fuse INFINITI QX56 2008 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 675 of 4083

CCS

DTC 90 STOP LAMP RLY FIXCCS-35

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B

N P A

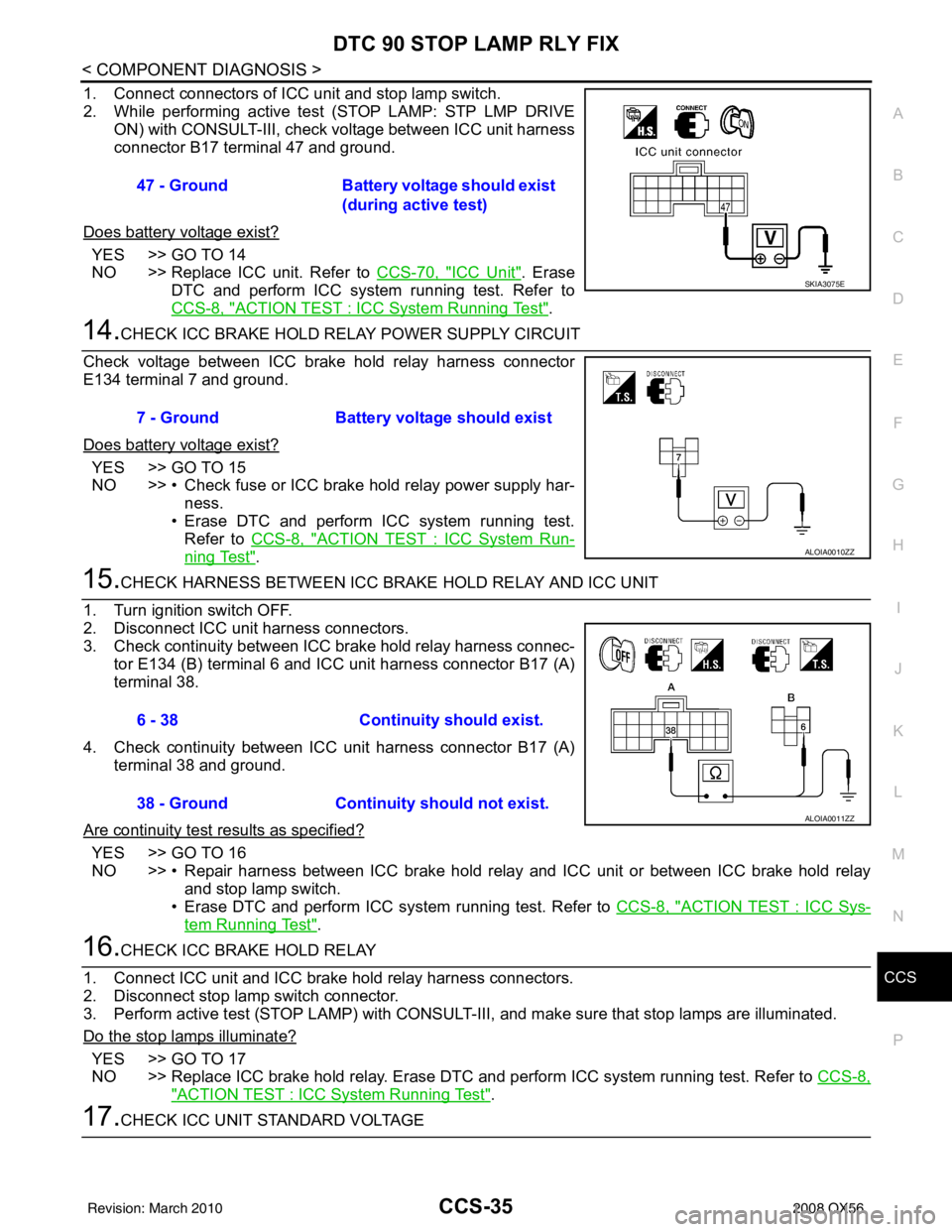

1. Connect connectors of ICC unit and stop lamp switch.

2. While performing active test (STOP LAMP: STP LMP DRIVE ON) with CONSULT-III, check voltage between ICC unit harness

connector B17 terminal 47 and ground.

Does battery voltage exist?

YES >> GO TO 14

NO >> Replace ICC unit. Refer to CCS-70, "

ICC Unit". Erase

DTC and perform ICC system running test. Refer to

CCS-8, "

ACTION TEST : ICC System Running Test".

