warning light INFINITI QX56 2008 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 901 of 4083

![INFINITI QX56 2008 Factory User Guide DLK-108

< COMPONENT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

HAZARD FUNCTION

HAZARD FUNCTION

DescriptionINFOID:0000000001539023

Perform answer-back for each operation with number of blinks.

Component INFINITI QX56 2008 Factory User Guide DLK-108

< COMPONENT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

HAZARD FUNCTION

HAZARD FUNCTION

DescriptionINFOID:0000000001539023

Perform answer-back for each operation with number of blinks.

Component](/img/42/57030/w960_57030-900.png)

DLK-108

< COMPONENT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

HAZARD FUNCTION

HAZARD FUNCTION

DescriptionINFOID:0000000001539023

Perform answer-back for each operation with number of blinks.

Component Function CheckINFOID:0000000001539024

1.CHECK FUNCTION

Check hazard warning lamp "FLASHER" in ACTIVE TEST.

Is the inspection result normal?

YES >> Hazard warning lamp circuit is OK.

NO >> Refer to DLK-108, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001539025

1.CHECK HAZARD SWITCH CIRCUIT

Operate the hazard lights by turni ng ON the hazard warning switch.

Do the lights operate normally?

YES >> Replace the BCM. Refer to BCS fo r replacement and configuration procedure.

NO >> Repair or replace hazard warning switch circuit. Refer to EXL-68, "

Wiring Diagram".

Revision: March 2010 2008 QX56

Page 938 of 4083

![INFINITI QX56 2008 Factory User Guide BCM (BODY CONTROL MODULE)DLK-145

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

Te r m i n a l Wire

color Signal name Signal

input/

output Measuring condition

Refe INFINITI QX56 2008 Factory User Guide BCM (BODY CONTROL MODULE)DLK-145

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

Te r m i n a l Wire

color Signal name Signal

input/

output Measuring condition

Refe](/img/42/57030/w960_57030-937.png)

BCM (BODY CONTROL MODULE)DLK-145

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

Te r m i n a l Wire

color Signal name Signal

input/

output Measuring condition

Reference value or waveform

(Approx.)

Ignition

switch Operation or condition

1BR/W Ignition keyhole illumi-

nation Output OFFDoor is locked (SW OFF)

Battery voltage

Door is unlocked (SW ON) 0V

2SB Combination switch

input 5 Input ON

Lighting, turn, wiper OFF

Wiper dial position 4

3G/Y Combination switch

input 4 Input ONLighting, turn, wiper OFF

Wiper dial position 4

4Y Combination switch

input 3 Input ON

Lighting, turn, wiper OFF

Wiper dial position 4

5G/B Combination switch

input 2

Input ONLighting, turn, wiper OFF

Wiper dial position 4

6V Combination switch

input 1

9GR/R Rear window defogger

switch

Input ONRear window defogger switch

ON

0V

Rear window defogger switch

OFF 5V

10 G Hazard lamp flash Input OFF ON (opening or closing)

0V

OFF (other than above) Battery voltage

11 O Ignition switch (ACC

or ON)

InputACC or

ON Ignition switch ACC or ON

Battery voltage

12 R/L Front door switch RH Input OFF ON (open)

0V

OFF (closed) Battery voltage

13 GR Rear door switch RH Input OFF ON (open)

0V

OFF (closed) Battery voltage

15 L/W Tire pressure warning

check connector

Input OFF

—5V

18 P Remote keyless entry

receiver and optical

sensor (ground)

Output OFF

—0V

SKIA5291E

SKIA5292E

SKIA5291E

SKIA5292E

Revision: March 2010 2008 QX56

Page 1017 of 4083

![INFINITI QX56 2008 Factory User Guide DLK-224

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

HOOD

CLEARANCE AND SURFACE HEIGHT ADJUSTMENT

1. Remove the front grille. Refer to

EXT-17, "Removal and Installation".

