boot INFINITI QX56 2008 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 2085 of 4083

FAX-1

TRANSMISSION & DRIVELINE

CEF

G H

I

J

K L

M

SECTION FA X

A

B

FA X

N

O P

CONTENTS

FRONT AXLE

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution .................................................................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

SYMPTOM DIAGNOSIS ...............................5

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

5

NVH Troubleshooting Chart ................................ ......5

ON-VEHICLE MAINTENANCE .....................6

WHEEL HUB ......................................................6

On-Vehicle Inspection and Service ..................... .....6

REMOVAL AND INSTALLATION ................7

WHEEL HUB ......................................................7

Removal and Installation ..................................... .....7

DRIVE SHAFT ....................................................9

Removal and Installation ..........................................9

DISASSEMBLY AND ASSEMBLY ..............11

DRIVE SHAFT ...................................................11

Disassembly and Assembly ................................. ....11

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

16

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

16

Wheel Bearing ..................................................... ....16

Drive Shaft ...............................................................16

Boot Bands ..............................................................16

Revision: March 2010 2008 QX56

Page 2088 of 4083

FAX-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000001534447

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000001534448

Tool number

(Kent-Moore No.)

Tool name Description

ST29020001

(J-24319-01)

Gear arm puller Removing ball joint for steering knuckle

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

KV40107300

(—)