14.CHECK ICC BRAKE HOLD RELAY POWER SUPPLY CIRCUIT

Check voltage between ICC brake hold relay harness connector

E134 terminal 7 and ground.

Does battery voltage exist?

YES >> GO TO 15

NO >> • Check fuse or ICC brake hold relay power supply har- ness.

• Erase DTC and perform ICC system running test. Refer to CCS-8, "

ACTION TEST : ICC System Run-

ning Test".

15.CHECK HARNESS BETWEEN ICC BRAKE HOLD RELAY AND ICC UNIT

1. Turn ignition switch OFF.

2. Disconnect ICC unit harness connectors.

3. Check continuity between ICC brake hold relay harness connec- tor E134 (B) terminal 6 and IC C unit harness connector B17 (A)

terminal 38.

4. Check continuity between ICC unit harness connector B17 (A) terminal 38 and ground.

Are continuity test results as specified?

YES >> GO TO 16

NO >> • Repair harness between ICC brake hold relay and ICC unit or between ICC brake hold relay and stop lamp switch.

• Erase DTC and perform ICC system running test. Refer to CCS-8, "

ACTION TEST : ICC Sys-

tem Running Test".

16.CHECK ICC BRAKE HOLD RELAY

1. Connect ICC unit and ICC brake hold relay harness connectors.

2. Disconnect stop lamp switch connector.

3. Perform active test (STOP LAMP) with CONSULT-III, and make sure that stop lamps are illuminated.

Do the stop lamps illuminate?

YES >> GO TO 17

NO >> Replace ICC brake hold relay. Erase DTC and perform ICC system running test. Refer to CCS-8,

"ACTION TEST : ICC System Running Test".

17.CHECK ICC UNIT STANDARD VOLTAGE

47 - Ground

Battery voltage should exist

(during active test)

SKIA3075E

7 - Ground Battery voltage should exist

ALOIA0010ZZ

6 - 38 Continuity should exist.

38 - Ground Continuity should not exist.

ALOIA0011ZZ

Revision: March 2010 2008 QX56

Page 722 of 4083

CHG-10

< COMPONENT DIAGNOSIS >

CHARGING SYSTEM PRELIMINARY INSPECTION

COMPONENT DIAGNOSIS

CHARGING SYSTEM PRELIMINARY INSPECTION

Inspection ProcedureINFOID:0000000001696184

1.CHECK BATTERY TERMINALS CONNECTION

Check if battery terminals are clean and tight.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair battery terminals connection.

2.CHECK FUSE

Check for blown fuse and fusible link.

Is the inspection result normal?

YES >> GO TO 3

NO >> Be sure to eliminate cause of malfunction before installing new fuse or fusible link.

3.CHECK GENERATOR GROUND TERMINAL CONNECTION

Verify connector E206 terminal 5 (generator ground harness) is clean and tight.

Is the inspection result normal?

YES >> GO TO 4

NO >> Repair connection.

4.CHECK DRIVE BELT TENSION

Check drive belt tension. Refer to EM-13, "

Checking Drive Belts".

Is the inspection result normal?

YES >> Inspection end.

NO >> Repair as needed.

Unit Power source (Power supply terminals) Fuse or Fusible Link

Generator Battery (terminal 3)

Fuse 30

Battery (terminal 1) Fusible Link A

Combination meter Ignition switch ON (terminal 2) Fuse 14

Revision: March 2010 2008 QX56

Page 727 of 4083

CHG

S TERMINAL CIRCUITCHG-15

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

S TERMINAL CIRCUIT

DescriptionINFOID:0000000001696190

The output voltage of the generator is controlled by the IC

regulator at terminal “3” (S) detecting the input volt-

age. Terminal “3” circuit detects the battery voltage to adjust the generator output voltage with the IC regulator.

Diagnosis ProcedureINFOID:0000000001696191

1.CHECK VOLTAGE REGULATOR CIRCUIT CONNECTION

Check to see if connector E205 terminal 3 is clean and tight.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair terminal connection. Confirm repair by performing complete Starting/Charging system test.

Refer to Technical Service Bulletin.