2. Remove the hood loc INFINITI QX56 2008 Factory User Guide DLK-224

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

HOOD

CLEARANCE AND SURFACE HEIGHT ADJUSTMENT

1. Remove the front grille. Refer to

EXT-17, "Removal and Installation".

2. Remove the hood loc](/img/42/57030/w960_57030-1016.png)

DLK-224

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

HOOD

CLEARANCE AND SURFACE HEIGHT ADJUSTMENT

1. Remove the front grille. Refer to

EXT-17, "Removal and Installation".

2. Remove the hood lock assembly and adjust the height by rotating the bumper rubber until the hood clear- ance of hood and fender becomes 1 mm (0.04 in) lower than fitting standard dimension.

3. Temporarily tighten the hood lock, and position it by engaging it with the hood striker. Check the lock and striker for looseness, and tighten the lock mounting bolt to the specified torque.

4. Adjust the clearance and surface height of hood and fender according to \

the fitting standard dimension by rotating right and left bumper rubbers.

CAUTION:

Adjust right/left gap between hood and each part to the following specification.

5. Install the front grille. Refer to EXT-17, "

Removal and Installation".

HOOD LOCK ADJUSTMENT

1. Remove the front grille. Refer to EXT-17, "Removal and Installation".

2. Move the hood lock to the left or right so that striker center is vertically aligned with hood lock center (when viewed from vehicle front).

3. Make sure the secondary latch is properly engaged with the sec- ondary striker with hood's own weight by dropping it from

approx. 200 mm (7.87 in) height or by pressing it lightly approx.

3 kg (29 N, 7lb).

CAUTION:

Do not drop the hood from 300 mm (11.81 in) height or

higher.

4. After adjusting hood lock, tighten the lock bolts.

5. Install the front grille. Refer to EXT-17, "

Removal and Installa-

tion".

Removal and Installation of Hood AssemblyINFOID:0000000001542677

1. Support the hood striker with proper material to prevent it from falling.

WARNING:

Body injury may occur if no supporting rod is holding the

hood open when removing the damper stay.

2. Remove the hinge nuts from the hood to remove the hood assembly.

CAUTION:

Operate with two workers, because of its heavy weight.

Installation is in the reverse order of removal.

HOOD STAY

Disposal

Hood and headlamp (B–B) : Less than 2.0 mm

PIIA3806E

LIIA1443E

Revision: March 2010 2008 QX56

Page 1051 of 4083

![INFINITI QX56 2008 Factory User Guide DIAGNOSIS SYSTEM (TRANSFER CONTROL UNIT)DLN-21

< FUNCTION DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

WORK SUPPORT

When there is no malfunction with transfer and 4WD sys tem, the following s INFINITI QX56 2008 Factory User Guide DIAGNOSIS SYSTEM (TRANSFER CONTROL UNIT)DLN-21

< FUNCTION DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

WORK SUPPORT

When there is no malfunction with transfer and 4WD sys tem, the following s](/img/42/57030/w960_57030-1050.png)

DIAGNOSIS SYSTEM (TRANSFER CONTROL UNIT)DLN-21

< FUNCTION DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

WORK SUPPORT

When there is no malfunction with transfer and 4WD sys tem, the following symptoms in AUTO mode may be

claimed by a customer: vibration when accelerating on a low µ road (snow-covered or icy road) or a slight

shock is felt at a few hertz as if it were being pushed lightly from behind.

It is possible to deal with these symptoms by changing the CLUTCH FORCE RELEASE LIMIT VALUE. How-

ever, be careful when changing the value because it may adversely affect driving performance.

Operation Procedure

1. Connect CONSULT-III.

2. Touch WORK SUPPORT.

3. Select from CLUTCH/F RLS LIM ADJ, screen of data monitor mode is displayed.

Clutch Force Release Limit Adjustment

1. Initial CLUTCH FORCE RELEASE LIMIT value 0.3 kgm appears under CONDITION SETTING on CON-

SULT-III display.