Boot band crimping tool Installing boot bands

NT694

ZZA1229D

Tool name

Description

Power tools Removing bolts and nuts

PBIC0190E

Revision: March 2010 2008 QX56

Page 2093 of 4083

DRIVE SHAFTFAX-9

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

DRIVE SHAFT

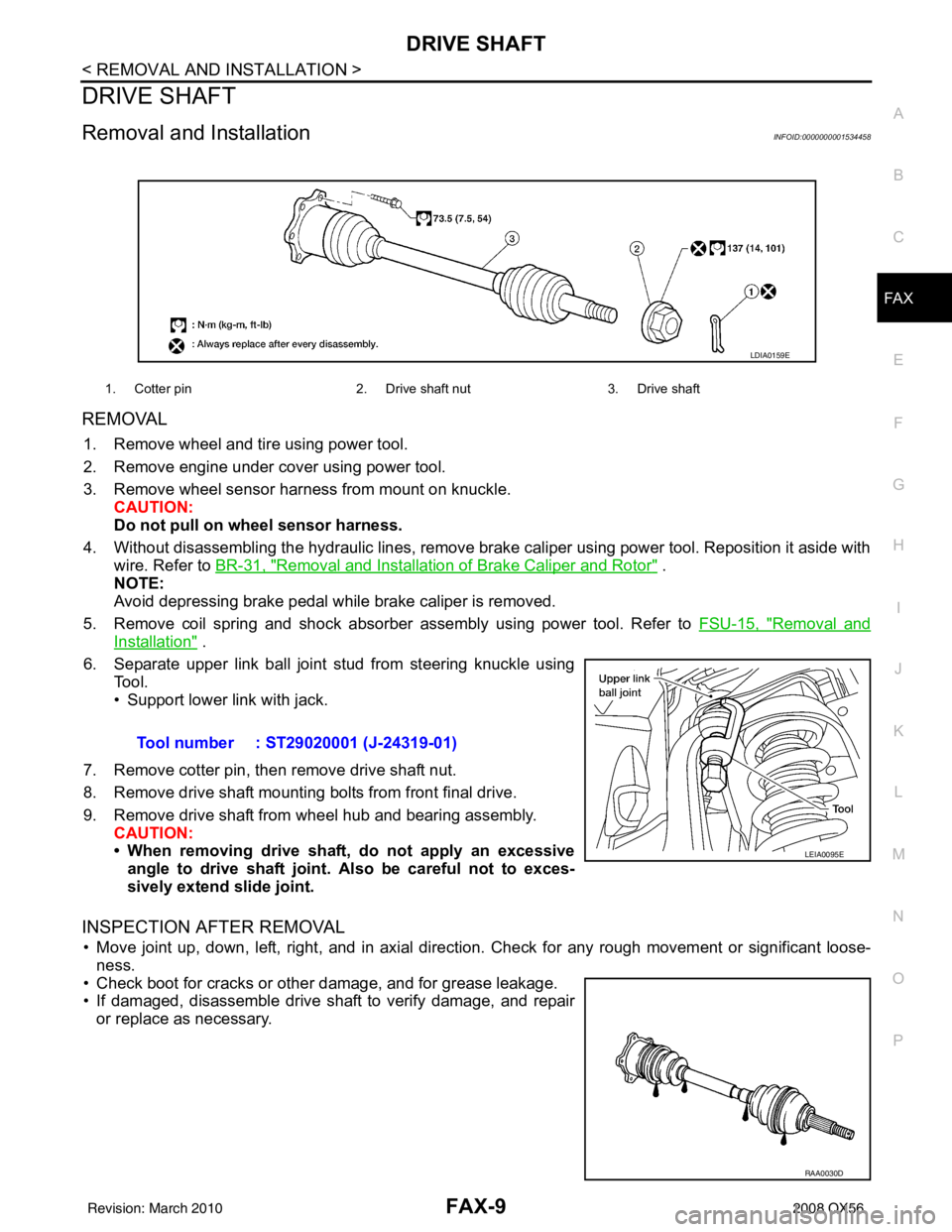

Removal and InstallationINFOID:0000000001534458

REMOVAL

1. Remove wheel and tire using power tool.

2. Remove engine under cover using power tool.

3. Remove wheel sensor harness from mount on knuckle. CAUTION:

Do not pull on wheel sensor harness.

4. Without disassembling the hydraulic lines, remove brake caliper using power tool. Reposition it aside with wire. Refer to BR-31, "

Removal and Installation of Brake Caliper and Rotor" .

NOTE:

Avoid depressing brake pedal while brake caliper is removed.

5. Remove coil spring and shock absorber assembly using power tool. Refer to FSU-15, "

Removal and

Installation" .

6. Separate upper link ball joint stud from steering knuckle using Tool.

• Support lower link with jack.

7. Remove cotter pin, then remove drive shaft nut.

8. Remove drive shaft mounting bolts from front final drive.

9. Remove drive shaft from wheel hub and bearing assembly. CAUTION:

• When removing drive shaf t, do not apply an excessive

angle to drive shaft joint. Also be careful not to exces-

sively extend slide joint.

INSPECTION AFTER REMOVAL

• Move joint up, down, left, right, and in axial directi on. Check for any rough movement or significant loose-

ness.

• Check boot for cracks or other damage, and for grease leakage.

• If damaged, disassemble drive shaft to verify damage, and repair or replace as necessary.

1. Cotter pin 2. Drive shaft nut3. Drive shaft

LDIA0159E

Tool number : ST29020001 (J-24319-01)

LEIA0095E

RAA0030D

Revision: March 2010 2008 QX56

Page 2095 of 4083

DRIVE SHAFTFAX-11

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

DISASSEMBLY AND ASSEMBLY

DRIVE SHAFT

Disassembly and AssemblyINFOID:0000000001534461

DISASSEMBLY

Final Drive Side

1. Mount the drive shaft in a vise. CAUTION:

When mounting the drive shaft in a vise, use co pper or aluminum plates between the vise and the

drive shaft.

2. Remove the boot bands.

3. Remove the stopper ring using suitable tool as shown, and pull the housing off.

1. Sliding joint housing 2. Snap ring 3. Ball cage, steel ball, inner race assembly

4. Stopper ring 5. Boot band6. Boot

7. Drive shaft 8. Circlip9. Joint sub-assembly

WDIA0054E

SRA249A

Revision: March 2010 2008 QX56

Page 2096 of 4083

FAX-12

< DISASSEMBLY AND ASSEMBLY >

DRIVE SHAFT

4. Remove the snap ring, then remove the ball cage, steel ball,inner race assembly from the drive shaft.

5. Remove the boot from the drive shaft.

6. Remove any old grease on the housing using paper towels.

Wheel Side

1. Mount the drive shaft in a vise. CAUTION:

When mounting the drive shaft in a vise, use copp er or aluminum plates between the vise and the

drive shaft.

2. Remove the boot bands, then remove the boot from the joint sub-assembly.

3. Screw a suitable drive shaft puller 30 mm (1.18 in) or more into the threaded part of the joint sub-assembly. Pull the joint sub-

assembly off of the drive shaft as shown.

