

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000004913899

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: March 2010 2008 QX56

Page 2820 of 4083

PG

HARNESSPG-53

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

BODY NO. 2 HARNESS

C5 B10 Y/2 : Front LH side air bag module

C5 B13 W/24 : ICC unit

C4 B14 Y/2 : Front LH seat belt pre-tensioner

C5 B15 Y/2 : LH side air bag (satellite) sensor

C5 B17 GR/24 : ICC unit

D4 B18 W/3 : Rear door switch LH

G3 B19 — : Body ground

B4 B32 W/6 : To B124

G5 B35 B/3 : Rear combination lamp LH

B4 B37 W/16 : To B200

A3 B38 Y/2 : LH side front curtain air bag module

A4 B40 W/24 : To E34

A4 B41 W/12 : To E35

A4 B42 W/2 : To E36

B4 B43 W/16 : To B111

G3 B48 W/18 : To D401

F3 B49 W/2 : To D402

F4 B52 W/2 : Rear power vent window motor LH

E4 B54 Y/2 : LH side rear curtain air bag module

F5 B55 W/26 : Back door control unit

F4 B56 GR/16 : Sonar control unit

G4 B63 W/6 : Back door close switch

A4 B69 SMJ : To M40

G4 B70 B/3 : Rear combination lamp LH

B4 B72 BR/6 : Subwoofer

E5 B73 W/16 : Rear view camera control unit

C4 B74 Y/4

: Seat belt buckle pretensioner assembly

LH (seatbelt buckle switch)

F5 B75 W/10 : To B400

F5 B76 GR/2 : Inside key antenna 2 (luggage

compartment)

Revision: March 2010

2008 QX56

Page 2821 of 4083

PG-54

< COMPONENT DIAGNOSIS >

HARNESS

G4 B101 W/16 : To M84

A4 B105 B/3 : Rear combination lamp RH

E4 B106 W/18 : To D301

G4 B107 W/8 : To E139

E4 B108 W/3 : Front door switch RH

G 3 B 111 W / 1 6 : To B 4 3

E4 B113 Y/12 : Air bag diagnosis sensor unit

E5 B114 Y/2 : RH side air bag (satellite) sensor

D4 B116 W/3 : Rear door switch RH

F4 B117 — : Body ground

F4 B118 W/3 : Front seat heater RH

A4 B119 W/2 : Condenser-3

A3 B120 W/2 : Condenser-4

F4 B124 W/6 : To B32

F4 B126 Y/2 : Front RH side air bag module

E5 B127 Y/2 : Front RH seat belt pre-tensioner

C3 B128 Y/2 : RH side rear curtain air bag module

G3 B129 Y/2 : RH side front curtain air bag module

A4 B130 B/3 : Rear combination lamp RH

A5 B132 — : Body ground

A5 B133 W/4 : Variable blower control (rear)

B5 B134 W/2 : Rear blower motor

E4 B136 W/8 : To B350

E4 B137 W/3 : Belt tension sensor

B3 B138 B/3 : Rear cargo power socket

A3 B139 W/16 : To D602

A2 B140 W/6 : To D601

D2 B145 W/16 : To R200

E2 B146 BR/24 : To R201

G3 B149 SMJ : To M36

B3 B150 W/2 : Rear power vent window motor RH

B2 B153 W/2 : Cargo lamp

F5 B154 W/2 : To B303

B4 B155 B/6 : Air mix door motor (rear)

B4 B156 B/6 : Mode door motor (rear)

F4 B157 Y/4 : Seat belt buckle pre-tensioner assembly

RH (seat belt buckle switch)

G4 B161 W/20 : To M157

C4 B162 W/6 : Third row power folding seat switch

RH side (front)

B4 B163 BR/6 : Third row power folding seat switch

RH side (rear)

C4 B164 BR/6 : Third row power folding seat switch

LH side (front)

Revision: March 2010

2008 QX56