2. Touch 1.2 on the display.

3. Display changes to NOW ADJUSTING in a short time.

4. When clutch force release limit value is set to 1.2 kgm, current value 0.3 kgm shown on display will be replaced by 1.2 kgm and ADJUSTME NT COMPLETE will appear at the same time. Clutch force release

limit value setting is now complete.

ATP IND [ON/OFF] ––×Control status of ATP warning lamp is dis-

played.

SHIFT POS SW1 [ON/OFF] ×–×Actuator position switch 1 (Low) signal status

is displayed.

SHIFT POS SW2 [ON/OFF] ×–×Actuator position switch 2 (high) signal status

is displayed.

SHIFT ACT1 [ON/OFF] –×× Output condition to actuator motor (clockwise)

SHIFT AC MON1 [ON/OFF] ×–×Check signal for transfer control unit signal

output

SHIFT ACT2 [ON/OFF] –×× Output condition to actuator motor (counter-

clockwise)

SHIFT AC MON2 [ON/OFF] ×–×Check signal for transfer control unit signal

output

T/F F SPEED [km/h] or [mph] ×–×Displayed, but do not use.

A/T R SPEED [km/h] or [mph] ×–×Output speed sensor signal calculated by

TCM.

Signal input with CAN communication line.

AT GEAR POSI [1/2/3/4/5] ×–×A/T actual gear position is displayed.

Monitored item (Unit)

Monitor item selection

Remarks

ECU INPUT

SIGNALS MAIN

SIGNALS SELEC-

TION FROM

MENU

1.2 kg-m : Tight corner braking symptom is alleviated. However, vibration may occur when acceler-

ating on a low µ road (icy road, etc.).

0.3 kg-m : Initial set value.

0.2 kg-m : Do not set to th is value because the tight

corner braking symptom will get worse.

Revision: March 2010 2008 QX56

Page 1130 of 4083

![INFINITI QX56 2008 Factory User Guide DLN-100

< SYMPTOM DIAGNOSIS >[ATX14B]

4WD SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

4WD SYSTEM SYMPTOMS

Symptom TableINFOID:0000000001737182

If 4WD warning lamp turns ON, perform self-diagnosis. Refer to DLN- INFINITI QX56 2008 Factory User Guide DLN-100

< SYMPTOM DIAGNOSIS >[ATX14B]

4WD SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

4WD SYSTEM SYMPTOMS

Symptom TableINFOID:0000000001737182

If 4WD warning lamp turns ON, perform self-diagnosis. Refer to DLN-](/img/42/57030/w960_57030-1129.png)

DLN-100

< SYMPTOM DIAGNOSIS >[ATX14B]

4WD SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

4WD SYSTEM SYMPTOMS

Symptom TableINFOID:0000000001737182

If 4WD warning lamp turns ON, perform self-diagnosis. Refer to DLN-18, "CONSULT-III Function (ALL MODE AWD/4WD)".

NOTE:

• Light tight-corner braking symptom may occur depending on driving conditions in AUTO mode. This is not a

malfunction.

• Heavy tight-corner braking symptom occurs when vehicle is driven in the following conditions: 4WD shift

switch is 4H or 4LO, steering wheel is turned fully to either side.

Symptom ConditionReference page

4WD shift indicator lamp and 4LO indicator lamp do not turn ON

(4WD shift indicator lamp and 4LO indicator lamp check) Ignition switch: ON

DLN-101

4WD warning lamp does not turn ON

(4WD warning lamp check) Ignition switch: ON

DLN-103

4WD shift indicator lamp or 4LO indicator lamp does not change Engine runningDLN-105

ATP warning lamp does not turn ON Engine runningDLN-107

4WD shift indicator lamp keeps flashing Engine runningDLN-109

4WD warning lamp flashes rapidly (2 times/second) While drivingDLN-110

4WD warning lamp flashes slowly

(1 time/2 seconds) While driving

DLN-111

Heavy tight-corner braking symptom occurs

(See NOTE.) • While driving

•AUTO mode

• Steering wheel is turned fully

to either side DLN-112

ATP switch does not operate

Engine runningDLN-114

4WD system does not operate While drivingDLN-116

Revision: March 2010 2008 QX56

Page 1355 of 4083

![INFINITI QX56 2008 Factory User Guide EC-56

< FUNCTION DIAGNOSIS >[VK56DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