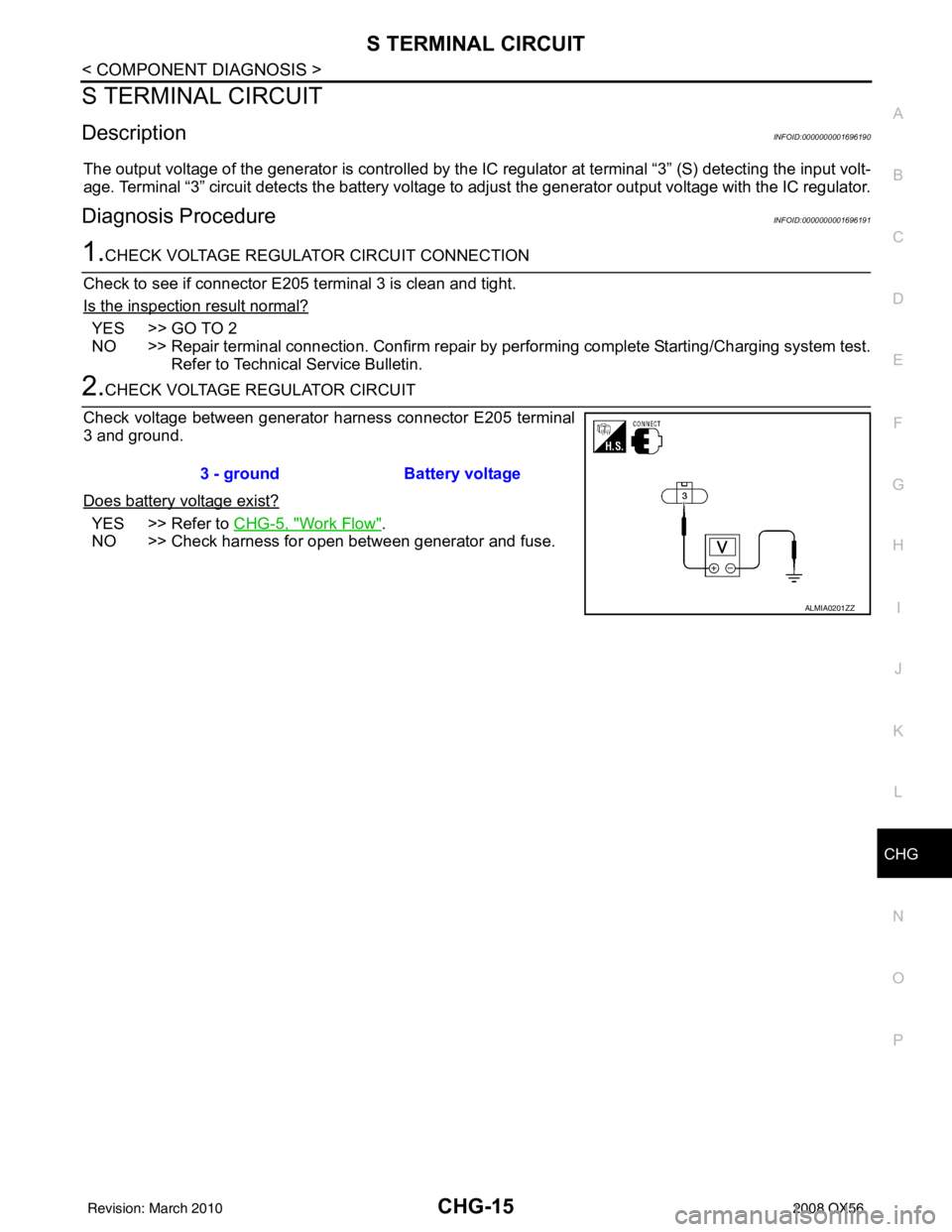

2.CHECK VOLTAGE REGULATOR CIRCUIT

Check voltage between generator harness connector E205 terminal

3 and ground.

Does battery voltage exist?

YES >> Refer to CHG-5, "Work Flow".

NO >> Check harness for open between generator and fuse. 3 - ground

Battery voltage

ALMIA0201ZZ

Revision: March 2010 2008 QX56

Page 768 of 4083

REAR WINDOW DEFOGGER RELAYDEF-9

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

REAR WINDOW DEFOGGER RELAY

DescriptionINFOID:0000000001735612

Power is supplied to the rear window defogger with BCM control.

Component Function CheckINFOID:0000000001735613

1. CHECK REAR WINDOW DEFOGGER RELAY POWER SUPPLY CIRCUIT

Check that an operation noise of rear window defogger re lay (located in IPDM E/R) can be heard when turning

the rear window defogger switch ON.

Is the inspection result normal?