NOTE:

Align the sliding hammer and drive shaft and remove the joint

sub-assembly by pulling straight out.

CAUTION:

• If the joint sub-assembly cannot be removed after five ormore attempts, replace the drive shaft and joint sub-

assembly as a set.

4. Remove the boot from the drive shaft.

5. Remove the circlip from the drive shaft.

6. While rotating the ball cage, remove any old grease from the joint sub-assembly using paper towels.

INSPECTION AFTER DISASSEMBLY

Drive Shaft

• Replace the drive shaft if there is any runout, cracking, or other damage.

Joint Sub-assembly

• Check for any rough rotation or unusual axial looseness.

• Clean any foreign material from inside the joint sub-assembly.

• Check for any compression scars, cracks, or fractures.

CAUTION:

If any defective conditions are found in the joint sub-assembly comp onents, replace the entire joint

sub-assembly.

Sliding Joint Side Housing

• Check for any compression scars, cracks, fracture s, or unusual wear on the ball rolling surface.

• Check for any damage to the drive shaft screws.

• Check for any deformation of the boot installation components.

Ball Cage

• Check the sliding surface for any compression scars, cracks, or fractures.

Steel Ball

• Check for any compression scars, cr acks, fractures, or unusual wear.

Inner Race

SFA514A

SDIA0606E

Revision: March 2010 2008 QX56

Page 2097 of 4083

DRIVE SHAFTFAX-13

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

• Check the ball sliding surface for any co mpression scars, cracks, or fractures.

• Check for any damage to the serrated part. CAUTION:

If any defective conditions are found, install a new housing, ball cage, steel ball, and inner race as a

set.

ASSEMBLY

Final Drive Side

1. Wrap the serrated part of the drive shaft with tape. Install the boot band and boot to drive shaft.

NOTE:

Discard the old boot band and boot and use a new one for

assembly.

2. Remove the tape wound around the serrated part of the drive shaft.

3. Install the ball cage, steel ball, and inner race assembly on the drive shaft, and secure them tightly using the snap ring.

NOTE:

Discard the old snap ring and use a new one for assembly.

4. Insert the specified quantity of Genuine NISSAN Grease or equivalent, onto the housing (indicated by * marks), and install it

onto shaft. Refer to MA-12, "

Fluids and Lubricants".

5. Install the stopper ring onto the housing.

6. After installation, pull on the shaft to check engagement between the sliding joint and the stopper ring.

SFA800

SDIA1125E

Grease capacity : 130 − 150 g (4.58 − 5.29 oz)

RAC0678D

Revision: March 2010 2008 QX56

Page 2098 of 4083

FAX-14

< DISASSEMBLY AND ASSEMBLY >

DRIVE SHAFT

7. Install the boot securely into the grooves (indicated by * marks)as shown.

CAUTION:

If there is grease on boot mounting surfaces (indicated by *

marks) of shaft and housing, boot may come off. Remove

all grease from surfaces.

8. Check that the boot installation length “L” is the length indicated below. Insert a suitable tool into the large end of the boot, as

shown. Bleed air from the boot to prevent boot deformation.

CAUTION:

• The boot may break if the boot installati on length is less than the specified value.

• Do not contact inside surface of boot with tip of the suitable tool.

9. Secure the large and small ends of the boot with the new boot bands as shown.

NOTE:

Discard the old boot bands and use new ones for assembly.

10. After installing the sliding joint housing to the drive shaft, rotate the boot to check that the boot is posi-

tioned correctly. If the boot is not positioned correctly , reposition the boot and secure the boot using a new

boot band.

Wheel Side

1. Insert the Genuine NISSAN Grease or equivalent, into the joint

sub-assembly serration hole until the grease begins to ooze

from the ball groove and serration hole. Refer to MA-12, "

Fluids

and Lubricants". After inserting the grease, use a shop cloth to

wipe off the grease that has oozed out.

2. Wrap the serrated part of the drive shaft with tape. Install the boot band and boot onto the shaft. Do not damage the boot.

NOTE:

Discard the old boot band and boot and use a new one for

assembly.