When there is an open circuit on MIL circuit, the ECM c

annot warn the driver by lighting up MIL when there is

malfunction on engi INFINITI QX56 2008 Factory User Guide EC-56

< FUNCTION DIAGNOSIS >[VK56DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

When there is an open circuit on MIL circuit, the ECM c

annot warn the driver by lighting up MIL when there is

malfunction on engi](/img/42/57030/w960_57030-1354.png)

EC-56

< FUNCTION DIAGNOSIS >[VK56DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

When there is an open circuit on MIL circuit, the ECM c

annot warn the driver by lighting up MIL when there is

malfunction on engine control system.

Therefore, when electrical controlled throttle and part of ECM related diagnoses are continuously detected as

NG for 5 trips, ECM warns the driver that engine cont rol system malfunctions and MIL circuit is open by means

of operating fail-safe function.

The fail-safe function also operates when above diagnos es except MIL circuit are detected and demands the

driver to repair the malfunction.

MIL Flashing Without DTC

When any SRT codes are not set, MIL may fl ash without DTC. For the details, refer to EC-462, "DTC Index".

HOW TO SWITCH DIAGNOSTIC TEST MODE

NOTE:

•It is better to count the ti me accurately with a clock.

• It is impossible to switch the di agnostic mode when an accelerator pedal position sensor circuit has

a malfunction.

• Always ECM returns to Diagnostic Test Mode I after ignition switch is turned OFF.

How to Set Diagnostic Test Mode II (Self-diagnostic Results)

1. Confirm that accelerator pedal is fully releas ed, turn ignition switch ON and wait 3 seconds.

2. Repeat the following procedure quickly five times within 5 seconds.

a. Fully depress the accelerator pedal.

b. Fully release the accelerator pedal.

3. Wait 7 seconds, fully depress the accelerator pedal and keep it for approx. 10 seconds until the MIL starts blinking.

NOTE:

Do not release the accelerator pedal for 10 seconds if MIL may start blinking on the halfway of this

10 seconds. This blinking is displaying SRT status and is continued for another 10 seconds. For

the details, refer to EC-462, "

DTC Index".

Diagnostic Test

ModeKEY and ENG.

Status Function

Explanation of Function

Mode I Ignition switch in

ON position

Engine stopped BULB CHECK

This function checks the MIL bulb for damage (blown, open

circuit, etc.).

If the MIL does not come on, check MIL circuit.

Engine running MALFUNCTION WARNING This is a usual driving condition. When a malfunction is de-

tected twice in two consecutive driving cycles (two trip de-

tection logic), the MIL will light up to inform the driver that a

malfunction has been detected.

The following malfunctions will light up or blink the MIL in

the 1st trip.

• Misfire (Possible three way catalyst damage)

• One trip detection diagnoses

Mode II Ignition switch in

ON position

Engine stopped SELF-DIAGNOSTIC

RESULTS

This function allows DTCs an

d 1st trip DTCs to be read.

Engine operating condition in fail-safe mode Engine speed will not rise more than 2,500 rpm due to the fuel cut