YES >> Rear window defogger relay power supply circuit is OK.

NO >> Refer to DEF-9, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001735614

1.CHECK FUSES

Check if any of the following fuses in the IPDM E/R are blown.

Is the inspection result normal?

YES >> GO TO 2

NO >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2. CHECK REAR WINDOW DEFOGGER RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between IPDM E/R connector and ground.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation of IPDM E/R".

NO >> GO TO 3

3. CHECK INTERMITTENT INCIDENT

Check intermittent incident.

Refer to GI-38, "

Intermittent Incident"

Is the inspection result normal?

YES >> Check the following.

• Battery power supply circuit.

• IPDM E/R.

NO >> Repair or replace the malfunctioning parts.

COMPONENT PARTS AMPEREFUSE NO.

IPDM E/R 15A46

IPDM E/R 15A47

Te r m i n a l s

Condition of rear

window defogger

switch Voltage (V)

(Approx.)

(+)

(–)

IPDM E/R con-

nector Te r m i n a l

E124 60 Ground ON Battery voltage

OFF 0

LIIA2190E

Revision: March 2010 2008 QX56

Page 771 of 4083

DEF-12

< COMPONENT DIAGNOSIS >

DOOR MIRROR DEFOGGER LH

DOOR MIRROR DEFOGGER LH

DescriptionINFOID:0000000001735623

Heats the heating wire with the power supply from the rear window defogger relay to prevent the door mirror

from fogging up.

Component Function CheckINFOID:0000000001735624

1. CHECK DOOR MIRROR DEFOGGER LH

Check that heating wire of door mirror defogger LH is heated when turning the rear window defogger switch

ON.

Is the inspection result normal?

YES >> Door mirror defogger is OK.

NO >> Refer to DEF-12, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001735625

1. CHECK POWER SUPPLY

Check if the following fuse in the IPDM E/R is blown.

Is the inspection result normal?

YES >> GO TO 2

NO >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2. CHECK DOOR MIRROR DE FOGGER POWER SUPPLY CIRCUIT

Check voltage between IPDM E/R connector and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Replace IPDM E/R. Refer to PCS-34, "

Removal and Installation of IPDM E/R".

3. CHECK DOOR MIRROR DEFOGGER POWER SUPPLY CIRCUIT 2

1. Turn ignition switch OFF.

2. Disconnect door mirror LH.

3. Turn ignition switch ON.

4. Check voltage between door mirror LH connector and ground.

Is the inspection result normal?

YES >> GO TO 4

COMPONENT PARTS AMPEREFUSE NO.

IPDM E/R 15A43

ConnectorTe r m i n a l

ConditionVoltage (V)

(Approx.)

(+) (-)

E120 23 Ground Rear window defogger

switch ON

Battery voltage

Rear window defogger

switch OFF 0

LIIA2049E

ConnectorTe r m i n a l

ConditionVoltage (V)

(Approx.)

(+) (-)

D4 10 Ground Rear window defogger

switch ON

Battery voltage

Rear window defogger

switch OFF 0

LIIA1456E

Revision: March 2010

2008 QX56

Page 773 of 4083

DEF-14

< COMPONENT DIAGNOSIS >

DOOR MIRROR DEFOGGER RH

DOOR MIRROR DEFOGGER RH

DescriptionINFOID:0000000001735631

Heats the heating wire with the power supply from the rear window defogger relay to prevent the door mirror

from fogging up.

Component Function CheckINFOID:0000000001735632

1.CHECK DOOR MIRROR DEFOGGER RH

Check that the heating wire of door mirror defogger RH is heated when turning the rear window defogger

switch ON.

Is the inspection result normal?

YES >> Door mirror defogger RH is OK.

NO >> Refer to DEF-14, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001735633

1. CHECK POWER SUPPLY

Check if the following fuse in the IPDM E/R is blown.

Is the inspection result normal?

YES >> GO TO 2

NO >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2. CHECK DOOR MIRROR DE FOGGER POWER SUPPLY CIRCUIT

Check voltage between IPDM E/R connector and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Replace IPDM E/R. Refer to PCS-34, "

Removal and Installation of IPDM E/R".

3. CHECK DOOR MIRROR DEFOGGER POWER SUPPLY CIRCUIT 2

1. Turn ignition switch OFF.

2. Disconnect door mirror RH.

3. Turn ignition switch ON.

4. Check voltage between door mirror RH connector and ground.

Is the inspection result normal?