3. Remove the protective tape wound around the serrated part of the drive shaft. Boot installation length

“L ” : 145 mm (5.71 in)

WDIA0287E

SFA395

SDIA1127E

SFA800

Revision: March 2010 2008 QX56

Page 2099 of 4083

DRIVE SHAFTFAX-15

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

4. Attach the circlip to the drive shaftm making sure circlip fits securely into groove on drive shaft. Then install drive shaft nut to

end of joint sub-assembly, and press-fit the circlip using a suit-

able tool as shown.

NOTE:

Discard the old circlip and use a new one for assembly.

5. Insert the specified quantity of Genuine NISSAN Grease or equivalent, into the joint sub-assembly and the large end of the

boot. Refer to MA-12, "

Fluids and Lubricants".

6. Install the boot securely into the grooves (indicated by the * marks) as shown.

CAUTION:

If there is grease on the bo ot mounting surfaces (indicated

by the * marks) of the drive shaft and joint sub-assembly,

the boot may come off. Remove all grease from the drive

shaft surfaces.

7. Check that the boot installation length “L” is the specified length. Insert a suitable tool into the large end of the boot, as shown.

Bleed the air from the boot to prevent boot deformation.

CAUTION:

• The boot may break if the boot installation length is less than the specified length.

• Do not contact inside surface of boot with the tip of the suitable tool.

8. Secure large and small ends of the boot using new boot bands using Tool as shown.

NOTE:

Discard the old boot bands and use new ones for assembly.

• Secure boot band so that dimension "M" meets specificationas shown.

9. After installing the housing to the shaft, rotate the boot to check that it is positioned correctly. If the boot is

not positioned correctly, remove the old boot bands then reposition the boot and secure the boot with new

boot bands. Grease capacity : 145

− 165 g (5.11 − 5.82 oz)

RAC0049D

Boot installation length “L” : 168.4 mm (6.63 in)

Tool number : KV40107300 ( — )

WDIA0288E

RAC1133D

Dimension "M" : 1.0 – 4.0 mm (0.039 – 0.157 in)

DSF0047D

Revision: March 2010 2008 QX56

Page 2100 of 4083

FAX-16

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel BearingINFOID:0000000001534462

Drive ShaftINFOID:0000000001534463

Boot BandsINFOID:0000000004913882

Unit: mm (in)

Wheel bearing axial end play0.05 mm (0.002 in) or less

Drive shaft joint typeFinal drive side Rzeppa

Wheel side

Rzeppa

Grease Quality

Nissan Genuine Grease or

equivalent

Capacity Final drive side

130 - 150 g (4.58 - 5.29 oz)

Wheel side 145 - 165 g (5.11 - 5.82 oz)

Boot length Final drive side "L"

145 mm (5.71 in)

Wheel side "L" 168.4 mm (6.63 in)

WDIA0055E

Dimension "M" 1.0 - 4.0 (0.039 - 0.157)

DSF0047D

Revision: March 2010 2008 QX56

Page 2137 of 4083

FSU-20

< REMOVAL AND INSTALLATION >

KNUCKLE

KNUCKLE

Removal and InstallationINFOID:0000000001534639

REMOVAL

1. Remove wheel hub and bearing assembly. Refer to FA X - 7 , "Removal and Installation" .

• Disconnect wheel sensor harness connector. Do not remove wheel sensor from wheel hub and bearing

assembly for this procedure.

2. Remove steering outer socket from steering knuckle using Tool. CAUTION:

• Be careful not to damage ball joint boot.

• Temporarily tighten nut to prevent damage to threads andto prevent Tool from coming off.

3. Remove the coil spring and shock absorber assembly using power tool. Refer to FSU-15, "

Removal and

Installation" .

4. Support lower link using a suitable jack.

5. Remove cotter pin and nut from upper link ball joint and discard the cotter pin.

6. Separate upper link ball joint from steering knuckle using Tool.

1. Disc rotor 2. Wheel hub and bearing assembly 3. Wheel stud

4. Splash guard 5. Steering knuckle Front

AWDIA0423GB

Tool number : HT72520000 (J-25730-A)

WGIA0130E

Tool number : ST29020001 (J-24319-01)

LEIA0095E

Revision: March 2010 2008 QX56