Revision: March 2010 2008 QX56

Page 1929 of 4083

EXL-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION EXL

A

B

EXL

N

O P

CONTENTS

EXTERIOR LIGHTING SYSTEM

BASIC INSPECTION ....... .............................4

DIAGNOSIS AND REPAIR WORKFLOW ..... .....4

Work Flow ........................................................... ......4

FUNCTION DIAGNOSIS ...............................7

HEADLAMP .................................................... .....7

System Diagram .................................................. ......7

System Description ...................................................7

Component Parts Location ........................................7

Component Description .............................................7

DAYTIME LIGHT SYSTEM .................................9

System Diagram .................................................. ......9

System Description ...................................................9

Component Parts Location ........................................9

Component Description ...........................................10

AUTO LIGHT SYSTEM ......................................11

System Diagram ......................................................11

System Description .................................................11

Component Parts Location ......................................12

Component Description ...........................................12

HEADLAMP AIMING SYSTEM (MANUAL) .......14

System Diagram .................................................. ....14

System Description .................................................14

Component Description ...........................................14

FRONT FOG LAMP ............................................15

System Diagram .................................................. ....15

System Description .................................................15

Component Parts Location ......................................15

Component Description ...........................................15

TURN SIGNAL AND HAZARD WARNING

LAMPS ...............................................................

16

System Diagram .................................................. ....16

System Description .................................................16

Component Parts Location ......................................17

Component Description ...........................................17

PARKING, LICENSE PLATE AND TAIL

LAMPS ..............................................................

18

System Diagram .................................................. ....18

System Description ..................................................18

Component Parts Location ......................................18

Component Description ...........................................19

TRAILER TOW ..................................................20

System Diagram ......................................................20

System Description ..................................................20

Component Parts Location ......................................21

Component Description ...........................................21

DIAGNOSIS SYSTEM (BCM) ...........................23

COMMON ITEM ..................................................... ....23

COMMON ITEM : Diagnosis Description ................23

COMMON ITEM : CONSULT-III Function ...............23

EXTERNAL LAMP ................................................. ....23

EXTERNAL LAMP : CONSULT-III Function ............23

FLASHER ............................................................... ....25

FLASHER : CONSULT-III Function (BCM -

FLASHER) ...............................................................

25

DIAGNOSIS SYSTEM (IPDM E/R) ...................26

CONSULT - III Function (IPDM E/R) .......................26

COMPONENT DIAGNOSIS .........................27

POWER SUPPLY AND GROUND CIRCUIT ....27

BCM (BODY CONTROL MODULE) ...................... ....27

BCM (BODY CONTROL MODULE) : Diagnosis

Procedure ............................................................ ....

27

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) .......................... ....

27

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) : Diagnosis Pro-

cedure .................................................................. ....