YES >> GO TO 4

COMPONENT PARTS AMPEREFUSE NO.

IPDM E/R 15A43

ConnectorTe r m i n a l

ConditionVoltage (V)

(Approx.)

(+) (-)

E120 23 Ground Rear window defogger

switch ON

Battery voltage

Rear window defogger

switch OFF 0

LIIA2049E

ConnectorTe r m i n a l

ConditionVoltage (V)

(Approx.)

(+) (-)

D107 10 Ground Rear window defogger

switch ON

Battery voltage

Rear window defogger

switch OFF 0

LIIA1456E

Revision: March 2010

2008 QX56

Page 857 of 4083

![INFINITI QX56 2008 Factory User Guide DLK-64

< COMPONENT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

INTELLIGENT KEY UNIT

INTELLIGENT KEY UNIT

: Diagnosis ProcedureINFOID:00000 INFINITI QX56 2008 Factory User Guide DLK-64

< COMPONENT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

INTELLIGENT KEY UNIT

INTELLIGENT KEY UNIT

: Diagnosis ProcedureINFOID:00000](/img/42/57030/w960_57030-856.png)

DLK-64

< COMPONENT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

INTELLIGENT KEY UNIT

INTELLIGENT KEY UNIT

: Diagnosis ProcedureINFOID:0000000001538958

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect Intelligent Key unit connector.

3. Check voltage between Intelligent Key unit harness connector M70 terminals 6, 11 and ground.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair or replace Intelligent Key unit power supply circuit.

2.CHECK GROUND CIRCUIT

Check continuity between Intelligent Key unit harness connector

M70 terminal 12 and ground.

Is the inspection result normal?

YES >> Power supply and ground circuits are OK.

NO >> Repair or replace the Intelligent Key unit ground circuit.

BCM (BODY CONTROL MODULE)

BCM (BODY CONTROL MODULE) : Diagnosis ProcedureINFOID:0000000004884061

1. CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

Connector Terminals Ignition switch position

M70 (+) (–) OFF

ON

6 Ground 0V Battery voltage

11 Battery voltage Battery voltage

WIIA1171E

12 - Ground : Continuity should exist.

WIIA1172E

Terminal No. Signal nameFuses and fusible link No.

57 Battery power supply 22 (15A)

70 F (50A)

11 Ignition ACC or ON 4 (10A)

38 Ignition ON or START 59 (10A)

Revision: March 2010 2008 QX56

Page 904 of 4083

![INFINITI QX56 2008 Factory User Guide KEY SWITCH (BCM INPUT)DLK-111

< COMPONENT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

KEY SWITCH (BCM INPUT)

Diagnosis ProcedureINFOID:0000000001539027

1.CHECK KEY SWIT INFINITI QX56 2008 Factory User Guide KEY SWITCH (BCM INPUT)DLK-111

< COMPONENT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

KEY SWITCH (BCM INPUT)

Diagnosis ProcedureINFOID:0000000001539027

1.CHECK KEY SWIT](/img/42/57030/w960_57030-903.png)

KEY SWITCH (BCM INPUT)DLK-111

< COMPONENT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

KEY SWITCH (BCM INPUT)

Diagnosis ProcedureINFOID:0000000001539027

1.CHECK KEY SWITCH POWER SUPPLY CIRCUIT

1. Remove mechanical key from ignition switch.

2. Disconnect key switch and i gnition knob switch connector.

3. Check voltage between key switch and ignition knob switch har- ness connector M12 terminal 3 and ground.

Is the inspection result normal?

YES >> GO TO 2

NO >> Check harness between key switch and ignition knob switch and fuse.

2.CHECK KEY SWITCH

Check continuity between key switch and ignition knob switch termi-

nals 3 and 4.

Is the inspection result normal?

YES >> GO TO 3

NO >> Replace key cylinder assembly (built-in key switch).

3.CHECK KEY SWITCH SIGNAL CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector M18 terminal 37 and key switch and ignition knob switch harness connector

M12 terminal 4.

3. Check continuity between BCM harness connector M18 terminal 37 and ground.

Is the inspection result normal?

YES >> Key switch (BCM input) circuit is OK.

NO >> Repair or replace harness between key switch and ignition knob switch and BCM. 3 – Ground

: Battery voltage.

PIIB4254E

Component Terminals ConditionContinuity

Ignition switch 34 Insert mechanical key

into ignition switch.