27

Revision: March 2010 2008 QX56

Page 1930 of 4083

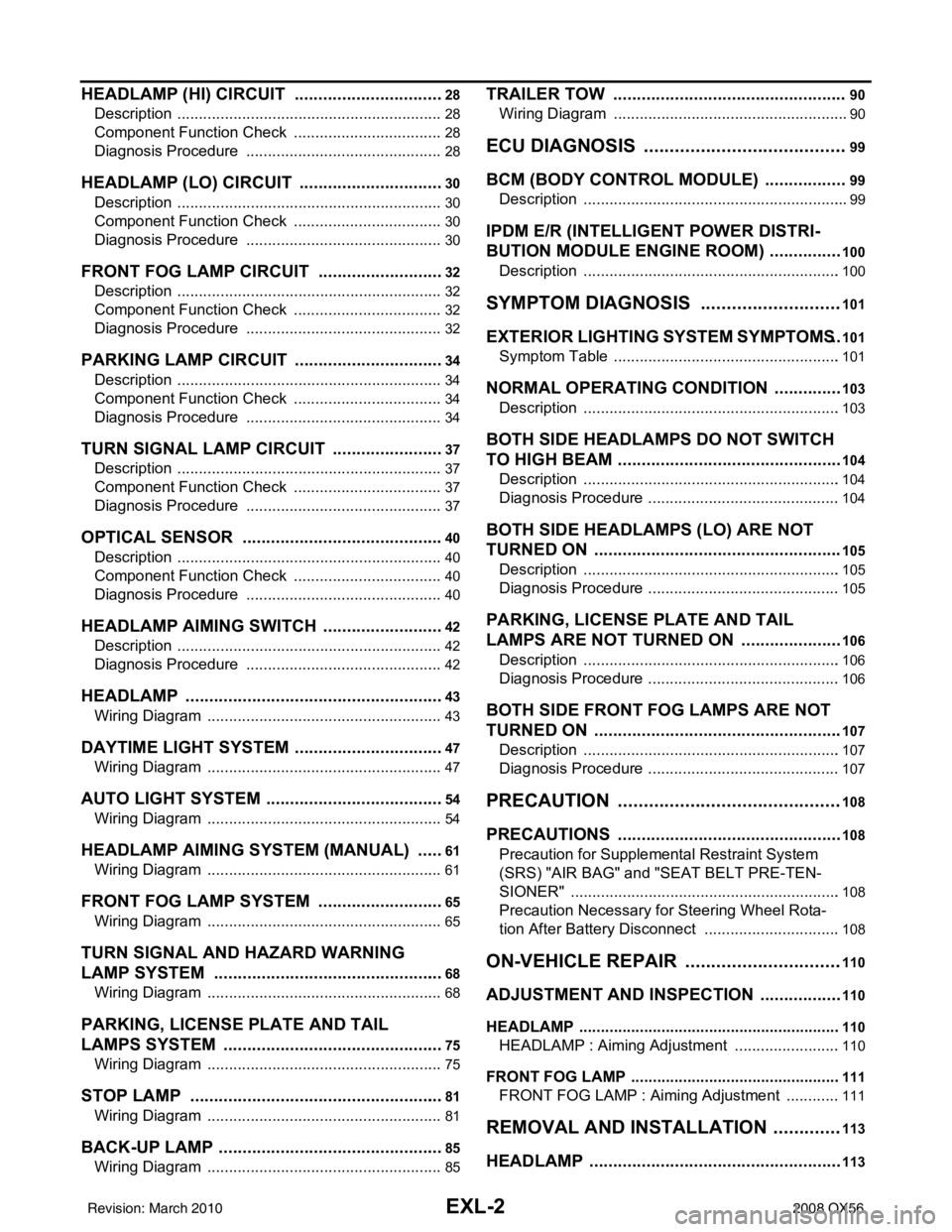

EXL-2

HEADLAMP (HI) CIRCUIT ................................28

Description ........................................................... ...28

Component Function Check ...................................28

Diagnosis Procedure ..............................................28

HEADLAMP (LO) CIRCUIT ...............................30

Description ........................................................... ...30

Component Function Check ...................................30

Diagnosis Procedure ..............................................30

FRONT FOG LAMP CIRCUIT ...........................32

Description ........................................................... ...32

Component Function Check ...................................32

Diagnosis Procedure ..............................................32

PARKING LAMP CIRCUIT ................................34

Description ........................................................... ...34

Component Function Check ...................................34

Diagnosis Procedure ..............................................34

TURN SIGNAL LAMP CIRCUIT ........................37

Description ........................................................... ...37

Component Function Check ...................................37

Diagnosis Procedure ..............................................37

OPTICAL SENSOR ...........................................40

Description ..............................................................40

Component Function Check ...................................40

Diagnosis Procedure ..............................................40

HEADLAMP AIMING SWITCH ..........................42

Description ........................................................... ...42

Diagnosis Procedure ..............................................42

HEADLAMP .......................................................43

Wiring Diagram .................................................... ...43

DAYTIME LIGHT SYSTEM ................................47

Wiring Diagram .................................................... ...47

AUTO LIGHT SYSTEM ......................................54

Wiring Diagram .................................................... ...54

HEADLAMP AIMING SYSTEM (MANUAL) ......61

Wiring Diagram .................................................... ...61

FRONT FOG LAMP SYSTEM ...........................65

Wiring Diagram .................................................... ...65

TURN SIGNAL AND HAZARD WARNING

LAMP SYSTEM .............................................. ...

68

Wiring Diagram .................................................... ...68

PARKING, LICENSE PLATE AND TAIL

LAMPS SYSTEM ............................................ ...