Ye s

Remove mechanical key

from ignition switch. No

PIIA6140E

37 – 4

: Continuity should exist.

37 – Ground : Continuity should not exist.

PIIB4256E

Revision: March 2010 2008 QX56

Page 933 of 4083

![INFINITI QX56 2008 Factory User Guide DLK-140

< COMPONENT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

HOMELINK UNIVERSAL TRANSCEIVER

Component Function Check

INFOID:0000000001539050

1.CHECK FUNCTION

Check that system receiver (garage door op INFINITI QX56 2008 Factory User Guide DLK-140

< COMPONENT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

HOMELINK UNIVERSAL TRANSCEIVER

Component Function Check

INFOID:0000000001539050

1.CHECK FUNCTION

Check that system receiver (garage door op](/img/42/57030/w960_57030-932.png)

DLK-140

< COMPONENT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

HOMELINK UNIVERSAL TRANSCEIVER

Component Function Check

INFOID:0000000001539050

1.CHECK FUNCTION

Check that system receiver (garage door opener, et c.) operates with original hand-held transmitter.

Is the inspection result normal?

YES >> GO TO 2

NO >> Receiver or hand-held transmitter is malfunctioning.

2.CHECK ILLUMINATION

1. Turn ignition switch “OFF”.

2. Press each of the transmitter buttons and watch for the red light

to illuminate with each button.

Is the inspection result normal?

YES >> GO TO 3

NO >> Refer to DLK-140, "

Diagnosis Procedure".

3.CHECK TRANSMITTER

Check transmitter with Tool*.

*:For details, refer to Technical Service Bulletin.

Is the inspection result normal?

YES >> Receiver or hand-held transmitter malfunction, not vehicle related.

NO >> Replace auto anti-dazzling inside mirror (homelink universal transceiver).

Diagnosis ProcedureINFOID:0000000001539051

1.CHECK POWER SUPPLY

1. Disconnect auto anti-dazzling inside mirror (homelink universal transceiver) connector.

2. Check voltage between auto anti-dazzling inside mirror (homelink universal transceiver) harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2

NO >> Check the following. • 10A fuse [No. 19 located in the fuse block (J/B)]

• Harness for open or short between fuse and auto anti-dazzling inside mirror (homelink universaltransceiver).

PIIA4815E

ALKIA0659ZZ

Auto anti-dazzling inside mirror

(Homelink universal transceiver) connector Terminal Condition

Voltage (V)

(Approx.)

R4 10Ground Ignition switch position: LOCK Battery voltage

Revision: March 2010 2008 QX56

Page 958 of 4083

![INFINITI QX56 2008 Factory User Guide INTELLIGENT KEY UNITDLK-165

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

INTELLIGENT KEY UNIT

Reference Value - Intelligent Key UnitINFOID:0000000001539057

TERMIN INFINITI QX56 2008 Factory User Guide INTELLIGENT KEY UNITDLK-165

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

INTELLIGENT KEY UNIT

Reference Value - Intelligent Key UnitINFOID:0000000001539057

TERMIN](/img/42/57030/w960_57030-957.png)

INTELLIGENT KEY UNITDLK-165

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

INTELLIGENT KEY UNIT

Reference Value - Intelligent Key UnitINFOID:0000000001539057

TERMINAL LAYOUT

PHYSICAL VALUES

WIIA1168E

Te r m i n a lWire

Color Item Condition

Voltage (V)Approx.

Ignition

Switch Po- sition Operation or Conditions

1L/Y Steering lock sole-

noid power supply LOCK

— 5

2 L CAN-H —— —

3 P CAN-L —— —

4GR Intelligent Key warn-

ing buzzer (front of

vehicle) LOCK

Operate door request

switch. Buzzer OFF

Battery voltage

Buzzer ON 0

5B/W Front door request

switch LH —Press front door request switch LH.

0

Other than above Battery voltage

6 G/R Ignition switch (ON) ON —Battery voltage

7 B/R Key switch LOCKInsert mechanical key into ignition key

cylinder.

Battery voltage

Remove mechanical key from ignition

key cylinder. 0

8G Remote keyless en-

try receiver ground

—— 0

9GR Remote keyless en-

try receiver signal —When remote keyless entry receiver re-

ceives signal from keyfob.

Stand-by

11 Y Power source (Fuse) — —Battery voltage

12 B Ground —— 0

OCC3879D

Revision: March 2010 2008 QX56