75

Wiring Diagram .................................................... ...75

STOP LAMP ......................................................81

Wiring Diagram .................................................... ...81

BACK-UP LAMP ................................................85

Wiring Diagram .................................................... ...85

TRAILER TOW ..................................................90

Wiring Diagram .................................................... ...90

ECU DIAGNOSIS .......................................99

BCM (BODY CONTROL MODULE) ............... ...99

Description ........................................................... ...99

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

100

Description ........................................................... .100

SYMPTOM DIAGNOSIS ...........................101

EXTERIOR LIGHTING SYSTEM SYMPTOMS ..101

Symptom Table .................................................... .101

NORMAL OPERATING CONDITION ...............103

Description ........................................................... .103

BOTH SIDE HEADLAMPS DO NOT SWITCH

TO HIGH BEAM ................................................

104

Description ........................................................... .104

Diagnosis Procedure .............................................104

BOTH SIDE HEADLAMPS (LO) ARE NOT

TURNED ON .....................................................

105

Description ............................................................105

Diagnosis Procedure .............................................105

PARKING, LICENSE PLATE AND TAIL

LAMPS ARE NOT TURNED ON ......................

106

Description ........................................................... .106

Diagnosis Procedure .............................................106

BOTH SIDE FRONT FOG LAMPS ARE NOT

TURNED ON .....................................................

107

Description ............................................................107

Diagnosis Procedure .............................................107

PRECAUTION ...........................................108

PRECAUTIONS .............................................. ..108

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

108

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ................................

108

ON-VEHICLE REPAIR ..............................110

ADJUSTMENT AND INSPECTION ................ ..110

HEADLAMP ............................................................ .110

HEADLAMP : Aiming Adjustment .........................110

FRONT FOG LAMP ................................................ .111

FRONT FOG LAMP : Aiming Adjustment .............111

REMOVAL AND INSTALLATION .............113

HEADLAMP .................................................... ..113

Revision: March 2010 2008 QX56

Page 1945 of 4083

TURN SIGNAL AND HAZARD WARNING LAMPSEXL-17

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

Component Parts LocationINFOID:0000000001547112

Component DescriptionINFOID:0000000001547113

1. Combination meter M24 2. Combination switch M283. Hazard switch M55

4. BCM M18, M20 (view with instrument panel removed)

ALLIA0384ZZ

Part name Description

BCM Controls turn signal and hazard flasher operation.

Combination switch Lighting and turn signal switch requests are output to the BCM.

Hazard switch Hazard flasher request signal is output to the BCM.

Combination meter Outputs turn and hazard indicator as requested by the BCM.

Revision: March 2010 2008 QX56

Page 1953 of 4083

DIAGNOSIS SYSTEM (BCM)EXL-25

< FUNCTION DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

1: The item is indicated, not monitored.

FLASHER

FLASHER : CONSULT-III Function (BCM - FLASHER)INFOID:0000000001547121

DATA MONITOR

ACTIVE TEST

FR FOG LAMP ON

Transmits the front fog lamp light request signal to IPDM E/R via CAN

communication to turn the front fog lamp ON.

OFF Stops the front fog lamp request signal transmission.

CORNERING LAMP

1

RH —

LH

OFF

CARGO LAMP ON

Tramsmits the cargo lamp request signal to the IPDM E/R via CAN com-

munication to turn on the cargo lamp.

OFF Stops the cargo lamp request signal transmission.

Test item

Operation Description

Monitor item

[Unit] Description

IGN ON SW

[ON/OFF] The switch status input from the ignition switch

HAZARD SW

[ON/OFF] The switch status input from the hazard warning switch

TURN SIGNAL R

[ON/OFF] Each switch condition that BCM judges from the combination switch reading function

TURN SIGNAL L

[ON/OFF]

BRAKE SW

[ON/OFF] The switch status input from the brake switch

Test item

Operation Description

FLASHER RH Blinks right turn signal lamp.

LH Blinks left turn signal lamp.

OFF Turns turn signal lamps (right and left) OFF.

Revision: March 2010 2008 QX56